- Reports and messages

- Geography

- Metal alloys

A long time ago, people noticed, speaking about biology, for example, that if you combine two organisms, the third will surpass its parents.

It turns out that the same principle works in chemistry, so the history of the appearance of alloys can be considered straightforward. Someone simply noticed that when melted, metals are mixed and something new and more durable is obtained. According to the modern definition, an alloy is a chemical compound that must contain at least one metal, while the remaining components may not be metals.

For example, bronze, which is an alloy of copper + tin, is more durable, which is why people most often use alloys. Moreover, there are countless different variations of alloys, although at the moment only eighty-odd types of metals are known.

The alloys are also characterized by high resistance and hardness in addition to the fact that they have excellent casting properties. For example, tin bronze (copper + tin) lends itself better to casting than plain copper, so it is often used in sculpting works of art. Similar casting alloys also include cast iron (iron + carbon), duralumin (aluminum + copper + magnesium + manganese), etc.

Let's consider the classification of alloys:

- Compound. Alloys are divided according to their predominant components, for example: titanium, copper, nickel, etc.

- Value. Alloy names refer to the value of the components, for example: brass, tungsten steel, etc.

- Black metals. The name is most often used in metallurgical production. This group includes absolutely all alloys that contain iron.

- Non-ferrous metals. Again the name is used in metallurgy and refers to other metals besides iron.

Accordingly, the above groups are divided into subgroups with a narrower selection of common components or properties, for example.

Option No. 2

Alloys

1) Reasons for use 2) Classifications 3) Components and ligatures 4) Applications

Man took a revolutionary step when he realized that a mixture of copper and tin was much harder than any of these metals in their pure form. It is believed that this happened at least eight thousand years ago.

Tens of thousands of alloys are used in the modern world, and the development of new ones continues. Several criteria are used to classify alloys.

First of all, there are two large groups: ferrous metals (i.e. alloys based on iron) and non-ferrous metals (based on other elements).

Depending on where the metal will be used, it is classified as a general-purpose or special alloy. Further, binary and complex (ternary, quadruple, etc.) alloys are distinguished according to the number of elements included in its composition.

Alloyed alloys are distinguished. Special impurities are added to them to obtain the desired properties. From the point of view of the production process, alloys can be cast, powdered (sintered) and wrought.

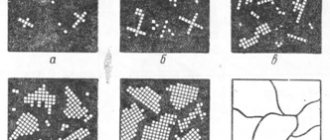

The degree of connection of elements in an alloy can be different, so a distinction is made between a mechanical mixture (each element forms a separate crystal), a solid solution (different elements are built into a common crystal lattice) and a compound (atoms form a chemical bond).

To make iron more hard, carbon is added, but at the same time the metal becomes more brittle. Steel contains 0.3-2.14% carbon. Low-carbon steel is used as a structural material, while harder grades are used to make tools. Alloy steel is used in mechanical engineering and the manufacture of tools with high cutting speeds. Steel is alloyed by adding chromium, manganese, titanium, vanadium, etc. In this way, strength is increased without loss of hardness.

Cast iron contains from 2 to 4% carbon. Products with good abrasion resistance, strength, and rigidity are made from it by casting.

Cadmium slows down the wear of copper alloys. In copper alloys, zinc increases ductility and corrosion resistance. Titanium greatly increases the operating temperature limit. Nickel and, to a lesser extent, chromium increase the strength of ferrite without affecting ductility.

9th grade in chemistry

Where did the Pound Sterling come from?

Sterling is the name of an alloy of 92.5% (or higher) silver and 7.5% other metals, usually copper (sterling silver and higher). Pure .999 silver is too soft and unsuitable for creating large objects, so it is usually alloyed with copper to provide strength while maintaining the ductility and beauty of the precious metal.

The name "sterling" appeared in the 12th century. This was originally the name given to an ancient English silver coin. 240 coins weighed 1 pound (453.6 g). The cost of large purchases was calculated in pounds sterling. On the other hand, it was a way of checking the weight of the coins: if the weight of 240 coins was not equal to 1 pound, the coins could be counterfeit or too worn.

Share link

Popular message topics

- Horse pet

The horse is one of the most beautiful and noble animals. It was domesticated four thousand years ago. Soon he modified her appearance according to his plans. And now all kinds of breeds appeared before us - from miniature ponies - Properties of ice

Every person has seen ice at least once in his life. But not everyone knows at what temperature ice begins to melt, where there is most ice on the planet and what properties it has. Today we will try to find out a little more about this cold and slippery substance. - Water hardness and its elimination

Water hardness refers to the presence in it of such physicochemical properties that are associated with a certain amount of alkaline earth metal salts contained in the water in a dissolved state, most often magnesium or calcium.

