Products made of steel and cast iron are subject to intense corrosion under the influence of atmospheric oxygen and water. In this case, loose iron hydroxide is formed on the surface, which, due to weak adhesion to the surface and high porosity, does not protect the underlying metal layers from oxidation. One of the most technologically and economically advantageous ways to protect steel and cast iron products from corrosion is the application of a durable protective coating that will prevent contact of the metal with water and the atmosphere.

Galvanizing is one of the most widespread methods of protecting products made from iron-carbon alloys from corrosion in the atmosphere and fresh water.

Advantages of hot dip galvanizing

Advantages of using the hot-dip galvanizing method:

- Ability to reach the smallest elements and gaps;

- The resulting coatings are resistant to mechanical damage, abrasion, erosion and impact;

- Hot-dip galvanizing technology is a diffusion phenomenon that involves the penetration of zinc atoms into the outer layer of steel in molten zinc;

- The coating obtained during the hot-dip galvanizing process has a layered structure;

- Composed of iron-zinc alloys and a layer of pure zinc, and the presence of alloy layers makes the zinc coating inextricably bonded to the steel substrate;

- The zinc coating has anti-corrosion properties;

- The zinc coating protects the steel for many years and does not require maintenance;

- Aesthetic value;

- Possibility of applying paint or just paint (the so-called duplex system).

Cold galvanizing technology

The cold zinc coating method is sometimes preferable to hot zinc coating. The following factors can be considered the main advantages of the method of cold protection of metals:

- high level of coating adhesion, which makes it possible to achieve good adhesion of various paints and varnishes to a galvanized surface;

- there are no strict requirements for the geometric shape of the product being processed;

- no serious financial costs are required for pre-treatment of the product before galvanizing;

- Products with a cold-applied zinc coating lend themselves well to welding;

- Cold galvanizing can be done even at home, using a paint roller, brush or spray device;

- This type of work can be performed directly on site, which eliminates the work of dismantling structures and transporting them to production and back.

In addition, the protective galvanizing composition can be applied coldly at temperatures from -20 to +40 °C. Of course, there are also disadvantages to using this method of metal processing, the main one of which is poor resistance to mechanical damage to the surface of the product. In some cases, such a disadvantage can be neglected, since it is always possible to re-apply the zinc coating to the same product.

The specified cold metal galvanizing technology is carried out using various anti-corrosion compounds. GOST 9.305–84 describes their structure and properties. It provides the characteristics of all existing inorganic (non-metallic and metallic) coatings applied by chemical and electrochemical metal processing. According to the standard, cold galvanizing compounds are used on any metals, with the exception of magnesium alloys and high-strength steels.

In cold galvanizing technology, much attention is paid to the pre-treatment of the metal before applying the protective composition. All work is carried out in accordance with GOST, where each stage is prescribed:

- first, any contaminants, traces of coking and salt are removed from the metal by washing it off the surface;

- to give the surface a certain level of roughness and eliminate scale and rust, cleaning is carried out using a waterjet, hydrodynamic or abrasive blasting method;

- then it is necessary to dry the surface if it has been exposed to water;

- final cleaning is done only by hand, mechanically removing burrs, cooking splashes, sharp edges and corners;

- The preparation is completed by removing dust from the metal surface, which is done using a jet of air under high pressure.

After performing preliminary cleaning and checking its quality, they begin to apply a special composition for cold galvanizing of metal. In accordance with the technology, it is necessary to maintain a certain air temperature. For each protective composition, it is indicated by the manufacturer in the instructions. As for the temperature of the product itself, the surface should be 3 degrees warmer than the dew point. Otherwise, there is a high probability of moisture appearing on the surface, which will significantly reduce the quality of the protective coating.

What is hot dip galvanizing

Hot-dip galvanizing occurs by immersing the product prepared for this process in zinc (Zn), heated to a temperature of approximately 450-500 degrees.

The result of such a bath is the creation of a thick layer of zinc both outside and inside the product - the thickness of zinc, for example, in bicycle racks ranges from 40 to 110 microns - in practice, 1.5 microns is enough for about 1 year.

Before the bath, a pre-treatment is recommended, which is used to clean the steel elements from contaminants such as rust, welding slag, grease or oils.

After a few minutes (the time required for the iron and zinc to complete the reaction between them), the steel is removed from the zinc bath. The hot-dip galvanized surface is thicker than the electroplated surface.

- Hot-dip galvanizing results in a tough, durable and completely corrosion-resistant coating that effectively protects steel parts, including hot-dip galvanized wire, rods and other metal products.

- This type of coating is also resistant to mechanical damage. Galvanization is done layer by layer. All layers are extremely durable and together form an effective protective barrier, without losing their properties even in the event of local damage.

- This is facilitated by a multi-layer structure - the outer layer is soft and absorbs pressure and shock, and the inner layer is hard and protects the base from damage. In addition, hot-dip galvanizing gives steel elements a special aesthetic appearance, since their connection produces different colors.

- This is possible due to the difference in the heat capacity of individual elements - parts with a lower heat capacity acquire a metallic sheen, and elements with a higher heat capacity become gray.

