A ball valve is a quarter-turn valve that uses a ball-shaped disc to stop or start flow. If the valve is open, the ball rotates to the point where the hole in the ball aligns with the inlet and outlet of the valve body. If the valve is closed, the ball rotates so that the hole is perpendicular to the flow holes of the valve body and the flow stops.

Most ball valves are quick-acting and require a 90° turn of the valve handle to operate. But if a large valve requires significant force to open or close the valve, a gear drive is used. With this arrangement, a small handwheel is sufficient to operate a fairly large valve.

Ball Valve Parts

Ball valves are mainly available in three versions: full bore, venturi port and reduced bore. A full bore valve has an internal diameter equal to the internal diameter of the pipe. The Venturi and reduced port versions are typically one pipe size smaller than the line size.

Ball valves are manufactured in a variety of body configurations, and the most common are:

- The top-split ball valve allows access to the internal parts of the valve for maintenance by removing the valve cover. There is no need to remove the valve from the pipeline.

- A ball valve with a split body consists of two parts, one of which is smaller than the other. The ball is inserted into the larger part of the body, and the smaller part of the body is bolted together.

Valve ends are available as butt weld, socket weld, flanged, threaded and more.

Peculiarities

For the normal functioning of the pipeline, it is necessary to install check valves, the main purpose of which is to prevent accidents and serious, costly breakdowns.

The main task of a check valve is to ensure the circulation of liquid in a specifically designated direction without the possibility of changing its course in the opposite direction. That is why fittings of this type are usually installed in those places of the system in which the reverse flow of coolant is unacceptable or undesirable. Failure to comply with such rules can lead to an emergency situation, as well as cause problems and failures.

As an element of safety valves, check valves help the heating system maintain the optimal operating conditions.

Advantages and design features of valves of this type

The key element of a ball check valve is the ball, which can be made from steel, aluminum or cast iron. To achieve optimal reliability, the ball is covered with a special layer of rubber.

This type of equipment can be installed on both vertical and horizontal surfaces, regardless of the complexity of the structure used and the level of its operation. The ball check valve is characterized by complete versatility, therefore it is manufactured in several diameter variations. This made it possible to use it both on an industrial scale and in domestic conditions.

Additionally, they are equipped with several ball valves, which are used for heating residential buildings and structures, pumping stations, and industrial facilities. Separately, the systems can be equipped with an additional removable cover, which will allow you to easily carry out surface repairs or replace components, eliminating the need for complete dismantling of the area.

The cover is secured with bolts on the body itself. A sealing gasket will be needed to achieve optimal tightness. If we are talking about the use of large-sized pipelines, pumping or heating devices, then it is recommended that they be additionally equipped with high-quality ball check valves.

Necessity of application

Installation of a check valve may be mandatory or recommended. For industrial purposes, they are installed by professionals. As for residential buildings and apartments, there are several cases when such fittings are necessary:

When installing a water meter

This is a mandatory condition, without which it is impossible to obtain documentary approval from water supply companies.

The valve does not allow water to circulate in the opposite direction, which may be caused by differences in pressure inside the pipes.

When using storage type water heaters

The installation of such fittings on boilers for gas and electrical equipment is required at the cold water inlet.

For circulation pumps

When using circulation pumps, valves are installed at the outlet.

This allows you to avoid accidents and failures in the system, which can be caused by the reverse movement of water in a circuit with a weaker pump when the coolant is displaced by a more powerful unit.

On the heating return line

On the heating return line, the valve is mounted just before the entrance to the boiler.

If an accident occurs, the protective fittings will not allow the coolant to leak out, and during normal operation of the system, it will not allow it to move in the prohibited direction.

For deep well pumps

In addition, such protective elements are used when operating pumps designed for deep operation so that when not working, water cannot flow out of the pipeline.

Classification

These products are used not only in heating and water supply systems, but also when installing sewerage and ventilation equipment. The fittings perform the same function, differing in size, shape, body material, launch method, and also the type of shutter.

According to the material of manufacture

Stainless steel valves are considered the best. They are more expensive than cast iron, used for large-diameter pipes, or brass, which is considered an excellent option for domestic purposes.

But they are distinguished by time-tested durability.

Many modern manufacturers make check valves from several types of materials (stainless spring, brass body and plastic plate).

By connection method

Safety valves can be of the following types:

- flanged (used for large diameter pipes);

- wafer (small in size and installed in the space between the flanges);

- coupling (having threaded transitions intended for fastening).

