Liquid level sensors in the tank allow you to both perform a current measurement of the amount of liquid filled and report when its limit values have been reached. Such devices consist of a sensitive sensor that responds to certain physical parameters, and a measurement, control and indication circuit. Depending on the area of application, devices are used that differ in their operating principles.

The information presented in the article will help you learn about the operating principles of different types of sensors and their areas of application. A brief overview of their advantages and disadvantages will be carried out, and the main manufacturers that have proven themselves on the market will be indicated.

Classification of devices

Liquid level sensors in a tank can be level meters or alarms. The first of them are designed to continuously measure the liquid level at the current time. They use sensors that operate on different physical principles. Further processing of the signals coming from them is carried out by analog or digital electronic circuits that are part of the level gauges. The obtained indicators are displayed on the display elements.

Alarms warn when a certain value of the liquid level in the container, preset by the setting elements, has been reached. Another name for them is water level sensors in the tank to shut off its further supply. Their output signal is discrete. The warning may be provided in the form of a light or sound alarm. In this case, the operation of the filling or draining systems is automatically blocked.

Popular models

The modern market offers many models of alarms . The most popular of them:

- DE-1 (capacitive sensor). Most often, this alarm is used in aggressive environments in the chemical and metallurgical industries. It allows you to control the temperature and level of bulk and liquid substances. Often used in emergency protection installations.

- ESU-1 (electronic level switch). The body of this model is made of high quality steel and fluoroplastic. Most often, ESU-1 is installed in explosive and aggressive environments. The power source is located outside the process environment. The sensor measures the level of oil, alcohol and water. The power supply is made of durable aluminum alloy.

- RU-305 (level relay). This device is designed to monitor the condition of liquid media. Its body is made of special material and can easily withstand temperatures from -50 to +50 degrees Celsius. However, RU-305 must not be used in aggressive chemical environments. Among the disadvantages of this level gauge, consumers note only that it works only in one position, without tilt. Level measurement is carried out by moving a magnet with a float and triggering a reed switch. Measurements have an accuracy of no more than 5 mm.

- SU-100 (level alarm). Sensor for measuring the level of bulk and liquid substances. The SU-100 design contains an electromagnetic relay.

- Rosemount 5600 This radar level sensor allows non-contact measurement of any type of substance. To achieve the most accurate readings, the level gauge must be installed correctly. The device's reading accuracy may be degraded by exposure to electromagnetic radiation. The housing has an explosion-proof design and a display that displays all the necessary information. The Rosemount 5600 can be used to measure tank temperatures. To fully evaluate the capabilities of this equipment, it requires qualified adjustment taking into account the diameter of the pipeline, the length of the level gauge and the distance between the level and the reference point.

It is advisable to purchase complex models only for industrial use. The simplest versions of level meters are suitable for domestic purposes.

Level measurement methods

Depending on the properties of the liquid whose level in the tank needs to be determined, the following measurement methods are used:

- contact, in which there is direct interaction of the liquid level sensor in the tank or its part with the measured medium;

- non-contact, allowing to avoid direct interaction of the sensor with the liquid (due to its aggressive properties or high viscosity).

Contact devices are located in a container directly on the surface of the liquid being measured (floats), in its depth (hydrostatic pressure gauges), or on the tank wall at a certain height (plate capacitors). For non-contact meters (radar, ultrasonic), it is necessary to provide a zone of direct visibility of the surface of the liquid being measured and the absence of direct contact with it.

Inexpensive industrial devices

There are also inexpensive models of liquid level control sensors, which can be purchased in stores for about 2 thousand rubles

Various modifications of ARS

Such float sensors are usually used in reservoirs. The measuring head in devices of this type is small, which makes the device compact. The load capacity, according to the operating instructions, can reach 1 ampere. The wire entry into the devices is sealed. The body is made of plastic. The operating differential is 45 degrees. The maximum pressure for correct operation of devices is 3 bar. The cost is about 2 thousand rubles, depending on the modification.

“Crystal” container filling control devices

These float type sensors can be used in harsh environments. Very compact. The measuring head is 2.3 centimeters in diameter. The maximum pressure for correct operation reaches 3.3 bar. The wire input is made in the form of a plastic seal. The devices are equipped with a spark protection barrier. Can work in hot environments. The price is slightly higher than 2 thousand rubles, depending on the modification.

