In any systems whose design includes a pipeline, it is provided that the working fluid is transported in one direction. In order not to encounter a change in the direction of its movement, which can lead to failure of the entire system, various technical devices are used, one of which is a wafer check valve. It is equipped with pipelines used by oil refining and chemical industry enterprises, through which both liquid and gaseous working media are transported.

Wafer check valve - “flap” made of stainless steel for use in various aquatic environments

What is this device and what is it for?

This is one of the types of shut-off valves. It looks like a small piece of pipe, as can be seen from the photo of the check valve for water. The purpose of this device is to prevent the flow from moving in reverse and thereby preventing a drop in water pressure.

In home garden water supply systems, the valve is designed for the pump to hold water in the suction device.

Specifications

Main technical characteristics of shut-off valves:

- Shut-off valve control: manual, gear, electric.

- Technical specifications according to GOST 3326, GOST 9697,

- Nominal diameter: DN 15-400 mm,

- Nominal pressure: from vacuum 5·10−3 mm Hg. Art. up to 250 MPa.

- Temperature: -200 to +600 °C

Material versions of steel:

- carbon,

- alloyed cold-resistant,

- heat-resistant stainless steel,

- stainless steel with special properties.

Source

What does this valve consist of?

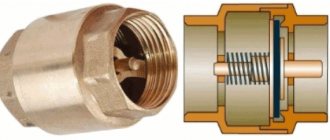

In addition to the body, the valve contains a small spring, a shutter, and a seal. Depending on the material from which the element is made, the modification of the device, manufacturers supplement check valves with springs, levers, bearings, and other auxiliary elements.

Installation location

Sewer and water systems are not the only places where installing a valve is a necessity. Other areas are:

- Autonomous heating system circuit. The rooms where heating radiators or heated floors are located differ radically in hydraulic and pressure indicators, and therefore require the installation of automatic shut-off valves. The device fits in front of the boiler and allows you to balance the technical indicators.

- Water heater inlet. A check valve installed in front of the boiler prevents the hot water mass from moving back into the cold water pipeline.

- Submersible pumps. If the water supply system is connected to a well or borehole, it is important to install a submersible pump. Its main task is to lift water masses from depth and transport them under pressure to the house. When there is a power outage, the pumped water naturally flows into the pressure tank. To avoid this, a shut-off valve must be installed in front of the pump.

- In front of the water flow control meter. All metering devices, in particular the household water meter, are especially sensitive to disturbances and changes in water supply. Water hammer has a negative effect on the device, up to its failure. Also, the locking device prevents the turbine from turning in the opposite direction.

The safety valve does not allow reverse circulation of water in any of the cases described above.

Types of check valves

Experts subdivide these devices not depending on the diameters of the check valves for water, but by the type of shut-off element in them. So, valves can be:

- Disc-shaped.

- Disk.

- Ball.

- Bivalve.

The ball valve is considered quite reliable. The system is based on the fact that the ball moves inside the valve and closes the seat when necessary. However, it does not always fit tightly enough, which creates a pressure problem.

Poppet valves are divided into lift and rotary valves. The latter function under the influence of water. Lifting ones are equipped with a spring-loaded rod, which, under water pressure, presses the spring and the lock comes up.

The disc return element is the most popular and recommended by experts. It is also called spring. The valve is small in size with a simple and reliable latch system. The disk stands across the flow, which presses the spring when pressure appears.

The shutter of a leaf or double leaf valve consists of a pair of flaps mounted on the same axis. The petals are held in place by a spring, but as soon as water hits it, it pushes them out. With such a system, water circulation is reduced, which creates high voltage in the hydraulics.

Classification of the valves under consideration

There are quite a large number of different shutters. The differences are as follows:

- The shutter can be a flat disk or in the form of lens surfaces.

- Classification is also carried out according to the type of material used in manufacturing. The most common models are made of cast iron or stainless steel.

- The interior of some structures can be lined with rubber liners.

The control design is similar to that used when creating ball valves. Some models have a gearbox or flywheel that can increase the force applied to the handle.

In addition, the main classification lies in the diametrical size of the passage hole.

Where is it recommended to use check valves?

These elements are required to be used in the water supply system. In addition, they are indispensable in sewer lines, heating devices, pipes near water meters, in pipe branches in water heating devices, and plumbing units. Shut-off valves in the heating system eliminate the supply of reverse flow, which is important during the operation of water heating devices.

Expert advice

Experienced plumbers recommend:

- choose a valve based not on its lower price, but on its quality, since the costs of purchasing a device are not comparable to the costs of repairing a home if it is flooded with sewage;

- Before installation, be sure to check the device for leaks. If it is not sealed enough, noise and vibration will be heard during operation. To fix the problem, you need to remove the cover and replace the edging or the shutter itself;

- position the valve correctly so that the arrow on its body is directed towards the sewer outlet;

- install the device in a place where it will always be accessible for cleaning and maintenance;

- if the system is made of cast iron pipes and the valve is plastic, then you must first install an adapter from metal to plastic.

Main tasks of the device

It stabilizes the pressure in the system, protects against water hammer, and prevents reverse fluid circulation. If the valve is installed in a submersible pump in front of a well in a summer cottage, it allows the pump to operate without failures or breakdowns.

