You can find forged products in various areas of human life. Window grilles, fences, lanterns, garden furniture and other products made through the forging process look elegant and attract the attention of passers-by. Even with the development of homemade technologies, metal forging did not fade into the background. She continues to gain popularity with renewed vigor.

Forged gates

Interesting about metal forging

Interesting fact, one of the most common surnames in the world comes from blacksmithing. This is Kuznetsov in Russia, in France - Ferrand, in Britain - Smith. This indicates the prevalence of this craft throughout the world.

blacksmith craft

The basis of the word deceit is the verb forge. The fact is that many peoples and tribes considered blacksmithing to be obscure and shrouded in mystery. Kovar (blacksmith) makes forges, knits shackles, so over time the noun cunning denoted wisdom, skills, ability. Over time, it began to mean evil plans and intentions. At the same time, the phrases “forge your happiness” and “forge your destiny”, which have a positive meaning, also appeared.

During the mass unification of production and the use of equipment such as rolling, stamping, the use of computer control practically displaced blacksmithing from heavy industry, but it remained and is popular with designers and interior design specialists. Modern blacksmiths make products that are used to create fences, stairs, architectural design of buildings, etc.

Rolling equipment for cold forging

Hot stamping

But our century has led to the fact that the design of forged products is carried out using special 3D design programs intended for the development of parts for various purposes.

Open forging is used on a variety of metals. With the help of this operation, both household items and objects of artistic value are performed. By the way, this method of metal processing is also used in jewelry. In fact, the most malleable metal is gold. It has plasticity, fluidity, ductility and many other properties that make it possible to obtain priceless products from it.

Jewelry forging

In practice, two main types of forging are used - hot and cold.

Cleaning of forged products

Usually forged products are coated with paint. Once rust forms, marks remain on the paint. In most cases, old paint and rust can be removed by sandblasting. However, you should not resort to this method right away, since such cleaning will damage the secondary scale formed when rolling iron. It cannot be damaged, much less removed, otherwise the forged product will begin to quickly deteriorate.

Therefore, in all possible cases, experts recommend chemical cleaning of forged products from old paint, followed by steam cleaning of chemical reagents. Thus, the forged product will appear before you in its original form, as it originally looked before the first painting. Rust is usually removed by heat treatment of the product; it does not spread further if the metal is calcined. As the metal expands, the rust falls off and is easy to remove. In addition, if a forged product is heated to red heat, it will become covered with a protective film similar to secondary scale. Very often, parts of a forged product with traces of rust require calcination as one of the stages of the restoration procedure.

Attention: forged products are often coated with paints containing lead (up to 75%). When cleaning forged products from this type of paint using the sandblasting method, appropriate safety precautions must be observed.

Hot forging method

As already noted, hot forging is possible when the metal is heated to temperatures at which it changes its strength characteristics and acquires plasticity, which makes it relatively easy to process using impact tools and various devices. Hot metal processing involves the use of certain metal processing technologies that allow a variety of finished products.

Meanwhile, heating the metal also has certain disadvantages. Firstly, heating the metal means that a forge or muffle furnace must be installed in the workshop. It should be immediately noted that the presence of such equipment implies the presence of costs for its maintenance and fuel. Secondly, the use of open fire is an unsafe activity and requires the master to observe increased safety measures. Thirdly, hot forging requires that the master have certain knowledge and skills regarding the temperature parameters of the metal.

Punching, bending and twisting

To make a hole in a metal workpiece, it must be punched. This manipulation is performed under high temperature conditions. A punch (punch) is mounted on the area in which the hole is planned, then blows are applied with such force that the punch penetrates 75 percent of the thickness of the workpiece.

Punching a hole in a product: 1. Pre-punching. 2. Turning the workpiece over. 3. Final punching.

The part of the workpiece where the hole will be made must be placed on the anvil clearly above its round hole. If it does not fit in size (very small), then use a square-shaped hole. After the first blows under the punch, bulging is observed in the lower layer of the workpiece. After this, the product is moved to the front side of the anvil, while the punch is not removed, and a small force is struck on the punch. At the convex place there should be a clear trace of the area in which you need to install the punch for the second time. The punch is removed, then the product is turned over and the punch, cooled with water, is installed exactly at an elevation above the hole obtained after the first blows. It is necessary to take into account that for this work it is necessary that the punch has a cone-shaped working part. The resulting hole is slightly smaller than the diameter of the punch. After this, a mandrel of the same diameter is mounted in the hole.

Bending the product at right angles: 1. On an anvil. 2. On a shaped mandrel. 3. On the bracket. 4. On a ledge. 5. On the fork. 6. On a plate with removable pins.

To ensure that the resulting hole in the workpiece has the shape of a square, the lower part of the lining is used to hold the square during impact. To form a hole with a large cross-section, an anvil horn is used: the product is cut through, spread with the largest mandrel, the heated one is placed on the anvil horn and forged with a handbrake.

When forming holes, a cleaver can be used, the blade of which will not be straight, but curved.

Forgings are bent to give the product a curved shape. Bending thick layers of metal implies curvature of the original shape and cross-sectional size in the bending area, whereas when bending thin workpieces this can be neglected. To eliminate shrinkage and distortion of the shape, you need to settle the work area before starting bending. The smaller the radius of curvature and the larger the bend angle, the more the workpiece will tighten. The shrinkage cannot be eliminated by straightening, but the original cross-sectional shape can be returned by ironing and straightening.

There are several types of forging bending:

- Bending the product along the radius: 1. On the anvil horn.

