The joy of a rich harvest is sometimes overshadowed by the need to figure out how to process it. Fruit pies quickly become boring; there is not always enough time for vegetable wraps or making jam. Thrifty housewives want to have another option for processing raw materials. This opportunity is provided by a press for squeezing juice - in addition to the main product, it is also used for the production of alcoholic beverages (wine, cider), pressing cheese or meat, and other operations. Convenient and easy to use, it helps to cope with any number of fruits - from two pieces to kilogram volumes.

Features and principle of operation

The operation of such a device is based on the use of strong pressure to extract juice from fruits or berries (apples, grapes, plums and apricots, citrus fruits, and other fruits). Although different models differ in the type of control and complexity, they always consist of several required parts:

- basket for raw materials;

- juice tray;

- filter;

- press that creates pressure.

There is still no exact information whether this design is a type of juicer or whether they are two different devices for similar purposes. Most often, such devices are called press-type juicers.

Basically, a juicer press is used to extract juice. The device is suitable for any fruits and vegetables, with the only caveat - the harder the fruit, the more it needs to be crushed beforehand, and the more effort it will take to obtain juice. However, all efforts will be justified - the final product retains the maximum amount of minerals and vitamins. In addition, even the simplest press models are easy to use. A household appliance can be useful at home or in the country, and large, complex types of products are actively purchased by factories and farms.

The best premium citrus juicers

Citrus juicers in the premium segment are the most expensive, and their prices can vary significantly. Devices in this group are characterized by high quality materials, manufacturability, and high performance. Much attention is paid to product design.

Premium segment devices are produced only by well-known brands.

Our rating includes three models of juicers costing from 4,500 to 10,000 rubles.

3 Kitfort KT-1115

In third place is an automatic juicer with direct juice supply from the Russian brand Kitfort KT-1115.

Control of this model is very simple and intuitive: you need to place half of the fruit on the cone attachment, close the lid until it clicks and press the start button. Extracting juice from one fruit will take about 12 seconds, at a power of 50 W. The juicer has a memorable original design. The internal elements of the device are made of high-quality food-grade plastic, the body and lid are made of plastic for household appliances.

The juice spout supports the Anti-drip function. If you need to change the filled dishes while the appliance is operating, you just need to lift the spout up. The juice will be temporarily collected in the 350ml internal juice tray.

For comfortable use of the product, there is a tray filling indicator, a special compartment for the cord, a universal nozzle size, and a simple system for assembling/disassembling the structure. Users rate the model as reliable, convenient, with thoughtful functionality and beautiful design.

Pros:

- Automated, simple control.

- Ergonomics.

- Anti-drip function.

- Performance.

- Quality of materials.

- Volume of the internal tray.

- Design.

Minuses:

- There is no protection against an open lid.

- The warranty is only 1 year.

Juicer Kitfort KT-1115

2 Caso CP 300

The juicer of the German brand Caso CP 300 takes second place in the subcategory.

This model has many positive reviews from users who appreciated the build quality and materials, high performance, power (160 W), functionality, and reliability of the device. The model is made of high-quality stainless steel, with some plastic elements (base, decorative edging). The handle of the clamping mechanism with which the device is equipped has a durable and comfortable soft-touch coating.

The juice supply in the device is direct, into a separate container. The juicer's spout has a "drop-stop" function to prevent juice from splashing during draining or pauses in operation.

To operate the device you will need a minimum of effort; simply press the handle of the clamping mechanism and the device will start working.

The cone attachment is designed for medium and large-sized fruits; it is also convenient to squeeze juice from small citrus fruits. Such versatility is the advantage of this model in comparison, for example, with the CP 200 model.

The dimensions of the device are substantial for citrus presses, but it also works quietly, quickly and efficiently.

Pros:

- Power and efficiency.

- Housing and filter mesh made of stainless steel.

- Build quality.

- Versatility.

- Drip-stop function.

- Clamping mechanism.

- Simple controls.

- Easy to clean.

Minuses:

- Marking surface.

Juicer Caso CP 300

1 Smeg CJF01

The leader of premium models is the Italian citrus juicer with direct juice supply Smeg CJF01.