Classification

Metallurgists classify metal alloys according to several criteria:

- manufacturing method:

- cast;

- powder;

- production technology:

- foundries;

- deformable;

- powder;

- homogeneity of structure:

- homogeneous;

heterogeneous;

- type of metal - basics:

- black (iron);

- non-ferrous (non-ferrous metals);

- rare metals (radioactive elements);

- number of components:

- double;

- triple;

- and so on;

- physicochemical characteristics:

- refractory;

- fusible;

- high strength;

- heat resistant;

- hard;

- antifriction;

- corrosion-resistant, etc.;

- purpose:

- structural;

- instrumental;

- special.

Types of alloys based on them

Metals and alloys based on them have different physical and chemical characteristics.

The metal having the largest mass fraction is called the base.

Aluminum alloys

As we have already said, it is absolutely impossible to imagine modern industry without them. Judge for yourself: aluminum alloys are actively used in aviation, space, military, scientific and engineering and other industries. Without aluminum, it is impossible to imagine manufacturers of modern household and mobile appliances, since cases made of this metal are increasingly used by modern flagships of these industries.

About light alloys

As we have already said, the properties of metals and alloys differ in that the latter in many cases have higher characteristics. This is especially noticeable in relation to modern industry. In recent years, it has required a huge amount of light alloys, which have increased mechanical strength, as well as resistance to adverse environmental factors and high temperatures.

Most often, aluminum, beryllium, and magnesium are used for their production. Compounds based on aluminum and magnesium are especially in demand, since the scope of their possible application is extremely wide.

Basic definitions

In general, metal alloys are materials obtained by smelting, in the production of which two or more metal elements (in the chemical sense) were used, as well as (optionally) special additives.

One of the first materials of this kind was bronze. It is composed of 85% copper and 15% tin (80:20 in the case of bell bronze). Currently, there are several varieties of this compound that do not contain tin at all. But they don't occur very often. It is necessary to clearly understand that metal alloys in most cases are formed without any human involvement at all. The fact is that it is possible to obtain a material that is absolutely pure from a chemical point of view only in the laboratory. Any metal that is used in everyday life probably contains traces of another element. A classic example is gold jewelry. Each of them contains a certain proportion of copper. However, in the classical sense, this definition still means a compound of two or more metals, which was purposefully obtained by man.

The entire history of man is an excellent example of how metal alloys were able to have a huge impact on the development of our entire civilization. It is no coincidence that there is even a long historical period called the “Bronze Age”.

Become

All iron compounds containing up to 2% carbon are called steels.

If the composition contains chromium, vanadium or molybdenum, then they are called alloyed. We encounter these materials constantly, daily and hourly. The number of steels today is such that listing them alone could fill a not-too-thin book. We have already said that the mechanical properties of metals and alloys are very different, but in the case of these materials, even different types of steel often have opposite qualities, which is why their areas of application differ greatly.

If the material contains less than 0.25% carbon, then it is used in some technical structures. If the steel contains more than 0.55% carbon, it is ideal for the production of a variety of high-quality cutting tools, including lathe cutters, drills and surgical supplies. But if we are talking about devices that are used for fast cutting, then only alloy steel is used for their production.

Examples of problem solving

| Exercise | How many kg of tin must be added to a piece of bronze (m=4kg) containing 15% tin in order to increase the tin content in it to 60% of the total mass? |

| Solution | Let two alloys be mixed, the second alloy containing 100% tin and no other components. Let's find the masses of tin in the alloys: |

Then the mass of alloys will be:

The ratio of the mass of tin in the new alloy to the mass of the new alloy is:

Source

Cast iron

If an iron alloy contains more than 3-4% carbon, then it is called cast iron. In addition, its important element is silicon. A lot of parts and finished products are made from cast iron. For example, engine blocks for cars. In the case of a high-quality casting without cavities or cavities, the product has impressive mechanical strength. In this regard, it is worth recalling at least the guns of the 14th-15th centuries, which often withstood a three to fourfold increase in the powder charge.

Of course, the use of metals and alloys was never limited exclusively to the military industry, but it often turned out that it was this branch of industry that constantly found new methods of metal processing, moving forward the entire civilization.

Read the chemistry essay: “Metal alloys” Page 1

(Back)

The “read” function is used to familiarize yourself with the work. The markup, tables and pictures of the document may be displayed incorrectly or not in full!

