The need for welding work often arises not only in production, but also in everyday life. Welding of aluminum products and structures at home is carried out quite often, despite the occurrence of some difficulties. The difficulties are due, first of all, to the characteristics that this material has. the conditions necessary for working with aluminum .

However, situations arise when it is necessary to repair aluminum products. In such cases, the work is performed at home, by the contractor’s independent efforts. Therefore, in this article we will look at the main features and nuances of aluminum welding.

What is the difficulty of welding aluminum

Since aluminum does not occur in completely pure form and reacts almost immediately with oxygen, a particular difficulty is the difference in temperature at which the chemical element itself and its accompanying oxide begin to melt.

More precisely, the temperature at which aluminum transitions into the liquid state is 660 C, while the oxide is 2043 C. Boiling point

- Formation of an oxide film, which can be removed mechanically using special grinding devices and sandpaper;

- Instability of aluminum under the influence of elevated temperatures. That is, the use of additional funds can get rid of increased fluidity. For example, special substrates are used to remove heat and direct it only to those areas where arc formation is required;

- Disturbances of the alloy surface. Due to the presence of hydrogen in the alloy and its further release during the heating process, the surface of the metal is often covered with pores and cracks;

- A change in color is a sign that the metal is overheated. As mentioned earlier, the melting point of aluminum is quite low. Consequently, many people make mistakes by overheating the metal. This occurs due to the fact that during the welding process the specialist is wearing a mask, which does not fully reflect the color changes in the environment.

Welding aluminum using fluxes

Fluxes for welding aluminum have been used for a long time. They are represented by a wide range of models, where there are materials for different aluminum alloys. Their main purpose is to destroy the oxide film. When heated, the applied flux dissolves and destroys the oxide, and the two elements are immediately connected.

Manufacturers offer fluxes that are used only in gas welding of aluminum, or only in arc welding. In the latter case, graphite or carbon electrodes are used.

Advantages and disadvantages

As mentioned earlier, welding aluminum is not an easy task and requires a certain skill and knowledge. However, this type of work is still in demand. The only explanation for this is the quality of manufactured parts and structures, despite belonging to the group of light metals.

Moreover, aluminum is so highly valued in industry that almost any tool necessarily includes this substance.

The advantages of cooking include the following:

- This process does not require much time, and the product of your activity can be seen a few minutes after the end of welding;

- This type of work is considered budget-friendly because it does not require the master to have any special equipment;

- Lack of a scale assessing the quality of the resulting seam;

- The result is a strong, seamless seam.

The disadvantages include the following:

- Despite the lack of criteria and requirements, the seam is still of poor quality;

- It is difficult to follow all the TB rules;

- From time to time, a specialist is faced with a problem in choosing auxiliary materials.

Work order

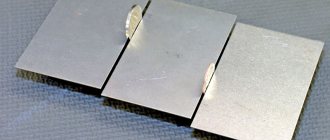

The sequence of operations for resistance spot welding of aluminum is as follows:

- Installation of blanks.

- Pressing materials tightly between the electrodes of a resistance welding machine.

- Energy supply through electrodes.

- Heating of parts.

- Formation of a molten core.

- Power outage.

- A short exposure of the workpieces between the electrodes in a compressed position in order to cool the welded zone and reduce the shrinkage cavity during crystallization of the molten metal.

The work process is automated and begins from the moment the operator presses the start button.

Aluminum welding methods

It is recommended to use several methods for welding aluminum, which are time-tested and popular in certain circles.

These include:

- Submerged arc welding. This material is used to protect joints from oxidation.

- Welding under the influence of gases. Since in this case it is almost impossible to see how aluminum changes color, preliminary training is required to carry out high-quality welding.

- Welding using laser. Laser radiation is used to connect two elements. This in turn promotes melting and forms a nice, smooth joint line.

- Welding using contacts. In this method, two connection methods are appropriate - linear and point. The contact method is good only for fastening sheets;

Welding by increased friction of two elements: this process cannot be called easy; available tools will not be enough depending on the level of complexity of the work.

- Special equipment with a rotating nozzle is required.

- Due to rotation, the aluminum begins to heat up and subsequently melt, after which it is connected to the desired element.

- At home, it is appropriate to use an angle grinder.

What type of aluminum welding machine is best?

To decide on the type of device to purchase, answer the following questions:

- What types of metals will you be working with, in particular, will you be welding only aluminum or other metals as well?

