Hot stamping process

The method consists in the fact that when high pressure is applied, the metal of a hot billet undergoes a series of successive deformations, and, without violating its integrity, flows into the free space of specially prepared dies, repeating their spatial shape and achieving the specified dimensions. Protrusions and depressions in the corresponding local areas of the die limit and direct the movement of the metal, bringing the configuration and dimensions of the blank closer to the parameters of the final product with each pass. During the last working pass, they form a closed single stream (cavity), coinciding with the configuration of the finished product.

Technological process of hot die forging

The term hot metal stamping indicates that the dimensions and geometry of the workpiece change not in one, but in two or three dimensions.

Hot stamping uses round or rectangular products as blanks, as well as hot-rolled sheets. Hot die forging is also carried out directly from the rod, if the configuration of the part is not very complex and one or two passes are sufficient. Subsequently, individual parts are cut off from the rod.

According to their shape, final forgings are divided into two main classes:

- Disc: flanges, covers, hubs, other round (rectangular) forgings with a length that is small relative to the diameter. Here the basic technological scheme for upsetting the end of the initial blank is selected.

- Elongated: levers, shafts, connecting rods and parts similar in configuration. The blank is placed flat on the die and is shaped into its final shape through several roughing and stamping operations. Before the final pass, molding is performed in streams and on rollers.

According to technological schemes, the two most commonly used ones are actively used:

- stamping in closed dies

- stamping in open dies

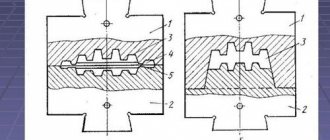

Hot die forging in closed dies is carried out in a die with a small gap between its halves. It is assumed that the volumes of the workpiece and the finished product are the same. This equipment is equipped with two separation surfaces located at a certain angle. The scheme is used in the production of parts that are relatively simple in shape and makes it possible to achieve the greatest homogeneity of the internal structure of the part and less roughness.

When using the hot die forging scheme in open dies, there is no exact correspondence of volumes between the workpiece and the final product; an active redistribution of the metal mass between the parts of the forging occurs. Part of the metal is squeezed out of the stamp into a special groove and is called a flash. The scheme makes it possible to stamp parts of almost any configuration, since it allows for a large number of roughing and finishing passes with intermediate turning of the blank.

Progressive methods of sheet metal stamping

There are several innovative cold stamping methods:

- Liquid treatment. With the help of high pressure and liquid, the metal is deformed. As a result, it takes the form of a matrix. This method is used for the manufacture of hollow, oblong parts.

- Explosion stamping. To change the shape of the metal, explosive gases (RDX, methane, propane) are used. The explosion creates high pressure. Because of this, the initial blank takes the shape of a previously prepared stamp. The pressure created by explosive gases makes it possible to produce parts of large sizes and complex shapes. The main advantage of such processing is the minimal cost of processing workpieces and eliminating the need to purchase expensive equipment.

- Rubber treatment. This method is used only for processing thin sheet metal (up to 2 mm).

- Electrohydraulic processing. The peculiarity of this method is that a high voltage electric charge is an energy carrier. The discharge passes through the liquid and causes a shock wave. Under the influence of pressure, the shape of the workpiece changes. The key advantages of this method are high accuracy and low energy consumption for the production process.

Every year new metal processing technologies appear that are more economical and more productive than the old ones.

Electrohydraulic processing

Advantages and disadvantages of the process

Hot stamping has the following advantages:

- Manufacturing of forgings of very complex shapes.

- Reduced material losses.

- Reduced specific labor intensity.

- There is no need for highly qualified stampers.

- Accuracy of dimensions and configuration.

The disadvantages of the hot die forging method include

- Complexity of operations

- Significant energy intensity

- Significant cost and labor intensity of design and manufacture of equipment. The stamp must be made from high-quality materials, and it is applicable only to this product.

- The need to use more force than forging

- The weight limit of the finished product is up to 3-4 tons.

Advantages and disadvantages

In general, it makes sense to use hot die forging for the production of medium and large series, and also if the complexity of the shape and thickness of the part do not allow the use of cold molding.

The technological process of hot die forging covers many preparatory and working operations, from the receipt of material to the receipt of the final product.

Hot stamping scheme

Technology development includes the following stages:

- The hot stamping scheme is determined - in open dies or closed, and design documentation is issued.

- Process transitions are determined, and the dimensions of the blank are set taking into account tolerances.

- Based on the required force of hot die forging, equipment (press, hammer, etc.) is selected.

- Dies are designed.

- The heating method and temperature-time regime for each operation are set.

- Finishing and finishing operations are determined.