The metal objects around us rarely consist of pure metals. Only aluminum pans or copper wire have a purity of about 99.9%. In most other cases, people deal with alloys. Thus, various types of iron and steel contain, along with metal additives, small amounts of carbon, which have a decisive influence on the mechanical and thermal behavior of the alloys. All alloys have special markings, because... alloys with the same name (for example, brass) may have different mass fractions of other metals.

Various metals are used to make alloys. The most important among all alloys are steels of various compositions. Simple structural steels consist of relatively high purity iron with small (0.07-0.5%) additions of carbon. Thus, cast iron produced in a blast furnace contains about 10% other metals, of which approximately 3% is carbon, and the rest are silicon, manganese, sulfur and phosphorus. And alloy steels are obtained by adding silicon, copper, manganese, nickel, chromium, tungsten, vanadium and molybdenum to iron.

Nickel, along with chromium, is an essential component of many alloys. It gives steels high chemical resistance and mechanical strength. Thus, known stainless steel contains on average 18% chromium and 8% nickel. For the production of chemical equipment, aircraft nozzles, space rockets and satellites, alloys are required that are stable at temperatures above 1000 ° C, that is, they are not destroyed by oxygen and flammable gases and at the same time have the strength of the best steels. Alloys with a high nickel content satisfy these conditions. A large group consists of copper-nickel alloys.

An alloy of copper, known since ancient times, bronze contains 4-30% tin (usually 8-10%). Bronze products from masters of Ancient Egypt, Greece, and China have survived to this day. In the Middle Ages, tools and many other products were cast from bronze. The famous Tsar Cannon and Tsar Bell in the Moscow Kremlin are also cast from an alloy of copper and tin. Currently, in bronzes, tin is often replaced with other metals, which leads to a change in their properties. Aluminum bronzes, which contain 5-10% aluminum, have increased strength. Copper coins are minted from such bronze. Very strong, hard and resilient beryllium bronzes contain approximately 2% beryllium. Springs made of beryllium bronze are practically eternal. Bronzes made from other metals: lead, manganese, antimony, iron and silicon are widely used in the national economy.

Cupronickel alloy contains from 18 to 33% nickel (the rest is copper). The melting point of cupronickel is 1170 °C. It has a beautiful appearance. Cupronickel is used to make dishes and jewelry, and mint coins (“silver”). An alloy similar to cupronickel - nickel silver - contains, in addition to 15% nickel, up to 20% zinc. This alloy is used for the manufacture of artistic products and medical instruments. The copper-nickel alloys constantan (40% nickel) and manganin (an alloy of copper, nickel and manganese) have very high electrical resistance. They are used in the production of electrical measuring instruments. A characteristic feature of all copper-nickel alloys is their high resistance to corrosion processes - they are almost not subject to destruction even in sea water. Copper alloys

Properties of alloys

The properties possessed by metal alloys are divided into:

- Structurally insensitive. They are determined by the properties of the components and their percentage. These include :

- density;

- melting temperature;

- thermal and elastic characteristics;

- coefficient of thermal expansion;

- structurally sensitive. Determined by the properties of the element - the base.

- All alloy materials exhibit characteristic metallic properties to one degree or another:

- shine;

- plastic;

- thermal conductivity;

- electrical conductivity.

- In addition, properties are divided into:

- Chemical, determined by the relationship of the material with chemically active substances.

Mechanical, determined by interaction with other physical bodies.

- The main characteristics of alloy materials that influence their suitability for use in a particular engineering structure are:

- Strength is a characteristic of the strength to withstand mechanical loads and destruction.

- Hardness is the ability to resist the penetration of solid bodies into a material.

- Elasticity is the ability to restore the original shape of a body after deformation caused by external load.

- Plasticity is the opposite property of elasticity. Determines the ability of a material to change the shape of a body without its destruction under an applied load and maintaining this new shape.

- Viscosity - the ability to resist rapidly increasing (shock) loads

Mechanical properties

To quantitatively express these properties, special physical quantities and constants are introduced, such as the elastic limit, Hooke's modulus, viscosity coefficient and others.

Magnesium alloys

They have extremely low weight and are also characterized by very impressive strength. In addition, these materials are excellent for the foundry industry, and the workpieces are perfectly amenable to turning and milling. Therefore, they are actively used in the production of missiles and aircraft turbines, instrument housings, car wheel rims, as well as some types of armor steel.

Some varieties of these alloys are distinguished by excellent viscous damping properties, and therefore they are used for the production of parts and structures that have to work under conditions of extremely high levels of vibration.