Burkle devices

These devices are designed for contaminated environments, but can also be used in clean ponds and clean water tanks. The maximum pressure for correct operation is 4.1 bar. The maximum possible load is 1A. It is possible to work in environments heated to 170 degrees, in liquids with a density of up to 3 kg per square meter. cm. The average price of the device is 2,200 rubles and depends on minor modifications made by the manufacturer.

Fine Tek and Wilo sensors

These float type devices can be used in harsh environments. They are used for drainage purposes and can also be installed in wells. The sensors can withstand loads up to 2 amperes. The measuring heads are compact and measure 2.5 cm. The wire inputs are made in a specialized seal. The cases are made of heat-resistant plastic. The devices are equipped with fuel probes, which allows their use in flammable environments. The price ranges from 2 thousand to 2500 rubles and also depends on the modification.

Wilo float-type devices are the cheapest, but are not functionally designed for aggressive environments and can only be used in clean water. The sensors have small measuring heads and are compact in appearance. The maximum temperature of use is 140 degrees. The operating differential is only 30 degrees. The maximum operating pressure does not exceed 2 bar. The price of such sensors fluctuates around 1900 rubles.

Operating principles

Both level gauges and alarms use different operating principles to perform their functions. The most common types of devices are:

- float sensors for liquid level in the tank;

- capacitive;

- hydrostatic liquid level sensors;

- radar type devices;

- ultrasonic sensors.

Float valves, in turn, can be mechanical, discrete and magnetostrictive. The first three groups of sensors include devices using the contact measurement method, the other two belong to non-contact devices.

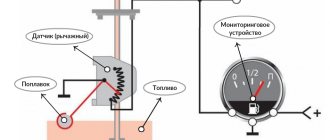

Mechanical float sensors

A light float, constantly located on the surface of the liquid in the tank, is connected by a system of mechanical levers to the middle terminal of the potentiometer, which is the arm of the resistance bridge. With a minimum amount of liquid in the container, the bridge is considered balanced. There is no voltage in its measuring diagonal.

As the reservoir fills, the float monitors the position of the liquid level by moving the movable contact of the potentiometer through a system of levers. Changing the resistance of the potentiometer leads to an imbalance in the bridge. The voltage that appears in its measuring diagonal is used by the electronic circuit of the display system. Its analog or digital readings correspond to the amount of liquid in the tank at the current time.

Selection rules

Selecting a level gauge for tanks must take into account a large number of factors. Among them:

- water composition;

- the volume of the container and the material that was used to make it;

- the need to control the maximum and minimum liquid levels or monitor the actual condition;

- the possibility of introducing automatic control into the system;

- switching capabilities of the device.

To select household devices, it is important to consider the capacity volume, control circuit and operating principle.

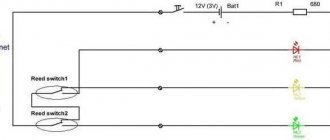

Discrete float sensors

A discrete signal in the form of closing or opening the reed relay contacts is used by the electronic indication and signaling circuit to notify that the liquid level in the container has reached a certain value. Metal contacts, made of a material with low contact resistance when they are closed, are placed in a hollow, insulated glass bulb.

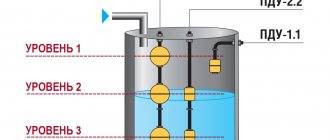

A water level sensor in a tank with a discrete output includes a guide in the form of a hollow tube into which liquid from the tank does not enter. The contacts of one or more reed relays are fixed inside the guide. Their location depends on the case in which it is necessary to receive an alarm when the liquid level reaches a given value.

The sensor float with a small permanent magnet built into it moves along the guide when the liquid level in the container changes. The contact group is triggered when it enters the magnetic field of the permanent magnet of the float. The signal through the wires connected to the contacts of the water level sensor in the reed switch tank is sent to the alarm circuit.

Types of sensors

All level gauges are classified according to the principle of their operation. Main types of measuring devices:

- Float _ This is the simplest option for measuring the water level in the tank. The design of the float level gauge includes 2 reed switches, a magnet and a float. As the fluid level increases, the float rises to the first reed switch, which turns off the motor relay. If the reservoir is empty, the float drops to the second reed switch, which triggers the relay and turns on the pump that pumps liquid from the well. You can make a reed limit liquid level sensor with your own hands. Moreover, it will work even if there is a voluminous layer of foam in the tank.

