Metal drills are indispensable tools that are used in production and at home to drill holes in objects with increased strength. When choosing this type of tool, first of all, it is necessary to focus on its declared performance characteristics, material of manufacture, sharpening angles and coating. Experts first of all recommend paying attention to the sharpening angles of cutting steel. The best metal drills, the ratings of which are presented below, have proven themselves to be the best and have received the largest number of positive reviews from consumers.

Irwin TurboMax 10503992

Irwin TurboMax 10503992 opens the ranking of the best metal drills. The tool is designed for work such as drilling holes in metal objects, plastic, and wood. The drills are also suitable for drilling holes in stainless steel with the obligatory use of coolant. The tip of the tools included in the kit is distinguished by a special sharpening, which ensures high drilling speed. The set includes 15 drills of different diameters and are highly durable. The cost of the kit is approximately 3,000 rubles.

Marking and color of metal drills

Probably, each of us has thought about what drills are made of, what does the marking stamped on the tool mean? How do you drill something like yourself using metal? This is because the product is made from high-quality and high-strength steel, and not from raw material, which penetrates the market from dishonest manufacturers.

9.Hawera HSS-C SpiralBohrer GQ-32692

Hawera HSS – C SpiralBohrer GQ -32692 is included in the list of the best metal drills. The set contains 25 twist drills with diameters from d 1.0 mm – 13.0 mm x with diameter increments of 0.5 mm. The surface of the working tools is coated with titanium nitride, which gives them special hardness and heat resistance. The tools are made of high-quality high-speed steel and are fully ground. These drills boast a long service life and impeccable operation throughout the entire period of operation. GQ-32692 is excellent for steel, alloy and non-alloy castings, brass, bronze, cast iron and cast iron. You can buy such a kit for 6,000 rubles.

Drill color, what it affects and what it means

If the marking is erased or there is no way to read it, you can try to determine the type of drill by its color. By the color of the drill, you can determine the quality of the drill and the material from which it is made.

- The black color of a metal drill means that during the production of the drill, namely at the end, the drill was treated with superheated steam, due to this the drill becomes more reliable. However, black drills can often be found of poor quality, so do not buy drills from unknown manufacturers.

- Gray color of the drill - This is a regular drill that has not undergone any additional processing. Such a drill will be less reliable, and during active work, it will require sharpening faster.

- Dark gold or golden color of the drill - During the production of the drill, tempering was used, which relieves the internal stress of the material. Due to this, the strength of the drill increases.

- Bright golden color of a drill for metal - Such drills are the most expensive, since in their manufacture a titanium alloy, namely titanium nitride, is used, which gives maximum reliability to the drill. Due to titanium, friction during drilling is reduced, which gives the drill durability. Such drills have a high price, but if you buy a drill more than once, it is worth spending money and buying a reliable drill.

DeWALT DT7926 Extreme2 HSS

DeWALT DT7926 Extreme2 HSS is one of the best metal drill bits that can be used both in production and at home when working with drills. They provide the cleanest and most accurate drilling possible, and are also characterized by high operating speed. The nanotechnology design of the tool prevents damage to the edges of the hole. The tip of the device has three flat edges that provide secure mounting in the chuck. The kit includes 29 drills with a diameter from 1 to 13 mm. The cost of a complete set is 5,000 rubles.

Metal drills: external differences

A drill is designed as a tool capable of making a hole in solid metal (concrete, tile, wood). Therefore, it has a special design that can overcome the resistance of the metal layer; There are three parts in any drill.

The cutting part is the first to come into contact with the material in which the hole is made. Behind the cutting blade there is a working part that helps remove chips. The back part is also called the shank or fastening part; it is fixed in the drill chuck. The question of what types of drills there are can be answered based on their appearance; There are several types of cutting tools.

Flat (feather)

The working part is solid or with replaceable cutting plates, narrow, reminiscent of a feather (hence the name). Allows you to drill stepped and shaped holes. The device has a simple design and is inexpensive. But with its help it is difficult to drill a wide hole, and the chips must be removed manually.

Prefabricated feather drills for metal Source prom.st

Spiral

The most common type is in the form of a rod with two (less often four) spirally cut grooves through which chips are removed. If the spiral grooves twist to the left, then this is the left-handed variety, which will help remove the fastener. There are products of a higher accuracy class, but in everyday life, spiral cylindrical drills of normal accuracy with a diameter of up to 82 mm are more often used.

