Stamping, which is performed using a metal press, is one of the most common technological operations for processing this material. The essence of this procedure is to give a workpiece made of metal the required shape, for which plastic deformation is used, squeezing out a certain relief, patterns or punching holes. Presses for metal processing, depending on the list of tasks for which they are intended, differ from each other both in their technical parameters and design.

Presses for metal processing are used in any production: small-scale, serial or mass production

Types of stamping technologies

The stamping process of processing blanks can be carried out using the hot or cold method. These technological varieties involve the use of special equipment and the use of certain metal processing conditions.

Cold stamping is one of the types of stamping

The hot stamping method processes workpieces that are preheated in special devices to a given temperature. Hot stamping is necessary when there is not enough equipment power to process a cold alloy. Heating devices can be electric or plasma ovens. This method requires accurate calculation of the parameters of the finished part, taking into account the shrinkage of the metal during the cooling process.

In cold stamping, parts are formed due to the mechanical pressure of the elements of the stamping press. Cold stamping is considered a more common method of metal processing. It does not require additional equipment, complex calculations or mechanical modification of parts. Thanks to this method, the strength properties of the material increase. The resulting products are distinguished by high surface quality and precision.

Types of stamping and equipment

Two types of stamping are used in production:

With the hot method, heated metal is processed. At the same time, the quality of the material improves: it becomes denser and more homogeneous. The advantage of the cold method is that a layer of scale does not appear on the surface, the dimensions of the part are more accurate, and the surface is smoother.

Stamping can be sheet or volumetric. The sheet method is used to produce: dishes, jewelry, watch parts, climate control equipment and microcircuits, weapons, medical equipment, parts for automobile, mechanical and machine tool manufacturing. The resulting parts do not require further processing. During volumetric pressing, cold or hot metal is forced into molds.

In metalworking, presses are used for:

- production of forgings;

- pressing of gears and bearings;

- volumetric and sheet stamping.

Pressing machines can be based on mechanical or hydraulic principles and process materials statically or percussively.

Crank machines perform cold and hot metal stamping by pressure: drawing, punching and cutting. Hydraulic presses are used for volumetric forging of metal. According to technological capabilities, presses are divided into: universal, special and specialized. Universal ones can be used for almost any type of forging (for example, a hydraulic forging machine). Specialized machines perform only one technological process (example: crank pullers). Special presses produce a specific type of product using one technology.

Types of technological operations

Technological operations with metal sheets are separating and forming.

Separation stamping operations are performed on equipment equipped with special tools. As a result, a certain part is separated from the workpiece along a straight line or a given contour. The separation of part of the sheet occurs in the following processes:

- Segment _ To perform this action, the equipment is equipped with disk, vibration devices or guillotine shears.

- Trimming . This operation separates the extreme parts of the resulting product.

- Punching . Holes of various configurations are created in a metal sheet using a stamp.

- Felling . A shaped part with a closed contour is obtained from the workpiece.

Form-changing operations are intended to create a product with different parameters and dimensions without mechanical destruction. The following types of these operations are distinguished:

- Beading. The contour of the workpiece or the internal holes are exposed to the stamp to form beads of certain sizes.

- Hood. This operation is a type of volumetric stamping, in which a spatial element is obtained from a flat material.

- Crimping To narrow the ends of a hollow workpiece, a stamp with a conical-type matrix having a narrowing working area is used.

- Flexible. As a result of the operation, the curvature of the surface changes by bending the metal and deforming the workpiece.

- Molding is a change in the shape of individual sections by reducing the thickness of the part without disturbing the external contour of the product.

- Puklyovka. Connecting two plates with a stamp without using additional elements.

Hot forming hammers

Stamping is carried out using a special tool - a stamp, which consists of two or more parts. The cavities of the stamp are called streams. The workpiece, deformed in the streams, fills the cavities and takes the form of a forging.

The flow of metal during stamping is forcibly limited by the surfaces of the tool, which causes a redistribution of the volume of the workpiece. There are hot and cold volumetric, sheet and special types of stamping. Stamping is carried out using hammers, presses, horizontal forging machines, bending on bulldozers, rolling and such methods as rolling, rotational forging, etc. The most widespread is stamping using hammers (steam-air, friction, rollless), presses (crank, screw, hydraulic) and horizontal forging machines.

steam-air stamping hammers are designed for stamping forgings of various shapes, mainly in multi-strand open dies (Fig. 1).

Rice. 1. Double-action steam-air punching hammer

Their operating principle is similar to that of forging hammers. In them, the energy carrier is also supplied to the cylinder 6, however, to ensure high accuracy of the forgings, their design is made more rigid, the guides 4 for the movement of the head 7 are longer. The hammer posts 5 are installed on the hammer 1 and connected to it with bolts 3 and springs 2, which absorb the shock, protecting the bolts from breakage.

Steam-air stamping hammers are manufactured with a mass of falling parts of 0.5. . . 30 t. These hammers are always installed on a vibration-proof foundation.

Friction stamping hammers with a board (Fig. 2) are manufactured with falling parts weighing from 500 to 1500 kg. During operation, the board 3 with the head 5, after pressing the pedal 7, is released by the cams 2 and raised by the rollers 1 to a certain height. Then the head, together with the upper part of the stamp and the board, rushes down and deforms the workpiece in the lower part of the stamp, which is installed on the block 6

For stamping, hammerless hammers are widely used, in which the upper and lower heads move towards each other. More common are hammerless hammers with a belt mechanism (Fig. 3). They consist of a frame, which includes four racks 7. In the upper part of the racks there is a working cylinder 5 with a piston 4 and a rod 3, to which the upper woman 2 is attached. The upper 2 and lower 1 women are connected by a belt connection mechanism consisting of a tape 8 (20 -30 steel strips with a thickness of 0.3... 0.8 mm) and rollers 6. When the piston moves downward along with the rod and the upper woman, thanks to the belt connection mechanism, the lower woman moves upward.

