With proper installation of the water meter and normal operation of the water supply system, the liquid moves in the intended direction. However, situations are possible when, for some reason, the water flow begins to move in the opposite direction. This situation is especially true for apartment buildings.

According to the principle of communicating vessels, when the pressure in certain areas of the overall system decreases, a reverse flow of water flow is possible. To eliminate incorrect operation of the water meter and possible technical malfunction in this situation, a check valve is used.

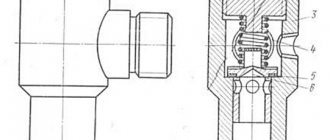

Design

A non-return valve is an automatic device that prevents the flow of liquid in the water supply in the opposite direction. In relation to a water consumption meter, this element can be used:

- as a separate node;

- as a structural part of the water meter.

A water meter additionally equipped with a check valve is more difficult to repair and less reliable due to the complexity of the design. But such a device facilitates the assembly of the finished unit - there is no need to install additional elements.

Using a check valve as an additional element is preferable, since if it fails, it can be individually replaced or repaired without dismantling the meter.

Is it necessary to install: legal requirements

There are discussions online on thematic forums about the need to comply with the requirements of management companies for the installation of metering devices and related fittings.

The confusion is caused by the fact that three documents are available for review:

The documents have the same name: “Internal water supply and sewerage of buildings.” Despite the similarities, upon careful reading you can see differences in the issue regarding the installation of check valves. In addition, commentators do not always understand what equipment they are talking about.

In clause 1.1. it is expressly stated for which objects and when the requirements are applicable, namely:

- for the design of internal water supply at newly constructed facilities;

- for designing networks of reconstructed objects.

The objects include public buildings up to 55 meters high and residential buildings no higher than 75 meters. Government Decree No. 354 “On the provision of public services...” does not provide a direct indication of the owner’s obligation to install the device.

Where is it installed?

The composition of the equipment that is installed in internal water supply networks is discussed in Section 7 of SP 13. 30.13330.2016 . Management companies often refer to clause 7.1.4, which lists all devices that can be used.

Further paragraphs of the document list the exact installation locations. It is paragraph 7.1.9 that is devoted to check valves that install:

- on water pipelines supplying liquid to group mixers;

- on the circulating water supply.

Faucets located in apartments, even if there are a large number of them, are not grouped . In group devices, cold and hot water are mixed to the desired temperature in a separate container and only then supplied to the tap.

Hot water circulation pipelines belong to common property, so these points cannot justify the obligation to install a check valve in apartments.

Clause 7.2.1. In conjunction with the meter, it provides for the installation of check valves on the supply and circulation water pipes. But upon careful reading of the entire clause, it becomes clear that the requirements apply to the entrances to the building, and not for an individual apartment .

On what basis may installation be required?

The only clause of SP 13.13330.2016, on the basis of which they can require and achieve the installation of check valves, is the requirements of clause 7.2.11.

Two conditions are important in this paragraph:

- the organization must supply water directly to the subscriber;

- requirements must be agreed with local authorities.

In each specific case, it is necessary to familiarize yourself with local legislation in order to decide whether or not to fight with the supplier over an “extra” device.

In Moscow, for example, the procedure for paying for devices and installation is determined by a separate Law No. 35 of July 5, 2006. Lawsuits addressing the need for check valves to one degree or another are not uncommon.

For example, you can look at Appeal Determination No. 12-27/2014 dated August 12, 2014 in case No. 12-27/2014, in which the judge clearly indicated the illegality of the supply organization’s requirement to install equipment.

What can the supply organization do?

The metering unit should be equipped in accordance with the technical specifications and the design, which will include a check valve. In addition to newly designed and reconstructed objects, any apartment can be included in the list.

For example, in these:

- the meter stopped displaying readings;

- there are signs of unauthorized interference in the operation of metering devices;

- seals are broken;

- mechanical damage to devices, etc.

If the unit is found to be out of order, to put it into operation it is necessary to obtain new technical specifications and prepare a project in which the supplying organization has the right to specify a check valve.

Principle of operation

The principle of operation of the device is based on the fact that a directed flow of water overcomes the resistance of a spring-loaded closing element and, due to the energy of liquid pressure, opens the passage. When pressure arises in the opposite direction, the passage cross-section is blocked, since the lock is pressed against the seat.

This device performs the following tasks:

- plays the role of a locking device in case of reverse direction of liquid;

- divides the general water supply system into separate sections according to functional use between individual consumers;

- prevents the negative consequences of water hammer.

In the absence of a check valve, especially for apartments in a multi-storey building, it is possible to bypass water from a cold pipeline to a hot one or vice versa through faucets in bathrooms and kitchens, if a corresponding pressure drop or other emergency situations occurs.

