Reinforced concrete structures in construction are the strongest, which is why they are used in the construction of house foundations, load-bearing beams and floor slabs, bridges, columns and other critical objects. Without reinforcement, concrete poorly resists tensile and bending loads, which cause its destruction. This problem is solved simply - they “stuff” the concrete with steel rods, which serve as a rigid frame in its body. The reinforcement, the weight of which is necessary for design calculations and determining the required amount of material, can have different shapes and cross-sectional diameters.

Samples of reinforcement of different diameters Source permglavsnab.ru

Why and how to determine the weight of reinforcement

Most private developers wondered how much 12 mm reinforcement weighs per meter - it is what is most often used for pouring foundations, monolithic basement walls, and armored belts. The answer to this helps solve at least two problems.

- Determination of the carrying capacity of the vehicle required to deliver materials to the construction site.

Not all developers use delivery services, and not all small sellers provide such a service. If you don’t need so many rods, it’s cheaper to pick them up yourself, but you need to know whether the load will be excessive for the car. Since the standard length of the reinforcement is 6 or 12 meters, many people cut it in half right on the spot and transport it on a trunk or in a trailer. Or they select short rods from unmeasured lots.

The number of short rods in unmeasured batches can reach 7% Source prom.st

See also: Catalog of companies that specialize in the design and installation of metal structures (canopies, greenhouses, etc.)

- Determination of reinforcement footage in ton.

Large volumes of rolled metal are sold using not meters or pieces as a unit of measurement for calculations, but a ton. If you know how many linear meters of reinforcing bars are contained in one ton, it will not be difficult to calculate the weight required for ordering and purchasing.

In theory, knowing the diameter of the required products and the density of the steel alloy from which they are made, you can independently calculate their weight. But in practice, such calculations will have a large error, since the reinforcement bars do not have a constant cross-section, but a periodic one, with longitudinal and transverse stiffeners. And they have two diameters - minimum and maximum.

Reinforcement cross-section - drawing Source ugmk.com

But there is no need to do this. A table compiled on the basis of GOST 5781-82 will help you find out how much the reinforcement weighs. This document regulates all parameters of these metal products. Their mass depends primarily on their diameter.

- The thinnest rods have a diameter of 6 mm and the weight of one linear meter is slightly more than 220 grams.

- The thickest 80 mm reinforcement is much heavier - more than 39 kg per linear meter.

The larger the diameter and denser the reinforcement pattern, the more important it is to know how much a meter of reinforcement weighs. The mass of the metal frame must be taken into account when calculating the load on the base, and an error can lead to unpredictable consequences.

If you don't have a table at hand

Not everyone has the necessary GOST, but each of us studied at school. To independently calculate the weight of a linear meter, basic knowledge of mathematics and physics is sufficient. Everyone knows that mass is equal to the volume of a body multiplied by the specific gravity of the material. The volume is calculated using the formula:

V = F x L, where

- V – body volume, m3

- F – its cross-sectional area, m2

- L – body length, m

The cross section of the reinforcement is a circle. Its area is easy to calculate, knowing the diameter of the rod:

F = 3.14 x D2/ 4 = 0.785 x D2, where

- D – reinforcement diameter (in meters)

- 3.14 – the well-known constant value π (it is dimensionless)

As you can see, calculating the cross-sectional area and volume of the rod is not difficult. Now you can calculate the weight of a linear meter. This is also done simply, using the formula:

M = V xp, where

- p – specific gravity of steel. It is equal to 7850 kg/m3.

There is some inaccuracy in these calculations: the reinforcement is not a smooth rod, and we do not take into account the dimensions of the corrugations. But if you calculate the weight of a meter rod in this way and compare it with the tabular data, you will see that your result is not much different from them.

Calculation examples

As examples, let us consider calculating the weight of a linear meter of reinforcement with the most common diameters of 6 mm and 12 mm of class A III. This material has a periodic profile (longitudinal ribs and transverse protrusions are applied to its forming surface). Special steel is used to manufacture A3 reinforcement. Thanks to the complex surface, metal and concrete form a single monolith.