- The technical and economic characteristics of the designed technical process are determined.

Hot die forging requires technologists, designers and shop personnel to have in-depth knowledge of materials science and extensive practical experience in working with this process.

The hot die forging process itself is divided into the following stages:

- Cutting rolled products into blanks,

- Bringing workpieces to operating temperature

- Stamping operations

- Removing flash

- Shape correction (if necessary)

- Heat treatment

- Descaling

- Calibration

- Reception by technical control service.

Lubricant for the hot stamping process

Before submitting to the stamp, the blanks must be heated completely and evenly. In modern enterprises, this process is controlled by automation, ensuring a given temperature increase schedule, uniform heating of all workpieces throughout their entire volume and eliminating the formation of oxide films and zones of low carbon content. The following are used as heaters:

- electrical contact installations. Heating is carried out by connecting the blank to an electrical circuit and passing a strong current through it.

- induction systems. Heating is produced by eddy currents excited in the surface layer of the workpiece;

- gas ovens. The temperature rise takes place in a chamber isolated from the atmosphere, filled with an inert gas, which prevents the formation of scale.

Removing flash and punching films is used in the case of an open hot stamping scheme. In this case, special cutting and punching dies and crank presses are used.

Sometimes, during the removal of products from the stamp, cutting off the flash, or heat treatment, the axes of the product are bent or the cross sections are disrupted. Then a shape correction operation, or editing, is applied. Large workpieces or those made from high-quality steels are straightened while hot. The operation is carried out in a clean stream after removing the flash. Sometimes the editing operation is combined with trimming. Small-sized products are adjusted using screw presses after heat treatment and cooling are completed.

Heat treatment in hot die forging

Heat treatment is carried out in order to bring the physical properties of products to the specified parameters and to facilitate final processing. The operation also allows you to remove residual stresses, reduce grain size, increase viscosity and plasticity.

Volume stamping

To simplify control operations, ensure precise positioning of the blank and reduce tool wear at the machining stage, products are cleaned of scale. Shot blasting systems are used for this purpose. In an insulated forging chamber, air under high pressure accelerates steel shot and directs it to moving products on a conveyor. Numerous impacts knock down films and flakes of oxides in the surface, giving it a matte appearance and at the same time compacting the surface layer. For small products, another installation is used - a tumbling drum. In it, a large number of parts are poured together with metal balls or stars added to them. Due to numerous collisions of parts, scale is knocked off them.

Sometimes another transition is added to the sequence - calibration. It is carried out in order to avoid finishing processing, leaving only grinding. By means of planar calibration, vertical dimensional accuracy is achieved. Volumetric calibration serves to adjust dimensions in several directions, while also allowing for a reduction in roughness. For calibration, special dies with particularly precise grooves that repeat the configuration of the forging are used.

Tools and equipment

Stamping production using cold and hot methods requires a number of tools and devices. The equipment used for stamping is conventionally divided into main and auxiliary.

The first group of tools includes dies, which in turn are divided into forging dies for making products and trimming dies for eliminating burrs after stamping.

All of them are intended to create exclusively a given part, but sometimes you can also find options with removable parts and blocks that allow reconfiguration.

Stamping tools for hot technology are made from high-quality alloy tool steel, because the products are subject to high mechanical pressure and thermal load during operation.

But this is a rather expensive material, so to save money, stamps are made with inserts made of cheaper metals.

Cold metal stamping involves the use of equipment that operates under high specific loads and ensures high accuracy of product shapes and sizes. It is characterized by high productivity and increased stroke, as it has high structural rigidity.

The process of obtaining volumetric stamps.

The second group of tools and devices for stamping includes:

- devices that allow the delivery and loading of metal into the furnace, its supply from the furnace to the hammer and the transfer of blanks from one hammer to the next;

- equipment for feeding blanks under the stamping press with their subsequent transfer from one die strand to another;

- tools for removing forgings from dies after production;

- measuring instruments and templates for periodic inspection of stamped forgings.

On a note! The design of the stamp must have such operational parameters that it allows changing the shape of the workpiece according to specific requirements, is firmly fixed on the equipment, and provides the opportunity to maintain the accuracy of its installation and comfortable transportation.

To process metal parts using hot stamping, you will need the following equipment:

- hammer dies;

- hot stamping crank presses;

- horizontal forging units.

The most common options today are double-action steam-air hammers and simple friction driven hammers. They work due to the shock-deforming effect on the metal workpiece.

High-quality redistribution of metal can be ensured by simultaneous regulation of the stroke of moving parts and impact force in combination with tilting the workpiece. Note that hammers are classified as fairly inexpensive stamping equipment.