The check valve protects the owner from improper operation of the water supply system. At the same time, the consumer is excluded from the possibility of unauthorized intervention in the operation of the meter by creating a reverse flow through the metering device.

Purpose of the device

Functionally, a check valve belongs to an automatic shut-off valve.

Its task is to pass liquid in the forward direction and automatically close the pipeline if the flow movement changes to the opposite direction.

This situation is possible, for example, when both cold and hot water mixer taps are opened, when the liquid pressure in one of the pipelines significantly exceeds that in the other.

The problem worsened with the advent of plumbing devices such as hygienic hoses. There is a water supply button on the watering can, so the mixer is often set to the required temperature and then not turned off.

The check valve, thanks to its properties, performs technical tasks:

- Prevents liquid from flowing from the cold water supply system into the hot water supply pipes or vice versa.

- Reduces the likelihood of water hammer under certain operating conditions. For example, if there are several water points installed in an apartment (house) and they are used at the same time (turned on and off). This became especially important after the massive replacement of worm-type (valve) type crane axle boxes with disk ones, which shut off the flow instantly.

- Stops water from flowing down risers when the supply is turned off. The function is important for private houses with deep-well pumps, and for high-rise buildings.

- Installed on boiler piping, it protects against hot water running off, which saves money when reheating.

Other functions are important for supply organizations:

Reducing the likelihood of interference with the operation of metering devices by supplying air or water to the meter in the opposite direction.- Elimination of mixing cold water into hot water or vice versa, at different pressures in the networks.

If in the morning subscribers have to drain the water from the tap for a long time before the hot water comes out, complaints from residents follow, followed by recalculation of payments.

Taking into account the positive properties and functions performed, the installation of check valves is beneficial to both parties - the consumer and the supplying organization.

Reluctance to install the device is manifested in two cases:

- the owner hopes to reduce the readings by winding up the meter, but the valve complicates this task;

- the owner does not want to incur additional costs for the purchase and installation of equipment.

Supply organizations try to install a device on each meter, relying on governing documents.

Types of valves for meters

The industry produces the following types of check valves used in domestic water supply systems:

- spring couplings - characterized by a cylindrical body consisting of two parts connected by thread. The locking is carried out by a spring-loaded plate placed on a plastic rod;

Spring Clutch Valve - spring spool valves - the brass body is made of one piece and has a spherical spool chamber. This design feature allows you to increase the throughput of the device. The mechanism works in a similar way, due to the spool overcoming the force of the installed spring. View passport .

- spring, containing drainage and air vent - mainly used for heating systems and hot water pipelines, providing the possibility of bleeding air and releasing working fluid collected after the valve. This allows you to relieve pressure, simplifies the assembly of such systems, and increases their reliability. View passport.

Check valve with air vent - spring propylene - mounted in plastic water pipes. Structurally, the valve elements are built into a separate outlet, which allows repair and replacement of individual parts without dismantling the body. View passport.

Other types of check valves are used in water transportation systems, but are not used in conjunction with household meters.

Repair

Like any other mechanism, a check valve may require repairs. In most cases, this is due to the influence of contaminants contained in the water, deposited on the elements of the device and preventing its normal operation.

For repair and maintenance, the element must be dismantled, cleaned of dirt and reinstalled. If necessary, individual parts must be replaced.

Some valve models provide the possibility of repair and inspection without dismantling the body. In this case, the task of restoring the device's functionality is simplified.

Taking into account the peculiarities of operation of water supply systems, the serviceability of an individual metering device throughout the standard service life and calibration interval cannot be guaranteed without a check valve installed with it. Together with the safety function, this element will eliminate possible claims against the consumer from regulatory organizations.

| Share on social networks: | Rate this article: |

Source: isanshop.ru

How to choose

The check valve is selected taking into account the following characteristics:

- nominal diameter and thread of pipes on the pipeline and meter;

- maximum and minimum operating pressure specified in the technical parameters of the device in relation to the characteristics of a particular water supply system;

- compliance with established quality standards.

Features of using a check valve depending on the nominal diameter are presented in the table:

| Nominal diameter, in inches | Features of application |

| 1/2 | Infrequently used product with low traffic. |

| 3/4 | A product with acceptable technical parameters, most suitable for MKD apartments. |

| 1 | The most popular standard size of the device. |

| 1 1/4 | It is used in large-scale water supply networks, mainly in the private sector. |

| 2 | Installed in dachas and rural houses that consume water from a well. |

The product is selected individually for specific operating conditions. The selection of the device must be entrusted to a qualified plumber. You must first study the technical documentation of the water meter developed by the manufacturer and the operating conditions of the device, taking into account the characteristics of the water supply network.