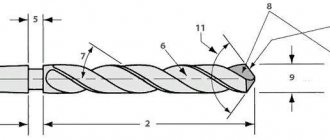

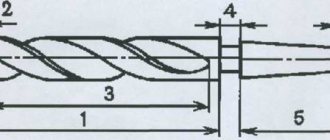

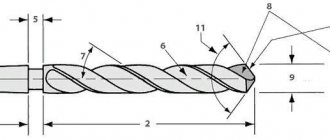

Design of a twist drill Source kerner.ru

Crown (ring, hollow)

They have the appearance of a hollow cylinder, are more efficient (fast) and less expensive than spiral models. Feature: material is removed along the periphery of the hole (in). Core bits are especially useful when it is necessary to drill into curved surfaces (such as pipes).

Metal annular cutter for magnetic drills Source snabzhenie.com.ua

Countersink

It has a conical working part with longitudinal cutting notches (there can be 3 or more cutting edges). Used where high precision is required, especially in mechanical engineering. Countersinking is more often used to clean the surface before cutting threads and to calibrate holes.

Drill with countersink for metal Source stroy-podskazka.ru

Conical (stepped)

The working part is in the shape of a cone with notches that allows you to create and expand holes. Thanks to the complex stepped surface, the tool is easier to center than its spiral counterpart, which is especially convenient when working with thin material. Each stage corresponds to a specific diameter, which allows you to obtain holes of different sizes without changing the drill bit in the drill chuck.

Step metal drill with helical flute Source amazon.com

See also: Catalog of companies that specialize in finishing materials and related work

Bison MET-SH H19 R6M5

Bison MET-SH H19 R6M5 is a drill from a domestic manufacturer, included in the list of the best. Used for drilling both alloy and carbon steel. The tools are made of high-speed steel R6M5, have a cylindrical shank and are characterized by high accuracy and drilling speed. They are self-centering due to the cross-shaped point. The set contains 19 pieces of devices with a diameter from 1 to 10 mm. You can purchase MET-SH H19 in an eraser box for 1000 rubles.

Classification by color

By color you can determine the characteristics of the tool: strength, durability, purpose. Drills are available in three colors: gray, black and gold. Gray drills are among the simplest, cheapest and most short-lived. They do not have a protective coating, so their performance characteristics are quickly lost during operation. They are not suitable for high temperatures or heavy mechanical stress. But they are often used as a one-time use for simple work.

Black drills are treated with high temperature steam during manufacturing. Thanks to this treatment, the material is hardened and becomes durable. They wear out less and last longer than gray ones.

Golden drills can be lighter and more saturated. Light yellow very durable. They are made from high-speed steel using heat treatment technology. Bright gold cutting tools are even more durable than light gold ones. They have a titanium nitride coating. When drilling a hole, the gold drill experiences almost no friction force, which significantly extends its service life.

AEG HSS-G 4932430416

AEG HSS-G 4932430416 are one of the best metal drills in an affordable price category. The devices are completely ground and made of high-strength and heat-resistant steel. The cutting head of the tool has a cross-shaped sharpening with an angle of 135 degrees, which ensures good alignment without the need for a core. 4932430416 are able to withstand high temperatures resulting from heating during drilling. Suitable for working with high-alloy steel and metal with a strength of more than 1000 N/mm². The set contains 19 pieces with a diameter from 2 to 10 mm. You can buy a set for 1500 rubles.

Types of drills

The ideal drilling result depends not only on the professionalism and experience of the master, but also on the correct selection of the drill. The right tool will make the job much easier. Types of drills for metal surfaces differ in the type of configuration and the material from which they are made.

1. Twist drills are standard cylindrical products. They reach 80 mm in diameter. Made from high quality steel. Their design is such that the working surfaces are sharpened at an angle of 118 degrees. They are needed for almost all basic drilling work in metal. This is a versatile, durable tool.

2. Conical (or stepped) drills - are made in the form of cones with a stepped surface (spiral). They can easily drill a two-millimeter hole. They are also used to correct small defective holes that were formed as a result of poor performance of another tool.

3. Core drills are serrated hollow bits. They are also called annular cutters. The craftsman needs them to work with thin metal to make neat holes up to 30 mm. This tool can drill to great depths, due to the fact that the chips pass into the cavity of the crown.

4. Feather (flat) drills consist of replaceable working plates. They are designed to drill perfect deep holes in metal of any strength. The peculiarity of this type is that the flat drill practically does not distort during drilling. In addition, they are the cheapest, so they attract the attention of craftsmen.

