Check valves are installed on hot and cold water pipes. As an example, consider a standard city apartment in a multi-story building. The following are connected to the riser with cold and hot water:

- Washing machine,

- Kitchen sink,

- water heater,

- Bathroom,

- Bathroom and washbasin.

Water check valve: features of selection and installation

For the normal functioning of the water meter, water supply and heating system, a check valve must be installed on the water. This is one of the elements for protecting pipeline fittings, allowing the systems for supplying water and heat to the house to function without failures and frequent repairs.

As we wrote in previous articles, for the correct installation of a water meter it is necessary to install several elements, it would not be superfluous to list them again

For the normal functioning of the water meter, water supply and heating system, a check valve must be installed on the water.

This is one of the elements for protecting pipeline fittings, allowing the systems for supplying water and heat to the house to function without failures and frequent repairs.

In some emergency situations, reverse flow of water may occur, which leads to water hammer, which causes longitudinal cracks to appear in the pipeline.

Also, if we remember the principle of communicating vessels, we can see another possibility of the occurrence of reverse flow of water. Water will flow from a pipeline with high pressure to a pipeline with lower pressure. In this case, the hot water meter can take into account the consumption of cold water. A water check valve ensures that water flows only in a given direction, eliminating the return of liquid back.

Options for working connection schemes

Heating systems are very diverse and the presence of a check valve is not necessary in all of them. Let's consider several cases when its installation is necessary. First of all, a check valve must be installed on each of the individual circuits in a closed circuit, provided that they are equipped with circulation pumps.

Some craftsmen strongly recommend installing a spring-type check valve in front of the inlet pipe of the only circulation pump in a single-circuit system. They motivate their advice by the fact that in this way pumping equipment can be protected from water hammer.

This is in no way true. Firstly, installing a check valve in a single-circuit system is hardly justified. Secondly, it is always installed after the circulation pump, otherwise using the device loses all meaning.

If two or more boilers are included in the heating circuit, the occurrence of parasitic flows is inevitable. Therefore, connecting a check valve is mandatory

For multi-circuit systems, the presence of a reverse-acting shut-off device is vital. For example, when two boilers are used for heating, electric and solid fuel, or any others.

When one of the circulation pumps is turned off, the pressure in the pipeline will inevitably change and a so-called parasitic flow will appear, which will move in a small circle, which can lead to trouble. It is impossible to do without shut-off valves here.

A similar situation arises when using an indirect heating boiler. Especially if the equipment has a separate pump, if there is no buffer tank, hydraulic arrow or distribution comb.

Here, too, there is a high probability of a parasitic flow, to cut off which a check valve is needed, which is used specifically for arranging a branch with a boiler.

It is mandatory to use shut-off valves in systems with bypass. Such schemes are usually used when converting a scheme from gravitational fluid circulation to forced circulation.

In this case, the valve is placed on the bypass parallel to the circulation pumping equipment. It is assumed that the main mode of operation will be forced. But if the pump is turned off due to lack of electricity or breakdown, the system will automatically switch to natural circulation.

When installing bypass units for heating circuits, the use of check valves is considered mandatory. The figure shows one of the possible bypass connection options

This will happen as follows: the pump stops supplying coolant, the check valve actuator unit ceases to experience pressure and closes.

Then the convection movement of the liquid along the main line resumes. This process will continue until the pump starts working. In addition, experts suggest installing a check valve on the make-up pipeline. This is not necessary, but highly desirable, since it allows you to avoid emptying the heating system for a variety of reasons.

For example, the owner opened a tap on the make-up pipeline to increase the pressure in the system. If, by an unpleasant coincidence, the water supply is cut off at this moment, the coolant will simply squeeze out the remaining cold water and go into the pipeline. As a result, the heating system will be left without liquid, the pressure in it will drop sharply and the boiler will stop.