Reinforcement with a diameter of 6 and 12 mm is used in the construction of dachas, private houses - for reinforcing strip foundations.

- Let's calculate the weight of a linear meter of reinforcement A3 with a diameter of 6 mm: Sectional area F = 3.14 x 0.006 x 0.006/ 4 = 0.000028 m2

- Volume per linear meter V = 0.000028 m2 x 1m = 0.000028 m3

- Weight M = 0.000028 m3 x 7850 kg/m3 = 0.221 kg

- Let's calculate the weight of a linear meter of reinforcement with a diameter of 12 mm: Sectional area F = 3.14 x 0.012 x 0.012/ 4 = 0.000113 m2

- Volume per linear meter V = 0.000113 m2 x 1 m = 0.000113 m3

- Weight M = 0.000113 m3 x 7850 kg/m3 = 0.887 kg

According to the GOST table, weight is 1 linear. m of reinforcement 6 is 0.222 kg, reinforcement 12 is 0.888 kg. As you can see, the discrepancy in numbers is small. It must be admitted, however, that the data presented in the table also does not claim to be highly accurate. They were also calculated theoretically.

In fact, the actual weight of a linear meter may differ from the table by 0.2 - 3%, both plus and minus.

Weight table

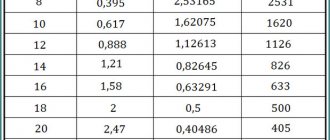

In accordance with the current standard, reinforcement of classes A240, A400 and A500C is used in construction. All weight values in 1 linear meter, in a rod 11.75 m long and in 1 ton of timber are summarized in the table. The error is acceptable, but insignificant, no more than a few percent.

Summary table for all diameters Source vezetnerud.ru

How to use the table

The table shows:

- Reinforcement diameter

- Sectional area of the rod

- Weight of one linear meter

- Steel grade

First, in the “diameter of reinforcement” column, you find the product with which you are going to reinforce the structure, then, moving along the horizontal line of the table, you look for the weight of a linear meter.

Table - weight per linear meter of reinforcement

Examples of calculations

To find out how much 1 meter of 12 mm reinforcement weighs, just find this diameter in the first column. The following gives the mass of 1 l.m. – 888 grams. And there are only 1126 meters in a ton, or, if you divide this value by the length of the rod, almost 96 pieces.

The design documentation may only indicate the diameter and weight of the reinforcement without indicating the footage. When purchasing individually, you will have to calculate how many pieces you need. For example, you need to buy 1.5 tons of 16 mm reinforcement to install a strip foundation.

- We find from the table how much 1 meter of reinforcement weighs - it is 1.58 kg.

- We convert 1.5 tons into kilograms, multiplying by 1000 - 1500 kg.

- Divide 1500 by 1.58 and we have 950 m.

- Or divide 1500 by 18.56 (the weight of one bar) and get 81 pieces.

These simple calculations will allow you not only to avoid making mistakes when purchasing, but also to check the amount of material delivered to the site.

When you need to find out how much a certain number of rods will weigh, do the opposite: multiply the weight of the rods of the required diameter by their number or footage. For example, you need to buy 30 rods, the thickness of the reinforcement is 20 mm. With a mass of one rod of 29 kg, the total weight will be 30 x 29 = 870 kg.

How much do reinforcing bars weigh?

Reinforcement is metal rods that are used to strengthen concrete monolithic structures. The construction of the frame requires an accurate calculation of the quantity and mass of the required material already at the stage of drawing up project documentation in order to accurately determine the cost of the upcoming construction.

Determination of basic quantities

Specific gravity is the mass of 1 linear meter of iron wire. Weighing is the easiest way to determine. The procedure is carried out on industrial scales, because special equipment does not exist. For weighing, select a metal rod and measure its length. Then the value indicated on the scales is divided by the length and the weight of a meter of reinforcement of a given diameter is obtained.

