| METALS | ||

| Active | Medium activity | Inactive |

4.2.1. Ratio of metals to water

In water, the oxidizing agent is the hydrogen ion; therefore, those metals whose standard electrode potentials are lower than the potential of the hydrogen ion in water can be oxidized by water. The latter depends on the pH of the environment: . In a neutral environment (pH = 7). Thus, active metals will react with water, medium-active metals are passivated by water, and low-active metals do not react.

For example: alkali and alkaline earth metals react violently with water, releasing hydrogen under normal conditions:

Magnesium reacts only when heated:

and less active metals interact only with water vapor:

4.2.2. Relation of metals to acids

The oxidation of metals by acids can occur both due to hydrogen ions and due to ions of the acid residue.

Oxidation of metals with hydrogen ions

occurs in aqueous solutions of those acids whose anions do not exhibit oxidizing properties. This

Metal oxidation reactions in these cases proceed according to the following scheme:

.

Moreover, reactions occur if, i.e., all metals that are located in the electrochemical series of metal voltages up to hydrogen interact with acid solutions, for example:

Oxidation of metals due to acid residue

occurs in aqueous solutions of those acids whose central atom can reduce its oxidation state, as a result of which the anion of this acid can act as an oxidizing agent.

This

Depending on the strength of the oxidizing agent and the activity of the reacting metal, the following cases are possible:

1. When interacting with dilute nitric acid

Formally, nitrogen in the oxidation state +5 acts as an oxidizing agent. The data is given in table. 4.

Table 4

| (oxidizer ) | |||

| Active | Medium activity | Inactive | |

| React | React, react and passivate: | React: | Not responding: |

| The acid is reduced mainly to the following products | |||

| – |

For example:

Reactive metals react as follows:

Medium activity metals reduce nitrogen to N+1:

Low-active metals react with the release of NO or NO2:

Metals characterized by a high degree of oxidation form oxygen-containing acids:

2. When interacting with concentrated nitric acid

deeper N+5 reduction may occur. The data is given in table. 5.

Table 5

| (oxidizer ) | |||

| Active | Medium activity | Inactive | |

| React | React, react and passivate: | React: | Not responding: |

For example:

Active metals deeply reducing nitrogen:

Medium activity metals release NO or NO2:

Low-active metals reduce nitrogen to N+4:

Metals characterized by a high degree of oxidation form oxygen-containing acids:

3. When interacting with concentrated sulfuric acid

Formally, the role of the oxidizing agent is sulfur in the oxidation state + 6, which is part of the sulfate ion. Therefore, concentrated sulfuric acid oxidizes all metals whose standard electrode potential is less than the electrode potential of the oxidizer, as well as some low-active metals. The data is given in table. 6.

Table 6

| (oxidizer ) | |||

| Active | Medium activity | Inactive | |

| React | React, react and passivate: | React: | Not responding: |

| The acid is reduced mainly to the following products | |||

| – |

For example:

Active metals reduce sulfur to the following compounds:

Medium activity metals release free sulfur or sulfur dioxide:

Low-active metals reduce sulfur to S+4:

4.2.3. Interaction of metals with mixtures of acids

The oxidizing ability of nitric acid is enhanced by adding hydrofluoric or hydrochloric acids to it. In the latter case, the resulting mixture is called “royal vodka”. These mixtures dissolve the most inactive metals, which is facilitated by the formation of intermediate reactive particles and complex compounds as products.

For example:

The following are dissolved in aqua regia: gold, platinum, thallium:

And zirconium, hafnium, niobium, tantalum dissolve in a mixture of hydrofluoric and nitric acid

4.2.4. Ratio of metals to alkalis

In the presence of alkalis, the oxidizing effect of water can be more pronounced. When metals are oxidized with water, hydroxides and hydrogen are formed. If the oxide and hydroxide are amphoteric compounds, then they will dissolve in an alkaline solution. The data is given in table. 7.

Table 7

| (oxidizing agent) + alkali (for example, ) | ||

| Active | Medium activity | Inactive |

| Reacts only | React: | They don't respond |

For example, when metals of medium activity interact with an aqueous solution of alkalis, hydroxo complexes are formed:

Refractory metals react with oxidative-alkaline melts consisting of alkalis and alkali metal nitrates: osmium, rhenium, tungsten, ruthenium.