The quality of materials and workmanship in this device is at a high level. But most of all, users admire the design, which, in their opinion, absolutely justifies the high cost. The device is made in the style of 50s technology, and is distinguished by its laconicism and elegance of form. Cast aluminum is used as the material for the body. All parts that the juice comes into contact with are made of stainless steel and transparent Tritan plastic, reminiscent of glass in appearance. The protective dome cover is also made from it.

The cone attachment of the model is universal and suitable for fruits of any size. The power of 70 W allows you to quickly squeeze juice from citrus halves with maximum efficiency. A mesh filter with round holes does not allow seeds and most of the pulp to pass through. Drip protection prevents juice from splashing around the device.

A number of other advantages include the quiet, soft operation of the device, the stability provided by non-slip feet, a compartment for storing the cord, and the ability to wash removable parts in the dishwasher.

Pros:

- Build quality and materials.

- Design, 7 colors.

- Efficiency and spin speed.

- Reliability of the device.

- Universal conical nozzle.

- Not noisy.

- Drip protection.

- Easy operation and maintenance.

Minuses:

- Price.

Juicer Smeg CJF01

Varieties of design

Regardless of the type, all presses are manual, automatic or semi-automatic. When choosing, it is important to focus not only on performance indicators, but also on personal needs. For home preparations, minimal or medium power is sufficient.

Screw

The most common option with the simplest device:

- perforated container;

- lid;

- screw device;

- pallet.

Fruits or berries are placed in a container, under the pressure of the lid they release juice, which flows through the holes into the tray. The screw is responsible for setting the lid in motion. A simple device allows you to get about 30 liters of juice per hour of operation - for summer cottages with an average harvest, this is quite enough. The main advantage of screw presses for squeezing juice is their low cost, but the quality is not always satisfactory. However, in working condition they are very effective.

Despite its simplicity, even this design can be of two types - with a screw and a frame screw press. The first is the most budget-friendly, but has a significant drawback - the grease of the screw gets into the raw material and spoils its taste. You don’t have to lubricate this part, but then it will fail faster. In the second type, between the container with raw materials and the screw there is a pad that prevents their contact - this way the quality of the finished product is preserved.

Manual screw presses can be used to extract wax from honeycombs, as well as to make homemade cheese.

Garden hydraulic

If you need greater productivity, it makes sense to choose a hydraulic electric or manual juice press. The fruits are no longer placed in a container, but between several drainage frames. Some models have membrane mechanisms - they are responsible for squeezing the maximum juice out of the raw materials. As in the case of the screw model, there are also two varieties:

- With a jack. In this rectangular (sometimes square) shaped product, the mechanism is always located in the center and is located either at the top or bottom. Almost no effort is required; a juice jack press is easy to handle. The main problem is the insufficient length of the rod, so to process the entire volume of raw materials it may be necessary to place one or more wooden blocks.

- With hydraulic cylinder. If the previous types are more suitable for households, then this one is more often used in industry. There are manual and semi-automatic devices in which the cylinder is activated by pressing a button.

Models with a two-stage jack eliminate the need to place bars; the juice is squeezed out completely.

Combined

This option combines the advantages of hydraulic and screw presses for squeezing juice, thereby increasing the efficiency of processing raw materials and obtaining the maximum amount of the final product. True, due to the expansion of the design, the cost of the product also increases, so it is more often used for large volumes of raw materials. This juicer is easy to use and provides a high speed of the process, and it also saves a lot of effort.

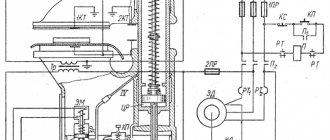

The first spin is carried out using a screw device that presses on the drainage bags. During the second stage, the jack releases the remaining juice. As a result, pressure is applied to the fruit from two sides: from above (the screw part is responsible for this) and from below (hydraulic). The screw device presses on the drainage bags, and a membrane with tap water props up the fruit from below.