In the circuits described above, it is important to use the correct valves. To cut off parasitic flows between adjacent circuits, it is advisable to install disk or petal devices. In this case, the hydraulic resistance will be lower in the latter option, which must be taken into account when choosing.

In heating systems with natural coolant circulation, the use of spring check valves is impractical. Only paddle rotators can be installed here

To install a bypass unit, it is preferable to choose a ball valve. This is due to the fact that it provides almost zero resistance. A disc-type valve can be installed on the make-up pipeline. This should be a model designed for fairly high operating pressure.

Therefore, a check valve may not be installed in all heating systems. It is necessarily used when installing bypasses of all types for boilers and radiators, as well as at pipeline branch points.

When is it necessary to install a water check valve?

A water check valve is an essential element of a plumbing system. Experts identify a number of points at which the use of the device becomes necessary.

The apartments' water supply system is designed in such a way that cold and hot water are supplied through separate pipes. The cold water supply system and the hot water supply system have different operating pressures, when you open the water in the mixer, the flow with higher pressure goes first, and the flow with lower pressure can begin to flow back into the riser and main pipeline. To avoid this, you need to install a water check valve.

When installing a water heater (boiler), installing a check valve is mandatory. The fact is that during the process of heating water, the pressure in the working chamber of the heater increases and can squeeze a suitable flow, which leads to a reverse flow of water. Installing a check valve eliminates this situation.

In private homes, the heating system may consist of two or more circuits. For example, one circuit of the system is used for a water heater, the second is for the heating system, and another is for the flooring system. Each of these circuits has a different operating pressure and different pumps. To prevent the flow of water from one circuit to another, check valves are used.

Is it necessary to install: legal requirements

There are discussions online on thematic forums about the need to comply with the requirements of management companies for the installation of metering devices and related fittings.

The confusion is caused by the fact that three documents are available for review:

- SNiP 2.04.01-85;

- SP 30.13330.2012;

- SP 30.13330.2016.

The documents are called the same: “Internal water supply and sewerage of buildings.” Despite the similarities, upon careful reading you can see differences in the issue regarding the installation of check valves. In addition, commentators do not always understand what equipment they are talking about.

Today, when installing a water supply system, the Code of Rules (SP) 30.13330.2016 applies.

In clause 1.1. it is expressly stated for which objects and when the requirements are applicable, namely:

- for the design of internal water supply at newly constructed facilities;

- for designing networks of reconstructed objects.

The objects include public buildings up to 55 meters high and residential buildings no higher than 75 meters. Government Decree No. 354 “On the provision of public services...” does not provide a direct indication of the owner’s obligation to install the device.

Where is it installed?

The composition of the equipment that is installed in internal water supply networks is discussed in Section 7 of SP 13. 30.13330.2016 . Management companies often refer to clause 7.1.4, which lists all devices that can be used.

Further paragraphs of the document list the exact installation locations. It is paragraph 7.1.9 that is devoted to check valves that install:

- on water pipelines supplying liquid to group mixers;

- on the circulating water supply.

Faucets located in apartments, even if there are a large number of them, are not grouped . In group devices, cold and hot water are mixed to the desired temperature in a separate container and only then supplied to the tap.

Hot water circulation pipelines belong to common property, so these points cannot justify the obligation to install a check valve in apartments.

Clause 7.2.1. In conjunction with the meter, it provides for the installation of check valves on the supply and circulation water pipes. But upon careful reading of the entire clause, it becomes clear that the requirements apply to the entrances to the building, and not for an individual apartment .

On what basis may installation be required?

The only clause of SP 13.13330.2016, on the basis of which they can require and achieve the installation of check valves, is the requirements of clause 7.2.11.

It says that the use of meters in sets with a built-in check valve, as well as the installation of additional protection against manipulation of readings, can be carried out at the request of the supplying organization.

Two conditions are important in this paragraph:

- the organization must supply water directly to the subscriber;

- requirements must be agreed with local authorities.

In each specific case, it is necessary to familiarize yourself with local legislation in order to decide whether or not to fight with the supplier over an “extra” device.