The type of device purchased will depend on this - only with direct current or with AC/DC. “Permanent” is used to work with steel, stainless steel, and copper. AC/DC devices are universal and can operate on both direct and alternating current. - Will you be welding workpieces less than 1 mm thick, stainless steel?

If yes, then your installation must be equipped with a pulse mode. - How intensively will you use the device?

For continuous operation, it will be useful to acquire an aluminum welding machine and liquid-cooled torches. - Where will you use the device?

For professional needs, TIG installations and semi-automatic machines are used. If you need an installation for occasional work at home, then a regular MMA device will do. - How long will your seams be?

For short seams, you can buy a TIG device. It is possible to provide long connections using semi-automatic devices.

This is enough to understand the basic parameters of choice.

What do you need to know when choosing a device?

When purchasing a welder, pay attention to the following points:

- The thickness of the metal being joined.

The current range in the welder depends on it. If you mainly work with steel structures up to 6 mm thick, then a device up to 200 A is suitable, but aluminum of the same thickness will require over 200 A. If you need to work with very thin workpieces from 0.5 mm, then semi-automatic devices are suitable.

- Your experience in metal welding.

If you're a beginner, you'll benefit from a device that has features that make your workflow easier. It is also worth noting that welding using an MMA machine is easier than using a argon arc welder.

Modern high-tech machines for aluminum welding have a large number of capabilities, settings and adjustments.

Useful features in TIG welders

If you still decide that the quality of the weld is more important to you and want to purchase an argon arc machine, then it won’t hurt you to learn about the useful functions that TIG machines can have.

TIG devices for forming an even better quality seam can have the following functions:

- Pulse.

Alternating current strength. Necessary to reduce heat input and minimize the risk of burn-through. - "Pre/post gas".

Supply of shielding gas before and after seam formation. - Switch to AC.

TIG welding with an inverter is carried out only in AC. - Balance adjustment.

It makes it possible to extend the service life of the electrode and increase the penetration depth, or vice versa, reduce heat input and minimize the risk of burn-through.

Semi-automatic machines (MIG/MAG) can be produced with functions such as:

- Pulse.

Thanks to the pulsation of the current, at the moment of increase, the oxidized upper layer effectively melts, and during the decrease, the filler material is quietly fused. - Double Pulse.

Doubling the normal pulsation. Promotes thinner seams and increased speed of welding parts.

By selecting all the necessary functions, you will not only get high-quality work done, but also save time and also be able to extend the service life of the aluminum welding machine.

Preparation of material

To perform proper welding, it is worth preparing the edges of the part or structure that will have to be melted. This event can be carried out both at home and at the factory.

Preparation includes:

- High-quality cleaning of the metal working surface from dirt and degreasing. To carry out the latter, you will need a small amount of acetone or gasoline;

- When welding thin sheets of aluminum, they must be properly processed;

- While preparing, you can worry about cutting apart already welded parts;

- Before starting work, the entire part must be cleaned of oxide film. To do this you will need a stiff brush. You can clean it by resorting to special solvents.

Preparation of aluminum parts for welding

Due to the specific properties of aluminum, its preparation before welding is of key importance to the final result.

Particular attention should be paid to the location (edges of the product) for the planned weld. Mainly cleaning is performed in order to get rid of the oxide film.

Sequence of preparation:

- Cleaning and degreasing the material from plaque of any origin . This is done with acetone, solvent, or, less commonly, aviation gasoline.

- Cutting edges is necessary if their thickness exceeds 4 mm when using standard electrodes.

- Removing the oxide film . The tool is selected according to the thickness of the aluminum part. Usually a file, milling cutter or metal brush is used.

Necessary equipment

It is logical that to carry out work of this kind, the use of equipment is mandatory. First of all, it is necessary to ensure suitable conditions and prevent the occurrence of traumatic situations.

Moreover, it is necessary that this equipment helps control the energy transformation process.

For welding using gas, you will need an element with a gas supply, a cylinder with the necessary gas, a reducer and gas hoses.

Safety precautions

This type of activity belongs to the group of trauma-hazardous processes. Therefore, you should strictly follow the prescribed rules to avoid causing harm to others.

It should be remembered that:

- The specialist must wear: a special suit, a mask, thick gloves, shoes with rubber soles;

- The electrical circuit must be isolated and inaccessible;

- Welding can only be carried out in clean areas. It is prohibited to carry out work in the presence of flammable objects;

- The work area must have good ventilation to avoid gas poisoning.