Why do you need a reducer for a gas cylinder? The easiest way to answer the question is by comparing a household reducer for a gas cylinder with a mains voltage regulator. For a thrifty owner, the use of an electrical stabilizer has long become the norm. A gas reducer for a cylinder is used for exactly the same purpose - to stabilize the pressure coming from the gas cylinder to our household appliances.

Reducing gas pressure to operating parameters that ensure stable operation of the equipment - this is the main task performed by a cylinder pressure reducing device. The characteristics of the inlet pressure are important for household appliances where the energy source is blue fuel.

It would seem that after we have found out why a cylinder reducer for propane and butane is needed, we can finish the article, say goodbye to the readers, and submit the work for publication. However, not everything is so simple, and it turns out that the gas reducer operates according to completely two different operating principles and is divided into two types of devices.

Purpose of the gas reducer:

- Decreased pressure. The standard pressure at the inlet of a gas cylinder varies in the range of 150-250 atmospheres. With the help of a gas reducer, this output value is reduced to 1-16 atmospheres. There are also modifications that maintain outlet pressure up to 70 atmospheres.

- Maintaining constant pressure. The reducer allows you to prevent a drop in equipment power when the pressure inside the tank decreases. Thanks to this, it is possible to carry out all the necessary work even when filled to 5-10% of the maximum volume. But for this you need to buy a gas cylinder with a reverse-action reducer.

- Preventing air from entering the cylinder. Propane, butane, methane, hydrogen and acetylene, when mixed with air, form an explosive mixture that ignites even from the slightest spark. To increase the level of fire safety, it is strongly recommended to use containers with a reliable valve. This is especially true when refilling gas cylinders with propane or methane.

- Can function as a pressure relief valve. If the operating pressure increases to critical values, excess gas may be released. This helps prevent equipment damage and explosion during operation of the gas cylinder.

- Improves overall system reliability. The reducer is designed specifically to increase safety when using gas equipment. Helps prevent container rupture and gas explosion.

Required pressure and volume

The key characteristics of a gas reducer are inlet pressure, operating pressure and flow rate, or the maximum volume of gas passing through the device in an hour.

The inlet pressure is determined by the standard pressure in the cylinders and is usually 20 MPa.

Technical characteristics of gearboxes

The operating pressure for household unregulated gas reducers is set at 0.3 MPa ±5%

For adjustable semi-professional and professional adapters, the operating pressure is set by the user in the range of 0-0.4 MPa, and for certain high-performance models - up to 1.6 MPa

The consumption volume must exceed the volume consumed by the device (or group of devices) per hour.

How to choose a propane reducer model

When choosing a propane adapter, you need to study its characteristics, stamped on the body or applied with indelible paint. Critical to your choice will be:

- Working temperature.

- Maximum inlet pressure, kg/cm3.

- Working pressure, kg/cm3.

- Maximum gas consumption, m3/hour.

- Connection method.

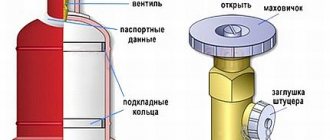

Propane reducer and its parts

Thus, the operating temperature of most models lies in the range of -15+45˚С. This is enough for reliable operation of the device in a temperate climate zone. The maximum inlet pressure is usually 25 kg/cm3, which will allow operation from a cylinder. The operating pressure must be no less than that required by the technical specifications for the consumer device. For most of them it does not exceed 3 kg/cm3. Using a propane adapter with a maximum flow rate less than the total of the consumer devices will lead to their unstable operation, combustion failure and the creation of a fire hazard.

The method of connecting the inlet pipe is usually common to all and is determined by the outlet connection of a standard gas cylinder. It is a ½" threaded union nut with a left-hand thread.

With the output, working pipe, the situation is a little more complicated. Some propane adapters, especially household ones designed to connect gas stoves or heaters, are equipped with a single option - a 6.3 mm nipple outlet. Such gearboxes will cost less.