By design

Ball (ball) valves are distinguished by the presence of a shut-off part, which is a metal ball that is pressed against the seat using a spring when the pressure in the system decreases or the movement of water stops. Such elements are considered expensive; they are usually used on compact pipes (up to 40 mm) when installing large pipelines in a centralized heating system.

Reed check valves can have 1 or 2 leaflets. The direction of the coolant flow is regulated by a steel plate, as well as a special hinge system that ensures the movement of the valves under pressure. A reed valve with 2 flaps guarantees minimal hydrodynamic costs, and an element with 1 leaf (rotary) is used for pipes from 50 mm in size and is usually made of cast iron.

A check-type spring disc valve is used for heating apartments and houses, and is also installed on radiators. It attracts with automatic operation, is distinguished by an affordable price, a wide selection of diameters, and is attached using the coupling method - the most accessible for household purposes. When purchasing, it is recommended to choose a part with a steel or brass core.

Types of locking elements

Any check valve (the outdated name is non-return) performs a simple task - it does not allow the coolant flow to change direction, passing liquid only in one direction. In water heating schemes, this function is not always needed and is implemented as needed.

The following types of check valves are used in heating systems of private houses and apartments:

- petal;

- disc-shaped;

- ball

For reference. In industrial production and the water supply sector, there are other types of products - double-leaf, lifting and disk, used as network elements on large pipelines. In private housing construction, such fittings are not used.

Industrial models are installed in large boiler houses and production facilities.

Let us analyze the design and operating principle of each type of valve separately. In the future, this will help you understand which product is best to select and install in a specific heating system.

Reed valves

The element, made of brass or stainless steel, consists of the following parts:

- body in the form of a tee with a unscrewing top plug (for maintenance);

- a butterfly valve mounted on an axis by means of a rotary lever;

- a seat with a seal into which the disc fits when closed.

Note. There are 2 versions of the products - with a free or spring-loaded petal. In the second case, the sash is forced to close with a spring so that the lock operates in a vertical position.

The general design of a reed check valve is shown in the detailed drawing. The principle of operation of the element is as follows: the coolant moving in the indicated direction deflects the locking disc and freely passes further along the pipe. When the direction of water flow is reversed, the valve, under the influence of gravity (or a spring), automatically slams shut and blocks the passage.

Typical gravity seal design

For reference. Due to the principle of operation, the products received several names - gravitational, rotary, “crackers”.

We list the important characteristics of petal check valves installed in heating systems of private houses:

- internal passage diameter – from 15 to 50 mm (½—2 inches);

- maximum working pressure – 16 Bar;

- low hydraulic resistance;

- There is a screw on the side of the body for disassembling and adjusting the shutter axis;

- The gravity version without spring can only work normally in a horizontal position.

The design and operating principle of the rotary valve is shown in detail in the video:

Poppet valves

The principle of operation of a poppet check valve is clear from its design, shown in the drawing:

- Inside the cylindrical brass body there is a platform with a round hole - a saddle.

- On the other side of the part there is a partition with a hole in the center.

- A rod with a disc-type valve at the end equipped with a seal is inserted into the hole in the partition.

- A spring is installed between the partition and the “plate”, pressing the disk to the seat.

Water flowing in the right direction overcomes the elastic force of the spring, opens the valve and moves on. Flow in the opposite direction is impossible - the duct instantly closes. What properties of a check valve are important for heating systems:

- ability to function in any orientation of the body in space;

- working pressure – not less than 10 Bar, diameters DN15 – DN100 (internal);

- type of connection – coupling (internal pipe thread);

- spring lock creates increased hydraulic resistance to fluid flow;

- The seal loses its tightness if solid particles, such as sand, enter.

In the utility networks of private houses and apartments, valves with coupling connections are used

Reference. There are more compact versions of spring check valves that are installed between flanges. Reducing the dimensions can be useful when installing boiler piping in conditions of limited combustion space.

Disc locks are also used in water supply networks, for example, in conjunction with submersible pumps. The valve prevents water from the pipelines from flowing back into the well or borehole.

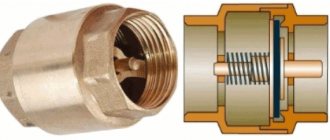

Ball valves

This is a check valve of the simplest design, operating on the following principle:

- Inside the cylindrical brass body there is a ball made of rubber, less often aluminum.

- The ball is prevented from jumping out by 2 partitions with holes made along the edges.

- The coolant flow presses the rubber ball against the partition with ribs. These protrusions form a gap where water flows freely.

