Description and use of cartridges

The drill chuck is used for drilling both with hand tools (this includes a drill or screwdriver and hammer drill), and on various machines. These cartridges are produced according to European and domestic standards. The devices must meet the requirements of fastening rigidity, radial runout of the standard size required for drilling, depending on the size of the drill, as well as the density of the material. The stiffer it is, the greater the load on the drill will be. And if the chuck is selected incorrectly, the drill will break.

Drilling machine chucks are divided into 2 large groups according to the type of fastening:

- Chucks that match the mounting hole in the lathe for taper fastenings.

- Chucks that have a threaded connection to the machine.

Types of tool fixation

There are several main types of tool holders for drilling machines:

- Three-jaw chuck for clamping a cylindrical shank.

- Double jaw chuck. Used for light loads and small diameter tools.

- Quick change devices with tapered shank.

- Self-aligning locking devices. Used for boring pre-drilled holes.

- Safety clamps are used to work with taps when preparing threads.

- Reversible chucks for drilling machines. Used when cutting threads on equipment without spindle rotation.

Fast-acting self-clamping drill chuck

The mechanism of standard chucks does not guarantee good centering and strong fastening of the clamped cutting device, which, of course, costs time when the tool is frequently changed during operation.

The drill chuck consists of the following elements: a housing, in which, thanks to the nut, there is a cage, as well as a screw shank with a left-hand thread. There is a ball bearing between the nut and the shank. In the frame, 3 grooves are milled at equal intervals from each other, and cams are placed in them. There are 3 radial L-shaped grooves cut on the top of the screw, provided for a movable radial connection of the cams with the screw.

When the shank rotates relative to the chuck body, the screw is unscrewed or screwed in and transmits axial as well as radial movement to the cams, forcing them to slide both inside the body cone and along the side of the holder. This method carries out combined axial and radial movement of the cams and clamps or releases the device.

When drilling, the shank rotates clockwise in the drill chuck body and unscrews the screw, which displaces the cams and strengthens the clamping of the drill. When changing the drill, you need to support the shank and rotate the core counterclockwise, while the screw moves the cams and opens them. Using a ball bearing, you can quickly release the part, even when the part is tightly tightened.

Drill chuck design

If we consider the design of a cam-type chuck, it includes the following main elements:

- frame;

- nut with cage;

- screw shank with left-hand thread;

- ball bearing between the nut and the shank;

- fists.

Three grooves with cams (clamps) are milled in the cage; there are also 3 L-shaped grooves in the upper part of the screw. The latter provide a movable radial connection between the clamps and the screw. Rotation is carried out using a key, which engages in gear engagement with the holder. The end part of the key is fixed in the cartridge body.

When the tail part rotates, the screw makes axial movements, giving the chuck clamps radial-axial movement. The cams slide inside the body and along the side of the holder, securing the tool or freeing it from compressive forces.

During the drilling process, the chuck shank rotates in its body in a clockwise direction. Thus, a tightening force is applied to the screw, which increases the fixing force of the tool. When changing a tool, the holder rotates counterclockwise using a key, thereby opening the jaws.

Purpose of these cartridges

Drill chucks are divided into several types. They come with a mechanical clamp or self-clamping, in addition, they differ depending on the cutting device being fixed:

- A drill chuck with a cone is divided into several types: B16, B18, B24, B32, etc. And if it is necessary to interact the cone with the spindle (first it must fit exactly to the inner hole of the latter), this chuck is already combined with it. In addition, some self-clamping drill chucks with a cone in the tail were specially produced for precise connections.

- A self-clamping drill chuck is a very precise device that can spontaneously clamp a cutting device with a cone-shaped shank. These chucks are also used on numerically controlled machines, as well as on jig boring and vertical drilling machines.

- Chucks that interact with core drills. They are used to secure core drills. Compared to spiral ones, these drill holes of large diameter in a very short time. The process is not only fast, but also very accurate.

Possible applications

Drill chucks are used to fix metal-cutting tools with a shank with a diameter of up to 20 mm. The design and variety of equipment options allows it to be used for a number of technological operations:

- Drilling holes in parts. It is possible to cut both through holes and blind holes to the required length.

- Drilling pre-drilled holes to a larger diameter.

- Reducing the roughness of the inner surface of a hole by countersinking.