Depending on the production material, drills are divided into cobalt and carbide. The first ones are made of cobalt. The second ones are made of high-strength alloys. — Cobalt drills are used at high temperatures, as they do not lose their qualities. Cobalt alloyed high speed steel tools allow you to work with very tough materials and highly tough metal products. Cobalt drills have an average price, but their quality and performance fully justify it. — Carbide drills have high cutting edge hardness. The equipment itself is usually made of simple steel for metalworking tools. And the plates are made of carbide alloy. Such models are needed for drilling products made of particularly strong materials of great thickness. The peculiarity of a carbide drill is that it can self-sharpen during operation.

5. Metabo Bestell-Nr. 27,094 HSS-G

Metabo Bestell-Nr. 27 094 HSS – G – one of the best drills designed for metal work. Spiral type devices have a cylindrical shank with a 135 degree sharpening of the tip, which ensures fast and accurate drilling. In total, the set contains 25 pieces, the diameter of working tools varies from 1 to 13 mm. The cost of the set is approximately 1,700 rubles.

Shank types

The tail part of the drill has different configurations - cylindrical, conical and hexagonal. Most often, cylindrical models are used in practice. They have a small feature: the diameters of the drill and shank may not match. Experts say that if you equip the drilling tool with a cylindrical shank of a slightly larger diameter, this maneuver will make the fixation stronger. There is also a minus - an increase in the recommended power of the tool. But the drill will not be damaged if such a drill jams during operation. Tapered shanks are suitable for drill bits in industrial drills. This is how workpieces are processed on factory machines. The hex shank tool holds well in special clamps and jaw chucks.

Anchor 25219

Enkor 25219 is included in the rating of the best metal drills. The set includes tools of various diameters (from 1 to 10 mm). There are 19 working items in total. The tip of the devices is made of high-strength hard alloy, which ensures high speed and long service life. Enkor 25219 belongs to the category of budget drills intended for metal. It is quite possible to purchase a set of 19 pieces from a Russian manufacturer for 1000 rubles.

3. Wurth Zebra Spiralbohrersatz HSS

Wurth Zebra Spiralbohrersatz HSS are one of the best drill bits designed for metal work. Made from high-speed steel HSS. The devices provide maximum accuracy and drilling speed, and are also characterized by increased strength. Ideal for drilling holes in structural steel with a strength of up to 1000 N/mm², cast iron and plastic. Suitable for use in vertical drilling machines and electric drills. It is recommended to use a special coolant during operation. The kit includes 13 drills with different diameters, which are supplied in a plastic case. The cost of such a kit is approximately 700 rubles.

Key indicators for selection

When choosing a tool for drilling metals, you must consider:

- the composition of the alloy from which they were made;

- method of additional processing and the presence of surface coating;

- manufacturer's trademark;

- diameter and design shape;

- design and sharpening angles of cutting edges.

Important! The cutting part of traditional twist drills has a front and rear angle of inclination of the plane of the cutting part. The geometric parameters of the rear sharpening angle determine the magnitude of the friction force during operation and the wear rate of the tool. Increasing this indicator allows you to process stronger metals, but leads to reduced heat dissipation and faster wear.

What can color say?

An important external parameter when choosing a drill can be the color of the surface, which indicates the composition of the alloy, the processing method and the surface reinforcing coating.

High-quality tools are made from high-speed alloys with the addition of titanium, molybdenum or tungsten. The international designation for such metals is HSS (High Speed Steel). However, even if the drill marking contains a similar inscription, but its surface is gray steel in color, you should not buy such a product. It has not been subjected to additional types of processing and does not have sufficient strength and wear resistance. The price in this case will be low, but it will also last a short time, with the need for frequent sharpening.

Drills can be:

- Black , after heat treatment with superheated steam and additional hardening. The cost of a black drill is slightly higher than that of untreated products, but it is quite affordable for use for domestic purposes. But increased strength significantly increases service life.

- After heating the finished drills in a furnace and gradually tempering the metal to relieve internal stresses, the surface acquires a light yellow tint . As a result, the wear resistance of the drill increases significantly, and its sharpening is required much less frequently.

- The bright golden color indicates the use of an alloy with the addition of titanium, which is characterized by maximum strength. These are the most expensive drills, but their use is fully justified by their long service life.

- Gray color indicates low quality of the instrument. Used for one-time work, after which it is thrown away. Accordingly, this drill is the cheapest on the market.