The second method is more complicated; it is used if suitable scales are not available. First, measure the diameter (D) of the rod. Then the cross-sectional value is calculated using the formula: S=3.14*D/2*D/2. The resulting value is multiplied by the steel density of 7850 kg/m3. This is precisely the value fixed by GOST for construction calculations. As a result of the calculations, the desired specific gravity is obtained.

The parameters used in the calculations must be reduced to common units of mass measurements, which are specified in GOST standards:

- kilograms (kg);

- meters (m).

All of the above calculations apply to a smooth type of surface that has a regular round cut. For products with a grooved profile, it is necessary to measure one diameter along the protrusions, the second - between them, and then find the average value.

The results of calculations carried out independently often differ from the data in the tables. If the deviations are insignificant for smooth wire, then for corrugated rods the error can be much greater. This is explained by the fact that the calculations are greatly simplified. The weight of the reinforcement given in the standards was calculated taking into account the specifics of the corrugation (size, pitch, longitudinal edge).

Calculation according to standards

The first step is always the preparation of project documentation. Experts determine the required pattern, as well as the diameter. In private construction, as a rule, wire with a cross section of 12 and 14 mm is used. Next, materials are purchased based on design calculations. Keep in mind that wire is measured in linear meters and sold by weight.

The mass of steel for purchase is determined by multiplying the total length of the circuit by the weight of 1 linear meter of reinforcement. The rods are sold in coils, so it is possible to cut the rods to the required length immediately upon purchase.

How much does reinforcement of different diameters weigh?

The standard ratio of mass and diameter is regulated by GOST 5781-82.

| Diameter, mm | Number of meters in 1 ton | Weight per meter, kg |

| 6 | 4504,5 | 0,222 |

| 8 | 2531,65 | 0,395 |

| 10 | 1620,75 | 0,617 |

| 12 | 1126,13 | 0,888 |

| 14 | 826,45 | 1,21 |

| 16 | 632,91 | 1,58 |

| 18 | 500,00 | 2 |

| 20 | 404,86 | 2,47 |

| 22 | 335,57 | 2,98 |

| 25 | 259,74 | 3,85 |

| 28 | 207,04 | 4,83 |

| 32 | 158,48 | 6,31 |

| 36 | 125,16 | 7,99 |

| 40 | 101,32 | 9,87 |

| 45 | 80,13 | 12,48 |

| 50 | 64,89 | 15,41 |

| 55 | 53,62 | 18,65 |

| 60 | 45,07 | 22,19 |

| 70 | 33,1 | 30,21 |

| 80 | 25,34 | 39,46 |

Using the table data is very simple: first find the size in the first column, and then find how much 1 linear meter weighs.

Online stores often post special calculators. You need to enter the diameter in a special window, and all the required values will be calculated automatically.

Author: Valentin Tokarev

| Related articles: | |

| Reinforcing bars brand A-240 Wire for bundling reinforcing bars Diameter of reinforcing bars for foundation strip | |

Weight of composite reinforcement

Nowadays, fiberglass reinforcement bars are increasingly being used instead of steel reinforcing bars. They have a lot of advantages, including light weight. In addition, fiberglass has better tensile strength than steel, which allows the use of products with a smaller diameter. For example, an 8 mm composite rod is equivalent in its physical and mechanical characteristics to a 12 mm steel rod. Accordingly, the load decreases even more noticeably.

Table for determining the equivalent diameters of steel and composite reinforcement Source luxkompozit.ru

Compare how much a meter of 12 mm steel alloy reinforcement weighs (890 g) and a meter of fiberglass rod with a diameter of 8 mm (110 g). The difference is 8 times.

Why do you need to know the footage of reinforcement?