Also, when hot stamping, crank presses with a rigid drive are often used, which does not allow changing the direction of the slide.

Forgings made using presses are distinguished by greater accuracy due to their rigid motion. This reduces the risk of machining allowances to a minimum.

The disadvantage of such equipment is the need to pre-clean the workpiece from scale, otherwise it will be pressed into the body of the forging.

When the heated metal comes into contact with the walls of the press, the workpiece cools down due to the large amount of time spent on the deformation process.

Stamping streams and their types

For simple product configurations, hot die forging is performed in a single pass.

Stamping streams and their types

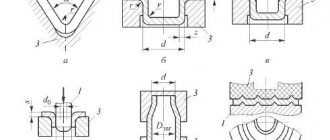

If you have to stamp an intricate product with differences in thickness and height, protrusions and bends, production is carried out in several passes, in each of which the molding is done by a separate depression on the stamp - a stream. They are divided into two types:

Procurement

They are used for shaping, bringing the blank material to a spatial configuration that allows hot die forging operations to be carried out with minimal loss of material.

Procurement streams

Types of harvesting streams:

- Drawing - stretches certain parts of the blank, narrowing their cross-section. A series of gentle blows is used with the blank turned over

- Taxable - thickens the cross-section of the blank, “driving” material from neighboring areas to this place. A series of gentle blows with turning the blank over is also used.

- Pinch - flattens the blank at the point of application, causing an increase in the local width. 1-3 strong blows are used,

- Bending – used for parts with a curved axis

- Sedimentary - used for products close to round shape. Reduces the height of the blank, achieving the desired height and radius

Stamping

They are used in final molding and come in roughing and finishing.

Roughing is used for products with complex configurations and to reduce finishing wear. Designed to bring the dimensions and configuration of the blank closer to the final product. It is deeper and narrower than the finishing stream, and has larger radii and slopes. These measures are used to freely place the blank in the finishing stream.

Stamping streams

The finishing stream is used for molding the final product and is manufactured with an allowance for shrinkage during cooling. It is installed in the middle of the die, since the pressure and stress generated during finishing stamping are maximum. To drain the extruded metal, a flash groove is located around the stream.

Stamping schemes

The specific configuration of hot die forging is selected by an experienced technologist, taking into account the following parameters:

- Part dimensions.

- Material.

- Form.

- Available equipment.

- Limits on labor intensity and material costs.

Currently, two main hot stamping schemes are used:

- with open stamp;

- with closed stamp.

Stamping in a closed die is carried out with a small gap between its halves. It is assumed that the volumes of the blank and the final part exactly match. Sometimes two adjoining lines are made, located at an angle to each other. The scheme is used for molding forgings with relatively simple configurations and makes it possible to achieve the greatest homogeneity of the internal structure of the part and less roughness.

Scheme of stamping in closed dies

When using the hot die forging scheme in open dies, there is no correspondence between the volumes of the blank and the final product, and an active redistribution of the metal mass between its parts occurs. Some of the metal is squeezed out of the die into a groove adapted for this purpose and is called flash. The scheme allows you to stamp parts of almost any configuration, since it allows you to carry out a large number of roughing and finishing passes with intermediate turns of the blank.

Hot stamping with hammers

The technology uses the phenomenon of converting the kinetic energy of a falling massive hammer into the energy of impact deformation of the workpiece. Hammers are raised to their original state by compressed air or steam and have a mass of 0.5 to 25 tons.

Hot stamping with hammers

By changing the height of the hammer, you can adjust the impact force. The stroke of the hammer is also adjustable, this makes it possible to rotate the workpiece during the next lifting of the hammer and more accurate stamping. All preparatory operations are available, including broaching and rolling.

The accuracy of manufacturing parts using hammers leaves much to be desired, which is explained by the inevitable shift of parts of the die relative to each other at the moment of impact. Tolerances when using hammers have to be given large, and to ensure the possibility of removing products from the press, large stamping slopes are made.

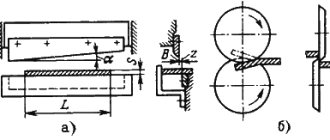

Other conditions

In the absence of a sufficiently powerful stamping press, all work can be carried out on less powerful equipment. But in such a situation, it will be necessary to use cutting or beveled edges on the punch or die of the press. In addition, staggered placement of the punches may be necessary.

In the process of producing the outer contour, the bevel is most often made on a die. But the punches must be flat. If you are punching a hole, then the bevel should be done on the punch. The matrix must be flat.

Hot stamping on presses

Hot stamping of metal is also carried out on crank presses. The main characteristic of the equipment is the force it develops, varying from 6 to 110 MN.

