In various pipeline systems there is a possibility of reverse flow of the medium. This phenomenon can lead to quite a large number of problems, for example, the pump breaks down or the pressure drops to critical values. You can eliminate the possibility of such a phenomenon by installing check valves. There are quite a large number of similar shut-off valves; the flanged ball valve is most often used. It is installed when creating a fairly large number of different systems, both domestic and industrial. Let us consider the features of such a mechanism in more detail.

Operating principle

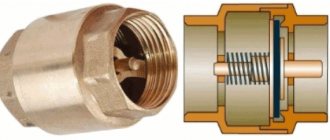

The name of the valve is due to the fact that a steel ball is used as the main shut-off element. The design features include the following points:

- The main element is the body. In its manufacture, steel or cast iron, as well as some other non-ferrous alloys, can be used. Steel is characterized by high strength, and due to the inclusion of various alloying elements in the chemical composition, corrosion resistance increases. Cast iron has been used for a long period, but such a material does not withstand strong mechanical stress. Non-ferrous alloys are lightweight, corrosion and chemical resistant, and are most often used to create valves for household systems.

- The locking element is made in the form of a ball, which in its original position closes the passage hole. In order for the ball to be in the closed position, a spring is installed at a certain angle.

- When the medium is supplied in the correct direction, the pressure created is sufficient to overcome the resistance created by the spring. Due to this, the passage opening opens.

- When the pressure drops for a variety of reasons (leakage, pumping equipment stops), the spring expands and the ball takes its original position. Due to this, the possibility of reverse flow of liquid through the system is eliminated.

The specific location of the spring determines that during reverse current the spring is not pressed out. In addition, to overcome the force created by the spring, quite a lot of pressure is required, which is not created by the reverse free current.

Recommendations for the use of steel flanged valves

Flanged ball valves are simple and easy to use. When using them, you should adhere to two basic rules:

- If the tap is actually used in only one position (open or closed), you should periodically change the position to the opposite one. This will reduce the risk of accumulation of scale and other deposits on the internal walls of the locking unit and increase the service life. Such manipulations must be carried out 2 to 4 times a year.

- Ball valves require routine technical inspections. Under standard conditions, the condition of the valves is monitored once every six months. When working in pipelines transporting aggressive media, inspections are carried out more often, in accordance with the technological regulations.

In the catalog, steel flanged ball valves are presented in a wide selection of modifications. This creates conditions for purchasing equipment with the required characteristics within the optimal budget.

Valve components

The ball check valve is characterized by a fairly simple design, which determines a long service life. The main structural elements can be called:

- Frame. Recently, monolithic type housings have been produced, which have high strength and reliability. The use of the casting method determines the absence of seams, characterized by low resistance to impact loads.

- Metal ball. The locking element of the valve in question is a ball, which is made of corrosion-resistant steel. The ball has a diameter that is slightly larger than the diameter of the passage hole. In addition, a special seat was created for it, which ensures a stationary locking element.

- The ball is in the closed position due to the spring. It is also made of corrosion-resistant steel, as it can withstand the environment.

- Sealing elements made of rubber provide a high degree of sealing.

Some valves can be serviced if necessary. The maintenance process involves replacing sealing elements that wear out under the influence of the environment. Access is provided by the location of the cover at the top of the housing, which is secured with bolts. Sealing is ensured by special seals. There are also non-removable designs on sale that are not equipped with a lid. If such a design malfunctions, it must be completely replaced.

The above information determines that the valve design is quite simple and reliable. Various materials can be used in the manufacture of basic elements.

Main advantages

The ball-type valve has become quite widespread due to the versatility of the device. The advantages of such a device include the following points:

- It can be installed in industrial and domestic systems.

- If installation work is carried out correctly, the device can last for a long period without jamming.

- Relatively low cost of the device.

The flange version is common due to its ease of connection. This type of connection can withstand high pressure.

Basic selection rules

Only with the right choice of device can its long-term operation be ensured. When choosing a check ball valve, two main characteristics are taken into account:

- Diameter of the catch passage. It is worth considering that the check valve should not create hydraulic resistance. Otherwise, the pressure in the system up to the valve increases, and there is a possibility of a leak.

- Operating pressure at which the device can operate correctly. When considering a check valve, it is worth considering the minimum and maximum pressure.

Almost all manufacturers indicate these parameters when marking check valves. Due to this, the work of choosing the most suitable design option is significantly simplified.

Another important selection criterion is the type of connection. In the case under consideration, the device has a flange type of connection, but there are also wafer and coupling types. In some cases, valves are installed, which are connected by welding.

