The most effective way to create a permanent connection of parts made of aluminum and alloys based on this metal, as practice shows, is welding aluminum with argon. Any welding technology that involves the use of shielding gas requires the use of special equipment, as well as the welder having the appropriate knowledge, qualifications and experience in performing such work. In addition, it is necessary to have at least basic knowledge in the field of metallurgy in order to understand what processes take place in the weld pool.

Aluminum argon arc welding process

What should you consider when welding aluminum?

Welding aluminum is complicated by the specific properties of the metal. For a quality connection, the following nuances must be taken into account:

- Oxide film. It is formed when metal comes into contact with oxygen in the air. The problem is the large difference between the melting temperatures of aluminum and film: 650 and 2000 °C, respectively. As a result, the oxide remains in the weld, creating its heterogeneity. Aluminum can only be welded efficiently by removing the oxide and excluding contact of the metal with oxygen.

- Low melting point and high melt fluidity. It causes rapid flow of molten metal from the welding zone and through burning of the workpiece. Aluminum begins to enter the liquid phase already at a temperature of 500-520 °C.

- Increased volumetric shrinkage coefficient. An incorrect temperature regime causes stress to appear in the seam, which leads to cracking in it and the seam zone, as well as to deformation of the part.

- High thermal conductivity of aluminum. When welding, the loss of thermal energy increases significantly, which quickly spreads throughout the workpiece. This requires increasing the power of the device.

- Fast crystallization. This property of aluminum leads to the appearance of gas pores in the weld due to incomplete gas release during rapid hardening of the metal.

- Aluminum practically does not change color when melted, which makes visual control of the process difficult.

All these features should be taken into account by a novice welder. Setup requires special care.

Aluminum welding methods

Aluminum can be welded in several ways:

- Electrode welding (MMA). Electrodes used are UANA, OZANA, OZA-1 and -2, OK 96.10 and 96.50. The method is used in low-critical structures and with a metal thickness of at least 4 mm. The main disadvantage is insufficient uniformity of the seam, porosity, and reduced strength.

- Semi-automatic or electric arc welding. Wire with filler material is constantly fed into the welding zone. The connection is ensured by an electric arc. The oxide film is destroyed by cathode sputtering provided by alternating current or direct current with reverse polarity.

- Welding in argon environment. The most common method is argon arc welding. The gas creates an inert environment without oxygen, which eliminates the formation of an oxide film. An arc is ignited between the tungsten electrode and the workpiece. Aluminum wire is fed into the welding zone.

Interesting: Methods of ultrasonic testing of welds and joints

The choice of method depends on the specific welding requirements and conditions, as well as the availability of the necessary equipment.

Preparatory stage of work

Solder for welding aluminum with argon will lie more evenly, and the seam will be stronger if the surface of the material is well prepared before starting work.

First, the aluminum will need to be degreased. For this, a solvent is used, for example, acetone or gasoline. Then the surface is mechanically or chemically cleaned of aluminum oxide. Afterwards, the material must dry if special means were used.

Mechanically, the oxide film can be cleaned using a brush with metal fibers or sandpaper. This method can be used at home. In production, preference is always given to chemical cleaning agents. The aluminum surface can be etched in an alkali solution, washed with hot and cold water, clarified and finally dried.

Aluminum welding technology using argon

With the advent of modern equipment, argon welding has become widely available even for use in domestic conditions. It can be carried out in manual (TIG welding), semi-automatic and automatic mode. Step-by-step instructions will help you weld aluminum with argon for beginners; it will allow you to do everything correctly and efficiently.

What is needed for welding?

Equipment for welding aluminum

To weld aluminum with argon, a novice welder must prepare in advance:

- The current source is a TIG inverter.

- Special argon burner. It is advisable to insert a gas lens (collet holder) into it to purify the gas.

- An argon cylinder and a hose for connecting it to the burner.

- Filler wire. It is selected taking into account the grade of aluminum or alloy. For pure aluminum, rod No. 5356 is recommended; for aluminum with impurities, rod with silicon No. 4043 is recommended.

- Tungsten electrodes. Recommended brands: WT 20 (has a red tip), WC 20 (gray tip) or WL 15 (yellow tip). The minimum electrode diameter is 2.4 mm.

Important! The inverter should be selected with the following functions: non-contact ignition, crater filling, current regulation.

How to properly prepare aluminum?

High-quality welding of aluminum is possible only after careful preliminary preparation of metal blanks. First of all, it is necessary to clean the surface of the parts from dirt, grease, machine oils and oxide film. Mechanical and chemical cleaning methods can be used.

The mechanical method involves the use of sandpaper, a scraper or a wire brush. It is best to use a special brush for aluminum with stainless wires with a diameter of no more than 0.15 mm. It should not be used on other metals to avoid leaving particles on it.

Chemical cleaning can be done with alcohol, acetone or special solvents. This composition has proven itself well: a solution of sodium hydroxide (50 g) and sodium fluoride (45 g) in water (1 l). After treatment with this solvent, the surface remains clean for up to 4 days.

Immediately before welding, aluminum workpieces should be thoroughly heated (calcined). To do this, they are heated to a temperature of about 300 °C for 20–30 minutes.

Interesting: Technology for visual measuring inspection of welds and joints

Preparations require the edges of the workpieces to be welded. If the metal thickness is more than 4 mm, they must be cut for butt welding. It is better to clean large irregularities with a grinder or file.

Preparing argon for welding

The preparation of argon for welding is important. The gas cylinder is installed at a safe distance and must be equipped with a pressure reducer. When purchasing, you should choose pure argon, without air impurities.

It is recommended to install a collet holder in the torch. It has a mesh that provides additional purification of the gas before it is supplied to the welding zone.

