A medium-power semi-automatic welding machine itself weighs a lot. In addition, a cylinder with protective gas, a hose, a torch, wires, and a mask must be delivered to the welding site. The tool for preparing the welding zone, cleaning seams, a supply of welding wire, and other consumables also takes up space and weighs a lot. A semi-automatic cart is useful for this. Everything you need for work is conveniently placed on it. Such products are mass-produced and have two, three or four wheels. Experienced craftsmen are not satisfied with industrial designs; they design and independently make carts “for themselves.”

Characteristics

The purpose of such equipment is to ensure the mobility and convenience of the welder, to reduce the loss of time preparing for welding, dragging tens of kilograms of equipment, tools, and materials. With the help of a trolley, a full-fledged mobile welding station is created, which contains everything that is needed to perform a weld anywhere in a workshop, workshop or construction site.

The main characteristics of such trolleys are as follows:

- Load capacity . The structure must support the weight of the welding machine, cylinder, hose, wires, consumables, and auxiliary tools. The total easily adds up to a hundredweight, or even more.

- Sustainability . The design of the trolley must prevent it from tipping over, even if a passing assistant touches it or the welder pulls strongly on the hose.

- Capacity . In addition to the welding machine and gas cylinder, a large number of large and small-sized items need to be placed in convenient trays, boxes or hangers. They should not wobble or fall out while moving.

- Dimensions and maneuverability . A trolley for a semi-automatic welding machine with a cylinder should take up little space, the dimensions of the vehicle should allow it to pass through passages up to 70 cm and turn almost at a right angle.

In addition, the device should have easy movement and a comfortable handle.

Welding trolley for semi-automatic machine - characteristics and requirements

The welding trolley must meet a number of characteristics that provide favorable working conditions. First of all, such a cart must have:

- a certain carrying capacity;

- sufficient capacity;

- reliable stability;

- high maneuverability.

In addition, the cart should not fall if the welder suddenly pulls the hose, because this can lead to adverse consequences.

Design of a cart for semi-automatic cylinders

The structure is a structure welded from metal beams on wheels. It is designed to make it easier to transport a gas cylinder, because it is not always convenient to transport it manually. Sometimes the length of the welding hose is not enough, and sometimes the weight of the cylinder does not allow you to constantly carry the structure yourself.

What should be considered when making a structure?

Most craftsmen make such a cart from improvised materials. But this does not mean that the cart should not meet a number of requirements. Typically, this list includes:

- weight that will correspond to the installed equipment;

- equipped with strong fastenings in the form of clamps;

- The diameter of the wheels must not be less than 20 cm, and they must be equipped with solid rubber tires. The hub size must be at least 18 mm;

- If the cart is equipped with 4 wheels, then one pair must be of the swivel type. This will ensure the maneuverability of the trolley;

- the shelf under the inverter should be made of dense material, this will help prevent small and foreign objects from falling.

Many users attach additional drawers and shelves to such carts to install additional structures.

Technical data

Manufacturers market several basic types of welding trolleys. Their main dimensions are determined by the dimensions of the welding machine and gas cylinder.

Typical parameters look like this:

- weight: 12-15 kg;

- overall dimensions: 1.25x0.35x0.71 m

- size of the platform for the device: 0.28x.45 m.

These parameters are specified based on the capacity and number of cylinders with which the mobile post needs to be equipped, as well as the selected layout.

The most popular are two of them:

- two-wheeled layout , a large-capacity cylinder is placed vertically, the platform for the device is located above the axis and parallel to it;

- three- or four-wheeled layout , dimensions are determined by the dimensions of the platform for the welder, cylinders of small or medium capacity are placed under the platform.

Two-wheeled options are created on the basis of a standard trolley for transporting 40- and 50-liter gas cylinders; a bracket holding the platform for the device is welded onto their vertical handle

Three- and four-wheeled models are created on the basis of mobile tool cabinets, to which cylinder mounts are added on the side or bottom.

To increase convenience and improve the working conditions of the welder, the cart is equipped with compartments for storing small tools, reels for winding and storing hoses and wires, etc.