Delivery throughout Russia and the CIS

Delivery countries: Azerbaijan, Armenia, Belarus, Kazakhstan, Kyrgyzstan, Moldova, Russia, Tajikistan, Turkmenistan, Uzbekistan, Ukraine.

- Delivery by transport companies SDEK, PEC, Business Lines.

- Expedited delivery by Khimmashneftekomplekt LLC transport to any facility in Russia and the CIS countries.

- Pickup of products from warehouses located in Podolsk, Saratov.

Publication date: May 17, 2022. Last modified: May 18, 2022.

If you have any questions, please contact us by phone +7 (499) 380-83-81, email or leave a request on the website. Our company’s specialists will provide assistance in selection and provide current prices for products.

Application area

The main design features of the device largely determine its scope of application. A ball check valve is installed in the following cases:

- To eliminate the possibility of reverse flow of wastewater in the sewer system. In such cases, the liquid may contain large impurities.

- On sale you can find versions designed for household and industrial systems.

- The mechanism performs well when the medium is supplied without impurities. The use of high-quality sealing elements allows us to achieve a high degree of sealing.

The scope of application largely depends on the type of materials used in manufacturing. An example is that in industrial sewer systems a cast iron version is installed. The use of this material has significantly reduced the cost of the product. In everyday life, mechanisms made from brass and other non-ferrous metals are most often used.

Installation features

You can carry out installation work yourself, taking into account the basic rules. They look like this:

- When creating critical systems, valve installation should only be carried out by specialists who have undergone appropriate training and received documented evidence of this.

- Before starting work, the working environment is switched off. In this case, you can limit the work of only the serviced area.

- Immediately before carrying out work, you need to make sure that the return valve is suitable for the specific system. As previously noted, the most important parameters are the minimum and maximum operating pressure, as well as the diameter of the bore

- At the time of installation of the device, climatic operating conditions are taken into account. It is worth considering that low ambient temperatures can lead to freezing of the ball and jamming of the device.

- Before installing the check valve, flanges are installed. They are designed to fix the mechanism in place.

- After installing the valve, the system is tested. At the time of the test run, it is determined how efficiently the valve operates.

Today you can find on sale a huge range of different designs of ball check valves. That is why there are no problems with selecting such a device. Some design options are unprofitable to install due to high cost. An example is ball check valves with a large bore diameter made of brass.

Specifications

- Maximum operating temperature: 70 °C.

- Maximum permissible temperature: 80 °C.

- Minimum ambient temperature: -10 °C.

- Tight closure at differential pressure: 0.5-0.8 bar (5-8 m.w.st.).

- Differential pressure opening: Max. 0.5 bar (5 m.v.st.).

1 - Housing; 2 - Ball; 3 - Housing cover; 4 — Housing cover gasket.

| Marking | DN | PN | L, construction length, mm | h, construction length from the pipe axis, mm | H, overall height , mm | a, passage diameter, mm | c, outer diameter of the connecting protrusion, mm | Weight, kg/piece |

| ABRA-D-022 NBR 040 | 40 | 10/16 bar (1.0/1.6 MPa) | 180 | 98 | 173 | 40 | 84 | 9,5 |

| ABRA-D-022 NBR 050 | 50 | 200 | 110 | 193 | 50 | 99 | 10 | |

| ABRA-D-022 NBR 065 | 65 | 240 | 125 | 218 | 65 | 118 | 13 | |

| ABRA-D-022 NBR 080 | 80 | 260 | 155 | 255 | 80 | 132 | 17 | |

| ABRA-D-022 NBR 100 | 100 | 300 | 200 | 310 | 100 | 156 | 27 | |

| ABRA-D-022 NBR 125 | 125 | 350 | 220 | 345 | 125 | 184 | 36,5 | |

| ABRA-D-022 NBR 150 | 150 | 400 | 260 | 403 | 150 | 211 | 54 | |

| ABRA-D-022 NBR 200 | 200 | 500 | 320 | 490 | 200 | 266 | 103 | |

| ABRA-D-022 NBR 250 | 250 | 600 | 360 | 563 | 250 | 319 | 195 | |

| ABRA-D-022 NBR 300 | 300 | 700 | 430 | 660 | 300 | 370 | 241 | |

| ABRA-D-022 NBR 350 | 350 | 800 | 610 | 870 | 350 | 429 | 321 | |

| ABRA-D-022 NBR 400 | 400 | 900 | 705 | 995 | 400 | 480 | 401 | |

| ABRA-D-022 NBR 450 | 450 | 1000 | — | — | 450 | 532 | 531 | |

| ABRA-D-022 NBR 500 | 500 | 1100 | — | — | 500 | 610 | 701 |