- Reaming conical and cylindrical holes.

- Preparation of chamfers and recesses for washers and countersunk heads by countersinking.

- Rolling out holes using a mandrel and hardened rolling elements (balls and rollers) to obtain a dense and smooth surface with low roughness.

- Cutting threads with a tap to the entire depth or part of it.

- Trimming the ends to obtain a flat surface at right angles to the axis of the hole.

Flaring of hollow rivets and many other metal-cutting operations are also possible.

Features and description of the 16 mm cartridge

Let’s take a separate look at the 16 mm quick-release drill chuck. It is specially designed for high-precision machines operating at high speeds. The inner cone of this cartridge has a diameter of 16 mm.

Its peculiarity is that, thanks to additional mandrels designed for placement on drill chucks, it makes it possible to install a chuck with a cone inside on a chuck with a cone outside.

Conventional and quick-release drill chucks according to GOST

The parameters and dimensions of the structure are specified in GOST 8522-79, GOST 14077-83, GOST 15935-88 and other standards, but in modern technology other modifications are used - on imported screwdrivers, drills, hammer drills and industrial equipment. Most often these are quick-release chucks with a metal or plastic body, some have a ratcheting mechanism to automatically tighten the tool as it is twisted.

Options for fixing the keyless chuck on the spindle of a drill, screwdriver or machine tool

Regular and shortened Morse taper. For installation, mandrels with external CM for lathes and drilling machines, mandrels with a cylindrical shank, recesses for fixation, slots, and a threaded connection are used. Threaded connection. The chuck is screwed onto an adapter, which is inserted into the spindle and secured. In most models, the housing is additionally secured with a screw with a left-hand thread, which prevents loosening. The screw is tightened through a cam clamp on the shank side.

- Regular and shortened Morse taper. For installation, mandrels with external CM for lathes and drilling machines, mandrels with a cylindrical shank, recesses for fixation, slots, and a threaded connection are used.

- Threaded connection. The chuck is screwed onto an adapter, which is inserted into the spindle and secured. In most models, the housing is additionally secured with a screw with a left-hand thread, which prevents loosening. The screw is tightened through a cam clamp on the shank side.

Keyless chuck with threaded connection and screw fixation and conversion to SDS-plus

Our catalog contains models with inch thread 1/2″-20 UNF, B16 cone, and adapter to SDS-Plus. If the machine has a spindle of a different design, additional mandrels and adapters are used. For example, when drilling with a magnetic machine with a chuck for Weldon shanks, you can select an adapter from a thread or Morse taper to a cylindrical one with a slot and quickly install the drill chuck without removing the standard one.

For what purposes are cartridges used?

Drill chucks are intended for clamping and fastening asymmetrical complex workpieces of cylindrical and non-cylindrical shape. In this case, self-centering chucks are distinguished for parts that have an axisymmetric shape, as well as chucks with independent jaws for asymmetrical ones.

Collet drills are used for fastening small-diameter drills with a cylinder-shaped shank.

Adapter cone-shaped bushings are used to secure a device with a cone-shaped shank if the cone number of the device shank does not correspond to the cone number in the spindle of the unit.

Quick-change – used to instantly change the cutting mechanism during processing, this reduces time and increases productivity when making holes.

Self-aligning - used in the manufacture of pre-made holes, they provide the ability to center the unit along the axis of the turning hole.

General operating rules

To ensure accuracy when performing work, durability of equipment, tools and equipment, it is recommended to follow the rules of safe operation:

- Select the chuck based on the minimum and maximum diameter of the tool shank.

- When choosing a chuck, take into account its design, pay special attention to the methods of connection to the spindle (cone number) and fixation of the tool.

- Use a variety of adapter bushings to secure the chuck and tools. When installing, make sure the surface of the cone is clean.

- Before drilling, mark the center of the future hole with a core.

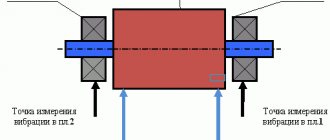

- When selecting a drill, take into account the vibration of the chuck, which increases the resulting diameter by 0.05 - 0.3 mm. For high-precision drilling, use precision chucks.

- Use vices, prisms and other clamps for workpieces.

- Use coolant to cool the tool and extend its life.

- When drilling large diameter holes, use a smaller tool and then drill out.