A cutting type tool is designed for finishing cleaning of holes obtained by drilling, boring and countersinking. Reaming, thanks to a large number of edges, from 4 to 14, allows you to achieve accuracy of up to 9 quality. The tool rotates while simultaneously making translational movements along the axis. To achieve maximum accuracy, it is recommended to use lubricating coolants.

Types of scans

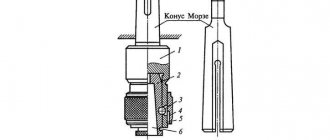

— Machine type , equipped with a shank in the form of a Morse cone or cylinder, necessary to obtain a smooth surface after drilling and adjusting the hole to the exact dimensions. They are distinguished between solid and mounted according to the method of fastening;

— Manual reamers , made in the shape of a cylinder, have sharp edges (helical and straight) along the entire length. For a comfortable grip, it is used simultaneously with the crank;

— Adjustable , allow you to set different diameters in the range from 1 to 3 mm;

— Expanding or sliding , inside of which there is a ball and a screw at the bottom. By driving the screw, the ball moves forward, thereby moving the edges apart and increasing the diameter of the tool;

— Conical , cone-shaped, used in industry.

Existing forms

Due to the fact that the creation of precise holes is an integral part of production in various branches of machine tool and mechanical engineering, reamers come in many shapes and sizes. Based on their form, they can be divided into three groups:

- In the form of cylinders;

- In the form of cones;

- Multi-stage.

The first are the most common and are used to create traditional round holes. Their grooves have a straight or helical shape with special recesses for removing chips.

The latter have a cone shape and a cut off top. With their help it is possible to work on both classic and conical holes. Either way, the end result is the creation of a tapered hole. Excess chips are removed through both straight and helical grooves.

Stepped models are considered the rarest due to their versatility, since they are capable of aligning holes in sheets of metal. Structurally, they have a conical shape, but their bevel occurs in steps, and not smoothly. This design is particularly whimsical, but if it is used competently and professionally for processing sheet metal (only a few millimeters thick), then it can last a long time.

Depending on how qualitatively the future hole should differ from the existing one, the device should be used in one or more approaches. As a rule, a professional turner can limit himself to 3 approaches - roughing and roughing, intermediate and finishing. The first pass consists of a rough trim, after which the second pass removes burrs and any protrusions that have formed. The final step is a finishing reamer, with which the insides of the groove become particularly smooth.

Differences from drills

A drill, by definition, is a tool that is designed to create initial holes. Reamers are not suitable for this, but are needed only for finishing already created holes to the required dimensions.

IMPORTANT! In principle, visually both objects are similar to each other, but are not interchangeable. Thus, each of them should be used only for its specific task.

Differences in area of use

The described tool can be used both manually and mechanically. For manual samples, the diameter can be set within the range of 3-50 millimeters. Its tail element has a special recess for a square-shaped profile for easy fixation in the collar. The smaller the diameter of the reamer, the easier it is to work with it, because the friction area will decrease. When working by hand, it is necessary to start screwing properly, as there is a risk that the entrance to the hole may become deformed and take on an oval shape.

Machine-type reamers are installed on machines. Their diameter is significantly thick, so they are convenient to fix in turret, lathe and drilling machines. Their shape can be either cylindrical or conical.

Sweep operating principle

The operating principle of the tool lies in its edges - teeth. There can be from 4 to 14. Thanks to the edges, the allowance is removed during the processing of the hole. Not only does the rotation of the tool help the drilling process, the feed, which is performed in the direction towards the axis of the calibrated armhole, is also important. Due to the principle of operation, it is possible to remove the thinnest layer of metal from the product without damaging either the surface or the tool. A metal-cutting product, mechanical or manual, can make an ultra-precise hole with minimal roughness.

Reamer design

The reamer consists of a cutting surface, a calibrating part, teeth, grooves, clamps, back and front cutting angles. The cone angle varies in the cutting part. For hand tools it is 1-2 degrees, and for machine equipment it reaches 15 degrees. The calibration part consists of a conical and cylindrical section.

