General characteristics of fittings

In order to understand how A1 reinforcement differs from A3, you need to know what properties characterize this type of rolled metal.

The profile type is divided into smooth and periodic. The first has a flat surface, and the second has longitudinal and transverse ribs protruding. The periodic profile adheres better to concrete, which increases the strength of the structure.

An equally important characteristic is the cross-sectional diameter. For each brand of reinforcement, GOST establishes acceptable dimensions. With an increase in cross-sectional diameter, both the strength of the reinforcement cage and the mass increase.

GOST also establishes the grade of steel from which the rods are made. Not only the strength of the structure depends on it, but also corrosion resistance, which is important in aggressive environments, places with high temperature changes and high humidity.

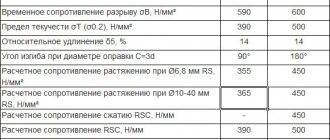

Based on the class of reinforcing steel and its diameter, the strength characteristics of the material are determined. GOST 5781-82 indicates for each grade and diameter the yield strength, tensile strength, relative elongation and other characteristics that will allow all calculations to be made before construction.

Composite reinforcement

When choosing between steel and composite reinforcement, you must remember that the solidity of the structure depends on the adhesion (adhesion) of the rods to the concrete. For steel it is 0.18, for composite materials - 0.03 MPa.

In practice, this means that variable loads on the structure will sooner or later lead to separation of the concrete from the plastic.

Reinforcement with mineral and organic (aramid) bases are produced in accordance with GOST 31938-2012. Composite polymer reinforcement (CPF) contains such continuous fibers.

- Glass.

- Basalt.

- Carbon.

- Aramid (Kevlar).

The type is designated accordingly: ASK, ABK, AUK, AAK. There is also ACC - combined composite. They are bound into a durable structure with thermosetting (polyester, epoxy, phenolic) resins.

The profile is periodic. Standard diameters are from 4 to 32 mm, length 0.5 - 12 m. It does not bend or weld. But it is corrosion resistant, does not conduct electricity, and is not magnetic.

Experts treat her with distrust. First of all, because its production can be organized in a garage. It is difficult to achieve strict adherence to technological regimes in such conditions.

In private construction it is used to reinforce masonry. Especially if the solution is aggressive: it contains sulfates, chlorides (anti-freeze additives, accelerators). In non-critical structures: strip foundations, supporting walls, blind areas. For reinforcing floor screeds.

Ready-made spatial composite frames are available for sale. Standard or made to order according to individual sizes.

Reinforcement of ACP floors, crossbars, grillages requires serious design calculations. It is unlikely that you will be able to do it yourself, on your knee.

But if you want to try, here you go: SP 295.1325800.2017 Concrete structures, reinforced with ACP. Design rules.

Characteristics and features of A1 fittings

Class A1 fittings have a smooth profile and are made of low-alloy steel (St3sp, St3ps, St3kp). The size of the produced profile can have a diameter from 6 to 40 mm. It is produced using cold rolling. Old marking A1, new A240.

The main advantage of A1 is its high corrosion resistance. It withstands sudden temperature changes and high humidity well. Also, reinforcement with a smooth profile is better welded. Disadvantages include weaker adhesion to concrete.

Features of the A1 brand:

- low price;

- less strength;

- high corrosion resistance;

- good weldability;

- poor adhesion to concrete mortar.

The difference between class AI and AIII fittings

Of the extensive list of fittings, classes AI and AIII are the most popular; but, despite the fact that both types of fittings are equally often used, they differ in appearance, they have different compositions, they have different areas of application and perform different tasks. There are four main categories of differences:

- geometric dimensions

- AI class reinforcement has a round cross-section and a smooth surface. Class AIII reinforcement has a corrugated surface of the rod: two longitudinal protrusions-ribs (along the entire length of the rod), between which there are inclined transverse corrugations; - material of manufacture

- for the manufacture of AI, carbon, unalloyed steels are used: St3 calm, semi-quiet and boiling (St3Sp, St3Ps, St3Kp). For the production of AIII, low-alloyed manganese and boron grades are used: 32G2Rps, 35GS, 25G2S; - mechanical properties

- Due to alloying additives, the strength of AIII reinforcement is higher than that of AI: - AIII, Brinell hardness: HB 10 −1=202 MPa

AI, Brinell hardness: HB 10 −1=131 MPa

For the same reasons, specific viscosity and elongation at break differ in favor of AIII, but AI has better weldability, ductility and cold resistance.