The first layer that appears on the surface of a galvanized steel element is a layer of almost pure zinc - Zn (minimum iron content). The next layers are the so-called alloy layers, that is, Zeta, Delta and Gamma.

The zeta layer contains about 6% iron (Fe), the next delta layer contains about 10% iron, and the last gamma layer is an iron-zinc alloy that contains about 25% iron.

Zinc coating

DACROMET 320 (“Dacral”, “Geomet”)

Zinc-rich coatings called "Dacromet 320" (Dakromet 320) were developed (USA). The coating is applied by immersing parts in a suspension of zinc particles in an aqueous solution of organic and inorganic components. After removing excess suspension by centrifugation to finalize the coating, the parts are subjected to stepwise heating, starting at 80°C and ending at a final temperature of 300°C.

The peculiarity of the Dacromet 320 coating is the presence of micron-sized zinc particles in the form of flakes, pre-treated in a chromate solution and tightly bound together with an inorganic binder. The thickness of the dry coating is 8-10 microns. The coating has a silver-gray appearance and, due to the presence of chromates in the system, has high corrosion resistance - about 500 in neutral salt fog, which is slightly higher than the anti-corrosion resistance of products obtained by electrolytic method.

The advantage of this method relative to electrolytic and hot-dip galvanizing methods is the absence of hydrogen embrittlement. This method does not have any advantages over thermal diffusion galvanizing.

Zincclamel coatings

The zinc lamel coating system includes a base layer consisting of thin aluminum and zinc flakes (lamellas) and, if necessary, one or more additional layers that give the coating special properties: friction, corrosion and chemical resistance, color and others.

Zinc clamel coating is applied to the previously prepared surface of parts by dipping into a highly dispersed suspension of zinc and aluminum powders in the form of flakes in a binder material or by spraying it, followed by heating the parts to 240°C for drying and curing. The formed base coating contains more than 70% zinc and up to 10% aluminum powder, as well as an organic binder material. It consists of many layers of aluminum and zinc particles less than a micrometer thick and about 10 microns wide, located parallel to each other and the surface to be coated, connected by a binder component. The corrosion resistance of coatings is over 700 hours in neutral salt fog, which is slightly higher than the anti-corrosion resistance of products obtained by electrolytic methods.

| Zinclamel coating (type 1) | Zinclamel coating (type 2) | Electrolytic galvanizing + passivation | Hot galvanizing | |

| Electrical protection | Conductive | Insulating | Conductive | Conductive |

| The danger of hydrogen embrittlement | No | No | Yes | Yes |

| Chromium (6-valent) | No | No | Yes | Yes |

| Friction coefficient 0,08-0,14 | Yes | Yes | No | No |

| Resistance to acid alkalis | No | Yes | No | No |

Mechanical galvanizing

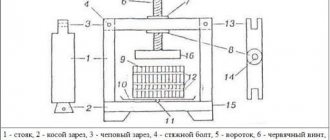

Chemical-mechanical method of coating. The parts to be coated are placed together with granules and zinc powder in a special drum, in which the zinc is applied to the surface of the parts using cold welding.

As a result of mechanical galvanizing, the part acquires properties similar to those of electrolytic galvanizing. The advantage of this method compared to the electrolytic method is that there is no danger of hydrogen embrittlement when using it.

Operation of zinc-plated fasteners

Practical experience in using coated fasteners allows us to determine the average annual volume of destruction of the zinc coating depending on operating conditions, which are presented in the table for reference.

Table Annual size of destruction of the zinc coating of steel fasteners from surface corrosion depending on the operating environment

| Environment | Annual destruction of zinc coating, in microns |

| Room | 1,0-2,0 |

| Countryside | 1,3-2,5 |

| Big cities | 1,9-5,6 |

| Industrial areas | 6,4-19 |

| sea coast | 2,2-7,2 |

The service environment of zinc coated steel fasteners can be classified depending on the thickness of the zinc coating.

Table Classification of zinc coating depending on the thickness of the zinc coating

| Classification of zinc coating (use environment) | Thickness of zinc coating, in microns |

| 0 “Extremely light” (Used as a decorative coating in unloaded conditions) | 3-5 |

| 1 “Light” (Operation in a warm, dry room) | 5-8 |

| 2 “Medium” (Operation indoors in conditions of condensation) | 8-12 |

| 3 “Hard” (Operation in moderate climates) | 12-25 |

| 4 “Very hard” (Operation in aggressive environments (industrial areas, sea coast) | 25 |

Hot-dip galvanizing is the best protection against corrosion

The protective coating obtained as a result of hot-dip galvanizing is a highly effective protection of steel elements from the harmful effects of corrosion processes.

As long as galvanizing is done correctly, we are virtually guaranteed that corrosion will not damage the rods or wires. Consequently, hot-dip galvanizing must be carried out on the basis of established standards, stipulating, among other things, that the thickness of the hot-dip galvanizing layer cannot be less than 40 microns.

Compliance with such standards ensures the efficiency of the process.