For example:

Iridium dissolves in molten sodium chloride by passing chlorine gas:

4.2.5. The ratio of metals to aqueous solutions of salts

Metals are capable of displacing each other from salt solutions. The direction of the reaction is determined by the relative position of the metals in the electrochemical voltage series. Almost mutual displacement of metals from salt solutions occurs in the case of metals located in the stress series after magnesium. It (magnesium -, displaces all metals from solutions of their salts located to the right of it:

For example:

Corrosion

– the process of destruction of metals under the influence of the environment, occurring spontaneously.

Corrosion is an oxidation-reduction process during which metal atoms give up electrons, and atoms of substances that make up the corrosive environment accept electrons. As a result of corrosion, compounds are formed that contain metal with a positive oxidation state (oxides, hydroxides, carbonates, sulfides, etc.), as well as reduction products of substances in the corrosive environment.

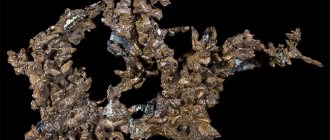

The cause of corrosion is the thermodynamic instability of the metal – corrosive environment system. Gibbs energy for the corrosion process. This is why most metals are found in nature in the form of compounds.

The possibility of corrosion, its speed, nature, as well as the nature of the resulting corrosion products are determined by the properties of the metal and the composition of the corrosive environment. In some cases, adsorption or phase layers (films) that appear on the surface of the metal as a result of the onset of the corrosion process form such a dense and impenetrable barrier that corrosion stops or is greatly inhibited. Therefore, under operating conditions, a metal with a greater affinity for oxygen may turn out to be more, rather than less, resistant. Thus, the free energy of formation of chromium or aluminum oxides is higher than that of iron oxides, and they are often superior in resistance.

Corrosion processes are classified:

§ by type (geometric nature) of corrosion damage on the surface or volume of the metal;

§ the mechanism of interaction of metal with the environment (chemical and electrochemical corrosion);

§ type of corrosive environment;

§ the nature of additional influences to which the metal is exposed simultaneously with the action of the environment.

Corrosion that has affected the entire surface of the metal is called continuous

.

It is divided into uniform and uneven depending on whether the depth of corrosion damage is the same in different areas. With local

corrosion, the lesions are local and leave a significant (sometimes overwhelming) part of the surface practically unaffected. Depending on the degree of localization, corrosion spots, ulcers and spots are distinguished.

Next, we will dwell in more detail on the above corrosion processes.

5.1. Mechanisms of interaction of metal with the environment

Chemical corrosion –

the process of metal destruction under the influence of a corrosive environment in which there is no liquid water. For example, chemical corrosion is observed when metal is exposed to dry gases (air or fuel combustion products, etc.), as well as liquid non-electrolytes (oil, gasoline, etc.).

The mechanism of chemical corrosion is associated with the occurrence of two conjugate reactions at the phase interface: metal oxidation and reduction of the oxidizing agent, and in space these two processes, as a rule, are not separated. The accumulation of oxidation reaction products also occurs in this place. These products (oxides, sulfides, etc.) form films on the surface of metals, the structure and strength of which determines the rate of chemical corrosion. Corrosion occurs especially quickly at high temperatures.

Electrochemical corrosion

– oxidation of a metal in the presence of an electrolyte, accompanied by the formation of a galvanic couple. Thus, with electrochemical corrosion, along with the chemical process, an electrochemical process also occurs - the movement of electrons from one part of the system to another.

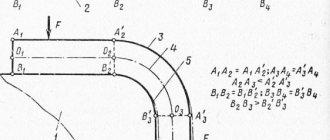

The process of electrochemical corrosion can be divided into two coupled electrode processes (Fig. 5.1):

§ Anodic process, which consists of the transition of metal atoms into solution in the form of hydrated ions, with an equivalent number of electrons remaining on the metal;

§ The cathodic process involves the binding of these excess electrons by an oxidizing agent from the environment.

Corrosion can only occur when anodic and cathodic processes occur simultaneously.