- If the coolant moves in the opposite direction, the ball will press against the second jumper - the seat. Since there are no ribs, the body of the ball will completely cover the passage hole.

The advantages of a ball check valve are low price, low hydraulic resistance and operation without any springs in any position, although vertical is preferable. The disadvantage is the loss of tightness when the pressure increases to 6-7 bar, which does not happen in individual heating networks.

Reference. Ball fecal valves, operating on a similar principle, are widely used in sewage systems. The purpose is to prevent waste from moving back to the plumbing fixtures.

To take a closer look at the ball valve, watch the following video:

Installation features

When installing such fittings, it is important to take into account the direction of the coolant indicated on the device body in the form of an arrow, and also to provide access to the valves for their possible maintenance.

For local work, American type cranes can be useful. If a lift rotary valve is installed, it must be installed exclusively horizontally.

Water supply system

Protective elements are installed at pipeline branch points, as well as on bypasses for boilers and radiators. If the system has a pump, then the fittings are cut into a point in front of the pumping station or on the suction pipe immediately after the ratchet.

In the case of a vibration pump, the valves are mounted anywhere in the system, but always before the receiver.

If the device is installed on an already functioning pipeline, then it is necessary to tear it apart, place the valve on one side of the pipe, and then connect it to the other part using a squeegee.

Equipping the check valve with a tee with a tap is necessary if the water supply system will be used only in the summer, and the water will be drained in the winter.

Sewage system

Installation of shut-off valves for the sewer system involves 2 types of insertion: vertical and horizontal. It is produced at the points where the pipes join. When working, it is necessary to use adapters (from metal to plastic and vice versa).

Heating system

In a heating system with natural coolant circulation, it is customary to install such fittings only on bypasses, which provide an intermediate line between the return and direct pipelines in order to distribute the coolant equally among the batteries (radiators). Installing a check valve can limit the movement of water through a small circle of the system if the electric pump is turned off.

Valves are built in between the discharge and suction pipes of the pump.

A standard heating system includes many elements. Each of them performs its own task, as a result of which the design works smoothly and accurately. One of these elements is a heating check valve that controls the flow of coolant.

We will introduce all types of check valves used today in the organization of heating circuits. The article we presented describes their design features in detail and provides technical characteristics. Do-it-yourselfers will find installation manuals and valuable advice here.

Double leaf

For heating systems with large cross-section pipelines, a special type of valve was developed - double-leaf. It is equally effective for both the supply pipe and the return pipe - the principle of operation will be the same.

Provided that the operating conditions are met, the check valve flaps on the heating return and supply open freely by coolant pressure. When the operating pressure changes and the water flow is incorrect, a special axis with flaps attached to it blocks the internal lumen of the pipe.

It is worth noting that this shut-off valve is the most reliable, which is why it is in demand in systems with high pressure.

Types of check valve

Despite the fact that all devices of this type perform the same task, they have structural and, therefore, operational differences. Let's take a closer look at each of these types.

Disc type devices

A distinctive feature of the product is the presence of a disc valve. This is a plastic or metal element, the dimensions of which allow it to completely block the flow of coolant if it begins to move in the opposite direction.

The disk is connected to a steel spring. When a liquid moves forward, it is in a compressed state. When changing direction, it straightens and moves the disk from its place, thereby blocking the pipe.

The valve design also includes a sealing gasket, which allows the valve mechanism to sit as tightly as possible in the seat. Therefore, leakage is excluded in serviceable devices.

Disc devices are widely used in the design of household heating systems, as they have significant advantages:

- Compactness. The dimensions of the products and their weight are small, which makes it possible to install them on any system.

- The device does not require regular maintenance.

- The cost of the device is low.

Among the significant shortcomings, it is worth noting that it is unsuitable for repair. Therefore, failed valves are immediately replaced with new ones.

And one more minus is the significant hydraulic resistance created by the device. For some systems, such as a geothermal heat pump, this can be critical. Over time, the butterfly valve becomes covered with a layer of mineral deposits, which leads to failure of the device.

Standard butterfly valves create some shock loads when closing. This does not affect their performance and technical condition in any way, but water hammer occurs in the system. Which is not desirable for her.

Disk devices with an additional mechanism that allows closing the hole as smoothly as possible do not have this drawback. Their cost is higher than that of standard analogues.

Ball check valves

Devices of this type use a metal ball as a shutter. It is made from aluminum, steel and other metals. To extend the service life, the element is covered with a layer of rubber.

