Stamping is one of the most profitable methods of processing steel by pressure. It requires a press, a washer and a matrix, a mold, and scissors. Depending on the operation (bending, cutting, drawing, etc.), different molds are needed. The metal is stamped, both hot and cold.

Making a mold is a long and expensive process that requires a high level of preparation. You cannot do without a mold when producing multi-production parts: expensive equipment lasts a long time and leads to a reduction in the cost of the final product.

Material selection

High-strength steels that can withstand impact loads are used for molds. These steels are highly hardenable and have high toughness. The most commonly used are 40Х13 and 5ХНМ. For dies, durable steels St45, St40X, U8 are chosen.

For cold stamping, a hydraulic press is used due to the variety of its configurations and low metal consumption. For cutting and punching, choose a tool with a large washer stroke.

IMPORTANT! U8A and 8HF steels are not used for the manufacture of mold parts. U10A steel is hard after heat treatment, but parts manufactured with it will have to be subjected to additional machining.

History of the process

Stamping of metal products dates back to the 16th century. The need for this process arose due to the development of weapons production, which required the production of a large number of identical products. In the 19th century, the active development of stamping production began. They began to produce household utensils, and there was also a need for serial production.

With the advent of automobile and shipbuilding, metal stamping played an important role in the development of these industries. This process made it possible to produce products of large dimensions.

Manufacturing methods

There are three ways to make a stamping mold:

- Remaking an existing mold;

- Manufacturing from scratch;

- Assembly from ready-made materials.

The first option is extremely rare due to the costs; it’s easier to do it yourself. In the CIS countries they create forms from columns to form-building ones. There is a trend towards specialization of molds. All parts of the mold are made in different factories, and finally they are assembled into the finished product.

The production of molds for stamping aluminum parts is reduced in cost by reusing, without repairs, molds that have already served their purpose on more high-precision parts. Aluminum parts do not have tight tolerances, so this option is acceptable.

How to make your own seal or stamp?

It’s not often that the average person needs information on how to make their own stamp. But there are still cases when advice of this kind will help in creativity or the implementation of creative ideas. We have put together several recommendations, but first we will look at the types of stamps and their purpose.

There are seals for official documentation:

- Stamp. Certifies the authenticity of government documents.

- A commercial. Used by individual entrepreneurs and legal entities.

- Stamp. Replaces handwritten text on institutional letterheads.

If everything is clear with the documents, then how to label your books, letters, personal belongings? Masters accustomed to standards are unlikely to make a creative sketch of an image. It's easier to make an impression yourself. Below we will tell you how to make printing at home.

Attention: the instructions contain tips on how to make a seal for personal needs. Illegal production of a stamp for commercial or other purposes is punishable by forced labor or imprisonment for up to two years. In the best case, you will have to pay a fine of up to 80 thousand rubles. (Article 327, paragraph 1).

Types of homemade prints:

- Bookplate. You can use it to mark, for example, books in your home library. The print may contain a beautiful image or your family crest.

- Logo. They are placed on hand-made products, paper bags, and packaging.

- Blank for wax impressions. Used to seal letters.

- Toy print for playing with children.

Metal impact stamp - another type of homemade impressions

Results

- Printing at home can be done quickly and easily.

- The variety of technologies allows you to choose a method that is suitable in terms of labor intensity and capital investment.

- Photo exposure will most accurately convey the details of the drawing, but it is easier to make a print using improvised means.

- Illegal production of stamps is a criminal offense.

Making molds from scratch

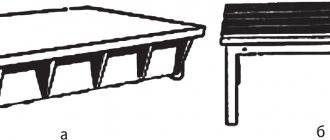

To create a mold, you need 2 sheets or bars of steel, depending on the shape of the product. One part will be responsible for the moving part of the structure (punch), and the second for the matrix.

Having selected materials for the workpieces and tools, you can create a form for stamping. Having the drawings of the part, the equipment is designed. Using a laser or lathe, holes and recesses are cut into the blanks for the mold. For reliability, you need to tightly fasten the two plates and fix them until the work is completed. Carefully debug the gating system. To make some parts of complex terrain, a milling machine and subsequent manual work with a file may be required.

The finished product is checked in operation on test products. This makes it possible to find out the result and adjust the mold in case of any inaccuracies. The gating system must be adjusted for best results.

Making a mold is a complex process, but necessary for mass production of parts.

The production of parts using stamping occupies a leading place in metal forming technology and is used in various industries.