Communities › DIY › Blog › Trolley for carbon dioxide cylinder - final

Hello guys with golden hands, I finally finished my cart for the cylinder which I talked about in the first part. From the comments to the first part I isolated the most adequate and very useful tips and tried to implement them. Firstly, I made braces to secure the cart in the car from lateral displacements. Secondly, I made two clamps to secure the cylinder itself on the cart. Thirdly, I prepared two fastenings for installing a “collar” on the cylinder that will keep it from longitudinal displacement when transporting a cart with a cylinder (I haven’t come up with a collar yet). Fourthly, I drilled two holes in the wheel brackets in order to later make locking pins that would keep the cart in the car from longitudinal movements. After all of the above, I wanted to start painting as soon as possible. This time I decided to try a new primer gun, but who am I kidding))) I just wanted to try to paint something with a gun that I bought not long before.

Again my perfectionism got the better of me and, turning a blind eye to the price, I decided to buy this

The price of this sheet in OBI is 1499 rubles o_O And I attached it to the bottom of the cart like this

I also bought a yellow sling and wrapped it around both crossbars, making the upper one in the middle part soft with the help of round pipe insulation (the gray one) it will become clear later why. The assembled cart looks like this

I used rubber spare tire mounting straps from a VAZ 2101 as clamps to hold the cylinder.

According to the master plan, the cart is not only for moving the cylinder around the garage but also for transportation in the car. I roll the cart up to the trunk and tilt it, resting it on the rear bumper with that same soft cross member that I mentioned above.

To hold the cart in a transverse position, I used a chain and two lanyards.

I haven’t found two studs to secure the wheels yet, but I’ll definitely do it! there is no need to write about this in the comments again))) We also welded two ears for which I will attach the “collar” to the cylinder.

Overall, I'm very pleased with the cart. I have already moved the cylinder to a better place in the garage. It was not difficult to load this entire structure as I wanted. I also discovered a “side effect” of the cart, which is that now it will be much more convenient to carry the cylinder even if two people hold the cart by the longitudinal pipes in the middle. Thank you for your attention.

Our page on DRIVE2:

Technological components

For the manufacture of trolleys, a metal profile of round or rectangular cross-section is used. For the platform, steel sheets, expanded metal mesh or a transverse set of corners are used. The blanks are welded together, then cleaned and painted with powder paints to protect the structural elements from corrosion.

If the device is used in enclosed spaces with a flat floor, cast wheels of small diameter are usually used. If you plan to go outside, choose pneumatic rollers with a larger diameter that can handle potholes and other obstacles.

The trolley must be equipped with a device that prevents its independent movement. For two-wheelers, this is a heel support; for three- or four-wheelers, wheels with a built-in pressure brake are used.

Additional requirements

Depending on the characteristics of the technological process that will be provided using the trolley, additional requirements for its design may be put forward, for example:

- additional shelf for placing a water cooling device;

- additional places for cylinders;

- hangers for replaceable burners;

- waterproof cups for storing rod electrodes;

- oil and acid resistant wheels.

For outdoor use, a casing can be added to protect the equipment from the elements.

Execution options

There are many options for the design of trolleys for semi-automatic welding machines.

Some of them are designed to transport only the apparatus, but more popular models are those that simultaneously transport a gas cylinder or cylinders, and all other items necessary for welding.

Two-wheeled options, made on the basis of a trolley for transporting cylinders, are distinguished by the greatest load capacity and maneuverability ; thanks to the large volume of gas cylinders, they provide greater autonomy. They are also distinguished by greater maneuverability and maneuverability.

Three- and four-wheeled models can only move on a flat floor or asphalt; even a 10-centimeter bump or high step can become an insurmountable obstacle for them. To increase maneuverability, the front wheel (or wheels) are made swivel. The main advantage of such structures is their high stability, ease of operation and access to contents.

Features of two-wheel design

The platform supporting the cylinder from below is made in such a way that it turns into a stand and support for the entire structure when the cylinder is placed vertically. It also acts as a reliable brake.

The two-wheeled trolley for transporting semi-automatic weapons has two positions -

- working, when the base is on the ground;

- transport, when the cylinder is tilted, the base is lifted off the ground, the structure can roll on wheels.