This valve works as follows: when the coolant moves through the body of the device in the desired direction, it lifts the ball, which moves into the upper compartment of the valve.

As soon as the direction of movement changes or the flow stops, the ball immediately descends and blocks the pipe. Thus, the movement of fluid in the opposite direction becomes impossible.

The advantages of these valves include:

- reliability - the design does not include rubbing or moving systems, which significantly reduces the possibility of breakdown and allows you to work in any position;

- maintainability - the upper part of the valve body is equipped with a removable cover, which provides easy access to the interior of the structure;

- low hydraulic resistance.

Considering the disadvantages, it is worth noting the rather large working diameter. For this reason, it is impossible to use them in domestic pipelines of small cross-sections.

Ball valves are difficult to install due to their design features. When installed horizontally, they must be placed with the lid up, otherwise the shutter will not be able to rise to allow the flow of water to pass through. Based on the same considerations, when installing vertically, you must strictly ensure that the liquid moves strictly upward.

Ball valves will not be able to function normally in pipelines with low pressure. Because the minimum value at which the sphere blocking the passage opening rises is usually 25 bar.

Petal type of shutter

The shutter for this type of valve is a thin steel plate. It is attached to a hinged structure that allows it to move.

There are two types of petal devices. Single-leaf or rotary are equipped with one plate that can rotate around an axis.

When the coolant moves in a given direction, it lifts the sash, thereby opening the passage hole. When the flow direction changes, the plate lowers. This can be done either with or without a spring.

Butterfly valves are designed slightly differently. They have two locking plates mounted on a rotating axis and located in the center of the passage opening.

The advantages of using these valves are:

- some models of gravity valves can operate without springs, which allows them to be used in gravity systems;

- relatively low cost of devices.

Among the disadvantages, it is worth noting the rather high hydraulic resistance. This is especially true for double-leaf models - the rotary axis is located directly in the center of the passage opening, which is a significant obstacle to moving liquid.

For this reason, butterfly valves are used exclusively in high pressure systems.

Lifting equipment

Lift valves are equipped with a spool that can move freely relative to a vertical axis. On the through hole there is a seat where the spool is located.

When liquid is supplied, the force of its pressure lifts the valve, and it moves along the axis, opening a hole for the movement of coolant. As soon as the flow pressure weakens or it changes its direction, the spool will lower into the seat.

The advantages of these devices are:

- Reliability. The equipment has a fairly simple design, which allows it to operate with minimal risk of breakdown.

- Low sensitivity to coolant quality.

- Possibility of repairs. For this purpose, a removable cover is located in the upper part of the device body.

Among the disadvantages, installation limitations should be noted. Due to the design features, they can only be mounted in a strictly vertical position.

Flanged ball check valve - structure, scope of application

In various pipeline systems there is a possibility of reverse flow of the medium. This phenomenon can lead to quite a large number of problems, for example, the pump breaks down or the pressure drops to critical values.

You can eliminate the possibility of such a phenomenon by installing check valves. There are quite a large number of similar shut-off valves; the flanged ball valve is most often used.

It is installed when creating a fairly large number of different systems, both domestic and industrial. Let us consider the features of such a mechanism in more detail.

Operating principle

The name of the valve is due to the fact that a steel ball is used as the main shut-off element. The design features include the following points:

- The main element is the body. In its manufacture, steel or cast iron, as well as some other non-ferrous alloys, can be used. Steel is characterized by high strength, and due to the inclusion of various alloying elements in the chemical composition, corrosion resistance increases. Cast iron has been used for a long period, but such a material does not withstand strong mechanical stress. Non-ferrous alloys are lightweight, corrosion and chemical resistant, and are most often used to create valves for household systems.

- The locking element is made in the form of a ball, which in its original position closes the passage hole. In order for the ball to be in the closed position, a spring is installed at a certain angle.

- When the medium is supplied in the correct direction, the pressure created is sufficient to overcome the resistance created by the spring. Due to this, the passage opening opens.

- When the pressure drops for a variety of reasons (leakage, pumping equipment stops), the spring expands and the ball takes its original position. Due to this, the possibility of reverse flow of liquid through the system is eliminated.

The specific location of the spring determines that during reverse current the spring is not pressed out. In addition, to overcome the force created by the spring, quite a lot of pressure is required, which is not created by the reverse free current.

Valve components

The ball check valve is characterized by a fairly simple design, which determines a long service life. The main structural elements can be called:

- Frame. Recently, monolithic type housings have been produced, which have high strength and reliability. The use of the casting method determines the absence of seams, characterized by low resistance to impact loads.