Tape

Such products are used in large enterprises and industries. They operate automatically on juice production lines. The efficiency of these berry and fruit presses is even higher compared to all previous models, but such options are not suitable for household use. These devices require virtually no operating costs or maintenance. They are easy to operate, easy to clean and maintain. It is also important to take into account that they are usually used in conjunction with other structures. These are decanters, which further reduce the content of suspended particles in the juice, as well as separators, which carry out the process of secondary clarification. On an industrial scale, the quality of the resulting product pays for all costs, but in everyday life there is no need for belt presses for squeezing out juice.

Hydropress

Semi-automatic design, which uses the pressure force of tap water (the water supply must have a pressure of 2 or 3 atmospheres). Fruits are poured into the raw material container and the lid is closed. Inside the container there is a rubber membrane, which expands under pressure and puts pressure on the product, causing it to release juice.

Typically, the volume of the basket of this model is from 20 to 200 liters, but even with the minimum parameters, the cost of this cold-press juicer is higher than that of screw or hydraulic ones. This is due to the automation of the process, simplicity and materials used to manufacture parts. Typically, those who produce products for sale choose this model - most likely, the pressing device will cover all costs. When making financial calculations, it is important to take into account the cost of the rubber membrane - over time it breaks down and needs to be replaced.

The main criteria for selecting a juice press

The basic design of a juice press has remained virtually unchanged for thousands of years. Here are its main elements:

- Container for storing chopped fruit.

- The piston, which is controlled by mechanisms or by manual force, is lowered onto the crushed raw materials and presses on it with increasing force.

- Tray for squeezed juice.

Before you go to the store, you need to determine the criteria by which you will look for a mechanical assistant.

What to look for?

- Control type: automatic or manual.

- Press type: mechanical, pneumatic, hydraulic.

- Press volume.

- Mounting location: table or floor press.

- The type of raw material the press is designed to process.

Manual floor-mounted screw press - a simple and reliable model

Choice depending on purpose

When choosing a press, it is important to focus on the raw materials used and production volumes. Large and complex machines are suitable for enterprises, but at home a manual juicer will do just fine.

| Criterion | Juice press |

| Mainly for berries | Small volume screw |

| To obtain juice from grapes | Screw capacity 10–20 liters |

| Mainly for apples and hard vegetables | Manual hydraulic about 30 liters |

| For kitchen work | Manual minimum volume (up to 5 liters) |

| For a summer cottage | Screw or combined |

| For production | Electric models |

For berries, a hand press is most suitable because their harvest is usually not as voluminous as grapes or apples. If the berries are collected in large quantities, a larger capacity press juicer would be the best choice.

The most affordable types include a mechanical screw-type device, and the most expensive are a hydraulic press with a membrane. As a rule, the productivity of models for home use is up to 10 liters per hour, for industrial use - from 10 to 30 liters. It is also important to pay attention to the quality of materials - the design should not contain aluminum parts.

When choosing, focus on the raw materials used and their volumes

Pay attention to the quality of manufacturing materials

How to make basic press parts

You can do everything yourself. Materials and tools are prepared in advance, this material is read, and then done in one go. It won't take long to do this, and the instructions will tell you where to expect surprises.

Pallet

If parts of a washing machine drum are used to make the press, then the outer drum casing is used for the tray:

- It is cut to the required height.

- All holes are blocked from below.

- Only one hole is made to drain the fruit drink. This hole should be on the side at the bottom.

Either a barrel or a plastic or metal basin can also be used as a pallet. There is also a hole in it to drain the juice.

Filters

This element of the apple press is made by hand from wooden dies or a washing machine drum. If wood is taken, then dense varieties are selected that do not absorb moisture, do not have resins and a strong odor of their own. If made from metal, all parts, including bolts and nuts, must be made of stainless steel.

In the drum of the washing machine, all unnecessary, large holes are plugged using a rubber gasket secured with a metal plate. If necessary, additional thin holes with a diameter of 1 mm are punched in the drum.

It is not difficult to assemble such a unit from wooden slats. The amount of material will depend on the volume requirement:

- The required volume of a barrel for processing the harvest from your own garden will be obtained from 20 wooden dies with a height of 40 to 50 cm, a width of 50-60 mm, and a thickness of 20 mm.