A universal outlet is also a threaded connection; you can attach both a union nut and an adapter to a 6.3 or 9 mm fitting. If you are going to connect several devices to the gearbox at the same time, then you need to choose the option with a threaded outlet, to which you will screw the manifold-distributor. For safety reasons, each collector outlet must be equipped with a separate valve that shuts off the pipe.

Medium or low gas pressure. Which is better for the home?

In this article I want to talk about the difference in gas supply to a private home with medium and low pressure gas.

More and more often, cottage buildings in our country are gasified with a network of medium pressure gas pipelines (about 0.1-0.3 MPa, as a rule), rather than low pressure (150-300 mm per station). On the one hand, this is additional equipment (pressure regulator), and the gas pressure is higher, but on the other hand, considering how powerful gas boilers people install at home these days, medium pressure is the only way to supply gas in sufficient quantities to the end user.

When gasifying with low pressure, the pressure at the final device (for example, at the descent to the boiler), as it moves away from the gas distribution center (gas control point - a kind of local gas distribution center, in simple terms) will decrease. For example: if in winter the maximum possible pressure (low) at the outlet of the hydraulic fracturing unit is 300 mm. V. Art. (but again, this is the maximum permissible, as a rule, it is set in exceptional cases, in very problem areas), then with a gradual distance from the hydraulic fracturing, the user will have lower and lower pressure during the heating period, and according to our standards, even less than 120 is allowed mm. V. Art. Until severe frosts begin, there is usually enough pressure in the gas pipe for everyone. But as soon as the frost hits and everyone turns on their gas boilers at full power, the owners of cottages on the outskirts, at the most remote points from the gas distribution center (distribution center) - the gas pressure drops and drops. And when the pressure drops below the 120 mm bar. V. Art. Such happy owners of boilers, especially powerful ones, begin to have the following problems: the boiler either begins to go out periodically (not so bad, usually boilers with automatic ignition these days), or they get an error that there is no gas and do not turn on until the error is cleared.

When supplying subscribers with medium pressure gas, natural gas compressed to 0.1-0.3 MPa is supplied through a pipe to the house, again, the further from the hydraulic fracturing station, the lower the pressure, BUT! This gas pressure is only up to the personal pressure regulator installed at the inlet. Then the regulator reduces the pressure to low (approximately 200 mm Hg) and your boiler operates successfully without suffering from a lack of gas pressure. But this has its drawbacks. In Belarus, for the population, according to technical conditions, 2 types of regulators are included in the project: One regulator is GDGD 2.0, which is produced by Belgaztekhnika (the official description of it can be seen here) and the other regulator is ALSI FE-10 produced (its description can be seen here ). Their price is about 80 US dollars. Currently, as far as I know, they do not provide specifications for the installation of other regulators on the territory of the Republic of Belarus. So we have to choose the lesser of two evils (in the sense of regulators). But the advantages and disadvantages of each of these two regulators are in the following articles. But if there is a choice between what pressure gas pipeline to connect to the house, the choice in my opinion is obvious.

Source

Classification of gas regulators

| Model | Inlet pressure | Outlet pressure | Gas consumption | Availability of adjustment | Availability of pressure gauge |

| RDSG 1-0.5 Belarus | 0.07-1.6 MPa | 2000-3600 Pa | 0.5 m3/hour | No | No |

| RDSG 1-1.2 | 0.07-1.6 MPa | 2000-3600 Pa | 1.2 m3/hour | No | No |

| Milano under eyeliner | 0.03-0.75 MPa | 1960-5880 Pa | 1.5 m3/hour | Yes | No |

| Milano under the sleeve | 0.03-0.75 MPa | 1960-5880 Pa | 1.5 m3/hour | Yes | No |