The cylindrical base grades the hole in the metal product, and the purpose of the reverse taper is to reduce friction during the calibration process. The rigidity and accuracy of the tool depends on the number of teeth. The more teeth there are, the more accurate and cleaner the hole is. The grooves in the reamer are responsible for control and smooth processing of products. For example, when working with uneven surfaces, a tool with a screw tooth is used - there the grooves are hollowed out in the direction opposite to the rotation - this is necessary so that the reamer does not jam during the drilling process. The rear cutting angle of the product is responsible for the durability of the equipment; it is usually made at an angle of 5-8 degrees. And the rake angle is zero.

Differences between manual and machine reamers

The tool used to perform the deployment, as mentioned above, can be manual or machine. The most important parameters that are taken into account when choosing reamers include the type and caliber of their cutting part, the number of teeth and their direction, cutting angles and uneven tooth spacing, as well as the profile of the grooves and the configuration of the clamping part of the tool.

The working part of the hand tool has a cylindrical shape, the cutting teeth that are located on it have sharp edges along their entire length. Such a tool is produced in a diameter range of 3–58 mm, in increments corresponding to 1 mm. In addition, hand reaming tools can be produced in increments as small as 3.5; 4.5; 6.5 (up to 15.5 mm). Specialists, as a rule, try to have a whole set of reamers at their disposal in order to process holes of any diameter using such a tool.

Manual conical reamer

The question of how to ream a hole using a hand tool, as a rule, does not arise. To do this, you need to have at your disposal not only the tool itself, but also a crank in which it is fixed by means of its shank with a square cross-section of the end part.

The front end of the working part of manual reamers - the approach - has a smaller diameter than the cross-sectional size of the main cutting part. This design feature is needed to ensure easier entry of the tool into the hole being machined. You can even notice this difference in the diameters of the main working part and the front end of the tool even in a photo of a manual scan.

The accuracy of the geometric parameters of the hole being machined, as well as the cleanliness of the formed surface, depend on the number of cutting teeth on the working surface of the reamer. The higher the number of teeth the reamer is equipped with, the higher the quality of the processing performed. Meanwhile, using a tool with a large number of cutting teeth also has its disadvantages, the main one being that in this case it becomes difficult to remove chips from the processing zone.

Accuracy of making holes by reaming

The vast majority of reamers used for manual processing have straight-shaped cutting teeth, but there are also models of tools whose working teeth are located along a helical line. The use of a tool with a helical arrangement of cutting teeth is advisable in cases where the holes that need to be processed are formed by a discontinuous surface along their length.

When asking the question of how to ream a hole using a machine-type tool, you should keep in mind that for this it is necessary to use not a crank, but equipment in the spindle of which such a tool is fixed using its shank. Taper shanks are standardized, and their geometric parameters depend on the diameter of the reamer itself.

The working part of a machine reamer equipped with carbide soldered plates

For the manufacture of machine tools, which experience significant mechanical loads during processing, a high-speed metal alloy is used. The best quality metal used is considered to be a machine tool made in Soviet times, but finding it on the open market today is quite problematic.

Why are adjustable reamers needed? This question often arises among beginner metalworking specialists. Using such a tool with an adjustable diameter of the working part, holes are processed whose cross-sectional dimensions correspond not to a whole number (say, 10 or 16 mm), but to a fractional value. The diameter of the working part of such a tool is changed quite simply; for this, ordinary wrenches are used, with the help of which the adjusting nuts specially provided for in the reamer design are loosened and tightened.

Hole Reaming Process

Reaming the holes is necessary to create an armhole with a precise shape in a metal product with an acceptable roughness of 0.16 to 1.125 micromillimeters. The unwrapping process is performed using unwrapping. The size of the tool is selected in accordance with the diameter of the hole. First, a rough hole is drilled in the workpiece. Then this workpiece is secured so that the equipment can freely pass through the product with the hole. For rough reaming, mineral oils are sometimes used to lubricate the surfaces of the tool and workpiece. After rough reaming, a finishing tool is inserted into the hole, and the operation is repeated again until the desired quality is achieved.

Types of manual metal reaming and features of work

The drilling method is usually used to make holes. But their walls in this case may be uneven even when the best brands of tools are used. And not only the walls of the hole may be far from ideal, but also its size. This is already a pretty serious problem. To achieve a perfectly accurate result, manual scanning is required. We will look at what it is in this article.

