Profile pipes of square or rectangular cross-section with a wall of 2 mm are in good demand among the population; in everyday life, they are used to make various types of building structures (gazebos, greenhouses), organize fences, make frames for canopies and canopies. The main method of connecting them is electric arc welding, and if the homeowner has purchased a welding machine and has no experience in carrying out welding work, he will immediately be faced with the question of what electrodes to use to weld a 2 mm profile pipe.

In addition to the selection of suitable electrodes, the quality of welding profile pipes largely depends on adherence to technology, selection of the correct operating modes of the device, knowledge of basic techniques and methods that facilitate the performance of electric welding work by a beginner.

Fig.1 Application of structures made of rolled profiles

General information

Welded structures made from this material are lightweight and also have fairly high strength indicators. It is obtained from an ordinary pipe by plastic deformation, in a hot or cold state. The most commonly used profile has a square or rectangular cross-section. The vast majority of it is made from low-carbon steel.

Low-alloy and stainless steels are used on a much smaller scale, due to the high price of the resulting structure.

For beginners, welding a profile pipe with an inverter is often a problem, especially if the wall thickness is 1.5-2 mm.

A welding helmet is one piece of welding equipment that you should not skimp on if you are going to be a skilled welder and preserve your vision. A good mask with a substitute will serve you for many years.

The sales consultant in the store will help you with the right choice. It's better to pay a little more and get the Maxa Chameleon, which automatically dims. This is convenient; you can see where the electrode is before welding begins. A regular mask with a dark glass filter will not provide this opportunity. Another advantage of the chameleon is that you can beat off slag without a shield. The mask itself will be used instead.

When performing welding work, you will need auxiliary tools and materials.

Basics of welding corrugated pipes

Profiled pipes are produced with walls of different thicknesses. At the same time, it is most difficult to work with thin-walled rolled metal. To perform the welding process efficiently, you need to have knowledge and experience. Therefore, it is necessary to understand how thin-walled pipes are welded. During this process:

- current used is 10-60 A;

- electrodes with a diameter of 0.5-2 mm are used;

- Only one pass of the electrode is carried out at the junction of the parts.

Welding speed affects the quality of the seam. The process must be completed before the edges of the two workpieces being joined cool down.

Important! Rutile electrodes allow for pull-out welding.

Electrodes with rutile coating Source temir.ru

To make quality connections, you also need to know how to properly weld a profile pipe, regardless of the wall thickness. When carrying out such welding work, it is necessary to take into account that during the process the metal melts and often fills or even completely covers the internal space of the pipe. If it is necessary to maintain the hollowness of the corrugated pipes, it is necessary to ensure that drops do not fall into the internal cavities of the parts being welded.

In addition, profiled pipes are more deformed when exposed to high temperatures compared to similar round products. It is also necessary to ensure the correct formation of the weld bead and evenly heat the metal while making end connections to prevent the appearance of high stress in the corners.

Types of welding used for profile pipes

Profile pipe is used in the production of metal frames and structures made of low-carbon steel. Profile sizes according to GOST are from 10-15 mm to 180-230 mm, and thicknesses are from 0.8-1.0 mm to 18-20 mm.

What is the best way to weld a profile pipe? To answer this question, you need to understand how such products are generally cooked. The following methods are used for welding:

- Manual welding with consumable electrode;

- Semi-automatic in CO2;

- In an argon environment with a non-consumable electrode.

The latter type is used for profiles of small thickness (usually up to 1.5 - 2.0 mm). For a small amount of work, these profiles are welded using manual arc welding using an inverter with stick electrodes. This method is convenient, the equipment is not expensive, and the process does not cause much difficulty.

In this article on the website mrmetall.ru we will reveal in detail the technology of manual welding with an inverter of structures made of this material.

Semi-automatic (mechanized) welding of profile pipes is used in the production of dimensional welded structures in production.

The undoubted advantage of this method is the possibility of carrying out the process at small thicknesses and minimal heat input, which reduces the resulting deformations by an order of magnitude.

This is especially true for long seams. Almost anyone can carry out the process semi-automatically, since the process is automated. Read about what you need for this in our article.

Of course, there is also a drawback in the form of difficulty in applying this method in installation conditions, due to the gas protection being blown away by gusts of wind. This leads to the occurrence of defects and unstable process flow.