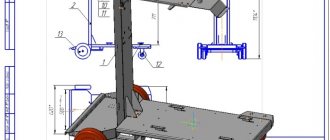

Drawing of a frame of a two-wheeled design.

A bracket for attaching a semi-automatic machine is hung on the frame in a convenient place. The bracket for the semi-automatic machine is welded to the handle. Since the trolley tilts at an angle of up to 45° during transportation, the device is secured to the bracket with straps

Additional brackets for boxes with tools and equipment, hangers for coiled wires and other parts are welded to the handle.

The process of manufacturing a trolley for a semi-automatic machine

After preparing all the necessary materials, you can begin the assembly process. For convenience, it is worth examining each step in more detail:

- Step 1 . At the first stage, the base is assembled. To do this, you need to bend the profile on a pipe bending machine. After this, all the elements necessary for assembling the base are cut. It is important that everything is done for a specific cylinder and equipment.

- Step 2 . Axles for future wheels are welded to the resulting base. To do this, long bolts are used, which are subsequently welded to the frame. It is worth remembering that the wheels must be of sufficient diameter, at least 20 mm. This is necessary so that the cart can move easily on the ground.

- Step 3 . In order for the cylinder to be attached to the structure, you need to weld a fork from a pipe. In the future, the cylinder will be secured using tight clamps.

- Step 4 . At this stage, all the necessary shelves are welded from pipes. It is best to use corrugated aluminum as cladding, which not only has high strength values, but also has an excellent appearance.

- Step 5 . Using a vice, the reinforcement is bent into arcs, which will later be used to strengthen the shelves.

- Step 6. Wheels are placed on the axle; if necessary, you can equip the structure with maneuverable wheels that will rotate 360 degrees.

Reference! It is best to use wheels like garden carts.

Once the assembly is complete, you can paint the cart and give it a more aesthetic appearance.

Manufacturing nuances

What can be attributed to the main nuances of making homemade products:

- the cross-section of the pipes must be at least 40x20, and the wall thickness must be at least 1 mm;

- the wall thickness of the corner must be at least 1 mm;

- The thickness of the sheet metal must be at least 1.5 mm.

The table shelves, as well as additional equipment, are made of corrugated aluminum or sheet steel and plywood. In this case, there should be a rubber coating on top. It is important to remember that the thickness of the aluminum sheet must be at least 2 mm, and the thickness of the plywood must be at least 5 mm.

Also, the user must immediately indicate the number of transported cylinders, because the size of the trolley directly depends on this.

Three-wheeled model

A three-wheeled trolley for a semi-automatic machine with a cylinder mount is much more convenient to use than a two-wheeled one . Free access to the device, other equipment and welding materials is provided; they do not need to be secured during transportation.

Its capacity is significantly higher than that of the two-wheeled version. It is possible to install drawers, additional shelves, cabinets, removable containers and much more.

Three-wheeled design drawing

With such a device you can transport everything you need for work to the far corner of the workshop and not have to return for every little thing you need. The convenient handle allows you to both pull the device behind you and push it forward. Swivel wheels provide sufficient maneuverability.

Do-it-yourself trolley for a welding machine according to drawings

You can make a cart for a semi-automatic machine yourself. To do this, you will need to prepare a number of tools, study drawings and a step-by-step manufacturing plan. The first step is to find a drawing according to which the homemade product will be made. It is worth analyzing the manufacturing process, starting from a specific example and drawing. This will help you more accurately and efficiently consider the process of assembling a cart for a semi-automatic machine with your own hands.

Necessary materials

The first thing to start with is preparing the materials. What you will need to assemble the structure:

Reference! At this stage, the user can either immediately visit a specialized shopping center or store, or look for all the necessary elements in his garage.

- profile pipe;

- fittings;

- reliable wheels;

- long bolts with nuts;

- corrugated sheet aluminum;

- two wheels from carts;

- welding machine;

- pipe bending machine;

- vice;

- Bulgarian;

- drill;

- roulette;

- marker.

It is very important that the materials meet the above requirements.