Materials, markings, sizes

The check valve for water is made of stainless steel, brass, larger sizes are made of cast iron. For household networks, brass is usually used - it is not too expensive and durable. Stainless steel is, of course, better, but it is usually not the body that fails, but the locking element. This is where you should approach your choice carefully.

For plastic plumbing systems, check valves are made from the same material. They come in polypropylene and plastic (for HDPE and LDPE). The latter can be welded/glued or threaded. You can, of course, solder adapters to brass, install a brass valve, then again an adapter from brass to PPR or plastic. But such a unit is more expensive. And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are check valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it’s hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to functionality. Plastic wears out faster, but it doesn’t jam. In this regard, it is more reliable. It’s not for nothing that some manufacturers of pumping stations install check valves with plastic discs. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to “poison” and is replaced.

What is indicated in the labeling

A few words about the marking of the check valve. It states:

- Type

- Conditional pass

- Conditional pressure

- GOST according to which it is manufactured. For Russia, this is GOST 27477-87, but there are not only domestic products on the market.

Return valve for water: marking according to GOST

The conditional diameter is designated as DU or DN. When choosing this parameter, you need to focus on other fittings or pipeline diameter. They must match. For example, you will install a check water valve after a submersible pump, and a filter next to it. All three components must have the same nominal diameter. For example, all should have DN 32 or DN 32 written on them.

A few words about conditional pressure. This is the pressure in the system at which the shut-off valves remain operational. You should definitely take it no less than your working pressure. In the case of apartments - no less testing. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. You can find out the pressure for your home from the management company or plumbers.

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it is indicated in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. That's why they are popular.

Opening pressure characterizes the “sensitivity” of the valve. For private networks it rarely matters. Only on supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external. Choose based on ease of installation. Don't forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of a check valve for water is calculated according to the nominal diameter and they are produced for all - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are the same sizes as all other shut-off valves: taps, valves, drains, etc. Conditional pressure can also be referred to as “dimensions”. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Next come the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And also, please note that for different companies, with the same nominal diameter, the external dimensions of the device may differ. The length is understandable. Here the chamber in which the locking plate is located may be larger or smaller. The diameters of the chambers also differ. But the difference in the area of the connecting thread can only be due to the thickness of the walls. For private houses this is not so scary. Here the maximum working pressure is 4-6 Atm. But for high-rise buildings it can be critical.

How to check

The easiest way to test a check valve is to blow into it in the direction that is blocking it. No air should pass through. At all. No way. Also try pressing on the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a check valve: blow into it and check for smoothness

Also inspect the seat and disc. Especially in the place where they are adjacent to each other. Everything should be even/smooth. The tightness of this type of fitting depends on how accurately everything fits. In more expensive models, a rubber/polymer/plastic sealing ring is installed on the plate. Needless to say, it should lie flat, without waves, and there should be no scratches or burrs.

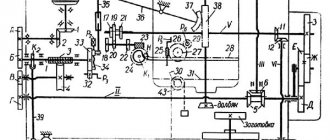

Check valve installation procedure

Despite the simplicity of the design of the device used in conjunction with a water meter, its effective and durable operation is impossible without preliminary installation with a filter element. Some valve models include additional strainers included in the design of the device. This guarantees long-term operation and protection of this element from contamination.

But in most cases, an additional filter is used, mounted in front of the water meter. A check valve is installed after the water meter.

Check valve installation diagram

Installation of the entire complex of components, including a filter, meter and check valve, is carried out in the following sequence:

- the water supply is shut off by closing the tap at the connection to the main water supply;

- a small section of pipe after the tap is cut off with a grinder;

- the remaining segment is unscrewed from the locking device;

- the filter element is installed. The position of the unit relative to the axis of rotation is adjusted by winding. The tightness of the connection is ensured by fum tape;

- A fitting with a union nut is screwed into the filter, then a water meter is mounted. The required number of revolutions with the choice of the optimal location of the metering device is ensured in a similar way;

- after connecting another fitting with a union nut to the outlet pipe, a check valve is mounted;

- The water supply is opened by gradually opening the tap to prevent water hammer. The tightness of the connections is checked.

When installing a meter and check valve, it is necessary to ensure the correct location of these devices, according to the direction of the arrows on the product bodies.

After installing the equipment, it is necessary to call representatives of the controlling organization to apply seals and draw up an act on the installation of an individual metering device.

Mechanism objectives

The working mechanism of most water meter devices is a multi-bladed impeller that does not have a locking element and rotates in both directions.

Some consumers, refusing to install a valve, pursue a selfish goal - rewinding the water meter readings. To rotate the impeller in a different direction, perform the following actions:

- the supply of liquid flow to the mixer is shut off;

- the remaining water is drained;

- Air is supplied through the hose of the vacuum cleaner connected to the mixer.