Argon welding is rarely used for this type of structure due to its high cost. Inert gas is expensive, and the method has low productivity.

It is used in cases where it is necessary to weld stainless steel products or profiles of very small thickness, then the use of this method is justified and irreplaceable.

Which consumables are best to choose?

There are four main types of electrode coatings, which affect the mechanical characteristics of the seam, the protective functions of the welding zone and ensure the stable functioning of the welding arc:

- sour;

- cellulose;

- rutile;

- basic.

Coated electrode for electric arc welding

In addition to the main ones, mixed coatings are used, which have the characteristics of both types included in the coating: acid-rutile, rutile-basic, rutile-cellulose.

All of these coatings, to a greater or lesser extent, perform their functions when welding low-carbon steels, which are mainly used for the production of profile pipes.

Electrodes with an acidic coating during operation are characterized by increased splashing and the release of toxic substances. The risk of hot cracks cannot be ruled out . For structures made of profile pipes, which are subject to strict requirements for ensuring strength characteristics, and in some cases there are decorative functions, the use of welding with acid-coated electrodes is not recommended.

Heavy splashes and the presence of hydrogen in the weld, which reduces its ductility, are the main disadvantages when welding with cellulose-coated electrodes. A frame made of profile pipes welded with such electrodes may collapse over time due to hydrogen embrittlement of the welds.

Electrodes LB-52U with the main type of coating ensure a high-quality seam when working with corrugated pipes

Electrodes with a basic coating are characterized by high ductility and good toughness. The seam does not contain hydrogen and other gases and impurities, which eliminates the formation of cold cracks . High requirements for the preparation of welded edges (absence of moisture, rust and other contaminants) are required to maintain the quality of the joint. Subject to all technological requirements, electrodes with a basic coating are used for welding critical metal structures made of profile pipes. For beginners, welding with such electrodes causes many problems, especially with sticking (see video below about this problem). Further in the article we will talk about electrodes with rutile coatings, which amateurs use to weld profile pipes without much difficulty.

Rutile coated

Rutile-coated electrodes (rutile-cellulose), in addition to producing a high-strength weld and a low amount of spatter, make it much easier for novice welders to work with them . The welding process is characterized by easy re-ignition, which allows beginners to perform a weld without nerves. It is possible to connect profile pipes with thin walls using tacks, preventing large heat input and, accordingly, the occurrence of burn-through of the base metal. The quality of the seam is not affected by surface preparation; a good connection of wet and rusty welded edges can be obtained. The presence of the above qualities of rutile-coated electrodes allows them to be successfully used for welding metal structures from profile pipes.

Resanta electrodes with rutile coating are suitable for welding profile pipes by novice craftsmen

Video: which is better, rutile or UONI 13/55

Diameter

Welding profile pipes is distinguished by one feature: the diameter of the electrode must be accurately selected depending on the thickness of the edges being welded . A diameter that is too small will not provide the required penetration of the metal walls; a large diameter will lead to burn-through. for selection : the diameter of the electrode must be of a size corresponding to the thickness of the profile pipe. So, for example, for thin walls 1.5-2.0 mm, you should choose an electrode with a diameter of 2.0 mm. Profile pipes with a wall thickness of 3.0-4.0 mm can be welded with a 3.0 mm electrode.

BUT! As practice has shown, on thin-walled pipes it may be more convenient to use 3mm electrodes. See the video above.

Operating mode

In addition to the correctly selected electrode diameter, in order to obtain a high-quality seam, it is necessary to set the required welding current value on the machine. Packs of electrodes usually have a table where the corresponding working welding current is indicated for each diameter . If there is no table, then welders are guided by a formula taken from practice: for 1 mm of electrode diameter, the optimal welding current is 30-40 A.

The Resant electrode pack contains recommendations regarding the amount of welding current when working with consumables of different diameters and in different spatial positions

All of the above serves as the basis for selecting the value of a specific welding current for the specific job being performed. In practice, on the device, based on all recommendations, the minimum current is first set . If metal penetration does not occur, then the current value is gradually increased . This continues until a high-quality seam is obtained.

Important: some welders over time show a current on the screen that does not correspond to reality. Therefore, the method of analyzing the quality of the seam is the most correct when choosing the desired operating mode.

