Bone glue in most variations is an appropriate base based on organic components. They allow you to effectively connect elements made of wood, cardboard, hardboard and other similar materials. The connection itself is characterized by maximum strength; even if the structure is destroyed, you can notice that it is not the adhesive layer that is deformed, but the adjacent layers of wood or analogues. The mixture in question includes safe organic components that are approved for use in educational institutions and children's rooms.

Types of bone glue

To prepare the base composition, several main types are used, differing in the main components:

- Flesh option.

- Fish composition.

- Pure bone glue.

The latest version is the most common, the composition is obtained from animal bone waste. The most valuable specimens are considered to be pellets obtained from horns. The set includes collagen, gelatin and cysteine, which have excellent viscosity and are capable of firmly gluing products made of wood and similar materials.

The leather analogue is made from waste from the leather industry. In fact, the main part of the material consists of subcutaneous tissue, cut off during the tanning of hides. Oligopeptides and natural leather trimmings are often added to the composition of this glue. Output – scales, tiles, powder.

Fish bone glue is prepared from bones, heads, scales, entrails, and fins. This substance is the most expensive, but it was often used for icon painting and other works that required maximum care and accuracy. A composition is produced for fastening dissimilar parts, produced in the form of granules or flakes. Let's consider the features of all variations, as well as the features of their operation.

"Titebond" - modern glue

A one-component adhesive, similar in composition to PVA, but characterized by higher adhesion performance. Produced in the USA, it is supplied to the Russian market in containers ranging from 250 ml to 20 liters.

Characteristics of Titebond glue:

- operation at temperatures from -30 to 50°C;

- water resistance class D3;

- hardening time – 5-10 minutes;

- complete drying time – 2-3 hours;

- strong adhesive seam.

The scope of application of this brand of glue is extensive: gluing soft and hard wood, including butt joints. It is also possible to attach veneer, plastic, paper, laminate and other materials to wood.

It is advisable to use Titebond wood glue in the production of furniture of medium and high price categories, railings, stairs, complex and expensive wooden elements. When using this composition, you can significantly reduce the pressing time and obtain a more durable seam. According to the manufacturer, Titebond is non-toxic and does not damage the surface of cutting blades.

Preparation

Carpenter's bone glue is mainly sold in dry form. The mass is small brown or yellow granules, sometimes this material is presented in the form of small slabs. Can the quality of the composition be determined visually? The purer and lighter the material, the better the product. The cooking process is also extremely important. For example, a tile needs to be crushed into crumbs, and then used for its intended purpose. The preparation of bone glue is divided into the following stages:

- Soak. Powder or granules are poured with cold, pre-boiled water. Tap liquid can negatively affect the quality of the finished mass. Fill the container so that all elements of the adhesive composition are covered. Soaking is considered correct if the substance becomes soft and gelatinous. The soaking process takes from 4 to 12 hours, depending on the amount of product being processed.

- Cooking. The swollen glue should be boiled for about 15 minutes in a steam bath. Maintain the temperature at about 60-80 degrees. The result should be a homogeneous liquid mixture without lumps. It is important not to heat the mass over an open fire and not to bring it to a boil. Otherwise, the protein from which the granules are made will begin to deform, and the adhesive ability will decrease. After a thin film has formed on the surface, the adhesive mixture is ready.

Production of hide glue

The production itself occurs as follows. Bone flesh glue is made from animal bones. Mostly these are cows. The bones are manually cleaned and then placed in a crushing machine where they are crushed into small pieces. Then, using a special solution, the bones go through the stage of degreasing and treatment with a solution of sulfurous acid. This is done in order to remove all the mineral salts contained in the bones of the animal.

Next, the bones are sent to special devices where they are cooked. In these machines they are first boiled in water and then steamed for some time. As a result, the output we get is glutin, which is formed due to the breakdown of collagen during cooking. This substance is the glue, but it is not yet ready for use.

When the drying process is complete, wood glue is not yet ready for use. Then it must again go through the cooking stage. After the glue comes out of the gluten production machine and the drying process, the glue is dry tiles, or an already crushed mixture, which is also called scaly hide glue.

In the first case, the tiles are sent to a crushing machine, and the result is a dry adhesive mass. After about one day, it is placed in cold water and soaked there. Then it is filtered and cooked in a steam bath at approximately 65 degrees, while constantly stirring. After all these processes, the hide glue is ready for use. It is sold under the name flesh glue GOST 3252-80. Where is it used? Let's figure it out.

Peculiarities

The readiness of bone glue for wood can be checked in another way. The stick used to stir the substance is raised above the composition. If the product drips down in drops, the process is not completed; complete readiness is indicated by the flow of the mass in a monotonous stream.

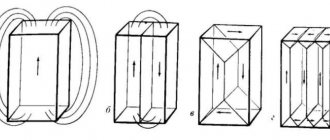

To cook natural glue, a special device is used - a glue gun. It consists of two vessels of different sizes, one of which is inserted into the other. A large container is filled with water, and the second reservoir contains the resulting glue. At the next stage, a small vessel is placed in a large tank and placed on fire. The optimal manufacturing material for the glue is copper.