Differences

The devices in question perform an almost identical task, but have several differences. Let's take the following points as an example:

- Gates serve to shut off flow, but can also be used for temporary adjustment. Manufacturers do not recommend using valves as a control mechanism.

- Valves are almost never used to regulate flow, due to design features. Such a device is used exclusively to block the flow.

- Valves primarily perform a control function. But there are also devices on sale that block the flow.

The valve and gates are adjusted manually or from a remote control unit. But many valves operate in automatic mode; the design is activated in certain situations. In addition, valves often have a more compact design.

Valve installation rules

Installation of a check valve for water is required in front of the meter. It is placed on the pump at the beginning of the suction device, or before the pump itself. But whether it will stand horizontally or vertically depends on the manufacturer’s instructions.

In addition, you need to make sure that you have purchased the right valve, since various modifications of these devices are intended for sewerage, water supply, and heating systems.

It is important not only to choose the right element, depending on its purpose, but also to take a responsible approach to its installation. Be sure to do this during water circulation. It’s easy to determine: by the arrow marked on the valve. It is also important to consider maintenance or replacement of this valve, so it should be installed in an accessible location.

If the device is mounted on a boiler, the device must be disconnected from the power supply and the water must be turned off. It must first be removed from the container.

As for the plumbing, since the pressure in the cold and hot water supply systems is different, each pipeline will require its own valve. Experts advise installing a water purification filter in front of this element. Otherwise, the locking mechanism will quickly become clogged and fail.

It is important to ensure that the valve is exactly suitable for a particular pipe diameter and in no way reduces it. Otherwise, the pressure may increase significantly, which is dangerous for the operation of the system.

Valves classification

The main feature of the classification is the type of locking mechanism. Based on this criterion, we distinguish the following types of design:

- Wedge valves.

- Hard wedge.

- Double disc wedge.

- Elastic valve.

- Parallel valve.

- Gate valve.

- Hose type valve.

Each variety has its own advantages and disadvantages that should be taken into account.

Selection and purchase

Before you decide where to buy a check valve for water, you need to inquire about the availability of a guarantee for quality work from the manufacturer. If there is none, it is not advisable to buy the element.

It is also worth paying attention to the permissible temperature of the working environment in which the valve will operate. From this we can conclude for which water supply systems it is intended (hot or cold water supply).

It is important to consider the type of connecting thread. Manufacturers produce valves with internal or external threads. Preference should be given to the element that is easier to install in a particular system.

The valve is easy to check. You need to blow in the direction of the lock to make it close. Moreover, it should not allow air to pass through.

Connection type

The product can be connected in two ways:

- For a common sewer pipe - a valve with a diameter of 110 mm or more, with greater throughput;

- for the outlet of each plumbing fixture. Internal wiring is usually made from pipes with a diameter of 50 mm. The valves should have the same dimensions. If the system circuit is assembled from pipes with a diameter of 32 mm or 40 mm, special adapters are used when connecting a device with DN = 50 mm.

The devices are installed at the junction of pipes, turning 90º both inside and outside buildings.

According to the method of connection to the process, they are divided into:

- threaded;

- coupling;

- flanged;

- for welding.

Photo of the water check valve device

Principle of operation

The work is based on the elementary laws of hydrodynamics and physics. When liquid stops entering the pipeline, the spring completely closes the valve . When pressure and pressure appear on the valve, the spring weakens, allowing water to pass through. After turning off the pump and reducing the pressure, the shutter mechanism is reactivated. The resistance of the spring increases under the influence of direct pressure. This prevents the valve from opening.

The safety structure in the sewer system has a different operating principle. The valve itself structurally consists of a round plate with a seal, a spring lever and a housing. When water enters the sink, the lever opens. When the pressure drops, the shut-off mechanism closes and prevents sewer water from flowing back.

Types of mechanisms

Locking devices are conventionally divided according to several criteria. The most common mechanisms:

- Disc or spring valve. Inside there is a spring with a locking element. When the fluid circulates in the right direction, the spring compresses and allows water to pass through. During reverse flow, the spring expands, closing the valve. These valves are inexpensive and require no maintenance. But over time, mineral deposits appear inside. In this case, the device must be completely changed.

- The lifting locking valve is characterized by the fact that the valve produces vertical translational movements. When water circulates under pressure, the shutter moves upward, opening the way for it.

- The ball locking mechanism is made in the shape of a ball coated with a wear-resistant sealant. The ball rises when the liquid circulates in the desired direction, and falls, closing the passage of water when the flow moves in the other direction. Devices of this type do not need to be replaced after wear. They are easy to repair. At the same time, breakdowns are quite rare, since the elements do not rub inside the structure. The disadvantage is that it requires a lot of space to install the valve lift.

- A butterfly valve is a type of rotary valve. It has two petals that open from the direct direction of water. These structures have high hydraulic resistance, that is, the fluid circulation rate is reduced. Most often they are used in difficult working environments (dirty water, oil), since in this case it is possible to select a suitable seal.

- A rotary or petal valve is a structure of petal plates mounted on hinges that open during forward flow of liquid and close during reverse flow. In this case, there are no springs that collect mineral deposits.

In domestic conditions, lifting valves are most often installed. This is due to the ease of repair: they just need to replace the spring.