Video: how to weld without burning

How to weld a profile pipe with an inverter

We will answer this question within the article. The information in the article will be aimed at novice welders and beginners. It is quite simple to weld a profile pipe with an inverter; therefore, welding using this method is used almost everywhere. The first thing to do is prepare the edges.

The first thing to do is clean the metal. You can clean it with a grinder, wire brush or file. This surface treatment will significantly improve the result. Rust, scale, oil, dust and other contaminants must be completely removed. It is advisable to degrease the surface.

Then you need to measure the thickness of the base metal. This will determine the further preparation and processing of the product, the technique and modes in which welding will be performed.

With a thickness of 1.5 mm to 3.5-4.0 mm, the process can be carried out without cutting edges. With a thickness of about 3 mm, it is better to use edge cutting to ensure complete penetration.

Polarity is reverse (“+” - on the electrode; “-” - to the product). You can read more about polarity here.

Briefly about the main thing

Welding of corrugated pipes is carried out with a current of 10-60 A and using electrodes with a diameter of 0.5-2 mm, which often perform only one pass. Craftsmen can use manual arc, electric arc in shielding gas, gas welding. Experts often use an inverter in their work.

One of the most popular electrodes are ANO-4 rods. OZS-12, UONI-13/55, MR-3S are also often used. When welding at 90° is carried out, first make a couple of tacks, and then create the main seam. To avoid burning through the metal, electrodes with a diameter of no more than 1.5 mm are used.

Welding of the corrugated pipe to the pole begins with a horizontally located part. The electrode is held at an angle of 45°, and the rod is moved by alternately tilting it towards the support and the crossbar.

Which electrodes are best for welding profile pipes 1.5 - 3 mm

Welding electrodes are best used with rutile or basic coating. For beginners, in our opinion, the best electrodes are OK-46, OZS-12, MP-3, which contain rutile as a coating. It provides easy ignition and stable arcing. In order to properly weld the structure, it is necessary to pay special attention to assembly.

In most cases, structures are assembled using tacks. We place potholders along the edges of the parts to be joined. After tack welding, we adjust the welding current on the test part. These parameters vary for different brands of electrodes. On the packaging with electrodes, the manufacturer gives general recommendations and applies them, setting the current values.

The profile pipe can be welded together either end-to-end, overlapping, or at an angle of 90 degrees. Carrying out the process on a test part, we change the current parameter to achieve optimal weld geometry.

The metal should not be burned, and the welding arc should burn steadily and be easily excited. For example, for MP-3 electrodes with a diameter of 2.5 - 3 mm. You can use a welding current in the region of 75-80 A.

Welding modes, welding current strength and joint dimensions must be taken from the technical sheet. If you need technical maps, you can write to us using the feedback form located at the very bottom of the page. We will send you technical maps specifically for your case by email.

The smaller the electrode diameter, the lower the current strength, and therefore the product will heat up less. When welding thin products, it is recommended to use electrodes as thin as possible so as not to burn through the metal.

Welding methods

You should determine in advance which electrodes and how to weld the profile pipe. There are several methods for joining workpieces by welding, each of them has its own characteristics, which determine the choice of pipe joining option.

Manual arc welding

One of the simplest methods to get an even seam. A transformer or inverter welding machine is suitable for the job. Arc welding is suitable for connecting profiles with different wall thicknesses and section sizes. If the thickness is more than 4 mm , then the edges of the workpiece are protected and degreased.

diameter of 2.3 mm are needed; the current on the device is set in the range from 50 to 60 A. The arc method allows welding horizontally, vertically and even from below.

Welding for beginners video

Features of electric welding

Welding is performed using non-consumable (tungsten) electrodes. The rod is placed at a short distance from the bath, this will allow the formation of a dense, continuous seam with a short arc.

The diameter of the electrode is selected based on the thickness of the profile. If its walls are no more than 2 mm thick, then a rod with a diameter of 1 mm will be required. If the workpieces to be connected are thicker, then it is better to take an electrode with a diameter of 1.6 mm. The filler wire is selected in a similar way, that is, it must match the thickness of the material being welded or be slightly thicker.

For electric welding you will need a transformer, an inverter, a power supply, and equipment for supplying shielding gas. The consumption of argon or other gas should be no more than 12 liters per minute, the current strength depends on the thickness of the profile and can be in the range of 50-120 A . You need to finish cooking by reducing the voltage. The gas is shut off 10-20 seconds after the current supply is stopped.