| Italy 694 | 1.6 MPa | 2900 Pa | 1.5 m3/hour | No | No |

| Italy 694 d/composite cylinders | 1.6 MPa | 3700 Pa | 1.5 m3/hour | No | No |

| RDSG 1-1.3 China | 0.07-1.6 MPa | 2000-3600 Pa | 1.3 m3/hour | No | Yes |

| RDSG 1-0.5 China | 0.07-1.6 MPa | 2000-3600 Pa | 0.5 m3/hour | No | Yes |

| GOK EN-61 | 1.6 MPa | 3700 Pa | 1.5 m3/hour | No | No |

| GOK for composite cylinders | 1.6 MPa | 2900 Pa | 1.5 m3/hour | No | No |

Design and types

Propane (CH3)2CH2 is a natural gas with a high calorific value: at 25°C its heat of combustion exceeds 120 kcal/kg. At the same time, it should be used with special precautions, since propane is odorless, but even with its concentration in the air of only 2.1% it is explosive. It is especially important that, being lighter than air (the density of propane is only 0.5 g/cm 3 ), propane rises upward, and therefore, even at relatively low concentrations, poses a danger to human well-being.

Operating principle of the gearbox

The device is connected to a gas cylinder using a union nut, the thread on which is strictly defined: Sp21.8LH (left). This is done in order to exclude the possibility of connecting a gearbox for other equipment. The connecting nut is made of brass and is necessarily equipped with a transition projection, which prevents possible gas leaks. When using propane cylinders manufactured according to the European standard KLF with an already installed sealing ring and a filter on the fitting, you will also need a special adapter.

A propane reducer works like this. The gas from the cylinder first passes through a mesh filter, from where it enters the lower chamber at high pressure. Next, the required operating pressure is adjusted. To do this, the adjusting screw is rotated clockwise, acting on the set spring. The spring pushes the pressure plate, and through the reducing spring, pusher and diaphragm transmits force to the reducing valve. It opens, and through the gap between the valve and its seat, it opens the way for propane into the working chamber. A low pressure gauge is used to monitor the actual gas pressure. In order to connect the hose of a roofing torch, cutter or other unit to the device, an outlet connecting nipple is provided. For connection, a union nut with an M16×1.5LH thread is usually used.

When gas is supplied under initial pressure, the following occurs: the membrane closes the inlet valve (the level of pressure required for this depends on the area of the membrane, its diameter and the setting of the drive spring). The level of propane pressure at the outlet of the reducer depends on the degree of blocking of the hole. Since the membrane moves abruptly when high-pressure gas is supplied, household gas reducers of this type are often called “frog”. “Frog” is a typical representative of a propane reducer, which is used to supply gas to simple household devices. Unlike the above-mentioned devices BPO 5-3, BPO 5-4, etc., the “frog” does not have a unit for adjusting the inlet gas pressure, and its performance is determined solely by the physical and mechanical characteristics of the membrane material. Therefore, such gearboxes are designed for use strictly in the conditions that are specified, as a rule, they have reduced operational capabilities (in particular, flow rate and outlet pressure), but are more compact and have a lower price (290 ... 350 rubles versus 450 ... 700 rub. - for single-chamber devices or 1200...1300 rub. - for two-chamber devices). The “frog” can be connected using a clamp.

How to convert a gas stove to bottled gas

In general, setting up a gas stove for bottled gas is not difficult; to properly adapt the stove you just need to change the gas supply nozzles to the burners. This can be easily done with your own hands without hiring specialists.

Gas is supplied to the burner using a special hole in the nozzle, which is an integral part of any gas stove. The hole can be of different diameters, depending on the pressure in the gas supply system. Of course, the pressure in the central gas lines is noticeably higher than in a conventional gas cylinder, and accordingly the diameter of the hole in the nozzle should be smaller.

Often, complete with a gas stove, the manufacturer also includes a set of jets designed for different types of gas mixtures - natural gas, propane-butane, etc. But if they weren’t there or the stove was bought a long time ago, it’s okay, you can buy the necessary jets in the store.