Operating principle

A metal reamer is a metal-cutting tool that has an axis of rotation and is designed to eliminate roughness from the inner surface of holes during final processing. With its help you can also perfectly adjust the size to the required one.

The tool has a range from three to sixty millimeters, and with its help you can achieve much greater surface cleanliness than drilling. The reamer should have a diameter slightly smaller than the final size of the hole being machined. The tool has cutting edges, which, depending on its type, range from four to fourteen, which ensures high quality processing. The work is done due to the rotation of the tool around its axis and at the same time translational movement along the axis of the hole.

Types of instruments

There are three basic types of reamer tools: cylindrical, conical and adjustable. Let's look at each of these varieties.

- Cylindrical. Used for cylindrical holes. This tool can be used with a drill (at low speed) or a winch. It can be solid or adjustable.

- Conical. It is divided into three categories: rough, finishing and intermediate. The roughing machine cuts off the chips with the teeth of the cutting edge. Such a tool has teeth located along the entire line. The intermediate one cuts chips of smaller sizes, and the finishing one works over the entire area. With the help of such a development, the hole turns from cylindrical to conical.

- Adjustable. There are two main types that are found on the market today - expansion and sliding models. They both work on the principle of moving up or down, narrowing or widening the diameter of the hole. The difference lies in both the type of tightening and the range of sizes. The expanding reamer has upper and lower nuts, with the help of which the diameter of the hole is changed from 0.25 to 3 millimeters. Sliding reamers are equipped with a screw, and when it is tightened, a special ball located inside the body is set in motion, pushing the cutting parts apart. This type of design is considered more precise, allowing the hole diameter to be increased in the range of 0.15 to 0.5 millimeters. The adjustable reamer consists of a body and knives, which are inserted thin plates made of tool steel. The cutting plates are removable, they can be sharpened and subsequently replaced with new ones. This type of tool allows you to change the diameter of the holes by tenths and hundredths of a millimeter and is more economical due to the possible replacement of knives.

Features of drilling holes

It is advisable to carry out boring in stages - first with a rough reamer, then with a finishing reamer. Before reaming, the end part of the hole must be ground so as not to dull the tool, this is especially important when working with cast iron parts. In the process of work, it does not hurt to be guided by the principle “the slower you go, the further you will go,” and the slower and more evenly the tool is fed into the hole, the higher quality the result will be. That is why it is recommended to work not with a drill, but with a crank, in order to be able to more accurately control the work process.

Subtleties of work

One of the important components of the process , as a rule, is the use of lubrication and cooling, which has a significant impact on the degree of accuracy of the reamed hole. Otherwise, the holes will turn out uneven and rough, and pinching and breakage of the reamer are also possible. Therefore, when working with products made of steel, copper and aluminum, various lubricants are used:

- steel parts are lubricated with mineral oil;

- copper - emulsion with oil;

- aluminum - with turpentine and kerosene;

- duralumin - with rapeseed oil.

The exceptions are bronze and cast iron - these materials can be worked “dry”.

It is strictly forbidden to rotate the reamer in the opposite direction, as this leads to breakage of the teeth and the appearance of scoring. To obtain a better result, use the so-called machine-manual deployment option. It consists in the fact that, depending on the size of the workpiece, either the part or the reamer itself is installed in the drilling machine chuck.

For example, when securing a reamer in the spindle of a lathe, small parts are held in hands or special devices during processing, and vice versa, rather large parts that are difficult to hold in hands are inserted into the chuck, and the reamer is held by hand.

Sharpening reamers

Sharpening of metal cutting tools should only be carried out by an experienced and highly qualified craftsman. Since a reamer is considered a finishing tool, the quality of its sharpening must be ideal. This is a complex operation that is performed on a special sharpening machine. The tool teeth are processed according to a roughness classification of at least 8th or 9th class. For accuracy of repair, the development angles are checked with a protractor or using a special microscope for instruments. After grinding, the reamer is further processed by finishing on a professional finishing mechanism.

What holes are machined with reamers?

The master can process cylindrical or conical holes with a cutting tool. Cylindrical armholes are created by reamers with the main part in the shape of a cylinder. Use hand or machine tools.