- Metal ball. The locking element of the valve in question is a ball, which is made of corrosion-resistant steel. The ball has a diameter that is slightly larger than the diameter of the passage hole. In addition, a special seat was created for it, which ensures a stationary locking element.

- The ball is in the closed position due to the spring. It is also made of corrosion-resistant steel, as it can withstand the environment.

- Sealing elements made of rubber provide a high degree of sealing.

Some valves can be serviced if necessary. The maintenance process involves replacing sealing elements that wear out under the influence of the environment.

Access is provided by the location of the cover at the top of the housing, which is secured with bolts. Sealing is ensured by special seals. There are also non-removable designs on sale that are not equipped with a lid. If such a design malfunctions, it must be completely replaced.

The above information determines that the valve design is quite simple and reliable. Various materials can be used in the manufacture of basic elements.

Main advantages

The ball-type valve has become quite widespread due to the versatility of the device. The advantages of such a device include the following points:

- It can be installed in industrial and domestic systems.

- If installation work is carried out correctly, the device can last for a long period without jamming.

- Relatively low cost of the device.

The flange version is common due to its ease of connection. This type of connection can withstand high pressure.

Basic selection rules

Only with the right choice of device can its long-term operation be ensured. When choosing a check ball valve, two main characteristics are taken into account:

- Diameter of the catch passage. It is worth considering that the check valve should not create hydraulic resistance. Otherwise, the pressure in the system up to the valve increases, and there is a possibility of a leak.

- Operating pressure at which the device can operate correctly. When considering a check valve, it is worth considering the minimum and maximum pressure.

Almost all manufacturers indicate these parameters when marking check valves. Due to this, the work of choosing the most suitable design option is significantly simplified.

Another important selection criterion is the type of connection. In the case under consideration, the device has a flange type of connection, but there are also wafer and coupling types. In some cases, valves are installed, which are connected by welding.

Application area

The main design features of the device largely determine its scope of application. A ball check valve is installed in the following cases:

- To eliminate the possibility of reverse flow of wastewater in the sewer system. In such cases, the liquid may contain large impurities.

- On sale you can find versions designed for household and industrial systems.

- The mechanism performs well when the medium is supplied without impurities. The use of high-quality sealing elements allows us to achieve a high degree of sealing.

Rules for choosing a locking device

Choosing a check valve intended for a heating system is a responsible undertaking. If knowledge in this area is minimal, it is best to seek help from specialists. This will ensure that your new heating system is functional and safe.

You need to know that, regardless of their type, all check valves differ in the way they are connected to the pipeline.

Coupling devices are equipped with a connecting threaded unit, which greatly facilitates their connection to the main line. Most often, such a unit is equipped with disc valves intended for installation in autonomous heating systems of an apartment or private house. Their distinguishing feature is their small diameter. Most often it is no larger than DU-50.

Flange products are a structure assembled on the basis of a part that has holes for fastenings. Using the latter, it is connected to the main pipeline. A flange connection is much stronger than a threaded connection.

Options for working connection schemes

Heating systems are very diverse and the presence of a check valve is not necessary in all of them. Let's consider several cases when its installation is necessary. First of all, a check valve must be installed on each of the individual circuits in a closed circuit, provided that they are equipped with circulation pumps.

Some craftsmen strongly recommend installing a spring-type check valve in front of the inlet pipe of the only circulation pump in a single-circuit system. They motivate their advice by the fact that in this way pumping equipment can be protected from water hammer.

This is in no way true. Firstly, installing a check valve in a single-circuit system is hardly justified. Secondly, it is always installed after the circulation pump, otherwise using the device loses all meaning.

For multi-circuit systems, the presence of a reverse-acting shut-off device is vital. For example, when two boilers are used for heating, electric and solid fuel, or any others.

When one of the circulation pumps is turned off, the pressure in the pipeline will inevitably change and a so-called parasitic flow will appear, which will move in a small circle, which can lead to trouble. It is impossible to do without shut-off valves here.

A similar situation arises when using an indirect heating boiler. Especially if the equipment has a separate pump, if there is no buffer tank, hydraulic arrow or distribution comb.

Here, too, there is a high probability of a parasitic flow, to cut off which a check valve is needed, which is used specifically for arranging a branch with a boiler.

It is mandatory to use shut-off valves in systems with bypass. Such schemes are usually used when converting a scheme from gravitational fluid circulation to forced circulation.

