Flanged ball valves for sewerage are a type of pipeline fittings that prevent a change in the direction of movement of the medium to the opposite. Such critical situations can arise due to operator error, a breakdown in the system, or destruction of a pipeline section. A check valve will avoid product leakage and cascading faults due to changes in the flow vector.

The tightness class of check valves is AA. Please note: they are not used as shut-off valves. Key characteristics for choosing a model are diameter DN and working pressure PN.

To order, contact us by phone +7 (499) 380-83-81, email or leave a request on the website. Our company’s specialists will provide assistance in selecting check valves and a set of mounting parts.

- Peculiarities

- Design and principle of operation

- Operating environments and applications

- Specifications

- Delivery throughout Russia and the CIS

Features of a check valve for sewerage

A check valve is necessary to shut off the flow of sewage waste. Apartments on the first floors of old houses are especially susceptible to this. All this is due to the improper use of toilets.

Therefore, the horizontal pipes in the basement become clogged. The result is that the waste rises, and having found the first exit, which will be the toilet on the first floor, it pours out into the room.

- It is worth noting here that not only apartments on the first floors can suffer from sewage waste, because this also happens on other floors.

- If the check valve is installed on the ground floor or there is a blockage between floors.

- The culprits in this situation are usually the apartment owners.

- By flushing unacceptable substances into the toilet, which form a blockage in the sewer. Therefore, feces can splash out on any floor.

The safest apartment, where such a phenomenon is unlikely, will be the living space on the top floor. On others, they advise protecting your apartments from surprises in the form of feces and installing a check valve.

As for private houses, their sewage system is designed in such a way that the return of waste is likely to be small. But still possible. Therefore, it is better to insure against an “unexpected invasion” and install a reverse-acting valve. Which has another advantage, protecting the home from the invasion of small rodents.

Delivery throughout Russia and the CIS

Delivery countries: Azerbaijan, Armenia, Belarus, Kazakhstan, Kyrgyzstan, Moldova, Russia, Tajikistan, Turkmenistan, Uzbekistan, Ukraine.

- Delivery by transport companies SDEK, PEC, Business Lines.

- Expedited delivery by Khimmashneftekomplekt LLC transport to any facility in Russia and the CIS countries.

- Pickup of products from warehouses located in Podolsk, Saratov.

Publication date: May 17, 2022. Last modified: May 18, 2022.

If you have any questions, please contact us by phone +7 (499) 380-83-81, email or leave a request on the website. Our company’s specialists will provide assistance in selection and provide current prices for products.

How does a non-return valve work in a sewer?

The main task of the valve is to prevent feces from returning through the toilet, polluting the toilet room.

And giving the owners of living space a lot of very unpleasant surprises.

- The system is a movable metal barrier.

- In its normal state, it is lowered down, closing the lumen of the sewer, which prevents reverse flow from passing through.

If feces appear, the flapper is moved back or raised and the flow passes unimpeded. The damper falls into place. How exactly the system operates depends on its type.

Blitz tips

- There is no point in saving on such an important part of the sewer system as a non-return valve. After all, financial losses, even with a single flood of sewage into an apartment, significantly exceed the cost of this mechanism.

- You should purchase a high-quality valve from trusted manufacturers.

- It is better to purchase a model equipped with a valve lock when closed. In this case, it is possible to more reliably close the sewer during a long-term emergency.

- If the plumbing fixtures are located below the level of the sewer drain, and water disposal is carried out forcibly, then check valves for each plumbing fixture cannot be dispensed with. In this case, you should choose a valve model that eliminates the possibility of water hammer formation.

Types of check valve

Manufacturers offer 4 types of check valves.

Rotary valve

This system consists of a so-called “plate”. It plays an important role in stopping sewage waste. If the feces go in the right direction, the membrane rises.

In the event that waste returns back, the “plate” blocks its path, closing the lumen of the pipe. These models also come with a manual shutter. It is an additional membrane that closes the pipe when you press a button installed on the system.

- The rotary valve is often called a "slam." Because the system lowers the “plate” if there is no waste activity.

- The valve has a fairly large diameter. Significantly exceeding the pipe itself.

- Therefore, the pipe first expands and then contracts. Allocating space for blockages to form.

It is to eliminate such defects that a cover is made on the top of the valve; when removed, the problem can be quickly eliminated.

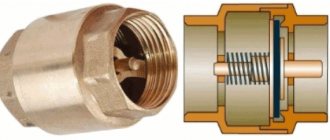

Lift valve

The device works as follows. When the feces follow correctly, the closure system lifts the membrane upward. This occurs as a result of the pressure of the flow on the “plate” spring.

- If there is no waste, the membrane is closed. Those. even when the feces flow back, the membrane will not open and the waste will remain in place.

- The reliability of this design is confirmed by positive reviews from many customers.

- The only thing is that the system needs to be cleaned periodically.