Gas welding

Welding using gas equipment is no different from other methods. The desired area is heated, after which filler wire is applied to it. Melting, the rod fills the joint. The rod is moved strictly in the direction of the joint; depending on the chosen method, two gas welding technologies are distinguished:

- From left to right . The additive moves behind the burner, so the working area is optimally heated. In this case, the welder can constantly monitor the process. This method is considered the most suitable when welding profiles with a thickness of 5 mm or more;

- From right to left . When choosing this method, workpieces burn out extremely rarely, but it is suitable for connecting only thin-walled profiles.

After the seams have cooled, it is advisable to clean them and coat them with an anti-corrosion agent.

Important! The edges of corrugated pipes with walls up to 4 mm thick should not be formed.

How to properly weld metal using gas welding video

Using resistance welding

More suitable for enterprises, as it requires the use of expensive equipment and is characterized by increased complexity. No filler materials are used during resistance welding. Welding of workpieces occurs under high pressure electrodes with simultaneous exposure to voltage at the joining point. This leads to the melting of the metal and the formation of a homogeneous medium, which turns into a monolith after cooling. That is, the resulting connection has the highest margin of safety.

Resistance welding video

Welding with inverter

A type of arc welding using an inverter welding machine. The inverter is suitable for welding profiles of different thicknesses. The operating mode of modern models is pulse. 2 mm thick profile pipe , you need a current of 50 to 60 A. Thick-walled rolled products are connected using a more powerful electric current.

The work uses a coated additive. When the arc is excited, it begins to burn, which leads to melting of the coating. Part of it goes into molten rolled metal and part of it is converted into gas. Due to this, the welding zone does not come into contact with air. Inverter machines ensure smooth and high-quality seams.

Welding inverter video

How to weld a profile pipe so as not to burn it

After completing the preparation, we begin to cook our product. With a part thickness of 1.5 mm, it is necessary to start on a tack so as not to burn through the thin metal.

Let's consider the correct sequence of how to butt weld thin-walled parts from a profile pipe:

- We light an arc on the tack;

- We move along the joint for a distance of about 10 - 15 mm at an angle backwards without oscillatory movements and return;

- We make the arc as short as possible so that the end of the electrode moves away from the melt of the weld pool by no more than 1.5 mm. This will provide better protection for the weld pool. When the process takes place on a short arc, the voltage decreases, resulting in a reduced temperature of the molten metal. This is exactly how you need to weld a profile pipe so that it doesn’t leak.

- When approaching the end of the joint, you cannot simply break the arc. It is necessary to return 20 millimeters to the weld metal and break the arc there. If this is not done, there will be a crater at the end of the seam.

- We beat off the slag and remove metal splashes.

Using potholders

If you are a novice welder, then it is better for you to weld a profile pipe with an inverter using additional tacks. They need to be made not only along the edges, but also one potholder in the middle.

As already mentioned, it is better to use electrodes as thin as possible: 2.0 - 2.5 mm. If your hand shakes during the process and the arc height fluctuates, hold the electrode with the index finger of your left hand. This is how you can gradually learn to cook.

For beginner welders, there are very useful videos at the end of the article, watch them. Another way to avoid burning your profile. If the metal still burns through, there is a life hack for you. It is necessary to install a rectangle or square of metal into the pipe, suitable in cross-section. For example, for a 20x40 profile, you can take rectangular metal 15x35.

After this, you need to dock the products together and start cooking. The square will remove heat and the part will not be burned. A useful trick for a beginner in welding.

How to weld a profile pipe with a thickness of 1.5 mm or more

Likewise, the only difference is that with a thickness of 3 mm or more, the diameter of the electrodes will be larger. Another way that can help you is to replenish the process with a gap. With this method, the arc is also ignited at the tack, a slight delay is made and it breaks off.

Next, the arc is ignited in the welded area, the “point” is welded again and breaks off again. With this method, the welding current can be higher than about 95 -115 A. The arc will ignite better, and the electrode will not stick.

Features affecting the selection of electrode

Profile pipes provide the required frame rigidity , having a small wall thickness. This advantage causes certain problems during welding operations. The thin wall of a profile pipe can be burned through if the electrodes and welding modes are incorrectly selected.

