Repair of commutator electric motors is one of the many services provided by our workshop. We accept orders for urgent, current and overhaul repairs of electric motors, including rewinding of the armature and stator, restoration of the commutator and other elements of crane, traction, elevator and other types of electric motors.

The main functional units of a commutator electric motor are the armature and the stator. They both have their own windings, to which electric current is supplied when the engine is running. The need to rewind the commutator motor arises in the event of the following winding faults:

- interturn short circuit;

- short circuit to housing;

- broken turns;

- reduction in insulation resistance as a result of wear and damage.

Most often, in the event of a breakdown, rewinding of the collector electric stator is required. engine, since the malfunction is most likely to occur there. This is a complex set of works, but it ensures full restoration of the machine’s functionality with minimal financial costs for this case. The price of rewinding even both functional units (armature and stator) is lower than the price of a new electric motor. Moreover, after a high-quality overhaul of commutator electric motors has been carried out, the customer receives a machine that is no less reliable than a new one.

What is a commutator motor

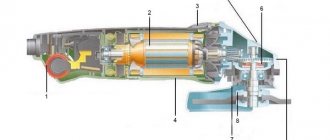

A motor of this type is most often a synchronous unit connected to a 220V power source and consisting of:

- stator;

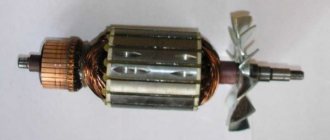

- rotor;

- brush-collector unit;

- bearings.

All parts are enclosed in a housing.

Preliminary check of the commutator motor

If the device does not work, first make sure that the problem lies with the motor itself. For this:

- Check if there is voltage to the device. Plug it into another outlet (the power source may need repairs).

- Inspect the cord for breaks.

- Check if the contact of the power and control buttons is lost, if there is any mechanical damage.

If there are no problems with these parts, disassemble the device. Use the instructions that the manufacturer necessarily includes in the passport.

Possible malfunctions of the commutator motor

Sometimes even people familiar with the structure of the mechanism have little idea how to check a commutator motor. Below we will talk about all possible malfunctions and ways to identify and eliminate them.

- Broken contacts. This is indicated by active sparking.

- Interturn short circuit (short circuit of windings in the collector). It also causes sparking.

- Wear of the brush-collector unit. At the same time, it turns black and sparking appears. Usually the problem is solved by replacing old elements with new ones. To remove the assembly, move the lock and unscrew the mounting bolt (depending on the engine model).

- Darkening of the contact part of the collector. Often it is enough to clean it with fine sandpaper.

- Formation of a groove at the point of contact of the brushes with the commutator. It is necessary to perform the grooving of the unit on the machine.

- Bearing wear. This malfunction can be determined by increased vibration of the housing during engine operation and beating of the cartridge. In this case, bearing replacement is required.

- The armature touches the stator. Sometimes replacing the armature is enough, but in some cases you will have to replace both the armature and the stator.

- Control failure on the microcontroller. Installing a new microcontroller is the optimal solution to the problem.

- Burnout or breakage of windings. Pay attention to their color and integrity. Blackening of the entire winding body or part thereof indicates burnout; a break is easily determined by visual inspection. In this case, they need to be replaced or rewinded.

- Graphite dust in the space between the lamellas. Your appliance just needs cleaning.

- Burnout of wire insulation. A characteristic odor will indicate this problem.

In all of the above cases, restoring the electric motor manifold with your own hands is quite possible if you have the necessary spare parts and tools. Only if you do not have experience in rewinding windings, it is better to contact the appropriate service. After troubleshooting, reconnect all parts in reverse order.

Checking the commutator motor with a multimeter

Let's say a visual inspection did not produce results - at first glance, all components are intact, no breaks were found, and there is no burning smell. In this case, check the device and its elements using a special device - a multimeter. The process consists of several stages:

- Set the device to resistance measurement mode up to 200 Ohms.

- Ring the paired terminals of the stator windings on the lamellas. The resistance values must be the same.

- Check the armature body and lamellas. Ideally, the resistance value tends to infinity.

- Ring the winding terminals. If there is no resistance in one or more circuits, the motor is faulty.

- Check the circuit between the stator housing and the winding terminals. If there is a breakdown in the housing, operation of the unit is impossible.

- Ring the rotor by placing the tester probes on the commutator at the maximum distance from each other. When the multimeter shows a value, turn the rotor slightly until the probes connect to the next winding. Check all windings in this way. If the resistance value in each circuit is the same or differs very slightly, the unit is working.

You should not immediately take a “jammed” device for repair or throw it away, as many people prefer to do. You will save money if you know how to restore the electric motor commutator yourself. The process is not too complicated and does not take much time, and the mechanism can last for a long time.

Check and enable

Before starting the engine for the first time after repair, it must be thoroughly checked. To begin with, all inserted “coils” ring. This will help you find out if there is a break or poor contact. The resistance is measured between the “layings” so that a short circuit does not occur when turned on.

You should not immediately supply 220 V to the engine; it is better to supply a reduced voltage. Let the rotor spin slowly, the main thing here is to find out if the engine is overheating. If everything went well and no smoke appeared, then the engine repair was successful.

There are many photos on the Internet on rewinding motors. This will help beginners visually familiarize themselves with the process.

To make the car look better and sound nicer

Our specialists will help you decide which muffler modification is right for you. GSAvto offers different options, differing in the degree of intervention in the design of the car, and, of course, in price. You can order here:

- Tuning to change the appearance. We are ready to offer a large selection of options: from installing nozzles on the exhaust pipe to more complex work (wiring, moving a muffler, etc.).