- You will need 3 metal strips 2-3 cm wide and 1 mm thick to attach the boards. These will make tightening hoops.

- To fix the boards, 60 screws and 3 pairs of stainless steel bolts and nuts are used.

Tools you will need:

- screwdriver or screwdriver;

- sandpaper;

- hacksaw for metal or wood.

The result will be a leaky barrel without a bottom. Let's look at it step by step:

- All wooden planks are leveled in height using a hacksaw and processed with sandpaper to remove burrs, roughness and sand them.

- Two metal strips are placed parallel to each other at a distance of 5 cm from the top and bottom of the resulting knot, and a third in the middle.

- The dies are laid out across the tapes with a gap of 10-12 mm between each other.

- The boards are attached to the strips with screws.

- The resulting structure is rolled up, and the tapes are fastened at the ends with bolts.

It will be better if the apple mass is placed in mesh bags. Or they take pieces of fabric and wrap the fruits in them, like in an envelope. All the pulp will remain in the fabric, and will flow into pure juice into the prepared dishes. The fabric acts as an additional filter.

Drainage grate

In such a unit, drainage gaskets are required; they help distribute the load of the press and better squeeze out the juice. They are usually made of wood:

- Either a fairly wide and thick board is taken, or from several dies, in 2-3 layers with transverse laying.

- The dies are tightened with screws or nails. Connection with screws is more reliable.

- Holes are drilled in the resulting gasket to allow juice to drain. This drainage design is made taking into account the possible high pressure on it.

- Fabric bags with chopped apples or apple mass are placed in the tank, sometimes the apples are placed whole. If these are cut or whole apples, then it is recommended to lay one layer of a bag with fruits, a second layer, a drainage grid, and so on.

If there is grated mass in the bag, then you can put 2-3 bags in one layer, depending on how finely the fruit is grated.

Chopper

If the press is powerful and the apples are small and not very hard, then you can crush them whole. If they are hard and large and the press is medium in power, then you need to cut the fruits or grind them.

As an option, a screw mechanism is used for grinding or a screw press is made directly.

Manufacturing materials

Wood or stainless steel is usually used to produce such devices. The latter option is valued for its practicality and ease of use. These cold-press juicers are easy to clean and leave no traces of raw materials on them. Wooden containers, on the contrary, absorb juice and change color. You can only wash them with a brush - and still, over time, the pigment from the berries and vegetables will be absorbed. If the wood is not completely dried, it will absorb foreign odors and mold may appear.

To be fair, it is worth noting that stainless steel is also not flawless. If processed poorly, it can interact with the acids of the raw materials, giving the final product an unpleasant taste. But even if we put this argument aside, for many people the tree is closer simply because it is familiar. It is more pleasant to work with and has been used for many generations. Another advantage of the material is its naturalness.

Tree

Stainless steel

Raw material type

Presses can be universal or special. Universal ones can work with any type of raw material: berries, fruits, hard fruits and vegetables, stone fruits. Many universal presses are also suitable for squeezing oil.

Special presses are designed to work with one type of raw material. As a rule, these are presses for berries and soft fruits. It is not recommended to press hard fruits or vegetables on them.

For example, a professional press for citrus and pomegranates is capable of processing about 50 kg of fruit in an hour. It will be useful not only to craft lovers, but will also be useful to owners of catering establishments that serve freshly squeezed juices. The cost of the press is 23,800 rubles.

Any press only works with crushed raw materials. Preliminary preparation of raw materials for pressing is a prerequisite. Use a special crusher to crush fruits.

Press basket volume

The variability of this parameter is very large, so it is important to determine the required volume in advance. The amount of juice obtained at a time will depend on it (up to 70% of the nominal value). The main selection criterion is the amount of processed raw materials:

- the smallest ones - 750 ml - will be useful for those who need a juice press for cooking a couple of servings;

- a volume of 3–5 liters is enough if preparations are made from purchased apples or grapes;

- for summer cottages, models with a volume of 10 to 12 liters are usually chosen (depending on the area and average yield), such products can easily be used for making homemade wine or cider;

- farms and large gardens require larger volumes, about 20–30 liters;

- For industrial use, a juice press with a volume of 50 to 200 liters is useful.