Important: it is generally accepted that the diameter of the electrode should correspond to the thickness of the metals being welded. With a profile pipe thickness of, for example, 1.5 mm. the diameter used for welding the electrode should be 1.5 mm. or close to it. A larger electrode diameter will overheat the already small weld pool, compromising its integrity. This leads to the formation of such a defect as a burn-through. But as the following video shows, it was experimentally determined that this is not entirely true. An electrode with a larger diameter creates a wider pool and a wider contact patch, so it is difficult to notice a big difference in burns with diameters of 2 and 3 mm. See for yourself.

What to do to avoid burns

Correct organization of heat removal from the weld pool will help to avoid burn-through so that the temperature in it does not reach critical values. There are several main ways to maintain an acceptable welding mode for profile pipes:

- welding with separation (tack welding);

- use of a short arc;

- welding in “robbery” (a continuous welding seam is obtained by changing the places where the electrode is applied);

- welding should be carried out at the lowest possible current level;

- use welding machines with the “arc force” option, which will maintain a stable mode (without sticking) of welding at low currents;

- It is important to choose the correct polarity; with a “+” polarity on the electrode, the weld pool will heat up more.

Experienced welders use electrodes with a basic coating when welding profile pipes without tearing off. At the same time, they use the movements and orientation relative to the seam of the electrodes and the speed of their movement developed during the work.

Methods for preventing burn-throughs when welding profile pipes are discussed in detail in the article “Welding a profile pipe.”

Features of welding a frame from a profile pipe

Frames made from profile pipes are very popular. They are light, durable, cheap, simple and quick to manufacture.

The differences when welding frames are the spatial positions of the welds. Another feature is the deformation to which all welding products are subject. Welded joints used for this type of product are regulated by GOST 5264. The most commonly used are butt joints C17, as well as T-joints T1.

Now about deformations and how to deal with them. It very often happens that during assembly it becomes clear that the pipe is not made well enough and has uneven side edges.

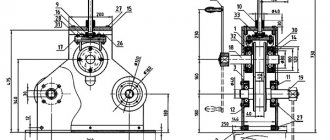

This increases the gaps during joining, and during the welding process more metal will have to be deposited and the product will heat up more. This is where welding deformations occur, the profile pipe “leads”. To prevent the structure from moving and to reduce these impacts, special devices - conductors - are used. They fix structural elements without allowing deviations from the specified dimensions.

The use of jigs significantly increases the speed and accuracy of product assembly, which is undoubtedly required in the serial production of structures. Large structures must be rigidly fixed to the slipway using clamps. The parts are tacked at the corners. Execution is carried out on the opposite side of the installed tacks.

We start cooking from the middle, gradually moving towards the edges. When welding profiles of different thicknesses, it is necessary to light the arc on a thicker pipe and switch to a thinner one. Oscillations can be made either circular or zigzag.

What electrodes are used for profile welding

Profile pipes are most often made of carbon or low-alloy steel. The following electrodes are most suitable for welding:

- ANO-4 . Universal and most popular type of electrodes. Suitable for various types of devices, does not require pre-calcination;

- OZS-12 . Allows you to obtain a high quality seam. But electrodes of this brand are not characterized by increased moisture resistance;

- UONI-13/55 . The best electrodes for forming a strong connection;

- MR-3S . They are rarely used and mainly in situations where the quality of the seam must be ideal.

Which electrodes are preferable for welding a fence from a profile pipe? As practice shows, it is easier for beginners to use brands such as MP-3, OZS-12. They contain rutile, which simplifies the initial stage of welding, and the joints are strong and resistant to moisture.

Advice! The necessary skills can be obtained by practicing welding various pipe scraps.

Vertical seam when welding a profile pipe

If you need to weld a profile pipe beautifully and efficiently in a vertical position, hold the electrode at an angle forward. Thereby preventing molten metal from flowing out due to arc pressure. If parts with different thicknesses are welded, then the arc is ignited on the thicker one. The simplest diagram looks like this:

- We light an arc on a thicker part, the process is carried out from the bottom up;

- We guide the electrode at an angle forward, thereby preventing the metal of the weld pool from flowing out;

- We move the electrode onto a thin part (with minimal delay on the surface);

- We break the arc (applicable for beginners);

- For the more experienced, we move to a thicker part only a little higher, oscillating the electrode in a sort of zigzag.