Choosing a jet for bottled gas

Jets (other names: nozzles, injectors, nozzles, etc.) for gas stoves are not in short supply; they can be bought at specialized retail outlets - markets, shops. In appearance, the nozzle is similar to a regular bolt with a thread applied, but unlike the latter, it has a hole in the center through which the gas actually passes. As we said earlier, the hole can be of different diameters, and usually its value is stamped on the end of the product.

Before buying a jet, you should determine what diameter is needed. This is an important point, since incorrectly selected jets will not allow the stove to work normally, or even make it impossible.

It is not difficult to understand that the stove is working correctly after replacing the jets:

the flame should burn without hissing, without yellow impurities and red tongues;

When lighting the burner, no popping noises are allowed, and the flame should not suddenly go out.

The required diameter of the nozzle hole is indicated in the instructions for the gas stove; if the instructions are lost, then information about your stove and its manual can be easily found on the Internet.

We categorically do not recommend changing the diameter of the nozzle hole yourself by caulking or drilling - new nozzles are not expensive, and “reworking” at home can have a detrimental effect on the operation of the stove.

What tools are needed?

To configure a gas stove for bottled gas and then connect it to a gas container, you will need the following tools:

first of all, new jets;

7 mm wrenches, wrenches or open-end wrenches;

a new flexible hose, 1.5 meters or more in length. Serves to connect the stove to a gas cylinder;

seal and gas reducer with outlet pressure 30 mBar.

Sequence of installation and use

A propane reducer of any type and design is considered a high-risk technique, therefore, when installing it, a number of mandatory requirements must be observed:

- The room (if the gearbox is mounted to an internal consumer) is thoroughly ventilated. Moreover, the window/vent must remain open throughout the entire duration of the initial start-up.

- The correct sequence for using the device is as follows: first, the valve on the propane cylinder opens smoothly. Then the valve of the reducer opens and only then the valve of the gas-consuming equipment. By rotating the adjusting screw handwheel, the required level of operating pressure is set. Disabling is done in reverse order. When extraneous sounds appear - clicks, hissing, etc. - the equipment is immediately turned off.

- After establishing a stable flow of gas through the reducer, monitor the readings of the pressure gauge needle, which should not deviate more than the pressure fluctuation values indicated in the passport. Otherwise, the use of the technology is stopped. A slow increase in gas pressure is considered especially dangerous.

- Once every 2...3 months, the tightness of all connections is checked, and if necessary, the threaded fasteners are tightened.

- If routine maintenance of the propane reducer is necessary - purge the valve - the device is disconnected from the gas main, after which the remaining gas is released from all working cavities of the device. All subsequent operations are performed only in special workshops that have test benches.

- After finishing use, the inlet valve on the gearbox is closed all the way. In this case, the binding of the spring is eliminated, and its performance increases.

- To comply with fire safety rules, it is advisable to provide flame extinguishing devices between the gearbox and the gas-consuming installation.

https://youtube.com/watch?v=lspIr9UNH7E

The use of bottled gas requires a thorough approach to ensuring safety and ease of use. We propose to consider the simplest example of connecting a propane cylinder to a gas stove: connection diagram, shut-off and control valves, organization of storage conditions.

Security zones

If complexes or buildings are being erected that are not involved in any way in the activities of the gas filling station system, compliance with the security zone is certainly taken into account, the length of which depends on the type of protected structure. Its dimensions:

- outside – 2 m on each side, even in cramped conditions;

- from underground - 3 m from the delimiting gas pipeline;

- CNG filling stations and gas filling stations are limited to a closed circle with a radius of at least ten meters from the established boundaries of the complex of capital construction projects.

Standard distances are the standard distance from the gas pipeline to communications. Water mains, power lines, roads and railway tracks must be located at a certain distance, which is regulated by a reference table. The minimum horizontal clear distances are taken into account (they depend on the pressure of the gas pipeline) and other existing requirements - electrochemical protection, climatic features, the presence of electrical installation regulations and high-voltage lines, etc.