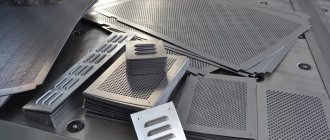

Of particular importance is the stamping of metal products from rolled sheets. It is based on plastic deformation of metal without heating it using special stamps. This method of plastic deformation of parts is widely used for the manufacture of parts of different sizes and complex shapes with great accuracy, which cannot be achieved using other processing methods.

They are used for assembling large-sized products in the engineering industry, in the automotive and shipbuilding industries, as well as in the instrument-making industry and everyday life, where various miniature parts are often required.

What kind of business can be organized in a garage?

When deciding what kind of production to create in the garage, you need to start first of all from the area where it will be located. The premises, located within the city, next to a residential complex, open up great opportunities to organize your own mini-business.

You can set up micro-production of some small products that are in demand, open a retail outlet, for example, selling auto parts, or organize a car wash.

Garage rental

There are fewer ideas for organizing a business in a garage if it is located in the depths of the cooperative, since it is further and more difficult to get to, and many people are very suspicious of such places. In this case, you can rely only on the local category of clients or organize activities in such a way that a potential client can easily find a mini-production.

The simplest option to organize your own business in a garage is to rent it out as a warehouse to some car owner for his vehicle. Of course, you can’t call it a business, there are practically no risks, but the income is appropriate.

To earn good money from rent, an entrepreneur first needs to invest in furnishing a garage:

- Conduct communication systems

- The garage can be insulated

- It is necessary to carry out finishing work both inside and outside the garage.

If you fulfill all these points, then the cost of renting a garage can be increased significantly.

To carry out repair work you will need the following materials:

- Construction materials

- Construction mixtures

- Insulation

- paints and varnishes

- Lighting and heating equipment

- Plumbing equipment

- Construction, plumbing tools

- Necessary finishing products

- Other consumables

Problematic issues may arise with the implementation of communication systems, since it is not always possible to connect to general city systems. In such a situation, the entrepreneur will have to solve the problem on his own, organizing local systems in the garage that must meet fire safety requirements and sanitary standards.

Technology of stamping parts from metal sheets and its types

Stamping is the process of giving parts the desired shape and obtaining the size specified by documents by mechanically acting on them using pressure. The main direction of stamping is the production of parts from blanks, which are used as rolled sheets. Under the action of a compressive force, the workpiece undergoes deformation and acquires the desired configuration.

There is a distinction between stamping performed by the hot method with heating of the workpiece and the cold method without preheating it. Stamping of sheet metal parts is carried out without preheating them.

Pressure deformation with heating of a workpiece is used in the manufacture of parts from metal that does not have sufficient ductility, and is mainly used in the production of small batches of volumetric products from metal sheets with a thickness of within 5 millimeters.

The technological process of hot metal stamping largely coincides with the sequence of operations for cold processing of workpieces. The difference lies in the preheating of the initial blanks in furnaces to a temperature that ensures the plasticity of the metal. This takes into account the degree of warping of the part during cooling, as well as its shrinkage during deformation processing, which affects its size. To eliminate deviations from the required dimensions for parts obtained by hot stamping, large tolerances are made.

Basic investments

The investment portfolio for starting your own business in a garage will depend on its focus:

- if the garage will be used as a warehouse, then it is enough to make inexpensive cosmetic repairs;

- if this is your own mini-store, then you will need to think about its design;

- when organizing a photo studio, a music base for training young singers, additional funds will be needed for good lighting, special equipment, and sound insulation;

- specialized equipment will also be needed if you organize a mini-production or your own repair shop. It is not recommended to organize the production of food products in a garage, as it will be quite difficult to obtain permits from the relevant government agencies and the SES.

Types of stamping technologies

During its existence, many stamping methods have appeared. Mass production requires a special approach, where the speed and quality of manufacturing products comes first. Hand stamping is now used exclusively privately, to create single copies.

Before considering methods of forming, let's consider other types of stamping:

- Magnetic pulse. Short-term pulses of electric current are used to change the shape of parts.

- Isothermal stamping of parts. Used for deforming alloy and heat-resistant steel grades. The peculiarity of the isothermal process is that the contact mold is heated to the deformation temperature of the workpiece. Hydraulic presses are used as working equipment.

- Explosion stamping. A type of pulse method. It is actively used in the production of aircraft. The operating principle is based on the transmission of the impact of a blast wave through air or water. As a result, the workpiece is deformed, acquiring the outline of the matrix used.

In addition to production functions, explosion energy is used as a drive for moving parts of equipment. The method was developed at the Kharkov Aviation Institute in 1949.

