Device Features

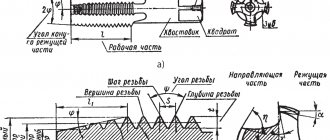

Regardless of the type, all taps are designed fundamentally the same. The differences are determined by the tasks set: type, technology of use. Structurally, the tap consists of the following elements:

- shank with a place for fixing auxiliary tools (wrench, chuck);

- calibrated thread;

- grooves for creating a cutting edge and removing chips;

- entry cone;

Each of the listed elements can be made in several versions to solve a specific problem. Almost every self-respecting home craftsman has universal taps. In production, many special models are additionally used that increase productivity and allow obtaining specified thread characteristics.

Types of taps

Depending on the material, type of thread, product configuration, and tool used, the device model is selected. The product range allows for each operation to use a product with the help of which the task is solved in an optimal way. Products are classified according to several criteria.

Video: About taps, dies and threads

By purpose

The list of products is very diverse. Products are produced for all profile cutting methods. GOST standards establish the dimensions, characteristics of taps, maximum tolerances, accuracy class and degree of surface roughness. Devices are:

- manual;

- machine;

- machine-manual;

- nuts.

Manual and machine-manual are used in plumbing. High strength and wear resistance of the products allow you to perform high-precision work even at home. But they are not designed for use at high rotation speeds.

Machine analogues are used for this. They are made from high-speed steels that can withstand the high temperatures caused by friction and cutting metal.

Machine taps and nut taps can be very similar. They have a long shank, which allows processing up to ten or more parts in one cycle. They are assembled on the body of the device and, as they are filled, are removed at a time. In this case, it is convenient to use a special device for installing the tool. At home, you can do this operation with a drill and a quick-release chuck.

By design

The tool can be made in several versions. Design features allow you to process materials with different characteristics in terms of hardness and viscosity. Each thread tap has all the basic elements, but they can be made as follows:

- with shortened grooves for viscous materials (aluminum, alloy steels);

- with helical grooves, which are made in a spiral to increase the volume of chips, which is necessary when used for cutting blind threads and working on machining centers;

- with stepped grooves, where each section performs its own function;

- broach taps for machine processing of large batches of products;

- combined devices that combine both a drill and a tap in one product;

- bells, consisting of separate parts, necessary for cutting large threads by machine.

It is not always possible to make the required profile in one pass, especially if the part is made of high-strength material. In this case, a tool set of two or three taps is used.

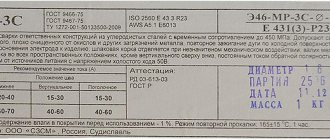

There is a marking on the body of the product. First, the hole is passed through device No. 1, which performs initial, rough processing. Then finishing cutting is performed using tap No. 2, after which the profile complies with GOST standards.

According to the type of thread being cut

The industry uses several basic standards, differing in the measurement system. The marking that marks the tap for threading indicates what type the product belongs to. Without taking into account the special profiles that are made on machines, three types of threads can be made with a conventional device:

- Metric. Denoted by the letter "M". The diameter and thread pitch are indicated on the product.

- Inch. The device is marked with the corresponding icon “. The diameter is indicated in fractional parts of an inch, and the pitch is indicated in the number of threads per unit of measurement.

- Pipe. Traditionally indicated as inch, but in the process of evolution the designation system has lost its identity, so pipe threading tools are determined using tables.

In addition, there are conical threads, for which a corresponding tool is produced. Parts made using this technology are used for plugs and special elements where penetration depth is fundamentally important.

In practice, this type of tap is extremely rare. More often you have to deal with parts that work in the opposite direction. To make them, a tap is used for cutting left-hand threads, which is marked with the Latin letters “LH”.

Machine-hand taps (single-pass)

Three types of taps for internal threading in comparison.

Differences: machine tap, machine-hand tap (single pass) and hand tap.

Sometimes the term machine-hand tap causes confusion, while machine taps and hand taps already have an indication of use in the name. In this post we want to show you the differences between these taps.

The machine-hand tap is actually a marketing invention from the 1970s. At that time, construction supermarkets were developing strongly, and threading tools were included in the range of these self-service stores. The idea behind this was to introduce a low cost internal threading tap. It had to be sufficient for short through holes and re-threading, and the customer had to buy just one thread tap, rather than a three-piece set with a pre-tapping, mid-tapping and finishing tap. Marketing strategists wanted to make it clear to us that you can only cut threads with one single pass tap.

Technically this was achieved by combining the long chamfer of the pre-tapping tap with the full thread of the finishing tap.

Differences between taps.

Actually, the technically correct name is “machine tap, form A.” Let's take a look at DIN 2184-1 and 2184-2 for orientation. There, the dimensions are defined for “long version” and “short version” taps.

Machine taps with a through and reinforced shank are usually manufactured in a long version, hand taps in a short version. For example, for an M 8 tap the difference in length is almost 30 mm, while the thread length is the same. When using taps in a machine or tapping with a tap, these differences make sense.

This is especially clear in our example image:

Machine-hand or machine tap.