Burn-through is the main defect when welding profiles

The thin walls of profile pipes do not allow the formation of a normal weld pool. It has such a small volume that any deviations from the welding technology lead to a sharp change in thermal parameters , which, in the case of increased heating, break the integrity of the bath . In this case, the welding edges melt on their own, thus creating a burn-through - a hole (through or partial) in the walls of the profile. The main cause of the defect is the improper organization of the heat removal process to prevent overheating of the welding zone.

Welding profile pipe – Ceiling position

When welding in the most inconvenient position, which is called the ceiling, the technique is the same as for a vertical position.

For novice welders, it is better to use the pull-off method. With this method, it is performed as if with dots. We lit an arc, melted a point, and cut it off. If you can cook without interruption, then it is best to make circular movements, not large in size.

We direct the angle of the electrode to the thicker part. The current strength in this position for the method with separation is 75-95A, and in the case of performing the process without separation it is less than about 65-75.

Butt welding

The butt profile is especially difficult to weld. A number of tips from experienced welders will simplify the task:

- The workpieces need to be grabbed at the corners of the section. Then the joining is checked, if there is an error, it is corrected, and only after that they start welding around the perimeter;

- Thin-walled pipes are connected in one pass; thick-walled pipes require 2 or more;

- The arc speed must be such that the edges of the workpieces melt, but the metal does not sag;

- Finish the work so that the first overlap and the edge of the seam coincide.

Method of welding profile pipe video

Welding a profile pipe at an angle. Welding horizontal seams.

In the case where products are located at an angle of 90 degrees to each other, several features must be taken into account. It is necessary to cook on a vertically located pipe, since it will have greater heat dissipation (on both sides of the weld). This will reduce the possibility of burning it and reduce the deformation of the structure. Tilt of the electrode towards the vertical stand.

The process with separation is the same as in the previous case. We cook each point with the arc ignited at the previous point. With the non-tearing method, it is necessary to move the electrode along the joint without vibration (back and forth). The result is a progressive movement towards oneself from oneself and again towards oneself. This method is also suitable for performing the process at various angles of 45, 60, 90 degrees.

The best welding electrodes with basic coating

Such rods are characterized by low oxidizing ability, and the resulting welding seam has a low content of hydrogen, oxygen, sulfur and phosphorus impurities. Therefore, it has good crack resistance.

Similar electrodes are used for welding hardening, deoxidized steels and multilayer structures.

ESAB UONII 13/55

4.9

★★★★★

editorial assessment

92%

buyers recommend this product

See review▶

Electrodes can be used for welding in almost all spatial positions. The deposited metal is resistant to crystallization cracks and is almost completely free of hydrogen.

The rods have a diameter of 2 to 5 millimeters, which allows processing materials up to 8 mm thick.

The permissible calcination temperature before work is 350-400°C. To avoid the formation of pores, welding should be carried out with direct current using a short arc.

Advantages:

- wide range of sizes;

- welding from any position;

- seam strength;

- economical consumption.

Flaws:

- sticking at high current.

ESAB UONII 13/55 are designed for welding low-carbon or low-alloy steel. The ease of operation in any position and the reliability of the resulting seam allow the rods to be used effectively in cramped conditions.

Lincoln Electric SSSI 13/55

4.9

★★★★★

editorial assessment

90%

buyers recommend this product

The main features of these consumables include low cost and increased service life.

Electrodes can be used when working with materials at sub-zero temperatures and high humidity levels and do not require special storage conditions.

The diameter of the rods is 4 millimeters, the maximum permissible welding current is 160 Amps. Their use is effective in any spatial position, which ensures ease of work with various structural elements.

Advantages:

- high impact strength;

- work at temperatures down to -40 °C;

- minimal splashing;

- stable arc burning.

Flaws:

- require long-term calcination.

Lincoln Electric UONI 13/55 is an excellent choice for arc welding of reinforcing, carbon and alloy steels. Recommended for work in difficult conditions or prolonged use in frosty weather.

PlasmaTec Monolith TsCh-4

4.8

★★★★★

editorial assessment

88%

buyers recommend this product

A special feature of the electrodes is the ability to work in unfavorable conditions. During welding, a gas bubble appears around the arc, preventing water or dust from entering the joint.