Hot stamping on presses

The design of the crank hot stamping press has a rigid drive and does not make it possible to regulate the press stroke and its force. These factors exclude broaching and rolling from the list of permissible operations, since they require gradually increasing pressure.

The absence of impacts, the constant stroke of the die and the use of guides eliminates shifting, which makes it possible to achieve precision processing that is fundamentally unattainable with hammers.

Accordingly, it is possible to set significantly smaller tolerances, stamping radii and slopes, which reduces material losses and increases equipment productivity.

In addition, static deformation penetrates deeper into the blank than dynamic deformation, and this makes materials with low ductility accessible for processing.

The negative features of crank hot stamping presses are:

- scale is pressed into the surface; to combat this, heating in an inert atmosphere or deep cleaning of the blank is used;

- Due to prolonged contact with the punch, the blank cools down, its ductility and fillability decrease.

Horizontal forging machines

Horizontal forging machines (HFO) produce stamping of forgings without flash and stamping slopes in split dies. When stamping from a rod, there is no need for preliminary cutting of the latter into dimensional blanks, since the GKM stamps have a cutting groove. The machine has a rigid structure, which increases the accuracy of forgings.

The GKM drive (Fig. 6) is carried out from an electric motor 9, which, through a V-belt drive 8, accelerates a flywheel with a friction clutch 10. The side slider is set into reciprocating motion by a cam 3 mounted on the shaft 4. When the slider 2 moves, the system of levers 1 sets in motion clamping slide 17 with a movable matrix 16, which presses the workpiece 15 to the stationary matrix 14 for the period of upsetting with a punch 12. The original workpiece-rod is advanced before stamping to the retractable stop 13. The clutch 10 is engaged, and the movement through the gears 7 is transmitted to the crankshaft 4, which through connecting rod 5 provides reciprocating movement of the main slider 11 with the punch 12.

When clutch 10 is disconnected, brake 6 is activated, stopping the crankshaft in the desired position.

Rice. 6. Horizontal forging machine : a - kinematic diagram; b - appearance.

GKM are produced with a force of 500. . .31 500 kN. They can be used to stamp forgings from round bars with a diameter of 20 to 270 mm.

Screw friction presses are designed for stamping small and medium-sized forgings in open and closed dies, chasing and straightening forgings. They are built with a nominal force of 400. . .630 kN, slider stroke length 240. . .600 mm and a number of strokes of 39-11 per minute. The deformation speed during stamping is 0.3. . . 0.5 m/s.

Rice. 7. Screw friction press

A general view of a friction screw press of a traditional design is shown in Fig. 7, a. From the electric motor 1, through a belt drive 2, a shaft with friction discs 3 attached to it rotates. By pressing the control handle 10 through a system of rods and levers, the shaft with rotating discs 3 can be moved along the axis and, thus, alternately bring the discs to the right or left to the flywheel 4 In this case, due to friction forces, rotation from the disks is transmitted to the flywheel mounted on the screw spindle 5. The latter, rotating in a fixed nut 6 in one direction or another, lowers or raises the slider 8 in the guides 12. The spindle 5 rotates relative to the slider 8 in bearing support. The dies are fixed on the table 11 and the slider 8. Before hitting the workpiece, the disk is automatically moved away from the flywheel, since a special protrusion 7 on the slider acts on the cam 9 attached to the rod and moves it down. After the impact, the lifting disk is pressed against the flywheel 4. The slider is raised using the rebound from the impact.

In the upper position of the slider, the discs do not touch the flywheel and the slider is held by a shoe brake mounted at the bottom of the spindle.

Slipping of the flywheel over the disc is a disadvantage of friction presses. Therefore, there are press designs where the flywheel is replaced by an electric motor rotor and a corresponding braking system (Fig. 7, b). When the stator windings 2 are turned on, the rotor 1 with the screw 4 rotates by electromagnetic forces in the bearings of the frame 3. The screw is fixed in the axial direction, therefore, when it rotates, the fixed nut 5 moves up and down together with the slider 6, rigidly connected to the nut and moving in the guides of the frame together with ejector 7 of the lower stamp. Such a press is called an electric screw press. There are also hydraulic screw presses, in which the rotation of the screw is carried out by supplying liquid under pressure.

Presses of modern design have:

- device for programming the energy of series of impacts;

- upper and lower ejectors;

- scale blowing device;

- device for mechanized installation and removal of dies;

- device for loading blanks into the working area of the press;

- device for removing stamped products;

- a device for orienting heated workpieces and automatically feeding them to the loading device;

- programmable command device;

- inertial switching mechanism.