Hammers of this design are manufactured with impact energy up to 500 kJ. They are used for single-strand stamping.

Rice. 2. Friction punching hammer with board

Rice. 3. Crashless hammer with belt mechanism

Types of stamping equipment

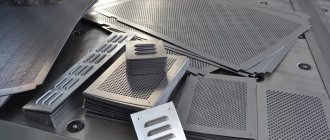

To produce products from sheet metal, presses equipped with various stamps are used. During operation of the equipment, the upper component of the die moves, the lower part remains stationary.

Deformation of the workpiece occurs at the moment of contact between parts of the equipment. There are various models of stamping presses, which allows you to choose the right machine to produce the required parts.

Hydraulic Punching Machine

Presses for metal stamping are:

- crank type;

- hydraulic;

- radial forging type;

- electromagnetic type.

Crank presses are a simple type of equipment and can be double or triple acting. The presses got their name from the crank mechanism, which is the main structural element of the machine. The principle of operation of the mechanism is based on the transformation of rotational motion from the drive into reciprocating periodic movement of the press element - the slide.

Overview of IPONMAC presses and their characteristics

| Model series | KD 23D | HL41 | PG41 |

| Nominal force, t | 10-80 | 40-315 | 40-315 |

| Opening height/clearance, mm | 130-280 | 800-1600 | 800-1600 |

| Table/bottom plate size, mm | up to 520*860 | up to 1400*1200 | up to 1400*1200 |

| Drive power, kW | 1,1-7,5 | 5,5-30 | 5,5-30 |

| Weight, kg | 600-5280 | 3000-36000 | 3-36000 |

Series KD 23D Series HL41 Series PG41

Mechanisms for metal processing

The hydraulic press is capable of developing significant force up to 2 thousand tons. It is used for bending or stamping operations of thick-walled products. The action of the mechanism is based on the movement of the pistons of two communicating hydraulic cylinders, which have different diameters. It is the difference in diameters that determines the amount of force that a metal stamping press can develop.

Drawing of a hydraulic press

The radial forging machine is designed to perform forming operations in order to obtain cylindrical products. The design of the mechanism includes an induction furnace for preheating the part. During the processing process, the workpiece rotates from an electric motor as it passes through the forging zone.

Drawing of a radial forging machine

Electromagnetic presses are new high-performance, economical equipment for stamping. The principle of operation is based on the movement of an electromagnetic core, which directs the actuator of the machine to the metal part.

Drawing of an electromagnetic press

Hydraulic presses

Hydraulic presses are used to stamp large-sized forgings that cannot be produced on other forging equipment due to its insufficient power, and forgings that require a long working stroke for stamping (with deep piercing). Hydraulic stamping presses (Fig. 5) can create a force of 12.5. . .750 MN. The principle of their operation does not differ from the principle of operation of forging hydraulic presses, but stamping presses have a more rigid structure, are equipped with ejectors, mechanisms for installing and changing dies, etc.

Rice. 5. Large hot stamping press of the Nizhnekramatorsk Machine-Building Plant

Features of open and closed dies

Closed stamping

Stamping equipment can be equipped with open or closed dies. In an open die, excess metal flows into a burr or flash that performs a specific function. The main disadvantages of this technology are: loss of alloy due to flash, reduction in product quality due to cut fibers when removing burrs.

Closed dies are used to produce simple shaped products. This flash-free technology is characterized by metal savings, no costs for cutting burrs, and high product quality due to all-round compression. Metal fibers are not cut. The closed die processing method is used for low-plasticity alloys. The main disadvantages are: the need for precise dosage of the alloy, the complex design of the die.

In modern manufacturing, stamping is primarily a preparatory operation that allows the production of parts for both electronics and aircraft or watercraft. The resulting products are subsequently subjected to welding, cutting, riveting and other processing methods depending on the technological process.

Hot stamping presses

Stamping on crank hot stamping presses (CGSP) successfully replaces, and in many cases surpasses, in terms of technological capabilities, stamping on hammers. Forgings with increased dimensional accuracy can be produced at the CGSP due to the constant stroke of the press. KGSHP make it possible to increase the coefficient of metal utilization, since the dies are equipped with upper and lower ejectors, which makes it possible to reduce stamping slopes, overlaps and tolerances. In addition, stamping on a CGSP is 1.5-2 times more productive than stamping on hammers, since deformation on the press in each groove occurs in one stroke, and on a hammer - in several blows.

KGSHP are manufactured with a nominal force of 6.3. ..125 MN. The kinematic diagram of the CGSH is shown in Fig. 4.

The lower stamp 10 is mounted on the wedge-shaped plate 11, the upper stamp 9 is mounted on the slide 8 of the press. The wedge-shaped plate serves to adjust the position of the lower die in height. The slider is driven through a connecting rod 7 from the crank shaft 1. The latter is rotated by an electric motor 3 through a V-belt drive 2, an intermediate shaft 5 and gears 4. The flywheel gear 6 can rotate freely on the shaft.

Rice. 4. Crank hot stamping press : a - design diagram; b - general view.

When the press is turned on for a working stroke, a pneumatic clutch connects flywheel gear 6 to shaft 1. The shaft makes one revolution, the clutch disengages, and the brake stops the shaft at top dead center. For one revolution of the shaft, the slider makes one working stroke, lowering and rising along the guides in the frame. The table and the press slider have ejectors for removing forgings from dies