Recommendations

You can prepare glutinous glue yourself. To do this, you will need to take two containers of different sizes. The outer shell could well be a tin can. Insert a tin can attached to a wire inside it.

The quality of the adhesive composition can be improved by adding various fixing substances. This will allow you to use glue for fastening not only wooden surfaces, but also other analogues.

Among the components used, the most popular, along with efficiency, are the following materials:

- Drying oil. About 10 grams of linseed oil or 40 granules of natural drying oil are added to the composition. This component allows you to increase the resistance of the working seam to moisture.

- Glycerol. An equally effective component makes it possible to use glue when processing leather surfaces. Added at the rate of two teaspoons per liter of finished substance.

- Chalk powder combined with wood ash. After sifting this mixture, add it in small quantities. The paste improves putty properties,

- Phenol, ammonia, borax. These components are an excellent antiseptic that prevents the formation of fungus and mold.

"Moment Joiner"

Professional wood glue made in Russia. The composition is easily applied to wooden surfaces; if necessary, you can immediately begin processing with varnish or paint. It is supplied to the market in different containers - from 200 ml to 30 liters.

Characteristics of “Moment” wood glue:

- water resistance class D2;

- preservation of properties when heated to 70°C;

- bonding strength – above 8 N/mm²;

- gluing time – 15 minutes;

- normal consumption is 150 g/m².

Most often, Moment Joiner glue is used for gluing decorative elements, small parts, plastic and veneer. Complete drying of the joints occurs 2 hours after applying the composition to the surface.

Storage

Natural protein-based adhesives have their own characteristics. Users who use such formulations for the first time should take into account some features.

Among them:

- Adding boiled water. This is necessary if you want to make the mass thinner or extend the cooking time of the composition.

- The optimal operating temperature varies from 30 to 70 degrees Celsius. After this, the finished adhesive mass retains its properties for two hours (provided the ambient temperature is 20-25 degrees). Then the composition begins to cool, and its properties are lost.

- Ready-made wood glue cannot be stored for long periods of time. Within a day it loses its properties. In this regard, to use it, it is necessary to use as many granules as required for a specific operation. On the third day, the composition begins to decompose and smell unpleasant, which is due to its protein base. The glue is applied in layers no thicker than 0.2 millimeters. A thicker layer simply will not set properly.

Scope of application of hide glue

There are a huge number of areas of life where this type of glue is used. For example, hide glue is very actively used in the woodworking industry. There they glue chipboard and fiberboard together. This glue is no less necessary in the paper industry. It is used to glue cardboard boxes and packaging for equipment such as televisions or computers. Furniture factories also use glue made from flesh to glue some furniture elements together. And many other areas where you cannot do without this glue: metallurgical, printing, typographic areas. All this is explained by the fact that the quality of gluing with hide glue is incomparable with all other glues, for example, the usual PVA glue or any other adhesive compositions.

Before use

In the store, hide glue is sold in ready-made or dry form. If the glue is dry, you must first prepare it before you start gluing the surfaces you need. To do this, dry glue is filled with a certain amount of water and stirred until it reaches the consistency of liquid sour cream. After this, you need to leave the glue for a while so that it settles. After about an hour or two, the glue can be considered ready for use.

Exploitation

Casein glue can serve as an analogue for gluing wooden furniture. It consists of sodium fluoride, kerosene, copper sulfate and slaked lime. This composition is not used very often because it has a short shelf life and is prone to drying out, changing color and decreasing in volume.

Working with wood glue is somewhat different from using synthetic analogues (for example, PVA (polyvinyl chloride analogue), which is also used for gluing cardboard and wood).

What can be glued with wood glue

Wood glue (hide and bone) is universal and is suitable not only for gluing wood.

- If you add 1/50 of glycerin to the volume of glue, then you can glue the skin with this composition.

- By adding glycerin 1:20, the heat-resistant properties of the glue are enhanced.

- The water resistance of wood glue increases by adding 10% by weight of potassium dichromate or 15% turpentine.

Subscribe to our Yandex.Zen channel

Preparation

The operating algorithm can be derived as follows:

- The glue is prepared according to the above method, with precise control of the cooking temperature.

- All bonding surfaces must be dry and clean. The maximum moisture content for wood is no more than 10 percent (veneer - half that).

- The adhesive mass is applied with a bast or bristle brush to both surfaces, the thickness of the seam is 0.1-0.2 mm.

- You need to wait three minutes. This will allow the adhesives to grip securely and not be squeezed out when connecting the parts.

- After fixing the elements, you will need to grind them together.

- It is advisable to tie the parts to be processed with twine or compress them with a clamp.

- Full use of the product is allowed no earlier than after six hours of exposure.

conclusions

All of these types of wood glue are environmentally safe. It is better to carry out construction operations with the hide version or PVA. These substances have excellent setting parameters and are affordable. For restoration and gluing of delicate and thin surfaces, glue made from fish raw materials is suitable.

Basic criteria for choosing wood glue:

- The lighter and more transparent the granules or tiles, the better the quality of the raw materials used.

- The most expensive and best glue is made from fish waste. It meets the highest standards. Used for restoration work and joining delicate surfaces.

- Bone and flesh composition is used for routine repair work.