In this case, the valve is placed on the bypass parallel to the circulation pumping equipment. It is assumed that the main mode of operation will be forced. But if the pump is turned off due to lack of electricity or breakdown, the system will automatically switch to natural circulation.

This will happen as follows: the pump stops supplying coolant, the check valve actuator unit ceases to experience pressure and closes.

Then the convection movement of the liquid along the main line resumes. This process will continue until the pump starts working. In addition, experts suggest installing a check valve on the make-up pipeline. This is not necessary, but highly desirable, since it allows you to avoid emptying the heating system for a variety of reasons.

For example, the owner opened a tap on the make-up pipeline to increase the pressure in the system. If, by an unpleasant coincidence, the water supply is cut off at this moment, the coolant will simply squeeze out the remaining cold water and go into the pipeline. As a result, the heating system will be left without liquid, the pressure in it will drop sharply and the boiler will stop.

In the circuits described above, it is important to use the correct valves. To cut off parasitic flows between adjacent circuits, it is advisable to install disk or petal devices. In this case, the hydraulic resistance will be lower in the latter option, which must be taken into account when choosing.

To install a bypass unit, it is preferable to choose a ball valve. This is due to the fact that it provides almost zero resistance. A disc-type valve can be installed on the make-up pipeline. This should be a model designed for fairly high operating pressure.

Therefore, a check valve may not be installed in all heating systems. It is necessarily used when installing bypasses of all types for boilers and radiators, as well as at pipeline branch points.

Scope of application

This type of device is often used in the construction of communication systems connected to private homes and public buildings. Thus, it was possible to avoid the occurrence of reverse movement in heating systems.

If the sewer system is clogged, sewage is not allowed to rise into the premises and the possibility of breakdown of the system pumps due to malfunctions in their operation is eliminated. It is also used at industrial facilities, making the technological process correct and continuous.

Based on the type of connections, valves can be either flanged or coupling. The latter are also called threaded, and are used in large-sized equipment. For them, a high working pressure is unacceptable. But flanged ones are applicable in main pipeline systems, where the passage diameter is very significant. When choosing equipment, you should focus on several indicators at the same time, such as the nominal pressure and the installed diameter.

Nuances of proper installation

During the installation of shut-off valves, several rules should be strictly followed:

- The valve is installed strictly in the direction of coolant flow. To avoid mistakes, the product body must be marked with an arrow indicating the working direction.

- Paronite gaskets can be used to seal connections, provided that they do not reduce the diameter of the passage hole. Otherwise, the valve will exert more hydraulic pressure than intended.

- The device must be installed so that other elements of the heating system do not exert additional pressure on its body.

- It is highly advisable to install a mesh in front of the check valve for rough cleaning. This will make it possible to prevent solid particles from entering the locking mechanism, which, in turn, can lead to a violation of the tightness of the device when closed.

Another important point: before installation, you need to once again make sure that the valve is selected correctly.

For example, for schemes with forced circulation, any type of device is suitable, but for gravitational systems, only a rotary petal device without a spring. Since the coolant moving by gravity will not be able to cope with the resistance of the spring.

Conclusions and useful video on the topic

Video #1. Where to use check valves:

Video #2. How to choose the right shut-off valves for a gravity heating system:

Video #3. How to arrange a heating make-up with a check valve:

A check valve is a necessary element of complex heating systems. For schemes with one circuit, it is usually not needed, except for arranging the make-up pipeline. But if the system is complicated by the connection of a second boiler, boiler or heated floor, you cannot do without the device.

It is important to select and install the check valve correctly. This guarantees trouble-free long-term operation of the entire heating system.

Would you like to tell us how your heating system has improved since installing a check valve? Do you have information on the topic of the article that will be useful to site visitors? Please write comments in the block below, post photos, ask questions.

One of the most important conditions for the correct operation of the heating and any other pipeline system through which liquid or gaseous working media are transported is the movement of such media in one direction. A technical device that allows such an important requirement to be met is a reed valve or any other type. Check valves in piping systems that transport gaseous and liquid media ensure that such media move in one direction and block them if the direction of their movement changes.

Installing the valve correctly

To avoid making mistakes when choosing and installing a check valve in the right place in the heating system, listen to these simple recommendations:

- To avoid stray flows in adjacent branches, install petal or disc type products. The former are preferable because they do not create increased hydraulic resistance.

- In the bypass assembly of a gravity system, use a ball valve that has virtually zero resistance.

- For refilling, choose an element with a poppet valve designed for high pressure.