2. In the device. 3. In the fork. 4. In a fork (with a hammer). 5.On the radius insert. 6. On a spiral with a raised central part. 7. On a mandrel. 8. On a wedge. Bending at right angles with no rounding radius; performed in a vice. The heated metal is bent on the anvil, clamped with a yew, and then struck at the end of the workpiece. In the area of the bend, there is a sedimentation of material (compaction), a supply of which will be needed to straighten the bend. - Bending with an angle. It is carried out on the edge of the anvil with a heated bend area. The metal is mounted in such a way that the bending edge expected on it corresponds to the front edge of the anvil, after which it is pressed from above with a sledgehammer. They hit the handbrake not on the back of the product, but closer to the rib.

The twisting operation is intended to rotate one piece of the workpiece relative to another around one axis.

There are two possible ways of twisting:

- A fragment of the product is twisted at an angle of up to 180 degrees. The operation is performed on the anvil horn on a shperak using a handbrake. If the workpieces are small in size, use pliers.

- A fragment of the workpiece is twisted several times 360 degrees. Relatively thin products are twisted by a pair of blacksmiths: they rotate the workpiece in opposite directions, grasping it at both ends with pliers. A wrench and a vice are used to tighten thick products. It is convenient to use a fork to fix wide forging strips.

During the twisting process, the metal must be heated to a bright red heat temperature, otherwise the operation will require much more effort from the master, and the product itself may become deformed.

Hand forged

Hand forging of metal must be performed in a specially equipped workshop. The list of equipment includes the following equipment and devices:

- forge or muffle furnace;

- air exhaust system;

An anvil, which is a solid-sized (weighing up to 250 kg) metal pig, which may have such technological devices as horns and calibrated holes. For its manufacture, 45L steel is used.

On an anvil, you can forge metal with your own hands and give heated workpieces the required shapes and sizes.

In addition, there is the possibility of forging a sheet on the surface of the anvil.

Assembly of forged products

Most often, forged products begin to corrode due to the constant accumulation of water on horizontal surfaces, at bends and in recesses, as well as on surfaces in contact with plants. If you completely prevent water from entering a forged product, it can last forever. After assembling the forged product, the joints and joints must be coated with paint as well as all visible surfaces. It is recommended to use waterproof but adhesive silicone resin as a filler material. In addition, lead putty is a traditional filler material, and if it is well insulated with paint, it will last a long time. The butt recesses can be filled with epoxy resin or tar, which will melt in the summer and adhere even better to the metal. Previously, molten lead was often used for this, but it does not adhere well to iron, as a result of which water penetrates into the joint, and the situation only gets worse.

Cold forging method

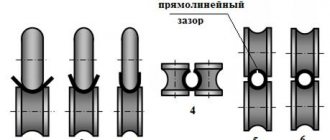

Most cold forging work is performed on equipment specially designed for this purpose. You can name a certain list of equipment that is used for cold metal processing. As a rule, such equipment shows its effectiveness when performing large volumes of work in the architectural design of buildings and structures.

Among the equipment used in the production of cold forging products are the following:

- torsion bar, it is used to twist the rod along its axis;

- wave, various wave-like parts are made on it.

In total, the fleet of cold forging equipment includes about a dozen units. Some are powered by the operator's muscular strength, some are powered by an electric drive. Some craftsmen are engaged in the independent production of such equipment.

Types of blacksmithing

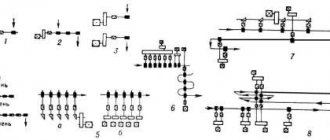

Forging is performed using manual or mechanical impact tools, this could be a sledgehammer or a press, which can be powered by an electric, pneumatic or hydraulic drive.

Forging and stamping provide the production of parts that have different overall weight parameters and shapes.

The use of forging leads to an increase in the mechanical parameters of steel and optimizes its internal structure. That is why critical parts, such as connecting rods, are produced using free forging or stamping. Forging can be divided into the following types - hand and machine. For the first, a hand-held percussion tool (hammer, sledgehammer, etc.) is used; all metal processing work is performed on an anvil. The second type of forging is performed on forging equipment equipped with a hammer, etc. When machining, heavy and bulky workpieces are processed under pressing equipment, and smaller ones with less weight are processed using a hammer.

Metal processing by impact can be divided into free forging and die processing. Free forging involves the workpiece being compressed between a press and a base. The formation of the finished part occurs due to the auxiliary tools used by the blacksmith.

Blacksmithing

When stamping, the metal takes on the shape and dimensions within the tool die. To produce a separate part, a new die must be made. In fact, forging and stamping are intermediate technological operations that lead to the production of workpieces, which will subsequently undergo additional processing, for example, milling or welding.

Types of modern forging equipment

A variety of forging and stamping equipment is widely used in industry. It can be classified according to the following parameters:

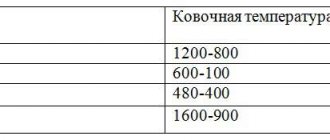

- according to the temperature of the workpiece being processed. For this operation, forging machines and equipment for hot and cold stamping, both flat and volumetric, are used;

- on operations performed on equipment. Divide the procurement, main and finishing CSW;

- according to the method of supplying and removing finished products from the workspace of the KShO. In practice, equipment is used on which all these operations are performed manually, in semi- and automatic mode.

- by type of drive. Presses and stamping machines operate on electricity, compressed air, hydraulics, etc.

- by key parameter. As a rule, this is the nominal force created by the press or operating torque.