Miniature models are sometimes used as gifts that have a decorative function - in this case, it is better to choose a wooden device with carvings.

From an activator type machine

A centrifugal juicer can also be made from an activator-type washing machine. The activator and shaft are removed from the bottom of the tank, and a shaft of the required diameter is installed. Three knives are installed on the shaft thread with nuts at an angle of 60 degrees. The drain hole closes. A stainless steel mesh with a mesh size of approximately 1.5 mm is placed on the wall of the centrifuge with an overlap of 40-50 mm. A complete rubber cap, plugged with a stopper, is placed on the bottom. Everything is washed with baking soda. The timer relay is turned off or its toggle switch is jammed.

Several apples are dropped into the tank onto moving knives. The fruits are crushed for 20-30 minutes. At a time, transfer no more than 3 liters of the resulting puree into the centrifuge so that it does not spill out. After 2-3 minutes, the mesh containing the waste is removed.

The assembled apparatus prepares 10-12 liters of juice with pulp per hour and works with juicy fruits. To remove sediment, the juice is allowed to settle and then passed through cheesecloth.

Which is better - screw or hydraulic?

Both varieties have their advantages and disadvantages, so the final choice should be based on the purpose of use. In terms of simplicity, a hydraulic juice press wins - it requires virtually no physical effort to operate. Another advantage is its repeated use on the same raw materials. You can run it several times to get maximum squeezing. But a screw-type press juicer can only be turned once. Although some consider this rather an advantage, since you can quickly cope with the entire volume of raw materials. This is true if you don't want to squeeze out all the juice completely. It is important to consider that with a volume of 10 liters or more, a manual press with a screw device will need to be fixed using self-tapping screws, while a hydraulic press can simply be placed on the table. If the volume is smaller, it will be enough to hold it with one hand and turn the screw with the other.

The choice depends on the purpose of use

The best mechanical citrus juicers

Mechanical citrus juicers have a very simple design. Unlike electric ones, it is not a motor that works here, but human hands and simple mechanisms. The productivity of such devices is lower, but if we are talking about squeezing a small amount of juice, these options are very convenient.

We included two models in our rating, with different principles of operation, which differ in quality of execution and are popular among users.

2 Endever HJ-007

One of the best manual mechanical models is the Swedish brand ENDEVER HJ-007 juicer.

This device does not have a traditional cone attachment for citrus fruits, since its purpose is universal, for any fruit, vegetable or berry. The juice is extracted using a screw and a rotation handle. The model is made of food grade plastic of excellent quality. The device is easy to disassemble and clean, and is very simple to use. Peeled citrus slices are loaded into the fruit receptacle. The finished juice ends up in a juice trap and in a special container with a fine-hole filter sieve. The drink turns out clean, almost without pulp.

The handle of the device rotates easily, without much effort, so preparing several servings of fresh juice is not at all difficult.

The juicer is fixed on the table surface using a rubber bottom, like a suction cup, and the fixation is reliable. Users note the bright, interesting design, simplicity of construction and safety of use. You can prepare juice together with children, who are very attracted to this process.

Pros:

- Spin efficiency.

- Does not require energy consumption.

- Quality of plastic.

- Easy to assemble.

- Convenient fixation on the work surface.

- The handle rotates easily.

- Price.

Minuses:

- The need to peel the fruit.

- Performance.

Endever HJ-007

1 BergHoff Zeno 1105451

A citrus juicer from the Belgian brand BergHOFF is in first position in the subcategory.

The company's products are distinguished by high quality materials and original modern design, which is completely true for this model. The BergHOFF Zeno 1105451 manual juicer has the simplest design: a container for juice and a cone nozzle with a grid for filtering juice. The product is made of durable stainless steel, with a beautiful mirror polish. The top of the container, where the nozzle is located, ends with a matte black polypropylene ring. The grooves in the ring gently and securely hold the nozzle. In addition, the ring serves as an interesting design element.