In Moscow, for example, the procedure for paying for devices and installation is determined by a separate Law No. 35 of July 5, 2006. Lawsuits addressing the need for check valves to one degree or another are not uncommon.

For example, you can look at Appeal Determination No. 12-27/2014 dated August 12, 2014 in case No. 12-27/2014, in which the judge clearly indicated the illegality of the supply organization’s requirement to install equipment.

What can the supply organization do?

The metering unit should be equipped in accordance with the technical specifications and the design, which will include a check valve. In addition to newly designed and reconstructed objects, any apartment can be included in the list.

In Government Decree N 776 of September 4, 2013 “On approval of the rules of commercial accounting...” there is clause 49, according to which the metering unit can be recognized as out of order.

For example, in these:

- the meter stopped displaying readings;

- there are signs of unauthorized interference in the operation of metering devices;

- seals are broken;

- mechanical damage to devices, etc.

If the unit is found to be out of order, to put it into operation it is necessary to obtain new technical specifications and prepare a project in which the supplying organization has the right to specify a check valve.

Types of check valves and their principle of operation

Check valves are divided into several types:

- Disk

- Two-blade

- Ball

- Lifting

- Petal

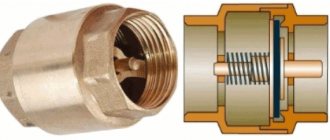

Disc valve

has the smallest dimensions. The locking disc under water pressure opens the working channel for the passage of water. When the pressure drops, the spring returns the locking disc to its original position, thereby preventing the reverse flow of water.

Two-blade valve

has significantly larger dimensions and is used in complex plumbing systems. An example of such a system is the plumbing system of a private house with water supplied by a pump. In such systems, if the pump fails, there is a possibility of a backflow of great force. The principle of operation of such an element is quite simple: when sufficient pressure occurs, the shut-off part of the valve folds in half. The reverse flow of water folds the shut-off element back.

Ball valve

The closing element of its design is a ball, which rises to the open position under the influence of water flow and, when the pressure decreases, returns to the opposite position, blocking the working channel. This type of valve is used in water supply systems with different pipeline diameters.

Lift type check valve

The design has a locking cup (lifting spool). With sufficient pressure in the water supply system, the cup rises, allowing the water flow to pass through. If the flow pressure decreases, the cup returns to the first position, blocking the flow of water. This type of valve can only be installed in a horizontal position.

Reed check valve

. The closing element of this type of valve is petals, which move apart under the influence of water pressure, ensuring the passage of liquid through the working channel. If a reverse flow of liquid occurs, the petals return to their original position.

How to install?

Clause 47 of Government Decree No. 776 of September 4, 2013 directly allows for independent installation and replacement of meters and other devices required in the metering unit.

Therefore, the supplying organization cannot impose its services and commercial structures for carrying out the work .

It is important that the user has sufficient skills - commissioning of the reconstructed metering units is carried out by a representative of the service provider.

Device selection

When choosing a check valve, consider:

- price;

- size of threaded connections;

- technical specifications for nominal and maximum pressure;

- design features.

The size and pressure parameters are indicated in the product data sheets ; they must provide a connection and withstand the pressure parameters in the system.

Types of structures

All check valves consist of the same elements: a body and a shut-off element. During operation, the liquid flows freely in the forward direction and presses against the locking element during the reverse stroke.

Common designs:

Disk. In the disk version, the locking element is pressed by a working spring.- Ball models use a steel ball as a shutter. The ball can be rubberized and pressed against the seat by a spring.

- Lifting. In lifting type devices, the spool moves freely. When the water moves forward, the liquid flows freely; when it moves in the opposite direction, the spool moves into the seat, locking the device. Lift valves are installed only on horizontal sections of pipes; the axle must be mounted in a vertical position.

- Petal and blade types are more often used for industrial equipment on large-diameter networks.