For this, as in the previous design, a removable cover is provided. It is secured with bolts; when unscrewed, the cover is removed and defects are removed or any elements are replaced.

Ball valve

The system is made in such a way that the lumen of the pipe is blocked by a special ball. It closes the passage when waste passes properly.

And it does not allow feces to return back, being located in the body of the pipe.

- The ball valve is not as popular as the above options, since the ball and the walls of the pipes do not close tightly.

- Thus creating places for waste to penetrate.

- Therefore, there is a possibility that waste will return to the toilet. But the feces will remain in the toilet and there will be no massive flooding of the toilet.

Wafer valve

This system is famous for its miniature size. Representing a cylindrical container with a damper located inside. It can be of two types. This is a damper in the form of a “plate” or a membrane on a spring.

To prevent sewage waste, such a system is rarely installed. Because it does not retain feces well. And in order to clean the valve, you will need to disassemble the entire system. Therefore, the wafer valve is more suitable for water supply.

Installation rules

The main thing to consider is the direction of movement of the wastewater. It is indicated on the body by a large arrow. The device must be rotated so that the normal direction of the drains coincides with the arrow. Further installation features are as follows:

- Installation of a plastic check valve on a sewer is carried out in a standard way for this type of pipe: there is a socket and a rubber seal. The straight edge of the pipe is inserted into this socket. Such a connection is already airtight, but for greater reliability, the joint can be additionally coated with plumbing silicone.

- Installation of cast iron models - using sealing rubber bands and bolts that tighten the mounting plates, there are models with sockets - for traditional installation on tow and filling the seam with sealant.

- It must be installed so that there is free access to the lid - periodically the check valve on the sewer becomes clogged, so it needs to be cleaned.

It will be necessary to provide access to the lid - install a removable grille

What are they made from?

The market offers such systems from two alloys - cast iron and plastic. Both materials are in demand among buyers.

- If the pipes are originally made of PVC, then you need to install a plastic damper.

- And vice versa, if the sewer pipe is made of cast iron, the damper is installed of a similar material.

- The main thing is to choose the right size. What these dampers have in common is that they are installed both vertically and horizontally.

- The difference is that the cast iron damper is heavier in weight and requires additional adapters for installation.

- All this makes the system significantly larger compared to a plastic damper.

Both cast iron and plastic systems are selected depending on the installation location. During installation, the rule is that you cannot install a damper smaller than the diameter of the pipe. To avoid restriction, which can be circumvented by properly sizing the valve.

For example, polypropylene dampers are used with a diameter of 110 mm. Made of plastic: 32, 40, 50, 90, 110 mm. Made of stainless steel 110 and 160 mm.

Specifications

- Maximum operating temperature: 70 °C.

- Maximum permissible temperature: 80 °C.

- Minimum ambient temperature: -10 °C.

- Tight closure at differential pressure: 0.5-0.8 bar (5-8 m.w.st.).

- Differential pressure opening: Max. 0.5 bar (5 m.v.st.).

1 - Housing; 2 - Ball; 3 - Housing cover; 4 — Housing cover gasket.

| Marking | DN | PN | L, construction length, mm | h, construction length from the pipe axis, mm | H, overall height , mm | a, passage diameter, mm | c, outer diameter of the connecting protrusion, mm | Weight, kg/piece |

| ABRA-D-022 NBR 040 | 40 | 10/16 bar (1.0/1.6 MPa) | 180 | 98 | 173 | 40 | 84 | 9,5 |

| ABRA-D-022 NBR 050 | 50 | 200 | 110 | 193 | 50 | 99 | 10 | |

| ABRA-D-022 NBR 065 | 65 | 240 | 125 | 218 | 65 | 118 | 13 | |

| ABRA-D-022 NBR 080 | 80 | 260 | 155 | 255 | 80 | 132 | 17 | |

| ABRA-D-022 NBR 100 | 100 | 300 | 200 | 310 | 100 | 156 | 27 | |

| ABRA-D-022 NBR 125 | 125 | 350 | 220 | 345 | 125 | 184 | 36,5 | |

| ABRA-D-022 NBR 150 | 150 | 400 | 260 | 403 | 150 | 211 | 54 | |

| ABRA-D-022 NBR 200 | 200 | 500 | 320 | 490 | 200 | 266 | 103 | |

| ABRA-D-022 NBR 250 | 250 | 600 | 360 | 563 | 250 | 319 | 195 | |

| ABRA-D-022 NBR 300 | 300 | 700 | 430 | 660 | 300 | 370 | 241 | |

| ABRA-D-022 NBR 350 | 350 | 800 | 610 | 870 | 350 | 429 | 321 | |

| ABRA-D-022 NBR 400 | 400 | 900 | 705 | 995 | 400 | 480 | 401 | |

| ABRA-D-022 NBR 450 | 450 | 1000 | — | — | 450 | 532 | 531 | |

| ABRA-D-022 NBR 500 | 500 | 1100 | — | — | 500 | 610 | 701 |