Products with gravity butterfly valves are always placed horizontally with the plug facing up - The gravity type reed valve is always mounted horizontally. Moreover, the head of the service nut must be vertical, otherwise the valve will not close and will begin to leak coolant in the opposite direction.

- Do not purchase fittings with a cast iron body. It is heavier and less reliable in operation.

- Check the correct installation by the arrow on the valve body indicating the direction of water flow.

- You cannot install fittings with a spring lock in a circuit with natural circulation - gravity flow will stop due to high resistance.

Disc and leaf valves require periodic maintenance and cleaning. If solids or deposits become trapped under the seat seal, the non-return valve will lose its seal. The best cleaning method is to remove the element and blow off the adjacent surfaces with a compressor.

Types of check valve devices

The modern market offers check valves of various types, each of which differs in both its design and technical characteristics.

Disc Type Check Valves

The design of such devices includes a housing, which can be made of brass or stainless steel, and a locking mechanism. The latter consists of the following elements:

- a metal or plastic disc valve, which ensures that the flow of the transported medium is blocked if it begins to move in the wrong direction;

- a sealing gasket that serves for a tighter fit of the butterfly valve to the seat;

- steel spring, which ensures that the valve is in the closed state if the flow of the working medium moves in the wrong direction.

Operating principle of a disc check valve

Disc spring check valves, which are ideal for equipping domestic heating systems and do not require regular maintenance, have the following advantages:

- compact size and light weight;

- affordable price.

However, spring disc valves also have disadvantages:

- When using check valves of this type in heating systems, significant hydraulic resistance is created, which is especially critical when such systems use a geothermal heat pump. That is why in such cases it is necessary to perform preliminary calculations.

- Spring disc type check valves, which are a maintenance-free type, cannot be repaired.

Poppet type check valve with brass disc

Unlike a disc valve, a ball valve has better hydraulic characteristics, which is the reason for its high popularity among consumers. The locking element of this device, as is clear from its name, is a rubber-coated ball that can be made of cast iron or aluminum. The principle by which a check-type ball valve works is quite simple.

- When the coolant moves through the ball valve in the required direction, the shut-off element - the ball - under the pressure of the working medium rises to the upper part of the device, completely opening the passage hole.

- In the event that the pressure of the working fluid flow decreases or it begins to move in the wrong direction, the ball, under the influence of its own weight, drops into a special niche, closing the passage hole and blocking the movement of the working fluid flow through the device.

Ball type heating check valve

A ball check valve is usually equipped with a cover that is attached to its body using several bolts. The presence of such a cover allows you to quickly and easily carry out repairs and maintenance of the valve, if the need arises.

When installing check ball valves on pipelines for various purposes, the following nuances must be taken into account.

- The ball valve should be positioned with the lid facing upward when installed on a horizontal section of the pipeline, so that the ball located in the working compartment of the device can freely roll into its lower part.

- When installing a check ball valve on a vertical section of the pipeline, it is necessary to take into account that the flow of the working medium passing through the device must move in the direction from bottom to top.

The operation of this valve is ensured by a ball moving inside the housing under the influence of the coolant

A petal check valve, the shut-off elements of which are two spring-loaded flaps (petals) located on a special axis, is installed on the pipeline systems of large boiler stations and heating points. One of the most significant disadvantages of petal-type check valves is weak hydraulics. This is explained by the fact that their valves, even when in the open state, create a significant obstacle to the flow of the working medium moving through the pipeline.

Leaf valve devices include a gravity check valve, the closing element of which is one flap mounted on a special axis and able to rotate freely. The gravity check valve operates according to the following principle.

- Under the pressure of the flow of the working medium, the valve opens.

- If the pressure of the working fluid flow drops or it begins to move in the wrong direction, the flap lowers under the influence of its own gravity, closing the device.

There is no spring in the horizontal petal valve for heating, which makes it possible for the valve to operate even when the water moves by gravity

The locking element of such devices is a spring-loaded spool moving on a special axis. Some models are not equipped with a spring; they can only be used for installation on vertical sections of pipelines. Like ball check valves, rotary check valves are equipped with a cover allowing them to be repaired and maintained if necessary.

When installing, lift-type spring check valves must be installed with the cover facing upward, which will provide access to their interior in cases where it is necessary to carry out their repair or maintenance.

Lift type check valve device

Check valves for water: types, design and principle of operation

Initially, all types of check valves were designed with one purpose - to prevent the flow of liquid through a pipeline in the opposite direction. This happens due to the pumping equipment stopping for one reason or another.