During construction, it is necessary to have an accurate idea of how much weight the entire reinforced structure has as a whole. There are a number of reasons for this:

- This makes it possible to withstand reinforcement technology.

- Guarantees the necessary reliability of the structure.

- It is more convenient to calculate the total cost of the structure.

The greatest attention is paid to a rod with a diameter of 12 mm, because this is the minimum diameter that can be used when creating structures for strip foundations. And of course, we should not forget about the significant factor that during construction, it is very important to know exactly how many meters of reinforcement will be required for one ton of planned products.

Briefly about the main thing

When starting construction and ordering materials for it, it is important to be able to calculate them correctly and control delivery, without allowing suppliers to deceive you. To do this, you need to know how many kilograms of cement are in a bag, how many boards are in a cubic meter, how many kg are in 1 meter of reinforcement with a diameter of 12 mm. Such knowledge can be very helpful in calculating loads on building structures and in solving transportation issues. In the case of fittings, everything is simple - you just need to look at the table and find the necessary data in it.

Class A500S fittings: GOST

To produce high-quality fittings of class A500C, it is necessary to choose the right raw materials and strictly follow the manufacturing technology. The regulatory document for A500S valves is GOST 52544 2006 with requirements for the production process: from the purchase and quality control of raw materials to the delivery of finished products to customers.

Production

According to the 4th part of GOST 52544, for rolling steel in the production of A500C reinforcement, we use the hot-rolled method, which is necessary for the production of thicker and stronger rods. At the time of production, a minimum amount of alloying elements is added to the raw materials, which significantly reduces the price of the finished product.

Marking

The marking of any fittings is a technical passport of the product, which informs about the main properties and characteristics of the raw materials and the finished product. A500C reinforcement stands for thermomechanically processed, high-flow material suitable for welding, where:

- “A” – thermal and mechanical manufacturing method;

- 500 – ultimate fluidity of molten raw materials;

- “C” – possibility of welding elements.

The nominal weight of a linear meter, diameter and cross-sectional area of the rod must correspond to the figures given in GOST in the table of norms for reinforcing bars.

Molding for delivery to the consumer

A500C fittings are supplied to customers in two types:

- Formed into skeins: typical for a rod up to 6 mm in diameter;

- They are cut into bars of the length required by the customer. For rods from 12 mm.

According to GOST, the maximum permissible curvature of reinforcing bars is 0.6% of the length.

Performance characteristics

The operational characteristics of A500C fittings include the following features:

- Increased plasticity: ensured by the low concentration of carbon compounds in the raw material.

- High weldability of metal rods to each other.

- Long service life.

Bend radius of A500C reinforcement

The bending radius is the most important point of instructions when using reinforcement in construction. It depends on the cross-section of the reinforcement and its classification. For reinforcement marked A500C, the bend radius is equal to 2.5 rod diameters, and the bend angle cannot exceed 180 degrees.

According to GOST, finished fittings must be checked for quality using one of two methods:

- One-time bend on the mandrel up to 180° in a cold state;

- Bend up to 90° and then bend at an angle of 20°.

The service life of the concrete product will depend on whether the conditions for the bend radius of the A500C reinforcement are met, because the bent rod becomes weaker.

Correct reinforcement

Concrete reinforcement is usually carried out using steel bars with a diameter of 8 to 14 mm, although its thickness depends on the overall thickness of the products. The vertical and transverse gratings serve more for bonding than for structural strength.

The main load in problem cases falls on the longitudinal rods, which must be made of ribbed rods.

The prepared mesh with a cell size of 20 or 30 centimeters is placed in the place of pouring into the formwork frame. Typically, two layers of mesh are used, which should fill the entire concreting space, and especially problem areas - the corners of the structure.

The upper and lower gratings are connected to each other with ordinary wire using metal rods. The mesh must be deep in the concrete and not on the surface. The layer of solution above or below the mesh should not be less than 20 mm. This will protect the metal from rapid corrosion and extend the service life of reinforced concrete.