The cone size is convenient for fruits of different sizes. The citrus fruit halves are placed on the cone and the squeezing process occurs with hand movements. The grid has middle holes through which the juice and part of the pulp enters the container.

According to users, this device produces juice of excellent quality, while maintaining all its beneficial properties. The model is indispensable if you need to prepare a drink quickly and without much hassle.

Pros:

- Quality of material.

- Design.

- Comfortable, thoughtful design.

- Universal nozzle.

- The grille is dishwasher safe.

- Ease of use.

- Taste qualities of juice.

Minuses:

- Price.

Juicer BergHoff Zeno 1105451

Popular manufacturers

The Russian market mainly presents models from domestic and Chinese companies. The latter are usually made of stainless steel. There is a fairly high risk of purchasing a product that will react with acids and add an unpleasant taste to the final product, so it is better to choose a juice press from Russian manufacturers.

| Firm | Peculiarities | Popular models |

| Farmer | Uses modern technologies to produce equipment for processing agricultural products | SVR-01M made of stainless steel - capacity up to 15 l/h, manual control. Additionally used for pressing homemade cheeses and obtaining wax |

| Magarych | The main task is to protect the population from counterfeit alcohol through the production of products for the production of high-quality homemade alcohol | SPM 15 - the main characteristics are the same as the previous model. You can also use it to compress meat. |

| Fork | Manufactured according to European standards, the product line includes not only press juicers, but also choppers, shredders, cheese factories and much more | Muromets P differs from its predecessors in productivity (30 liters per hour) and control system (pneumatic drive) |

| Good heat | They are engaged in the production of goods for moonshine and brewing, canning, and winemaking. We started as a small company, but in seven years we turned into a large plant | In addition to stainless steel, the product uses rubber and brass. Suitable for large production volumes (productivity up to 100 liters per hour). Operates hydraulically and has a pressure relief valve |

European companies are also represented on the Russian market, but you need to take into account that if parts break down, it will be more difficult to purchase spare parts.

Good heat Magarych

Farmer Forkom

How to make basic press parts

Initially, you need to prepare a metal base, then form the upper half of the frame, positioned horizontally. A very durable material with thick walls is selected for it, which will eliminate the deformation of the components under load. Corrosion can be prevented by treating the surface of the frame with paint. Then plywood is laid on the base, and a tank with a tray is installed on top. The plywood is varnished.

Pallet

If you make the press yourself, it is important to make the pallet correctly. Here they sometimes use a large pot, where a round hole is cut out near the side and a tube is secured

Through this tube, the juice will flow from the tray into the receiver. When working with the structure, you need to be careful. The tray may break if the tube, tray gets caught, or something is accidentally dropped on it. If you are not careful, you can tear out the tube. For this reason, it is preferable to choose a tray made of stainless steel, and weld a metal tube to the hole.

The tray can be made from a large plate or from a stand for a flower pot

Filters

Filters are bags in which the pulp is placed. The scraps of fabric that are needed to make bags of fruit must be durable. Suitable for this purpose: calico, cotton or burlap. Some people use linen. The density of the fabric should not reduce its filtration qualities, but it should not be fleecy.

To filter juice, you should use a durable cloth with a fine mesh, such as lavsan or polyester.

Drainage grate

A grid for drainage function in the form of a basket can be made from oak, birch or beech planks. Choose those whose thickness is 20 mm or more. To do this, take several identical planks, two steel strips, and self-tapping screws that have a special coating. The planks are screwed to the strips, the strips are bent in a circle, and secured with bolts. The basket is ready. The distance between the slats is about 10 mm. You should not take chipboard plates; such material will release resin, sawdust and other harmful substances into the juice.

To sew bags, use any durable fabric that will not tear under the pressure of the raw material. In addition, the fabric must have filtering properties.

Chopper

This part is a mandatory part of the presses, since their models work in conjunction with such a component of any pressing structure. The simplest among such grinding mechanisms is considered to be a steel grater drum, which is placed in a homemade casing with a hole for loading pulp. When you turn the handle, the chopper is set in motion, turning the fruits into pulp.