Conical holes are made with conical-shaped reamers, but not immediately. Typically, the process is divided into three stages: roughing, intermediate and finishing. The finished conical hole is checked using a cutting product with a conical gauge.

How to care for a reamer

Restoring this instrument can cost a lot of money. To avoid unexpected expenses, you should carefully monitor the condition of the reamers: protect them from moisture, buy a storage unit, and clean them after each use.

Contents: Hide Open

A reamer is a precision cutting tool used for finishing various shapes of holes, giving them the required accuracy and roughness. The main purpose of the reamer is to fine-tune holes after drilling, boring or countersinking; it allows you to achieve grade 6-9 accuracy and roughness up to Ra = 0.32...1.25 microns.

Classification of scans

In metalworking, various types of reamers are used, divided according to the following characteristics:

Hole shape:

- Cylindrical reamers.

- Conical reamers for various types of cones.

- Step developments.

Hole Reaming Accuracy:

- Quality number for cylindrical tools.

- Hole processing level (roughing, intermediate, finishing) – for conical ones.

- Adjustable reamers – sliding, pivot or expanding.

Clamping method:

- Hand-held with square shank.

- Cylindrical shank (machine reamers).

- Conical machine.

- Machine mounted.

Reamers are also divided according to the number of cutting edges, material and shape of the grooves for chip removal (spiral or straight).

Content

- 1 Construction

- 2 Reaming or drilling to required size

- 3 Types 3.1 Reamer chuck

- 3.2 Adjustable manual sweep

- 3.3 Direct sweep 3.3.1 Manual sweep

- 3.3.2 Machine scanning

- 3.6.1 Morse taper scan

- 4.1 Size - accuracy and repeatability

- 7.1 Bibliography

Reamer design

High quality processing is ensured by the design of the reamer - a large number of cutting edges providing a small allowance when removing metal. The cutting process is carried out during rotation and simultaneous translational movement of the tool along the axis of the hole being machined.

Above are pictures of four types of scans:

- a) Manual with a cylindrical shank.

- b) Machine made with a tapered shank, solid.

- c) Machine one-piece

- d) Machine assembly with replaceable cutting elements.

The tool has from 6 to 16 teeth (usually) unevenly distributed around the circumference to improve the quality of processing. Let's look at the design using the example of a manual solid reamer with a cylindrical shank. The tool consists of three main parts - the working part, the neck and the shank. In turn, the working part of the reamer consists of a guide, cutting and calibrating parts, as well as a reverse cone. The main part of the process is performed by the cutting part, which is much longer for a hand tool than for a machine tool.

Basic techniques for working with sweeps

The drill for preparing the hole is selected to match the diameters of the metal reamers. There must be a small allowance - the drill should be 0.2 - 0.3 mm smaller for rough reaming, and no more than 0.05 - 0.1 mm for finishing. Allowance values greater than those specified can cause rapid wear of the intake part of the reamer, deteriorating the accuracy of the result and the quality of the surface.

For manual sweep:

- The reamer is attached to the collar and lubricated.

- The intake part must fit in such a way that the axes of the reamer and the hole completely coincide.

- To check the position of the reamer, you can use a square in two planes located perpendicular to each other.

- Start rotating to the right with slight pressure from above.

- Rotate smoothly, at low speed, without jerking. Do not speed up the rotation even at a light speed.

- Reverse rotation is unacceptable, as it may cause breakage of the cutting edges and burrs on the surface of the hole. Reaming is carried out in one pass on one side.

Tips for machine scanning:

- The reamer is attached in the same way as a drill. The process itself is similar to drilling and it is advisable to perform it without changing the installation of the part, immediately after preparing the hole.

- Often the reamer is mounted in oscillating holders, which allows the tool to self-center along the axis of the hole.

- It is advisable to use automatic feed; the cutting speed should be 2-3 times lower than when drilling.

- A significant amount of lubricant must be used.

- The lower the number of revolutions and feed speed, the higher the quality of the hole and tool life.