- Ultrasonic . This type of measuring device is used for both dry and liquid media. Ultrasonic sensors can have a discrete or analog output. That is, the device can constantly monitor the water level or limit the filling of the container when it reaches a specific point. Such a level gauge consists of a receiver, an ultrasonic emitter and a controller responsible for signal processing. Ultrasonic type alarms are wireless and non-contact, so they can be installed even in explosive and corrosive liquids.

- Electrode (conductometric). Such level meters are not suitable for containers with distilled water. The standard design is equipped with a three-level alarm, in which the filling of the tank is controlled by a pair of electrodes, and the third is intended for emergency situations, to start the active pumping mode.

- Capacitive . Using such level gauges, the maximum filling level of a tank can be accurately identified. They are suitable for both liquids and bulk substances. Capacitive level gauges operate on the same principle as capacitors: the measurement is performed between the plates of the sensing element. When the peak value is reached, a corresponding signal is sent to the controller. Sometimes capacitive alarms operate on the “dry contact” principle, in which the device is triggered through the wall of the tank. These devices can operate effectively over a very wide temperature range and their operation is not affected by electromagnetic radiation. Such performance properties expand the scope of use of capacitive level meters.

- Radar . This type of alarm is universal, as it works with any type of process media, including explosive and corrosive liquids. In this case, the readings will not change under the influence of temperature and pressure. The device emits radio waves in a certain frequency range. The receiver picks up the reflected radio signal and determines how full the tank is, based on the signal delay period. The measuring sensor is not affected by temperature and pressure. The dustiness of the process environment also does not affect the readings. Experts note that radar devices have maximum accuracy, since their error does not exceed 1 mm.

- Hydrostatic . This type of alarm allows you to measure both the current and maximum filling of containers. The operating principle of a hydrostatic device is based on measuring the pressure of a liquid column. The popularity of such sensors is due to their low price and sufficient accuracy.

There are other types of devices, but they have specific purposes.

Magnetostrictive float sensors

Sensors of this type produce a constant signal depending on the level of liquid in the tank. The main element, as in the previous case, is a float with a permanent magnet inside, which takes its position on the surface of the liquid and moves in a vertical plane along the guide.

The inner cavity of the guide, isolated from the liquid, is occupied by a waveguide. It is made of magnetostrictive material. At the bottom of the element there is a source of current pulses that propagate along it.

When the emitted pulse reaches the location of the float with the magnet, the interaction of two magnetic fields occurs. The result of this interaction is the occurrence of mechanical vibrations that propagate back along the waveguide.

A piezoelectric element is attached next to the pulse generator, which records mechanical vibrations. An external electronic circuit analyzes the time delay between the emitted and received pulses and calculates the distance to the float, which is constantly located on the surface of the liquid. The display circuit constantly reports the liquid level in the tank.

Contactless water sensor Y25 T12V, or Stop making holes in barrels

I have published many reviews about dacha automation, many of which involved manipulation of water. Often you need to find out the fluid level, or the fact that it is missing. It is convenient to use such information in your crafts aimed at getting rid of routine procedures. To find out the level, many people, including me, use float sensors on reed switches, the main problem when using them is the need to make holes in the container; you must agree, this does not add reliability and versatility to the use of the container, and drilling with subsequent sealing is not the most pleasant manipulation . The device under review (which went on sale recently) is designed to get rid of this, ensuring scalability and configurability of the system... Let's see what kind of beast is under the cut. The sensors arrived in 14 days and were packaged quite well. The sensors themselves in bags:

Unpacking: The length of the lace is about 45 cm:

Dimensions:

At my dacha I have a homemade adjustable power supply built into the wall, let’s connect the power, 12 Volts:

We bring it to a bottle of water, the indicator lights up:

If you raise it above the water level, the indicator goes out:

By the way, if you lean your hand, the indicator also lights up:

Let's connect the multimeter to the power cables and make sure it's working.