It is made from a sheet of moisture-resistant plywood, a sheet of anti-corrosion steel or wooden planks. The resulting hopper is mounted on a circular shaft. Two blocks are attached to the bottom of the bunker for stability. At the bottom of the resulting container, a roller of wooden material is inserted onto which self-tapping screws are screwed in a spiral. The axis of rotation of the element is brought out, and the drill is inserted into it. It will act as a chopping drum. To do this, you can use a regular rolling pin, which is found in every kitchen.

When making a model of a device for obtaining juice, you should pay attention to its stability. To cope with this problem, three pieces of square pipe are welded at the bottom of the frame.

Instead of legs, they will give the unit stability. At the top of the improvised legs, a stand made of boards or a wooden slab is placed, where the pallet is placed.

You can independently make a press for high-quality extraction to obtain any juice without spending a lot of money or special skills, abilities or knowledge. The use of complex equipment is also not required.

Power element of the structure

Piston

DIY making

If there is no need for serious equipment, the simplest versions of the press can be made independently. Some craftsmen even use an ordinary saucepan as a container. Parts from old washing machines, wooden elements and other things that can be found around the household are used.

Most often they make a hydraulic press for fruits, since for a screw press, despite its simplicity, you will have to turn to a turner. The process of making a homemade hydraulic product must begin with the frame on which the jack rests. It can be made from a metal square pipe with a wall thickness of 3 mm. The length is determined by the thickness of the drainage walls (from 2 cm), gaskets, fabric with waste and the height of the jack. The width is selected independently - so that a pallet can fit in the opening. The jack is attached to the piston or fixed to the top crossbar.

It’s good if legs are welded to the bottom of the frame - this will make the homemade press more stable. The legs will house a storage container for juice. To make drainage gratings, you can use parquet boards - fasten them with stainless steel screws. The main thing is that it is a hard wood. There is only one requirement for the bags - strength; the fabric mesh should not tear under high pressure. It can be burlap, cotton, linen, jute fiber. Finally, the tank of a failed washing machine is usually allocated under the frame of a homemade appliance. An ordinary barrel with a hole cut out at the bottom and equipped with a drain is also suitable for the press.

To extract juice from the harvest and preserve vitamins and minerals as much as possible, it is convenient to use a press. For home use, a screw or hydraulic jack is better suited, for production - with a hydraulic cylinder, combined, belt or hydraulic press. When choosing, you should take into account the tasks, harvest volume, ease of operation and maintenance. Sometimes a mechanical juicer and a press are considered as one device, so stores need to check both categories of products. The simplest option is easy to make yourself, but the basic models are quite affordable. Although there are manufacturers from different countries on the market, it is better to opt for domestic companies. There are enough brands that have confirmed their reputation, but imported goods can cause a lot of trouble if you need to replace a part. Chinese analogues, in turn, are not always pleased with their quality: the juice easily absorbs any impurities, so it is better to take care of the purity of its taste in advance.

Welded frame made of metal corners and channel

The structure must be sanded and treated with metal paint

Oak slats for tank

Between the slats it is necessary to leave gaps of 2 mm through which juice will ooze

Cooking tank with tap and finished wooden grate

Piston made of oak planks

Jack as a pressing mechanism

Ready-made manual press for squeezing fruit juice

Advantages and disadvantages of a homemade press

Let's start with the good: you will make a press with your own hands, choose the size and design that is convenient for you personally. And if you have all the necessary tools at home, wood and stainless steel, such a press will come out cheaper than a store-bought one. You can show off your talent to your friends and family.

But let's look from the other side: for the first time you decided to make something with your own hands and chose a press. There are no tools, materials and a jack need to be purchased, but for food products wood and metal are more expensive. Without experience, it will be difficult to obtain smooth parts and welding.

Due to improper design, the spin will be weak, you will waste your energy, time and money.

For beginners, I advise you to start with something simpler, and if you really need it, buy a press in a store. Just choose stainless steel models. For example, this one even comes with a jack.