Despite the apparent simplicity of the procedure, there are several nuances that do not meet the expectations of consumers:

- manipulations take a long time;

- requires significant energy consumption;

- too little air pressure will leave people living in the house without water for the whole day;

- too much pressure can damage the impeller;

- To connect, you need to find a Soviet-made vacuum cleaner; most modern devices cannot supply air outside.

Whether a check valve is required on a water meter follows from the law of connecting vessels. Water supply systems (cold and hot) organized in apartment buildings converge many times in mixing devices. It is almost impossible to maintain the same pressure level in pipelines.

When the taps are opened simultaneously, both flows are mixed, the liquid flows from the system with increased pressure into the pipeline of lower pressure. The hot water meter can also determine the flow rate of cold water, which will affect the size of the water bill. In a situation where a “cold” water meter begins to determine the flow of hot water, there is also no benefit. Its elements are not intended for use in a hot liquid environment; the water meter will quickly fail.

An equally important factor explaining why a water meter with a check valve is needed is the operating conditions. The service period specified by the manufacturer is achieved only if the measuring chamber is constantly filled with water of proper quality.

Primary purification of the liquid from large particles is carried out using a mesh filter. In a flowmeter with a check valve, the chamber is not completely emptied.

A non-return valve is installed in faucets, but when the water supply is temporarily interrupted, a situation often arises when an impatient consumer opens the valve in the hope that it will turn on soon. The water located in the gap between the shut-off valve and the mixing device flows into the sewer pipe. If a water meter with a check valve is installed, only liquid will flow from the area from the mixer to the valve. The reason is that the valve turns on only under the required pressure. It doesn’t matter if the shutdown was short and the residents managed to turn off the water in time. If the water supply is interrupted for a long time, not only the water meter may be damaged, but also the neighbors will be reimbursed for repair costs - there is a risk that the pipe will burst.

When installing a boiler in an individual house, installation of a check valve is required. When water is heated in the working chamber of the water heater, the pressure increases significantly, leading to squeezing of the input flow. The water flows back.

The heating system of an individual home may include not one circuit, but two or more. For example, the first is intended for heated floors, the second for the boiler, and the third for the heating system itself. Each of them is equipped with a separate pump and has its own operating pressure. To prevent the reverse flow of water and its movement from one circuit to another, it is also necessary to install a check valve.

The data sheet for water meter models without an additional element indicates that a check valve should be installed after the meter.

Problems you face

A typical situation for an apartment building: different pressure in each of the risers. In a pipe with cold water, the pressure may be higher than in a pipe with hot water and vice versa. The pressure can easily increase at any time, but more often than not it drops unexpectedly due to a leak or even a pipeline break. The effect of the difference in flow pressure is often noticeable when two taps are opened in one apartment at once. For example, the faucet in the kitchen is open, hot water flows from it, and at the same time cold water begins to flow from the sanitary shower head. One stream replaced another.

In many houses with centralized water supply, hot water is turned off for at least two weeks in the summer. During this time, in apartments where heating devices are installed, the liquid supply valve from the central system is closed, and hot water from the boiler is released through the same pipes. Sometimes residents forget to turn off the valve on the water heater, including the water supply from the central riser. Cold liquid with high pressure blocks the flow of warm liquid, squeezing it out. As a result, only cold water is supplied from all taps. Then it goes to the central riser, in a few minutes all residents will be washed with cold water.

The second option is more common and can happen in any apartment. When using a shower mixer, a situation similar to the one described above occurs. If the pressure in the hot water riser is higher than in the cold pipe, you will get boiling water in both taps. In this case, the meter will spin very quickly, counting cubic meters even if water is not used. There will be hot liquid not only in the riser, but also in all apartments below and above.

There is one more reason that completely excludes the influence of the human factor. This situation occurs as a result of failure of the valve on the mixer. Inexpensive Chinese taps fall into disrepair every one and a half to two years. They are affected by water quality: chlorine, rust and other impurities. As soon as the shut-off lever breaks, water will rush into the adjacent pipe and the liquid will be displaced. A single-handle faucet in the kitchen can have the same effect. When the mixer handle is lowered, it opens both valves; if the pressure of hot or cold water is higher, one liquid displaces the other, spreading throughout the system.

In all the described cases, at the end of the month you will receive a very decent bill for the cubic meters of water pumped up by the reverse flow. Another trouble awaits children: injuries are possible as a result of supplying a hot stream to a cold tap. In addition, things can be damaged; instead of cold water, liquid at a temperature of up to 80 degrees is supplied to the washing machine through a hose.