The geometric shape also affects the mechanical characteristics: due to the corrugation, the AIII profile section for the same linear meter weight is less efficient than that of the AI, which puts the AI in a more advantageous position.

- since the area of the corrugated surface of AIII is larger than the smooth surface of AI (with equal diameters), the adhesion to concrete for AIII is significantly higher and the reinforcement effect is enhanced. An absolute plus seems to be such only at first glance. For example, rigid reinforcement of a roadway can lead to destruction due to short-term but large loads. And even minimal play (if you use smooth AI reinforcement) allows reinforced concrete to “give in” to fractions of a micron and maintain integrity under the influence of serious loads;

Characteristics and features of A3 fittings

A3 reinforcement has a periodic profile with longitudinal and transverse stiffeners. It is made by hot rolling from steel grades 35GS, 25G2S - with a diameter of 6-40 mm, and 32G2Rps - profile size from 6 to 22 mm. New marking A400, old A3.

The ribbed profile ensures good adhesion of the reinforcement frame to the concrete. This significantly increases the strength of the supporting structure. The disadvantage is lower corrosion resistance, which is why A3 brand reinforcement is not recommended for use in combination with certain types of concrete, in places with high humidity and aggressive chemical environments.

Features of the A3 brand:

- high price;

- high strength reinforcing mesh;

- good adhesion to concrete;

- low corrosion resistance.

Fittings for private housing construction

Of the 15 positions (Table 1), four are enough for an individual developer.

- A240 (Commonly AI). Hot rolled smooth. Distribution, anchor for embedded parts, diameter 6-8 mm. Bay.

- A400 (AIII). Hot rolled, periodic profile. Working, diameter 10-12 mm. Rods 12 m long.

- A500 (AIII). See point 2.

- В500 (ВрI). Wire for masonry, reinforcing mesh. Diameter 3-5 mm. In the form of ready-made meshes.

It is recommended to purchase fittings by the metre. This is time consuming. But it guarantees that exactly the footage that is needed is paid for.

When bending rods, it is recommended to adhere to the radii and angles indicated in Table 4 for welded reinforcement (C) with a special notch.

Table 4

These tables will help to distinguish low-quality fittings. Rods made from melted down rails break at smaller angles. It belongs to class 500.

A400 class rods cannot be welded; the bending angle should not exceed 90°.

Universal class

A500C is the most popular fittings. Due to its lower carbon content, it is perfectly welded together (including arc welding), which strengthens the frames for the concrete structure.

A reduced amount of alloying additives has increased ductility; brittleness is not inherent in it. This is clear from αmax, which is 180°. This additionally makes it possible to use this class as anchor reinforcement.

A500 can replace A400 without recalculating design loads. At the same time, reverse replacement only with a new calculation. Due to the increased strength of A500, up to 10% of material can be saved on reinforcement. This is a significant value for any project.

It is also important that the A500 is operated at -55 ° C, which is 10 ° lower than the A400.

Weldable reinforcement is 15% more expensive than conventional reinforcement of the same class. But the A500C is 6-8% cheaper than the A400. This is explained by the fact that steel for 500th due to the lack of alloying elements costs less.

Classification of construction reinforcement

Construction reinforcement is an indispensable building material in the process of installing reinforced concrete structures, since it is responsible for increasing the strength, and therefore the durability, of reinforced concrete products.

Depending on the strength, type of profile, chemical composition of the steel and a number of other indicators, construction reinforcement has many classifications. Let's look at the main ones.

The first thing that determines the division of construction reinforcement into types is the type of production. And here we are talking about hot-rolled construction rod reinforcement and cold-drawn wire construction reinforcement.