Of course, you can also use the finishing tap as a machine tap. The correct designation would then be a short machine tap, shape C.

Shape C means a very short chamfer. On the other hand, you can also clamp a machine tap into a driver and use them to cut threads. However, the dimensions of the shank quadrangle vary. Other tool holders can be used here. It is possible to cut full threads by hand using a machine tap, but we advise against doing so. As a rule, machine taps have a short tapping part. This makes it difficult to cut threads by hand. In addition, due to the length of the tap, the tool can quickly become distorted and broken. Because of this, high torques are possible.

Our recommendation: When cutting threads by hand, use a thread tapping set of three taps. The set consists of three taps - the first (rough), medium (semi-finishing) and third (finishing). Taps up to M6 have a thickened shank and 3 grooves. Taps from M7 have a through shank and 4 grooves.

Single-pass machine-hand taps GSR (PDF)

Tool material from which taps are made

The tool must have sufficient strength and wear resistance to process fasteners. It is produced from high-carbon steels, for example, U10A, U12A, HVG and others. Such products are optimal for handmade devices.

When machining metal, higher rotation speeds are used, so products of this class are made from high-speed steels such as R6M5, R9M4, R18. They are slightly more expensive than their manual counterparts.

Some industries use products with carbide tips, but they are rarely seen on sale. Powder steel products made by sintering under high pressure also have good performance characteristics.

Taps

Do you need taps for thread cutting? In Instrland you can purchase the necessary tools for use in your enterprise or for sale. We offer to buy taps in Moscow and other cities at competitive wholesale prices.

Basic elements of taps

The design of any thread-cutting tool includes such elements as a intake, calibrating, clamping part and a shank, a square. The grooves are located along the entire length on the side of the tap. They facilitate the supply of lubricant and cooling fluid to the machining zone and ensure unimpeded removal of chips from this zone. Manufactured from high-speed or hard steel alloys.

Types of taps by purpose

Manual. As a rule, they are sold in a set of 2 or 3 pieces. The roughing tool usually has undersized dimensions, while the finishing tool has a full thread profile. The length of the intake part for roughing is 4 turns, finishing - 1.5–2. In order to cut a thread with a hand-type tap, it must be secured with the tail part in the tap holder (driver for hand taps). Next, you need to insert the working part of the tap into the hole in which, when turning the driver with a reciprocating motion, the thread is cut.

Hand taps are not used for machine tools and are made from high-carbon tool steel.

Machine. The length of the intake part of the devices is 5–6 turns when cutting through holes and 2 turns when cutting blind holes. Such taps are used only on machine tools and are made from high-speed steel. The main difference between a machine tap and a hand tap is the shape of the lead. They are fixed on machines in a special chuck with axial compensation or in a simple collet chuck with a collet for a tap. In modern production, collets with axial compensation have become widely used, which can also be used for cutting threads on a machine using a machine tap.

Machine-manual. Taps of this type can be used for manual work or on machines. Thread pitch is measured in millimeters or inches depending on the model. Using such devices, you can make conical pipe threads, cylindrical, metric or trapezoidal. Taps of this type are suitable for working with through and blind holes. Made from hard alloys.

Nuts, with a curved shank. The device is used for cutting metric threads in nuts. The intake part has a conical shape, which tapers to the point where the chips are taken. The length of their intake part is 11–12 turns.

Types of taps according to the type of thread being cut

Pipe. This type includes conical and cylindrical instruments. Taps are used for cutting pipe connections.

Metric. Such instruments are marked “M”. The cut element of the metric thread has the shape of an isosceles triangle. Parameters are measured in millimeters.

Inch. These devices can cut threads that are measured in inches. They are used when working with through and blind holes. The working part of such instruments has a conical shape.

Have you decided to buy taps wholesale from us? Place your batch order on the website. Purchases can be made for an amount starting from 5,000 rubles.

How to cut threads by hand correctly and without wasting a tool

Thread cutting is not a complex operation. But inexperienced professionals often make typical mistakes. This is both a tool breakage and an incorrect profile of the cut thread. In order to avoid such problems, you must strictly follow the following rules:

- Drill a hole of the specified diameter. If it is less, the tap will jam, and if the load increases, it may break. When the hole is larger, the thread will be weakened, or it will not be coaxial. You can determine the exact diameter in the handbook of a turner, mechanic, or milling machine. There must be a table for cutting threads with a tap with an accuracy of 0.05 mm.

- Use cutting fluids. They prevent tool wear, guarantee high quality profile cutting, and reduce the labor intensity of the operation.

- Remove chips in a timely manner. If there is noticeable resistance, it is recommended to turn the tap back until it is completely removed in case of difficulties during rotation.

In production conditions, an accurate approach is adjusted using special equipment. This is more difficult to do at home. Incorrect direction causes poor quality carving.

It turns out uneven. On one side, the tap for cutting internal threads cuts into the body of the workpiece, and on the opposite side, the thread profile is not triangular, but trapezoidal. In the future, the bolt will twist crookedly, and the strength of the connection will be lower than the required value.