Next: minus to ground, and plus to signal output:

We bring it to the bottle and see the supply voltage at the output:

If you remove the sensor, the voltage at the signal output disappears:

The output current of the sensor is in the range of 1-50 mA. The seller states that it works with a power supply in the range of 5-24 Volts, let's try to reduce the supply voltage to 4 Volts: The sensor works fine, let's try to reduce it to 3 Volts:

The reliable operation of the sensors allows us to conclude that it can be successfully used with the esp8266 without any conversions - and this is great news! At other voltages, the sensor also works well:

I did not dare to go beyond 24 Volts. Let's set it to 5 Volts:

The sensor reacts to its bag:

The side of the bottle cap also reacts:

Glue it to the bottle with 3M double-sided tape:

The sensor responds perfectly. With two layers of tape, the sensor does not always work:

Consumption is about 5-6 mA:

And of course, we’ll try to apply it in real conditions, working with a controller. Let's take an Arduino Nano as a controller, and also add an indicator LED, so we get the following kit:

We will connect the LED to pin D3 and ground, and the signal output of the sensor to pin A0 (D14 - since we will use it in digital mode), and we will also supply power to the sensor from the controller:

Considering that the sensor is designed for water, when working with it it is very important to protect yourself from contact chatter, for example during waves when the pump is running. Also, I will show how to organize such protection without using delays in the program, the actual code: // Current state of the sensor bool SensorState = false; // Shift start time unsigned long SensorStartChange = 0; // Guard interval between state changes unsigned long TIMEOUT = 3000; // Current time unsigned long CurrentTime = 0; void setup() { // LED is an output pinMode(LED_PIN, OUTPUT); // Don't turn on the light at first digitalWrite(LED_PIN, LOW); // The sensor is an input pinMode(SENS_PIN, INPUT); } void loop() { // Set the current time CurrentTime = millis(); // read the sensor boolean CurrentState = digitalRead(SENS_PIN); // if the current state of the sensor differs by the amount read if (CurrentState != SensorState) { // if the state change timer has not started, start if (SensorStartChange == 0) SensorStartChange = CurrentTime; // if the new state took on its value in a time greater than the timeout time if (CurrentTime - SensorStartChange > TIMEOUT) { // change the sensor state SensorState=!SensorState; // reset the start time of the state change SensorStartChange = 0; // if the current sensor state is 1, then turn on the LED if(SensorState){ digitalWrite(LED_PIN, HIGH); // if the current state of the sensor is 0, then turn off the LED }else{ digitalWrite(LED_PIN, LOW); } } // the state change did not take place, reset the timer }else{ SensorStartChange = 0; } } I commented out all the lines to make everything clear. We initialize the outputs and check the change in the state of the signal output of the sensor with contact bounce protection. In this code, the guard interval is 3000 ms = 3 seconds, often it is advisable to increase this interval to a minute to eliminate the influence of waves from the pump. The code is simple, but on its basis it is easy, for example, to organize protection against dry running of the pump (it is very undesirable for most pumps to operate without water), such devices cost an unreasonable amount of money, but here you can get by with little expense, and even implement automatic recovery of the pump when water and a number of other pleasant goodies - such as indication. To do this, you need to glue such a sensor or somehow secure it closer to the bottom of the container, and connect the pump through a relay controlled by the controller. By default, the pump will be turned on; as soon as the sensor recognizes the lack of water, the controller will turn off the pump, and when water appears, it will turn it on. It is also possible to organize protection against leaks on this sensor, especially considering its moisture resistance; in general, everyone can adapt this simple code to their needs. And most importantly, the sensors can be moved around the container without damaging it - by adjusting the levels to suit you. Video illustrating the operation of the sensor and controller with the specified code:

I put together this layout for testing different capacities:

I walked around the dacha plot with the model, and the sensor was able to detect water in all non-metallic containers, including a rather thick-walled bucket. Therefore, at the current stage I can fully recommend it; time will tell about its reliability.

The sensor response time is about 500 ms. The wall thickness of a dielectric vessel can reach 1 cm.

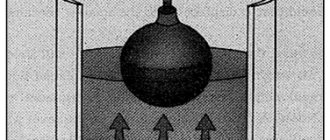

The principle of operation of the sensor is to change the capacitance from the parasitic capacitance of water; at a certain threshold, resonance occurs and the sensor is triggered. Supply voltage in the range from 3 to 24 Volts does not affect sensitivity in any way.