- Changing the sound of the exhaust system. To solve this problem, we offer different options. If your budget is small, or you don’t want to get into the standard exhaust system and change it, the company’s specialists will offer special exhaust pipe attachments that can change the exhaust sound. If you are ready to make changes to the design of the car, GSAvto will offer several options for solving the problem of how to change the sound of the muffler. This can be done, for example, by making a direct flow based on a standard plug, or by installing a ready-made product from a reputable manufacturer.

- Impact on vehicle dynamics. If you are interested in installing a direct-flow muffler and other types of tuning not only to change the sound and appearance, but to change the dynamic characteristics of the car, we are ready to offer you such solutions. You can get an increase in power by installing a sports muffler, replacing or reworking the exhaust manifold, changing the diameter of the exhaust system pipes, etc. What is right for you? GSAvto specialists will help you decide on this.

Typical design of electric motors

The design of electric motors is the same for all classifications. Power mechanisms are equipped with a stationary element - a stator, and a rotating element - a rotor, and in some types - an armature. The formation of a circular motion of the rotor occurs by the influence of the magnetic field of the stationary component on the rotating element (RE).

Electric currents flow in the stator windings. If the windings are in good condition, then the rated design currents pass through them. The latter create a magnetic field of the most optimal magnitude. A breakdown provokes a deterioration in the resistance of the conductors, which leads to the creation of a short circuit, interturn short circuit, and leakage currents. All of the above negatively affects the functionality of the device.

A minimum gap is provided between the static and rotating elements, separating the parts of the commutator motor (CM). It is violated:

- broken or worn bearings;

- abrasive and mechanical particles that got inside;

- manufacturing defects, improper maintenance followed by poor quality assembly.

The contact of the stator and rotor triggers destructive processes - additional mechanical wear is formed. This complicates the diagnosis and repair of electrical installations with collector units. This also includes an attempt to disassemble the assembly of units using “makeshift” tools. For maintenance, it is necessary to use special equipment to prevent damage to the shaft faces.

After disassembly, play and free movement of bearings are checked - their cleanliness, amount of lubricant, and fit. Due to the special design of the motor, the plates and brushes are additionally checked - parts may be heavily worn, which affects the performance of the motor equipped with a commutator unit.

Classification of CD

Depending on the type of power supply used, there are:

- motors operating on direct current - simple design, high starting torque, smooth frequency control;

- universal – capable of operating from a constant and variable power source. They have compact dimensions, simple controls, and low price.

The manufacturer indicates the technical characteristics of the unit on the plate. It is attached to the body. But modernization, repairs, changes in rewinding are factors that cause changes in passport information. This nuance must be taken into account when carrying out repairs.

In household power supply from 220V the following is used:

- collector installations equipped with a brush mechanism;

- asynchronous single-phase unit;

- three-phase synchronous and asynchronous electrical machines.

380V electrical systems use three-phase synchronous and asynchronous electric motors. They have different designs, but operate according to general principles of electrical engineering, which allows the same testing methods to be used. The latter consist of measuring electrical characteristics indirect/direct ways.

Maintenance and repair of brushes

In commutator motors, the contact brushes produce noise during normal operation, so when manually testing the free play of the motor shaft, it is necessary to be able to distinguish the nature of the sounds produced by the brushes. The characteristic clicks and rustling should be uniform, without chaotic grinding or jamming. Very often, the cause of loss of electrical contact is mechanical jamming of the commutator contact brushes.

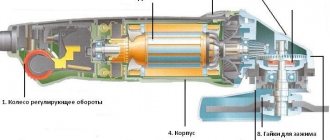

Some components of the commutator engine

The commutator brush consists of a holder, a graphite contactor and a pressure spring. Sometimes the spring gets weak and needs to be stretched a little to get more clamping force. Due to the abrasion of graphite, small crumbs are formed, which, together with dust and moisture, contaminate the gap between the graphite contactor and the holder. In this space, layers are formed that dry and harden from the heating of the brushes, thereby fixing them.

Commutator brush device

This jamming of the brushes due to hardened dirt in the holder is often the reason for the inability to start a previously properly working commutator motor. While the running engine vibrates, the pressure spring can overcome the resistance of the layers, and contact with the commutator lamellas is maintained. But after turning off, the accumulated dirt solidifies, the brush is fixed and shrinks due to cooling, forming a gap that breaks contact with the lamellas.

Motor armature commutator lamellas

You can check the clamping force of the brush by prying the graphite with a knife or a small screwdriver - the contactor should move freely in the holder, elastically rebounding, hitting the lamellas. Otherwise, the brush and holder can be cleaned, washed in solvent, or the edges of the graphite contactor can be slightly filed for greater clearance. If the brush has almost reached its service life limit, then it is better to replace it with a new one. If it is impossible to find an identical replacement brush, select the closest option and saw off the edges of the graphite contactor to the required size.

New brushes need to be filed to give the desired size.

WHAT MALFUNCTIONS MOST OFTEN AFFECT THE COLLECTOR?

Most often, motor commutators fail or show other signs of malfunction:

- Solid particles may get trapped under the brushes. As a result, roughness is formed on the surface of the collector; Shorting the brushes sometimes provokes the appearance of soot or oxidation. They can be eliminated by grinding the collector surface.

- As a result of brush friction (especially during intensive use), grooves and grooves appear on the commutator. To eliminate them, we turn the unit on a lathe and correctly position the brushes along the entire length of the unit.

- Intensive use causes the contacts to wear out and the insulation to appear on them. In this case, we deepen the grooves for micanite, mill the electric motor and grind the insulating material.

- Plate runout due to incorrect armature alignment or bearing wear. Using high-precision specialized equipment, we grind the part on a machine, then replace the worn bearing and center the armature.

Our employees repair electric motor collectors step by step, and before that they carry out a full diagnostic to determine the nature and intensity of damage.