The distance from buildings and structures to the gas pipeline must strictly comply with the standards. Distance standards are regulated by the pressure of the supplied gas and the type of gas pipeline constructed. For overhead low pressure, only a security zone is required due to existing operating rules. If necessary, it should be reconstructed.

Nuances

An additional application requires maintaining distances from boiler rooms, as fire-hazardous structures for industrial purposes. Two pipes - only 4 meters away from a residential building. Windows and roofing require at least 0.2 meters, and to the door - 50 cm.

Distancing from warehouses can be regulated by the enterprise, but it should not be less than in SNiP 2.07.01-89 and SP 42.13330.2011. The same applies to laying at the bottom of the slope, which can be regulated by builders and the Russian Railways administration (sometimes the distance from the gas pipeline to the railway tracks is reduced, but less than the norm is not allowed, especially near the embankment).

LPG tanks are taken into account separately. There are several types of them. For example, according to their orientation in space, they are divided into vertical and horizontal, depending on their location - underground and above-ground LPG tanks, single-wall and double-wall LPG tanks - according to the degree of endurance of the structure. The volume, location and type of complex regulate the distances. The standard GPC has a maximum pressure value.

Regarding tank installations, the standards of SP 62.13330.2011 are taken into account, but in each specific case the minimum distance is taken into account depending on the characteristics of a particular gas tank. Underground ones are deepened by 0.6 m, and the light distance between them is 0.7 m. A gas flow metering point is a prerequisite when using such installations; mixing stations, if necessary, are installed at 10 meters

A gas flow metering point is a prerequisite when using such installations; mixing stations, if necessary, are installed 10 meters away

Underground ones go 0.6 m deep, and the light distance between them is 0.7 m. A gas flow metering point is a prerequisite when using such installations; mixing stations, if necessary, are installed at 10 meters.

The design of buildings of any kind should be carried out near a gas pipeline only with the knowledge of regulatory and supervisory organizations, which calculate the norm depending on the type of structure and the supplied pressure of valuable chemical raw materials and fuel.

Direct gas equipment

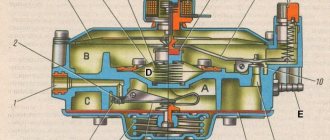

Gas enters the high-pressure chamber through the fitting and acts on the valve to open it. The reducing valve is pressed against the seat by means of a locking spring, thereby preventing access to high pressure gas.

The purpose of the membrane is to remove the reducing valve from the seat and provide access for high pressure gas to the working (low) pressure chamber. That is, two directly opposite forces act on the membrane.

On one side, a pressure spring presses on the membrane through a pressure screw to open the pressure reducing valve. And from the gearbox chamber (from the inside) low pressure gas acts on the membrane.

When the pressure in the working chamber decreases, the pressure spring straightens, the valve moves away from the seat and a new portion of gas enters the chamber.

If the pressure increases, the spring compresses, forcing the valve closer to the seat. This limits the flow of gas into the reducer. The operating pressure can be adjusted by decreasing or increasing the spring pressure using an adjusting screw.

If you turn it out, the pressure will decrease, if you turn it in, it will increase. You can control the pressure using a pressure gauge installed on the working chamber. In practice, another type of gearbox, described below, has become very popular.

What is a propane reducer?

The design of all propane reducers is very similar. They all have:

- Sealed housing made of aluminum, brass or plastic.

- Inlet pipe for connection to the cylinder.

- Outlet pipe for connection to the consumer.

- High and low pressure chambers.

- Flexible membrane.

- Valve and stem.

- Return spring.

- Working spring.

In professional gas reducers, a pressure gauge, an adjusting screw or flywheel, and a threaded connection of the supply pipe are added to the design. The gearbox housing has a cylindrical shape, which is due to the use of a round membrane that bends inside the operating pressure chamber. The inlet and outlet pipes protrude from the housing.