Operating procedure

To install a check valve you will need:

- the device itself;

- adjustable (gas) wrenches;

- seals - sanitary flax, FUM tape, sealant.

The diagram of the metering unit for the apartment is shown in the figure:

It is important to observe the direction of installation - on meters, filters, check valves, and reducers, arrows indicate which direction the water moves. After installation, a test run is carried out, and any leaks identified are repaired.

Everything you need to know about water meters is presented in this section of the site.

Check valve selection

When purchasing a water check valve, you need to pay attention to the material from which the valve is made: high-quality valves are made from CW617N brass.

Also examine the valve markings:

- The maximum operating pressure is indicated by the letters RU or PN. For example: RU-20: means that the valve can withstand a maximum pressure of 20 bar. Normal pressure in an apartment's water supply system is considered to be a pressure not exceeding 6 bar for cold water and 5 bar for hot water.

- The nominal diameter is marked with the letters DU or DN. For example: DN-20. This parameter must correspond to similar parameters of all neighboring elements

to prevent unnecessary loads and reduce pressure in the system.

Features of installing a water check valve

A water check valve is installed immediately behind the water meter to prevent reverse rotation of the water meter impeller. The most common type of check valves that are installed in apartments are disc valves

. Due to its small size, simplicity of design and low cost, this is the optimal choice.

The main feature when installing a check valve is the direction of water flow

. There is an arrow on the valve body that shows the direction of water flow. To seal the threaded connection, we recommend using plumbing sealant.

Otherwise, installing a water check valve is not difficult.

Source

Is it necessary to install a non-return valve in an apartment?

Check valves are installed on hot and cold water pipes. As an example, consider a standard city apartment in a multi-story building. The following are connected to the riser with cold and hot water:

- Washing machine,

- Kitchen sink,

- water heater,

- Bathroom,

- Bathroom and washbasin.

Manufacturing materials

Check valves are made from a variety of materials, which must be selected based on the valve's operating conditions, the type of operating environment, and other requirements placed on them in specific industries.

The most popular materials for check valves are:

- Stainless steel;

- Various steel alloys;

- Brass;

- Plastics, mainly polypropylene.

What a check valve must be made of is largely determined by the type of fluid flowing through it, including its physical condition, level of corrosiveness, and required opening pressure and flow rate.

Problems you face

A typical situation for an apartment building: different pressure in each of the risers. In a pipe with cold water, the pressure may be higher than in a pipe with hot water and vice versa. The pressure can easily increase at any time, but more often than not it drops unexpectedly due to a leak or even a pipeline break. The effect of the difference in flow pressure is often noticeable when two taps are opened in one apartment at once. For example, the faucet in the kitchen is open, hot water flows from it, and at the same time cold water begins to flow from the sanitary shower head. One stream replaced another.

In many houses with centralized water supply, hot water is turned off for at least two weeks in the summer. During this time, in apartments where heating devices are installed, the liquid supply valve from the central system is closed, and hot water from the boiler is released through the same pipes. Sometimes residents forget to turn off the valve on the water heater, including the water supply from the central riser. Cold liquid with high pressure blocks the flow of warm liquid, squeezing it out. As a result, only cold water is supplied from all taps. Then it goes to the central riser, in a few minutes all residents will be washed with cold water.

The second option is more common and can happen in any apartment. When using a shower mixer, a situation similar to the one described above occurs. If the pressure in the hot water riser is higher than in the cold pipe, you will get boiling water in both taps. In this case, the meter will spin very quickly, counting cubic meters even if water is not used. There will be hot liquid not only in the riser, but also in all apartments below and above.

There is one more reason that completely excludes the influence of the human factor. This situation occurs as a result of failure of the valve on the mixer. Inexpensive Chinese taps fall into disrepair every one and a half to two years. They are affected by water quality: chlorine, rust and other impurities. As soon as the shut-off lever breaks, water will rush into the adjacent pipe and the liquid will be displaced. A single-handle faucet in the kitchen can have the same effect. When the mixer handle is lowered, it opens both valves; if the pressure of hot or cold water is higher, one liquid displaces the other, spreading throughout the system.