Hot-rolled construction rod reinforcement is often made from pure carbon or alloy steel. At the request of the client and in order to improve the performance characteristics of the reinforcement, silicon and manganese, titanium and chromium can be introduced into the chemical composition of steel for its production. It must be said that the last pair of elements is used as alloying components when working with high-strength steel. Particularly popular among manufacturers of construction fittings are steel grades such as At400S , At500S , At600S , At600 , At600K , At800K , At800 , At1000K and At1000 . As for construction cold-drawn wire reinforcement, both high-carbon and low-carbon steel are equally suitable for its production.

The second division of construction reinforcement into groups is related to the type of its profile:

- smooth construction reinforcement (manufactured in accordance with state standard 5781-82, made from the following grades of steel (StZsp, StZkp and StZps) and, of course, its main difference is the absence of any corrugations on the surface),

- construction reinforcement of periodic profile (made from steel grades 25G2S and 35GS, has a ribbed surface, a circular cross-section profile with transverse projections and two longitudinal ribs and has high anchoring capacity). The latter helps periodic profile building reinforcement achieve the tightest possible adhesion to concrete and makes it an ideal building material when working with structures with an impressive concrete layer thickness.

Depending on the thickness of the rod, construction reinforcement is divided into:

- light (rod thickness does not exceed 12 millimeters),

- heavy (rod thickness ranges from 12 to 40 millimeters).

Also, the division of construction reinforcement is influenced by working conditions in concrete. And here we can talk about three main groups:

- prestressed construction reinforcement,

- non-tensioned construction reinforcement,

- construction reinforcement subjected to pre-tensioning.

There is another sign of dividing reinforcement into groups - flexibility-rigidity. When speaking flexible building reinforcement, we mean meshes, rods and frames. And by “rigid” we mean angles, channels and I-beams.

One of the most popular types of fittings on the Russian construction market is deservedly considered construction fittings 25G2S , made in accordance with state standard 5781-82 and technical specifications 14-1-55-41-06. Distinctive features of construction fittings 25G2S are:

- highest strength,

- corrosion resistance,

- excellent adhesion to concrete,

- excellent plastic mechanical properties,

- high levels of fatigue strength.

The designation of fittings is distinguished depending on the mechanical and physical qualities (from AI to A-VI). Each class is produced from certain grades of steel. For example, the brand A500C fittings can be supplemented with letters that indicate certain qualities of the fittings:

- “C” - intended for welding;

- “T” - thermally durable;

- “K” - corrosion resistant;

- “B” - strengthened by hood.

High-quality building reinforcement should:

- Be resistant to corrosion and metal fatigue;

- Possess high strength and ductility;

- Form a rigid and durable adhesion to concrete;

- Have a minimum expansion capacity in reinforced concrete products.

Today, construction reinforcement is divided according to the following criteria:

- Welded and knitted (installation method);

- Rolled, rod and wire (production method);

- Unstrained and strained (functions performed);

- Working, installation and distribution (purpose);

- Made of non-metal and steel (material of manufacture);

- Periodic profile, round and smooth (profile).

Reinforcing steels produced in accordance with GOST 5781 have mechanical and physical properties that are closely related to the chemical composition of the steel. The reinforcing profile is made of carbon steel (3-5sp), alloyed with silicon and manganese (25G2S, 35GS). The length of hot-rolled reinforcing bar can be 6-11m, 11.7m, 12m.

Still have questions? Call: +7 4722 365-217 and

A500C reinforcement is a new class of unified welded construction reinforcement. In the Russian Federation in 1993, a new standard STO ASChM 7 - 93 was developed and released, which regulates the requirements for this reinforcing steel of class A500C . One of the advantages of A500C fittings is the ability to use arc welding in the production of work.

The A500C fittings are weldable by electric welding, as evidenced by the letter “C”, which is present in its marking. A500C contains significantly less alloying components than reinforcement made from 35GS steel. A500S fittings are manufactured using the above technology from 3sp steel. Distinctive features of such reinforcement: increased ductility and strength, in the absence of brittle fractures of welded joints, significant savings in steel during production, as well as low production costs.