Adjustable reducer for gas cylinder

Adjustable gas reducers operate on the same physical principles as non-adjustable ones and have a similar design. The difference is that the compression force of the reducing spring supporting the membrane can be changed using an adjusting screw coaxial with the spring in the simplest models, or using a flywheel and a more complex mechanical transmission.

Adjustable reducer for gas cylinder

The principle of operation is that by changing the pre-compression force of the reduction spring, the user changes the threshold gas pressure in the working chamber required to operate and close the intake valve. A pressure gauge is also added to the parts, installed on the working pipe and allowing you to visually monitor the result of the adjustment.

Rules for operating gas equipment

Installation of gas equipment on cars requires periodic inspection and routine maintenance, the essence of which is as follows:

• constant checking of seals and connections, including those on the multivalve;

• replacement of gas and liquid phase filters every 10-12 thousand km (or if necessary). If filters with settling tanks are installed, drain the condensate (gasoline) as the container fills;

• replace repair kits for injectors and gearboxes in a timely manner - at least once every 40-50 thousand km. After a similar distance, bench cleaning of the jets is required, as well as cleaning the gearbox from carbon deposits;

• the service life of the cylinder is 10 years, pressure testing and pressure testing are required every two years. Touch up the cylinder if you notice signs of corrosion;

• spend time tuning the ECU. Gas equipment 4th generation

must be completely synchronized. If, due to incorrect settings, the ECU supplies more gas through the reducer than necessary, this is fraught with problems with the valves. In addition, tuning is an optimization of fuel consumption;

• change antifreeze and oil in a timely manner (according to the regulations, once every 2 years).

We strongly recommend checking gas equipment in Kharkov

or Kyiv only at specialized service stations that have a license from the manufacturer and where the installation took place directly.

For example, install gas equipment

at PRIDE GAS and check the gas equipment here. Finally, we will give some tips on how to extend the life of HBO:

• do not drive at high speeds too often. If you like to drive on the highways at the maximum capabilities of the engine, switch to gasoline;

• try to fill up only with high-quality gas at the same gas station;

• do not fill gas to more than 80% of the cylinder volume;

• listen to any changes in engine operation - they may be the first signal of problems with gas equipment.

Read also: Garden electric saw for pruning trees

Authorized PRIDE GAS centers (the official representative of AEB in Ukraine) are ready at any moment to provide you with high-quality practical and consulting assistance with gas equipment. From us you can buy 4th generation gas equipment for any number of cylinders, receiving a 3-year warranty. Our specialists will tell you in detail what routine maintenance needs to be done and when, and PRIDE by AEB kits will remind you of this (one of the built-in functions).

PRIDE by AEB – the best sets of gas equipment from Italy

for Ukrainian roads from PRIDE GAS!

System connection standards

Devices that support two standards for connecting the reducer to a gas cylinder are widespread:

- GOST - common in the CIS countries, used on locally produced steel cylinders.

- GLK is a European standard, used primarily on composite cylinders.

Connecting the reducer to the gas cylinder

To connect the working pipe:

- Threaded connection.

- Nipples 6.3 or 9 mm.

- Universal nipple.

- GLK.

Some gas reducers, for example, RGDS, are equipped at the factory with a 9 mm nipple pressed into the housing.

Reducers with adjustable operating pressure are equipped with a threaded half-inch outlet, which can optionally be secured with a union nut and a universal nipple.

It is safer to use devices that match the standard. Each adapter is an additional connection that increases the risk of gas leakage.

Connecting the plate to the cylinder

For this operation, you need to screw a fitting onto the gas stove pipe, and put a previously stored flexible gas hose on it and secure it with a worm-type clamp.

We attach the second end of the hose to the reducer and also tighten it with a clamp, and connect the reducer directly to the liquefied gas cylinder using paronite gaskets. Fastening is carried out using an open-end wrench; we place the gearbox in a horizontal position - this is important!