The technological process in which a product is produced by pressing molten metal is called liquid stamping. Due to the high cost of dies and punches, the method is advisable to use only in mass production.

Sheet stamping

Stamping of sheet metal parts is used in mass production to produce three-dimensional or flat structures. The process of forming the finished product occurs using a special tool called a stamp. Sheet stamping technology was used by ancient people. It was used to make dishes, jewelry and agricultural supplies.

The processing of workpieces is divided into two categories, which differ in operating temperature:

- Cold stamping. This method is considered the most effective. It is used for the manufacture of vehicle body parts. Proper cutting helps to rationally use the base material. The best performance can be achieved using carbon and alloy steels, as well as sheet copper and aluminum.

- Hot stamping. As the name suggests, this method involves preheating the workpiece. For this purpose, flame or electric furnaces are used. The technological operations of this method are absolutely no different from the cold production method. The only caveat is the thickness of the sheet metal: this indicator should not exceed 5 mm. This method is used to produce hull elements in the shipbuilding industry.

Volume stamping

A type of pressure treatment of parts. The peculiarity of the process is the use of blanks of the simplest geometric shape. This technology makes it possible to obtain a more complex product as a result of volumetric plastic deformation.

Hot stamping is characterized by an increased temperature at which the process takes place. The degree of heating depends on the materials used. Unlike stamping of liquid metal, the state of aggregation of the workpiece remains unchanged.

Let's consider the features of each process.

Hot die forging technology (GOSH)

Hot volumetric deformation of parts is performed under the influence of temperature and pressure on the workpiece. To obtain the required shape, the material is heated and placed in closed dies. There is no gap between the molds used. Thus, the finished product is formed in a closed cavity called a rill or engraving. The approach is characterized by a low percentage of flash, but requires attention at the harvesting stage.

How to make a stamp at home - Metalworker's Guide

It’s not often that the average person needs information on how to make their own stamp.

But there are still cases when advice of this kind will help in creativity or the implementation of creative ideas. We have put together several recommendations, but first we will look at the types of stamps and their purpose. There are seals for official documentation:

- Stamp. Certifies the authenticity of government documents.

- A commercial. Used by individual entrepreneurs and legal entities.

- Stamp. Replaces handwritten text on institutional letterheads.

If everything is clear with the documents, then how to label your books, letters, personal belongings? Masters accustomed to standards are unlikely to make a creative sketch of an image. It's easier to make an impression yourself. Below we will tell you how to make printing at home.

Attention: the instructions contain tips on how to make a seal for personal needs. Illegal production of a stamp for commercial or other purposes is punishable by forced labor or imprisonment for up to two years. In the best case, you will have to pay a fine of up to 80 thousand rubles. (Article 327, paragraph 1).

Types of homemade prints:

- Bookplate. You can use it to mark, for example, books in your home library. The print may contain a beautiful image or your family crest.

- Logo. They are placed on hand-made products, paper bags, and packaging.

- Blank for wax impressions. Used to seal letters.

- Toy print for playing with children.

Metal impact stamp - another type of homemade impressions

Image creation programs

Making a print begins with creating a design for the print. Graphic programs are used for this:

- Stamp is a popular and free software for creating image layouts. Intuitive, even an inexperienced user can work with it. You can only download the demo version for free.

- "Stamp" is a free program with wide functionality.

- Corel Draw, Illustrator - vector graphics editors for creating detailed images. Requires basic skills.

- Fine Print is a paid program for inserting a print image into a text document.

The process of creating a print layout in Corel Draw

Methods of making seals

Here are 3 main methods: complex, simple, for children.

Complex: photopolymer printing

Photo exposure technology is capable of conveying the smallest details of a drawing. However, it is financially expensive and difficult to implement: you need to master graphics programs, buy film and polymer, find an exposure camera and a suitable laser printer.

Step 1 : Need a mockup of the image. To create a professional drawing, use Corel Draw, but other programs are also suitable.

Step 2. To print the layout, use a laser printer with a resolution of 600 dpi. Lomond or Kimoto films are suitable as a base.

Step 3. Straighten the negative and place it face up on the glass. Before doing this, moisten the glass with water so that the negative sticks better. It is advisable to cover it with protective film. Using smoothing movements from the center to the edges, remove air and remaining water from under the film.

Step 4. Cover the edge of the negative with border tape, leaving the corners free.