In all the described cases, at the end of the month you will receive a very decent bill for the cubic meters of water pumped up by the reverse flow. Another trouble awaits children: injuries are possible as a result of supplying a hot stream to a cold tap. In addition, things can be damaged; instead of cold water, liquid at a temperature of up to 80 degrees is supplied to the washing machine through a hose.

Check valve installation

To avoid the problems described, it is enough to simply install two check valves. They are mounted after the ball valve on both risers of the apartment. If for some reason you do not yet have a strainer installed after the shut-off ball valve, be sure to install it. The check valve is always installed after the meter. When installing, you must follow the correct direction. If placed backwards, it will not be able to perform its functions. Some meters are already equipped with built-in valves. As a rule, they are not highly reliable. Miniature check valves are inserted into the opening of the half-flush or installed at the outlet of the meter.

Appearance: thick elastic band and a plastic circle with a crosshair inside. Due to their compact size and poor workmanship, they can leak. Therefore, it would not be superfluous to install another check valve.

Nuances of proper installation

During the installation of shut-off valves, several rules should be strictly followed:

- The valve is installed strictly in the direction of coolant flow. To avoid mistakes, the product body must be marked with an arrow indicating the working direction.

- Paronite gaskets can be used to seal connections, provided that they do not reduce the diameter of the passage hole. Otherwise, the valve will exert more hydraulic pressure than intended.

- The device must be installed so that other elements of the heating system do not exert additional pressure on its body.

- It is highly advisable to install a mesh in front of the check valve for rough cleaning. This will make it possible to prevent solid particles from entering the locking mechanism, which, in turn, can lead to a violation of the tightness of the device when closed. Or use special valves with mesh.

Another important point: before installation, you need to once again make sure that the valve is selected correctly.

For example, for schemes with forced circulation, any type of device is suitable, but for gravitational systems, only a rotary petal device without a spring. Since the coolant moving by gravity will not be able to cope with the resistance of the spring.

In what cases is a check valve installed?

The valve is installed to prevent the reverse flow of water, the return of liquid to the pipeline, or the replacement of one flow by another due to the difference in pressure. Valves should be installed:

- In front of the boiler

- After the counter,

- Along with the installation of pumping stations.

If you use a pump to pump out water, thanks to the check valve, water immediately flows into the tap and does not go back into the system. This valve prevents the meter from rotating in the opposite direction when using closed loops. In factory products, check valves can be found in the water meter in front of the mixer eccentric. When installing a water heater, the valve is installed on the cold water inlet, as well as on the hot water riser.

Design

The valve can be purchased separately or as a unit mounted in the meter outlet.

The device is a brass or polymer valve on a rod with a spring element. Under the pressure of the supplied liquid, the length of the spring shortens, moving the valve aside, the water rushes into the resulting passage. Reversing the flow of liquid is impossible, since the valve is tightly adjacent to the gasket with a straightened spring, which cannot be moved either by water or by air pressure.

The water meter has a mechanical pre-filter installed, but despite this, there is a possibility of oxidation of the valve elements. If the backflow prevention unit fails, it cannot be repaired, but can be easily replaced with a working one. If the check valve built into the flow meter breaks down, the device itself must be replaced.

Valve device

- Gate,

- spring,

- One or two rubber bands

- Metal pipe with or without washer.

In the standard position, the shutter is closed and supported by a spring. There are two shutter options: plastic and metal. Products with a metal shutter are used in heating systems, plastic ones in the general water supply system. A metal diaphragm check valve requires a lot of pressure to open. Therefore, if the system is low pressure, be sure to use only a plastic valve mechanism. Valves with metal shutters are longer than their plastic counterparts. The difference is 1 cm. When replacing already installed valves, this technical feature must be taken into account.

Source