If everything is done correctly, there should be no gas leaks, but it is better to check this personally. To do this, use the simplest method - applying a soap solution to the joints. If there is a leak, it can be easily seen by the inflating soap bubbles. In this case, it is necessary to change the gaskets, tighten the clamps, and if there is damage to the hose, replace it.

Installation and configuration of the gearbox

Installation of the gearbox is carried out only by specialists . You can regulate the operation of the device yourself if you strictly follow the instructions.

Cylinder reducers are mounted on the cylinder body. The regulator attaches directly to the outlet via an adapter. The degree of tightening of the screw on the adapter ensures sealing. A flexible gas hose no longer than 3 m . The hose is connected to the stove or boiler.

ValeraVoice of a construction guru It is prohibited to splice, pinch or twist hoses. You can only use special products; water or oxygen models are not suitable.

System connection standards

Connection of the device is regulated by 2 standards :

- GOST – used in the CIS countries, designed for steel cylinders;

- GLK is a European standard, used for the operation of composite cylinders.

Some gearbox models are equipped with a 9 mm press-fit nipple. This makes installation easier.

Adjustment

Adjustment of the gas reducer is only possible on models equipped with an adjusting screw or flywheel . In this case, the compression force of the spring acting on the membrane can be changed. In this way, the threshold pressure in the working chamber is reduced or increased. This changes the closing and opening parameters of the intake valve.

Adjustment is made by turning the nut . It is easier to do this if the cylinder is equipped with a pressure gauge on the working pipe: the pressure in the supplied mixture is reflected on the dial.

Area of application of devices

Wherever there is no stationary gas distribution, people use propane in cylinders. And each cylinder is connected to one or another reducer. The most popular applications are:

Using the gearbox for soldering and welding

- Household and portable stoves and grills.

- Gas water heaters and heat guns for heating rooms.

- Thermal umbrellas for heating recreation areas.

- Gas cutters and welding torches.

- Fuel for land and river transport.

In many countries, wide gas distribution networks have been created to ensure recharging and delivery of gas cylinders to consumers.

The gas cylinder reducer ensures safe and stable operation of gas consuming devices.

If you find an error, please select a piece of text and press Ctrl+Enter.

Liquefied gas, which is used to fill cylinders for subsequent use, is always under increased pressure. To lower it, it is necessary to install a special type of shut-off and distribution valves on the cylinder - a propane reducer. Subsequently, the reducer automatically maintains the specified level of gas pressure. According to safety regulations, the device is always painted bright red - the same color as propane cylinders.

Specifics

As already noted, gearboxes can be domestic and industrial. Also universal models.

Consumer versions may not be customizable.

These are simple models. They are used in everyday life and outdoors. RDSG products are installed together with household gas cylinders. They have a very simple design. Due to this, gas can only be used in household stoves. These products are inexpensive and very reliable. There is also a Frog type gearbox, there is the RDSG-1 model. They should only be used in cylinders with a volume of 12 - 50 liters.

The class of universal, customizable gearboxes has a more complex design and greater potential. This is an excellent option for domestic use and for work in the home workshop. The products are attached to the cylinders using a threaded method and are fixed securely.

They have a pressure gauge and an adjustment screw that allows you to vary the functional pressure within the range of 0 - 0.3 MPa. Their highest throughput capacity is 5 m3/hour.

The category of professional models is created from the best wear-resistant materials. They have the highest build quality and settings: 0.4 - 1.6 MPa.

Some modifications have two pressure gauges. They reflect input and functional pressure.

Often, many summer residents and hikers ask questions such as: is a reducer needed for a gas burner? And is a gearbox needed for a gas stove in the country? Stable and safe operation of any gas appliances and in any conditions is always necessary. Even if there is no urgent need for gearboxes, it won’t hurt to be on the safe side. It remains to decide which gearbox is needed for the gas stove.

Since the stove and burner are propane based, a propane reducer is needed. You need to select these products by studying them and comparing their characteristics. The key ones are:

- Purpose of the device.

- Higher inlet pressure.

- Functional pressure.