Current GOSTs

Defines scanning parameters according to GOST 29240-91. Tolerances are regulated by GOST 11173-76. Also, each type of reamer has its own current standard that determines its design and dimensions. For manual cylindrical ones - GOST 7722-77, for machine solid ones - GOST 1672-80, etc. for all types of tools.

Reamers for metal allow you to obtain holes of accuracy classes 2 and 3, and cleanliness classes 7 and 8.

There are 2 main types of sweeps:

Manual reamer sizes:

Cylindrical development:

— nominal diameter: from 3 (mm) to 50 (mm); — total length: from 80 (mm) to 360 (mm); — length of the cutting part: from 40 (mm) to 190 (mm); — length of the cutting part: from 4 to 10 d; - reverse taper value: 0.01 - 0.05 (mm) per 100 (mm); - rake angle: 5 - 10 °; — back angle: 5 — 12 °.

Conical reamer:

— diameter of the middle part of the cone: from 7.067 (mm) to 44.399 (mm); — minimum cone diameter: from 6.39 (mm) to 40.978 (mm); — maximum cone diameter: from 7.64 (mm) to 45.715 (mm); — total length: from 55 (mm) to 170 (mm); — length of the cutting part: from 24 (mm) to 90 (mm); — documentation: GOST 11181-71.

Machine reamer sizes:

Machine-mounted reamer with plates:

— nominal outer diameter: from 34 (mm) to 50 (mm); — internal diameter: from 13 (mm) to 22 (mm); — total length: from 40 (mm) to 55 (mm); — number of teeth: from 6 (mm) to 10 (mm).

Device and characteristics

A standard scan consists of the following parts:

- The working part has a direct impact on the material and is formed by longitudinal teeth.

- The transition neck is a cylindrical zone of the tool that acts as a transition link between the previous and next parts.

- Shank - necessary for clamping a tool in a driver or chuck of machinery.

The working part is divided into several zones formed by the edges of the teeth:

- The intake part, at the very beginning of which there is a guide cone. In this zone, each tooth has a sharply sharpened cutting edge that selects material from the inside of the hole.

- The calibrating part is responsible for calibrating the hole. Here the edges of the teeth form a so-called cylindrical strip (flat surface), which increases the dimensional stability of the tool.

- The rear cone is where the teeth join the transition neck.

Between the teeth there are grooves that remove chips.

They are straight (most common) and spiral (helical, preferable when working with discontinuous surfaces).

In the latter case, the direction of the screw formed by the grooves is opposite to the direction of rotation of the tool.

This ensures resistance to seizing and self-tightening.

Material

In the manufacture of reamers, we mainly use tool alloy steel grade 9ХС, as well as high-speed steels P18 and P9.

NOTE:

The grade of steel used in the production of tools is selected taking into account the material that is supposed to be processed.

Dimensions

Cylindrical manual models reach a length of 80 - 360 mm, where the working part occupies 40 - 190 mm.

The diameter of the tool is in the range of 3-50 mm, and the length of the cutting part is 4 – 10 diameters.

The front angle is from 5° to 10°, and the back angle is from 5° to 12°.

The length of the conical manual options is 55 – 170 mm, of which the cutting part occupies 24 – 90 mm.

The maximum and minimum diameters of the cone reach 7.67 - 45.715 mm and 6.39 - 40.978 mm, respectively.

As for machine reamers, in addition to standard options, there are models with an extended working part, the design and dimensions of which are specified in GOST 11175-70.

Reamers with a diameter of 1 – 120 mm with an allowance for finishing are designated by numbers from 1 to 6.

This numbering establishes a correspondence between the nominal diameter of the tool and its maximum deviations.

Teeth

The number of teeth varies from 6 to 14 pieces, however, there are options for 16 teeth, which are used mainly on high-precision equipment.

In general, the number of teeth depends on their own rigidity, and in inverse proportion.

The more of them, the higher the cleanliness of the final hole, but the worse the removal of chips and the lower the strength of each tooth.

NOTE:

To make it easier to control the reamer diameter, the number of teeth is always set to even.

Depending on the inclination of the teeth relative to the axis of rotation of the tool, the reamer can be straight-toothed or helical.

In addition, different models may have equal or different pitches, that is, the distance between adjacent teeth.

As for sharpening, there are sharpened (pointed) and backed teeth.