The diameter of the rods is 3 mm. They are characterized by arc stability, low spatter, and ease of both initial and re-ignition. This ensures high weld quality and rapid slag separation.

Advantages:

- protection of the welding zone;

- straight seam;

- economical consumption;

- do not require calcination.

Flaws:

- not intended for vertical welding.

PlasmaTec Monolith TsCh-4 is used for professional welding of thin sheet metal. An excellent choice for tank or pipeline work.

Kobelco LB-52U

4.8

★★★★★

editorial assessment

86%

buyers recommend this product

They are distinguished by high arc stabilization and large depth of material penetration. Due to the low hydrogen content, the resulting weld is resistant to cracking and has high impact strength.

The diameter of the electrodes is 3 mm, length 40 centimeters. The rods are used for welding metals corresponding to strength classes up to K54, K55-K60. Material processing can be carried out using both direct and alternating current.

Advantages:

- reliable connection;

- fast calcination;

- deep metal penetration;

- ease of slag separation.

Flaws:

- difficulty in re-ignition.

Kobelco LB-52U is suitable for reinforcing the back side of a weld. The rod will be useful for internal processing of pipelines or tanks.

READ ALSO

6 Best Welding Generators

Welding equipment for welding profile pipes

In most cases, when structures are welded using manual arc welding, the welding machine is an inverter. An inverter is a modern power source with low mass and a very wide range of capabilities.

Welding generators are also used, as well as rectifiers that ensure the welding process is carried out on direct current. For semi-automatic welding, devices are used consisting of: an inverter, a wire feeder, a welding torch and gas equipment.

Gas equipment in the form of a gas cylinder, reducer, hose and heater is not used if cored wire is used.

To carry out the process in argon, inverters and rectifiers are used, and the same gas equipment is used as for semi-automatic. The process is performed with a non-consumable tungsten electrode. The electrode is installed in the welding torch, and the welding process itself is carried out with it.

To weld a profile pipe with your own hands, not much knowledge is required. The main thing is the desire to solve the problem, and there are many resources for this. In our article we talked about possible methods and methods for welding profiles.

Recommendations for better performance of work with your own hands, how to cook correctly...

Home craftsmen use welding technology not only to create simple structures from profile pipes (fence frames, canopies, etc.) with their own hands. More complex metal structures in the form of greenhouses and gazebos are also in their field of vision. Here it is necessary to butt weld long profiles, create various corner joints and use a thin-walled profile in the work. To help amateur creativity, we provide below some recommendations for welding in various positions.

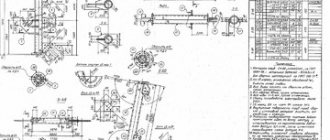

...end-to-end

If the profile pipe is not long enough, it can be lengthened by butt welding to another similar piece. Here it is important to ensure that the forming planes of the welded pipes are in the same axis. Why should you equip a simple equipment consisting of a table with a flat surface and a side support. The recommended work order is as follows:

- one of the pipes is placed on the table with support on the stop;

- the second pipe is joined to the end of the first;

- the coincidence of the axes is checked using a ruler applied to the joint;

- both pipes are pressed to the table with clamps;

- the correctness of assembly is checked again using a ruler, and if necessary, alignment is carried out with light blows of a hammer;

- tacks are made located on opposite sides;

- The upper horizontal part of the joint is welded.

Using a clamp ensures convenient and high-quality welding of profile pipes

Next, the pipe is freed from the clamps, after which the entire joint is sequentially scalded.

...at an angle of 90 degrees

In metal structures made from profile pipes, it is often necessary to make connections at an angle of 90°. The following sequence of actions is recommended:

- The part to be cut is marked on the profile pipe; it is more convenient to do it using a template in the form of a right triangle.

- The pipe should be firmly secured to the working surface before cutting;

- after completing the mechanical part of the work, check the 90° angle using a square;

- connect the pipe parts along the cut surface;

- make tacks on opposite sides of the cut;

- scald the joint.

Following these recommendations will allow you to connect profile pipes at right angles.

...a thin pipe

Before welding thin-walled profile pipes, you should select an electrode of the required diameter and test welding modes on samples. Professionals perform welding without tearing with an electrode with a base coating. Beginners are recommended to use electrodes coated with rutile and cook with oven mitts.