Step 5. Evenly, without breaking the stream, fill the negative with photopolymer. If bubbles appear, poke them with a needle or blow them out with a stream of air from a rubber bulb.

Step 6. Carefully place the film on the polymer with the rough side inward and the smooth side outward. Press it lightly in the middle and gradually release the ends. Place another piece of glass on top and use clamps (available at office supply stores) to secure it around the edges.

Step 7. Place the resulting “sandwich” in the exposure chamber. The front side should be on top. Set the exposure duration.

When the process is complete, turn the composition over and repeat the procedure. Each polymer has its own exposure duration. For example, VX55 and ROEHM should be kept for one minute.

To avoid mistakes, read the technical regulations.

Step 8: Carefully remove the glass and separate the negative from the resin. Leave the clear substrate in place. Use a toothbrush and a non-abrasive cleaner to remove any remaining uncured resin from the cliche. It is best to do this under running warm water.

Step 9. Soak the washed cliche in water for 5-10 minutes and re-expose it.

Step 10. Carefully cut out the cliche along the contour without touching the edges. Glue the workpiece onto the equipment. The print is ready!

Beginners often separate the substrate from the polymer after exposure. As a result, it is impossible to glue the stamp blank. Remember: the rough surface of the substrate comes into contact with the polymer, and the smooth surface sticks to the body.

This impression can be used to seal with wax or sealing wax.

Simple: stamp made using foil

Find an old stamp or board of a suitable size, preferably with a handle. Glue the resulting inscription to it, and you can test the quality of the print.

This technology does not require any special artistic talents from you. Materials for making blanks are available in every home. The wear resistance of such a stamp is lower than that of a photopolymer, but with its help you can make several hundred impressions.

Step 1. Choose a suitable pattern. Transfer it to tracing paper and then to foil. To do this, you can take a pencil or a non-writing pen and trace the outline with light pressure. Any foil will do: food foil on a roll or from a chocolate bar.

Step 2. Carefully pour strong putty or epoxy glue into the resulting recesses. Set the workpiece aside for two days to dry.

Step 3. At the end of the period, remove the resulting inscription from the foil. The cast should come off easily.

Step 4. Find an old stamp or board of the appropriate size, preferably with a handle. Glue the resulting inscription to it and test the quality of the print. Ready!

The basis may be a worn out rubber stamp

Prints for children

Who among us hasn’t drawn on an eraser and then enthusiastically stamped the last page of the notebook? Children love making prints. And you can make a whole collection of curly stamps with them.

You will need porous rubber (sold together with stationery), Moment glue, gouache, scissors, pencil.

Step 1. Draw a pattern with a pencil on the adhesive-based foam rubber. We recommend this particular material, since it can be used to create more detailed designs than foam rubber.

Step 2. Carefully cut out the resulting image. Make holes with a utility knife.

Step 3. Prepare several wine corks or plastic bottle caps. Glue the cut out images onto them.

Step 4. Dilute gouache in a small amount of water or take stamp paint. That's it, you can make the first print!

The essence and purpose of cold stamping of sheet metal

Cold stamping is the most popular technology for manufacturing various parts from metal and polymers. The versatility of the method lies in the fact that it allows the production of structures of any size: from kitchen utensils to elements of large ships.

Cold sheet plastic deformation is valued for the following advantages:

- Unlimited possibilities for mechanization and automation of the process.

- Low production costs.

- High material utilization rate.

- When manufacturing thin-walled elements, the strength of the structure is not reduced.

- There is no need for finishing processing of finished products.

High quality and manufacturability have a downside: setting up equipment requires qualified specialists. In addition, process design is a labor-intensive operation.

Cold stamping operations

Any working operation of sheet stamping can be classified as a group of separating or forming actions. Let's look at the basic procedures:

- Cutting. The operation involves cutting the material along a straight or complex line. Various types of scissors or guillotines are used as working equipment. Cutting can be performed both at the initial and final stages of production.

- Punching. Obtaining a hole of arbitrary shape.

- Felling. Cutting a structure along a closed contour. In this case, the separated part is a part, and not waste, as with punching.

- Beading. The operation of creating a side along an external or internal contour. Most often, the procedure is carried out at the end of the pipes, at the places where flanges are installed.

- Hood. Transformation of a flat product into a hollow volumetric part. The process may be accompanied by a change in wall thickness.

- Crimping Reducing the size of the end part by compression in a conical matrix.

- Flexible. Giving a curved configuration to flat parts. The most common are V- and U-shaped bending.

- Molding. Changing the local shape of a part while maintaining the dimensions of the outer contour.