- Higher gas consumption.

- Attachment method.

- Planned operational life.

- Price.

For example, if you plan to connect a desktop portable stove only on weekends, the gas consumption according to your calculations is 5 liters per month, then you need a 5 liter capacity and a Baltika RDSG-2 reducer.

For a static stove with an oven, a capacity of 27 or 50 liters is required. A suitable gearbox is the Frog RDSG-2.

Questions often arise here - what does a Frog gas reducer actually do? Why is it named like that? What is its purpose?

Why do you need a frog gas reducer? Its functions, like those of other gas reducers, are pressure stabilization, safety, etc.

Why frog? This device is direct. In it, gas flows through a fitting. The valve opens and is pressed against the seat by a spring. High pressure gas does not penetrate into the chamber. The diaphragm displaces the valve from this seat. The pressure gradually decreases to the operating values of the device to which the reducer is mounted.

The spring straightens. The valve is detached from the seat and does not interfere with gas flow. As the pressure increases, the spring presses the valve again, gas does not flow. This principle is reminiscent of frog jumping. And the device is similar in shape to it.

If it is necessary to connect a composite container to a thermal umbrella, it is better to use imported products with a KLF connector

The professional model BPO 5-3 Krass is optimally suited for gas welding in a home workshop. It guarantees a flow rate of a maximum of 5 m3 per hour and allows you to adjust the operating pressure to 0.4 MPa. And for this task it has a flywheel and a pressure gauge. Thanks to the latter, it is possible to scrupulously assign pressure to the needs of gas welding equipment.

Decor

The design of a gas stove for a cylinder is nominal - there is no need to visit any authorities, the requirements are easy to fulfill. The first was announced - the distance to the cylinder is at least 0.5 meters. Second: there must be at least 2 meters to the main lines - water supply, sewerage, metal heating pipes. That's all.

There are two options for official registration:

- When you fill up a new cylinder at a municipal gas station (not for cars, but specifically for refueling household gas cylinders), the station employee will fill out the paperwork for you. You will need to provide the address (at least approximately) and explain where the stove is located and where the cylinder is located. Here you have to be careful, at least say that it is worth it according to the rules. Yes, the cylinder must be purchased at one of the Gorgaz stores and you will need the registration number of the car on which this cylinder will be transported.

Refill dispensers for gas cylinders

For many, a gas stove for a summer house under a cylinder has been standing for years even without such “design”. But in this case, you will refill the cylinder yourself, without using the services of municipal gas stations or exchange machines. Also, if it is necessary to repair or maintain the stove, or reconfigure it, you will need to somehow resolve the issue of design (usually there are no problems) or use the services privately.

General rules for choosing a balloon reducer

Summarizing the rules for choosing a gearbox for a gas cylinder, it should be noted that:

Classification of reducers for gas cylinders

- it is necessary to sketch out a diagram of the planned system from the gas cylinder to the end user;

- clearly formulate the following requirements for the device:

- Purpose.

- Operating pressure.

- Need for adjustment.

- Maximum volume.

- Method of connection to a gas cylinder and to a working device.

- Availability of maintenance and repair.

- Allotted budget.

- From the variety of products on the market, you should choose those that meet the stated requirements.

- Next, you need to enter the models and their characteristics into the comparison table and conduct a price analysis.

If devices that meet the stated requirements do not fit within the allotted budget, then it is necessary to either revise the budget or simplify the requirements for the device.

Heating a country house with bottled gas

To create a high-quality heating system for a private home, gas boilers are usually used. Compared to alternative heating appliances, they are the most cost-effective and easy to use. But what about those who do not have the opportunity to connect a private home to a centralized gas pipeline? From this article you will learn whether it is possible to heat a house with gas from cylinders and how to properly set up safe heating with gas cylinders.

- What is more profitable - to use a convector or a cylinder?

- Proper storage is the key to safety

- Advantages of gas cylinder heating

- Disadvantages of heating with liquefied gas