Attack N802-6

Attack N802-6 are not only one of the best, but also the most affordable metal drills. The tools included in the kit have excellent strength and provide good speed. There are 8 pieces in total in the set. The diameter of the drills varies from 3 to 10 mm. The hardness is 65.8 HRC. H802-6 not only provide high performance, but can last quite a long time. You can purchase a reliable tool kit from a Russian manufacturer for only 600 rubles.

Bosch 2607017154

Bosch 2607017154 completes the list of the best metal drills. This set is designed for making both through and blind holes in sheets of alloyed and non-alloyed steel with an allowable tensile strength of 900 N/sq.mm., copper, bronze, plexiglass, etc. Bosch 2607017154 are made of high-strength, high-quality and high-speed steel coated with titanium nitride. Not suitable for drilling aluminum. When working with the product, it is recommended to use coolant to increase service life. The kit is sold in a special plastic, shock-resistant box. In total, the set includes 25 pieces, the diameter of the products varies from 1 to 13 mm. You can purchase a set for about 3,000 rubles.

18 29

TOP 10 most famous manufacturers

The manufacturer's brand is also a very important factor influencing the right choice. Well-known manufacturers of drilling tools guarantee the strength of the alloy, the quality of sharpening, high wear resistance and corrosion resistance. Therefore, if you are looking for a high-quality metal drill, you won’t be able to save money. The cost of well-known brands is quite high.

An exception to this rule may be rare drills made in the USSR. Having seen such a tool, you can have no doubt about its quality. Experts unequivocally speak about the excellent performance of Soviet tools in terms of alloy strength, long service life and stability of cutting edges. This is also due to the GOST requirements of that time for such a tool.

Among the ten best manufacturers of drilling tools, experts name:

- European concern Bosh , which produces drills made of high-strength high-speed steel with a surface coating of titanium nitride with a tensile strength of up to 900 N/mm2. Can be used for drilling any metals except aluminum and its alloys. The cost of a drill depends on its diameter and length. A set of 12 pieces costs an average of 3,000 rubles.

- Ataka trademark is distinguished not only by high quality products, but also by affordable prices. They are made from high-quality steel alloys that can provide long service life even under conditions of high-speed metal processing. The average cost of one drill is less than 100 rubles. 5500 - 7000 Cost of a set for professional use.

- Wurth Zebra Spiralbohrersatz HSS is one of the best twist drills for metal working. Capable of providing the ability to drill at high drive speeds, while guaranteeing high edge quality and dimensional accuracy. Used for drilling structural steel and all types of cast iron. Can be installed on stationary drilling machines and hand-held electric drills. The average cost of diameters up to 12 mm does not exceed 120 rubles per piece.

- Sets of the Russian trademark " Enkor ". The set consists of 19 items with a diameter of 1-10 mm and costs an average of 1000 rubles, therefore it belongs to the group of inexpensive high-quality tools. The durability and reliability of the drill is ensured by the presence of a tip made of high-strength high-speed alloy.

- The German brand Metabo Bestler produces a spiral-shaped tool with a cutting tip sharpened at an angle of 135 degrees. This condition makes it possible to achieve high drilling accuracy even at any rotation speed. The average price for a diameter of up to 12 mm is 100-120 rubles.

- AEG HSS are considered the best metal drills in the affordable price category. Special sharpening of the tool does not require preliminary punching on the metal surface, which greatly simplifies the work process. Designed for drilling alloy steels with a tensile strength of more than 1000 N/mm2.

- Drills of the Russian brand " ZUBR " (ZUBR) are used for processing all types of steels and ferrous alloys. Special cross-shaped sharpening ensures self-centering of the tool and high drilling accuracy. A set of 20 items costs 1000 rubles.

- DeWALT kits can be used at the industrial and household level. The special design of the drill completely eliminates the possibility of damage and defects along the edges of the hole. A tool set of 28 items with a diameter of 1-13 mm costs up to 5,000 rubles.

- The surface of Hawera drills from the European company Bohler is coated with titanium nitride, which increases their strength and wear resistance. In addition, all products are subjected to special grinding, which guarantees drilling quality at any drive rotation speed. However, a set of 20 items can cost up to 6,000 rubles.

- Irwin TurboMax belongs to the category of universal tools, designed not only for processing metals, but also plastics, wood, gypsum and other materials. When drilling alloy and stainless steels, a mandatory supply of coolant is required. The cost of a set of 15 drills is about 3,000 rubles.