The thickness of the coating depends on the following factors:

- Steel thickness;

- The chemical composition of steel (mainly influenced by the content of phosphorus and silicon);

- Temperature of the zinc bath;

- The time during which the element is in the zinc bath;

- Surface roughness.

For what purposes are metal structures galvanized?

The process involves applying a thin layer of zinc; before application, the surface is treated by mechanical and chemical means. The coating provides protection not only barrier, but also electrochemical reaction. Hot-dip galvanizing is used in most cases when working with metals, since it is most susceptible to grading processes. The hot-dip galvanizing method is the most acceptable, as it has a balanced process cost and high results.

Hot galvanizing method in production

The main purpose of galvanizing is to increase the strength of metal structures. A galvanized part does not need to be painted to protect it from corrosion; in total, the process is close to the cost of painting, but has more advantages.

Hot-dip galvanized rod and wire

Hot-dip galvanizing makes steel rods and wires highly resistant to corrosion.

The use of such elements is very wide today and includes, among other things, the production of:

- Panels and nets for fencing;

- Technical grids,

- Filters;

- Slings for hanging elements;

- Hangers;

- Bucket handles;

- Barbed, shepherd's and coated wire;

- Fences.

Features of galvanizing various designs

When processing metals with molten zinc, a number of mandatory requirements must be observed. One of the prerequisites is the absence of closed cavities, because the presence of gas bubbles in the product will prevent the hardware from being immersed in the bath (the density of zinc is 6.8 kg/dm3, and the density of steel is 7.5 kg/dm3). Large structures are suspended on ears welded at the edges and lowered into the zinc solution at an angle to allow the zinc to flow freely.

Features of hot-dip galvanizing of various steel products:

- Fencing. When galvanizing a section of railings, it is necessary to pay attention to some structural joints. The highest point of the intake element will serve as the exit point for flux gases. To eliminate obstacles to the free flow of zinc at the junction of horizontal and vertical parts in a vertical pipe, before welding with a horizontal pipe, a hole with a diameter equal to the diameter of the horizontal pipe is made.

- Traction. These are products made from a flattened pipe into which a fastening part is inserted. In rods that are subject to hot-dip galvanizing, after welding, holes are made on both sides of the product.

- Columns. When fusing zinc onto such products, it is necessary to remove metal at the right corners of the ribs, as well as make holes in the base to avoid excessive capture of the zinc solution by the surface. The corners are cut so that all areas are well galvanized (at points that form three planes, the flux evaporates earlier and the coating may be uneven). At least two holes are made diagonally in the base plate closer to the pipe wall.

- Farms. Trusses made from open profiles are welded in such a way that there is a gap between the elements for the free flow of zinc. The stiffening ribs of the structures are also welded with the gaps.

- Lighting supports. Such structures are made of pipes of different diameters, which are connected by spacer and outer rings. The spacer ring can be replaced by installing stiffeners. For processing metal with hot zinc, holes are provided in the parts and a technological loop for hanging at the pipe connection point.

- Reservoirs. The dimensions of containers that undergo hot-dip galvanizing should not exceed the size of the bath. With the standard arrangement of drain fittings (at the top and bottom of the tank), galvanizing is impossible; if the fittings are placed on the side surfaces of the tank, galvanizing is possible.

- Pipe-in-pipe products. When connecting pipes of different diameters, before processing with zinc, it is necessary to make technological holes for the free drainage of the zinc solution and the exit of flux gases. In products for galvanizing, a distance of at least 5 mm must be provided between pipes of different diameters.

The optimal size of holes for draining zinc in metal products is 1/7 - 1/10 of the cross-sectional area of the structural part.

Hot-dip galvanizing or galvanizing

Hot-dip galvanized and galvanized coatings differ in properties due to the course of individual technological processes.

Electrogalvanized products are characterized by a smooth, uniform, but very thin zinc coating from 3 to 6 microns.

The layer of galvanized zinc, unfortunately, is much thinner than the coating obtained by hot-dip galvanizing, which makes the resulting anti-corrosion protection less resistant to mechanical damage and weather conditions, as is the case with hot-dip galvanized products.

- An additional disadvantage of electrolytic galvanizing is the Faraday Cage effect, due to which the product is not galvanized in hard-to-reach places (internal recesses of the product, welds). This problem does not exist in hot zinc processing, when the rod or wire, parts and tools are completely immersed in molten zinc and it penetrates into all pores.

- This method does not allow galvanizing tightly closed profiles due to the high temperature, since it causes the air inside the material to expand and rupture. However, damage can be avoided by making very small holes in the profile.

Although the price of hot-dip galvanizing is slightly higher, this type of galvanizing is more profitable due to its much greater mechanical strength and corrosion resistance, because the product should serve us for many years without additional financial costs.

Areas of application

Metal structures used outdoors need protection. Hot zinc coating is used for the following products:

- power line supports, especially high-voltage ones;

- anti-corrosion coating of the lower part of the ship's hull;

- metal structures of bridges and pipelines;

- street lighting poles;

- building frames;

- steps of stairs;

- railings, balcony railings and other building elements;

- ventilation system pipes.

The method of hot-dip galvanizing metal is used for pipelines and various elements of garden and facade design.