They asked to check the sensitivity, so this illustration is better than any words:

It will work great as a leak sensor.

Various photos upon request

There’s no way with this at all - left-handed alcohol:

fairy:

thick canister 40 liters:

distilled water:

strong alcohol:

cooler bottle at its thickest point:

white spirit - no:

Through the ceramic toilet tank it is easy to find water:

I opened the lid, the inside was filled with compound, but there was a potentiometer output; after twisting it to the right, the sensor stopped responding to water; after twisting it to the left, it began to respond to lateral finger touches, it looks like this is adjusting the sensitivity.

If there is interest, I will continue to write about my country crafts. Thanks to everyone who read this review to the end, I hope someone finds this information useful. Full control over your water resources and goodness to everyone!

Capacitive sensors

The operation of sensors of this type is based on the properties of a capacitor to change its electrical capacitance when the dielectric constant of the material filling the space between its plates changes. Coaxial type capacitors are used, which are a pair of coaxial hollow metal cylinders of different diameters.

The latter are the plates of the capacitor, between which liquid can freely penetrate. The dielectric constants of air and liquid media have different values. Filling the reservoir leads to a change in the value of the total dielectric constant of the coaxial capacitor and, accordingly, its electrical capacitance.

The frequency of the oscillatory circuit, in the circuit of which the capacitor is connected, changes in proportion to the change in its capacitance. An electronic frequency/voltage converter monitors this change and displays a value proportional to the degree of filling of the tank.

Capacitive-frequency level switches Baumer CleverLevel

The electrode inside the tip and the sensor body form a capacitor. The material being measured has its own dielectric constant, on which the capacitance value depends. Baumer CleverLevel sensors measure the electrical capacitance between the probe and the wall of the container, in addition, together with the coil located in the contact part, a resonant circuit is formed. As soon as the measured resonant frequency reaches the set response threshold, the sensor output signal switches. INNOLevel alarms are rotary level sensors and are used to monitor the level of bulk products. They work perfectly as full, empty or intermediate level sensors.

Hydrostatic sensors

Another name for such a device is a detector, or pressure transducer. They can be stationary, fixed at the bottom of the container filled with liquid, or portable. In the latter case, the pressure transducers are equipped with a cable of considerable length. This allows them to be used for tanks of different geometric sizes.

The sensing element of a hydrostatic sensor is a membrane that senses the pressure of a liquid column above it. It is configured in such a way that atmospheric pressure does not lead to deformation of the membrane. Based on the pressure at the measurement point, you can determine the height of the liquid column or the degree of filling of the tank.

The amount of membrane deformation is converted into a proportional electrical indicator, which is then used to display the level of liquid in the reservoir. Corrections are applied that take into account the density of the measured medium and the acceleration of gravity at the measurement point.

Advantages of hydrostatic level gauges:

- Possibility of examining hard-to-reach places: pipes, wells, etc.

- Large measuring range.

- With additional sensors, continuous recording of several parameters of the aquatic environment (temperature, density, etc.) is possible.

- No need for complex maintenance.

- Relatively high accuracy and average price segment.

The error of hydrostatic level gauges mainly depends on the parameters of the medium being measured: its density, atmospheric pressure in the container, etc.

Radar type sensors

The container liquid level sensor uses a non-contact measurement method based on the properties of this medium of any density and viscosity to reflect an electrical signal. The frequency of the emitted signal from a radar located above the surface of the measured liquid level changes according to a linear law.

Reflected from the surface, it arrives at the receiving device with a delay determined by the length of the path traveled. Thus, there is a difference between the frequencies of the two signals. Based on the frequency shift, the radar analyzing device determines the path traveled by the signal or the level of the reflecting liquid relative to the location of the radar.

Ultrasonic level sensors

The measurement scheme used for sensors of this type corresponds to that discussed in the previous section of the article. The location measurement method is used in the ultrasonic wavelength range.

The received data determines the time difference between the signals emitted by the transmitter and the signals received by the receiver. Using data on the speed of propagation of ultrasound in the space above the surface of the liquid, the analyzing device determines the distance traveled by the signal or the level of liquid in the reservoir.