Business in a garage: main obstacles

People who have “entrepreneurial blood” flowing in their veins create businesses even in their own apartment. They even manage to organize a small kindergarten for children in such a room and a mini-production of set meals to order.

The garage is also ideal for starting a small business. For example, in such a room you can set up a workshop, small production, or a goods warehouse, which cannot be organized in an apartment. The main thing is that there is no need for rent.

What problems may arise when organizing a garage business?

- The legality of such a business remains questionable. According to our legislation, business activities in garage cooperatives are prohibited. A warehouse for storing goods organized in your own garage may, of course, not attract the attention of inspectors, but problematic issues may arise with mini-production.

- One of the problematic issues is that garage cooperatives are usually located within the city. If the territory on which they are built suddenly becomes of value to government agencies, then the garages will be demolished first. And in their place they can organize the construction of a residential complex, road, and other objects. Of course, in such a situation, the state will return the money for the garage to the owner, but you will have to forget about the investments made in the garage business.

But even knowing about possible problems, businessmen still equip garages for their business. The main thing is that such a mini-business is quite effective, and even if the entrepreneur has not officially registered it, the law does not provide for large fines for this.

Classification of stamping equipment

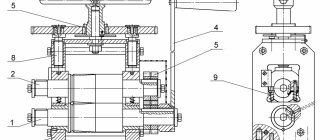

A stamping press is a machine with a crank or hydraulic drive. There is a wide selection of equipment on the market. The characteristics of stamping lines differ in the strength and size of the processed materials. Soft metals do not require high power machines.

Stamping production and equipment for it are regulated by the requirements of interstate standards. In addition, GOST establishes the maximum permissible consumption of materials and approves the rules for project development.

Let's consider the equipment that is used in manufacturing enterprises.

Crank presses

The principle of operation of the equipment is based on the conversion of torque by a crank mechanism into reciprocating movement of the slider.

Such equipment is classified as simple type mechanisms. They can be double or triple acting.

Hydraulic presses

The most powerful equipment, capable of developing a force of up to 2 thousand tons. The operating principle is based on the movement of two hydraulic cylinders of different diameters. The magnitude of the difference in size determines the degree of impact on the surface. The liquid is driven by special electrically driven pumps.

Radial forging presses

They are a molding press for the production of cylindrical parts. The machine is equipped with an induction furnace for preheating the ingots.

The equipment is used to produce forgings of square, round or rectangular cross-section.

Electromagnetic presses

A product of modern technology. The driving force is the energy of the electromagnetic field, which presses on the core with the wire winding. During the movement, it affects the executive part of the machine.

Registration of a garage business

Entrepreneurs often set up business in a garage illegally, without any permits. This can lead to its rapid closure after the first inspection; for example, neighbors complain about illegal business activities that allegedly interfere with them.

Without registration, you can work for the first few months of business development, when potential clients are only relatives, friends, and acquaintances. But then the business will need to be legalized and registered with a local tax organization.

- For a mini-business in a garage, the best option for registration is individual entrepreneurial activity. In this case, there are no difficulties with registration; it is possible to use a simplified taxation system and accounting reporting that does not require the knowledge of an experienced accountant.

- To organize a mini-production, which requires more serious capital investments, you can attract partners. It is better to register a joint business as an LLC so that each co-owner officially has their own rights to it. In this legal status, it is better to cooperate with client companies.

Automatic stamping lines

Modern machine tool manufacturing enterprises offer a wide selection of automatic stamping lines and complexes for solving various problems. The machines are high-tech equipment manufactured under the guidance of qualified process engineers.

Modern complexes are equipped with CNC systems with a central touch display, which reduces operator functions to a minimum.

Metal stamping is a popular technology that allows the production of parts with high performance characteristics. Do you think semi-automatic machines can compete with numerical control or is such equipment outdated? Share your opinion in the comments block.

Ideas for starting – what kind of business can you open in your garage?

The first clients will most likely be your friends, and then word of mouth will begin. Alone, in a month you can do at least two cars with medium body damage, or up to 6-8 with minor ones (painting 1-2 parts). A simple calculation shows: 2 cars for 20-30 tr. or 8 for 5-6 tr. – this is more than 50,000 rubles of net profit. As a result, your garage business will pay for itself in 2-3 months and begin to generate net profit. Yes, you won’t be able to take on serious slipway work, for which car repair shops charge from 100,000 rubles, but, as they say, “the hen pecks the grain, but he’s full.” If things go well, you will expand, especially since there is room for it.