Gas flow is adjusted. It depends on the diameter of the filler wire. For Russian-made argon, the following flow rate is set: with a diameter of up to 1 mm - 12-14 l/min, with 1.2 mm - 14-16 l/min, with 1.6 mm - up to 22 l/min. When using Czech-made gas, the flow rate is 7–10 l/min.

Aluminum argon welding process

Tig welding scheme

A novice welder should follow these step-by-step instructions:

- After all the preparatory work has been completed, the selected electrode with a diameter of 2.5–5.5 mm is inserted into the burner. Its overhang should be about 2 mm. The key to ensuring the desired arc is good sharpening of the electrode.

- Excitation of the welding arc. The torch with the electrode is taken in the right hand, and the filler rod (wire) is taken in the left hand. The electrode is brought to a short distance to the surface of the workpiece (2–3 mm), sufficient for an arc to occur. You cannot touch the metal with the electrode, because... I'll have to sharpen it again. The torch is held vertically and the arc is directed towards the beginning of the seam. By changing the distance between the electrode tip and the metal, you can change the size of the arc.

- Formation of a weld pool. It is achieved by melting aluminum wire. It should be applied after ensuring a stable arc. It is generally accepted that the number of seconds required to form a weld pool coincides with the thickness of the workpiece (in mm).

- Formation of the weld. After the formation of the weld pool, regular wire feeding and smooth movement of the torch along the workpiece joining line are ensured. The electrode is held at an angle of 60-80°, and the filler rod - 10-30°. It is desirable that the angle between the torch and the wire is about 90°. The seam is formed according to the “drop by drop” principle, which means you need to ensure that they are distributed differently and are of the same size.

- Finishing the seam. The last stage is filling the crater. The main goal is to get rid of toxins. To do this, the wire feed is reduced and the speed of the electrode is increased. The weld pool should gradually disappear.

Important! The work is completed by checking the strength of the connection and visual control of the quality of the seam.

Rules for holding the electrode and filler wire

Materials

Today, a large number of aluminum alloys are used. Each has its own physical and chemical characteristics. Filler wire for welding aluminum with argon must be used in a timely manner. If the packaging has already been opened, such products cannot be stored for a long time. Once oxidized, the surface of the filler wire will be unsuitable for welding aluminum with argon.

Before carrying out the process, the surface is cleaned of foreign contaminants. Even with a short stay in air, aluminum is covered with a film of Al2O3 oxide. Such material requires a protective environment of inert gases during the welding process. Argon is used for this.

But it is better to use this gas mixed with helium. This allows you to achieve a higher weld pool temperature. This is especially important for thick-walled workpieces. In some cases, aluminum welding is performed semi-automatically without the use of argon, but only helium.

Also, using a mixture of gases allows you to obtain a less porous seam.

Setting up argon welding for aluminum

Setting up the aluminum welding process includes the following steps:

- Setting up the welding machine. The following parameters are set on it: current balance with polarity setting (CLEAN WD.), welding current value (CURRENT), crater filling function (DOWN SLOPE toggle switch) or slow arc decay, gas purge function (POST TIME) for cooling the weld pool and torch .

- Setting up electrodes. The diameter of the electrodes and their projection from the burner are selected correctly.

- Argon flow setting. It depends on the diameter of the filler rod. When welding outdoors, consumption increases.

Interesting: Methods for quality control of welded joints and seams

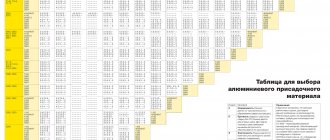

When setting the modes, the ratios given in the table are used:

| Thickness Al, mm | Current strength, A | Electrode diameter, mm |

| up to 1 | 30–42 | 1,6 |

| 1,1–1,5 | 46–60 | 2,3 |

| up to 2 | 71–80 | 2,3 |

| 3 or more | 90–300 | 3,2–5 |

It is necessary to configure equipment and modes with special care. It is better for novice welders to seek help from experienced specialists.

Instructions for the process

The machine for welding aluminum with argon initially supplies “mass” to the workpiece. The master should take the wire in his left hand, and the torch in his right hand. When you press a button on the equipment, the current will turn on and gas will begin to flow. An arc will form between the workpiece surface and the electrode. It will melt the aluminum filler wire and the edge of the part. At the same time, a weld seam will begin to appear on the surface.

For an experienced master, this process will not be difficult. For a beginner, it will be important to practice a little.

This process has been tested over the years by a large number of specialists. It has proven its consistency and durability of the final result.

By adhering to the instructions presented, as well as making several practice applications of solder on a test workpiece, even a novice welder will be able to complete the job quite efficiently.

Safety precautions

When carrying out work, it is necessary to take into account the presence of electric current, a bright glow of the arc, hot metal that can splash, and high temperatures. The welder must wear a special mask with a blue light filter. Gloves that protect your hands from melt splashes and clothing that can protect your entire body from them are required.

Electrical equipment must be reliably protected. It is necessary to use a residual current device and circuit breakers. The gas cylinder is equipped with a pressure reduction reducer. Before starting work, you must study the safety regulations and strictly follow them.

When welding aluminum one has to face difficulties caused by its specific properties. Argon welding, with the right approach and the use of high-quality materials and equipment, ensures a reliable connection.

Recommendations from experts

Experts note the features of welding aluminum with argon, which novice craftsmen should take into account.

The electrode is located as close as possible to the surface to be welded. This will promote the formation of a minimal arc. The wire should be fed smoothly, otherwise sharp jerks will lead to spattering of the material.

The stability of the arc is ensured by the vertical position of the electrode. The welding speed must be high. The quality of the final result will depend on this indicator. To ensure a smooth and strong seam, a beginner should practice welding before starting work.