Without a backflow valve, water from the system may flow back into the well or well, while the impeller of the pump or water meter will rotate in the opposite direction, which often leads to its breakdown.

All check valves have almost the same operating principle : when the pressure drops below a set limit, a special device is activated, which closes the internal passage for liquid. As the pressure increases, the shut-off device opens and water can flow in a forward direction.

There are four types of locking mechanism:

- rotary;

- ball;

- lifting;

- disk.

According to the type of connection, return flow valves can be with coupling threads, with flanges, wafer-type and with end welding outlets.

The material for the manufacture of the body and working elements of this plumbing fixture can be brass, cast iron or stainless steel. Household valves are most often made of brass; they are durable and wear-resistant.

Cast iron ones are used only on large-diameter main pipelines. They are cheaper, but are susceptible to corrosion. The most reliable and durable valves are made of stainless steel, but they are also the most expensive. They are used in special cases in critical areas of systems.

In the rotary type, the passage in the body is locked by a disc-shaped lock on the rotary lever under the influence of gravity. The water pressure raises the valve, and when the pressure decreases, the valve rotates under the influence of gravity and closes the passage for the movement of liquid in the opposite direction.

The disadvantage of this design is that such a device can only be used on horizontal sections of pipelines. Most often it can be found on large diameter main pipes.

The designers copied the idea of a lifting structure from a valve-type adjustable valve. Instead of a threaded rod, which serves to lift the spool, a spring made of corrosion-resistant steel is installed.

The pressure of the liquid presses on the shutter and lifts it, thereby opening the passage. When the pressure decreases, the spring presses the valve and closes the passage, eliminating the movement of liquid in the opposite direction.

In the ball version, the role of the shutter is played by a metal ball, which can be coated with a layer of rubber. In some models it is spring-loaded, in others it locks the passage under the influence of gravity. This variety is considered the most reliable. It is most often used both in everyday life and at industrial facilities due to its simplicity of design and low cost of production.

In design and principle of operation, a disc-type water check valve is similar to the lifting type. But there is a significant difference: the disc type has a horizontal shutter, while the lift type has a vertical shutter. The horizontal position of the valve reduces hydraulic resistance. This is important for the operation of large-diameter main pipelines.

The leaf check valve has a significant drawback - the valve closes very quickly, which creates the risk of water hammer. Therefore, this type is used in cases where the fluid flow has a low speed. The petal can have one or two wings.

In addition to their main purpose, check valves with a mesh filter at the inlet perform an additional function - purifying water from large mechanical particles. They are used in autonomous water supply systems and are installed at the point of water intake from a water source.

There are combination check valves that have an outlet for drainage and a special mechanism for removing air pockets. The pipe above the spool chamber is an analogue of the Mayevsky valve, and air is released through it. The lower drainage pipe is located after the valve. Through it it is possible to drain water from the system with the valve closed.

Installation methods

Check valves also differ according to the type of installation in heating systems and in other piping systems. So, depending on this parameter, several types of devices are distinguished.

- Flange-type devices are installed mainly on pipelines with a large diameter. Distinctive features of flange-type valves are two flanges welded to their body. On pipelines, flange-type check valves are installed using bolted connections.

- Wafer check valves are the most compact among all devices of this type. To install such check valves, flanges are also used, but they are fixed to the elements of the pipeline system. The valve itself is installed in special seats between two flanges, which are tightened together using threaded rods.

- As a rule, coupling-type check valves are installed on domestic pipeline systems. Their installation consists of simply screwing them onto the pipeline elements.

- There are check valves installed by welding. They are usually placed in systems equipped with pipes made of polymer materials.

Check valve in the heating system

Types of devices

There are several types of shut-off valves, and often different types of products are installed on the supply and return circuits. Depending on the metal used, the check valve may have its own characteristics.

The most commonly used are brass, cast iron and steel products. In addition, check valves differ in their design. Let's look at the main options.

How to perform installation correctly

When installing a check valve for heating, you need to follow simple recommendations.

- Focusing on the arrow on the body of the check valve, it is necessary to install it on the pipeline so that the direction of the arrow coincides with the direction in which the flow of the working medium will move in the pipeline.

- Do not use gaskets that will reduce the cross-sectional size of the bore.

- The elements of the pipeline system on which the check valve is installed must not exert pressure on its body.

- On the part of the pipeline through which the transported medium will flow into the check valve, it is necessary to install a strainer. Such a filter will prevent solid particles from entering the locking mechanism. It should be borne in mind that clogging of the internal part of the check valve can lead to a violation of the tightness of the device when closed.