The anodic and cathodic processes occur in different areas of the metal. In this case, the movement of ions occurs in the electrolyte solution, which is in contact with the metal, and the movement of electrons in the metal. At the anodic areas, the process of transition of metal ions into solution with their simultaneous hydration takes place: . Electrons move to the cathode areas, the potential of which is more positive.

The anode sections play the role of a negative electrode - anode. The cathode sections play the role of a positive electrode - cathode. At the cathode sites, electrons are bonded by the oxidizing agent: , where Ox

– environment oxidizer;

Red

is his restored form. The rate of electrochemical corrosion depends on a number of factors, including the electrode potential at the metal/electrolyte interface.

Rice. 5.1. Scheme of the corrosion process

The processes occurring during electrochemical corrosion are similar to the processes occurring in a galvanic cell, with the difference that during electrochemical corrosion there is no external circuit, and therefore electrons move inside the corroded metal, i.e. the corrosion element is short-circuited. Corrosive elements arise on the surface of a metal or alloy, where, due to the heterogeneity of the composition, the contacting areas of the metal surface have different electrode potentials. Such areas appear due to impurities in metals, inhomogeneities in the alloy, and also when different metals in the product come into contact.

When two metals come into contact, the one that has a more negative potential (is a stronger reducing agent) is destroyed, oxidizing and going into solution in the form of ions. In this case, the electrons move to the metal with a more positive electrode potential, at which depolarization occurs - the use of these electrons to reduce the oxidizing agent.

Various oxidizing agents can be reduced in the cathodic process. Most often, there are two varieties of this process: with oxygen (in a neutral environment) and with hydrogen (in an acidic environment) depolarization.

In electrochemical corrosion with oxygen depolarization, the oxidizing agent that accepts electrons is dissolved oxygen, and the following electrode processes take place:

anodic process: ;

cathodic process: .

In electrochemical corrosion with hydrogen depolarization, the oxidizing agent that accepts electrons is hydrogen ions:

anodic process: ;

cathodic process: .

For example, corrosion of iron in contact with copper in an acidic environment proceeds as follows. A galvanic cell is created: . Since iron is a stronger reducing agent than copper, it will oxidize, causing iron ions to go into solution, forming an iron salt; the iron becomes negatively charged. Electrons will move from the iron to the copper, and the hydrogen ions in the solution will move to the surface of the copper, where they will be reduced by these electrons:

On the surface of iron: .

On the copper surface: .

During corrosion of iron in a neutral or alkaline environment, when the concentration of hydrogen ions is insignificant, oxygen dissolved in the electrolyte is reduced at the cathode, i.e. the process takes place:

.

At the same time, the formation of iron (II) ions takes place:

.

Iron ions give iron (II) hydroxide with ions:

The latter is oxidized by atmospheric oxygen to iron (III) hydroxide, which is capable of partially splitting off water to form brown rust:

Areas of application

Chemicals are used in almost all branches of modern industry. But currently, mineral and organic acids are used in the following areas:

- Boric acid (H3BO3). It is in great demand in medicine as a reliable antiseptic. H3BO3 is used in soldering various metals, this substance is also added to fertilizers and used to control cockroaches.

- At home, when baking baked goods, you cannot do without citric and acetic acids; they are also used to remove scale from taps and kettles.

- The well-known ascorbic acid, which is also known as vitamin C, is used for colds.

- Sulfuric acid (H2SO4). Actively used in the chemical industry. H2SO4 is used for the production of effective mineral fertilizers and paints and varnishes. Often used in the food industry (for example, food additive E513), and also as an electrolyte when it comes to the production of rechargeable batteries.

- A special chromium mixture (a solution of potassium dichromate in H2SO4) is used in laboratory conditions to clean chemical glassware. This substance is a strong oxidizing agent, thanks to which it helps to quickly and efficiently remove traces of contamination with organic substances. Chromium mixture is also used in organic synthesis.

- Nitric acid (HNO3). Due to its unique properties, it is in demand in the production of explosives. It is HNO3 that is used in the production of nitrogen-containing fertilizers that are in demand in the agricultural industry (for example, potassium and ammonium nitrate), as well as for the production of medications (“Nitroglycerin”).

When using any of the acids, you must follow safety rules, as such substances can cause serious harm to health.

In 8th grade, chemistry lessons provide general information on acids. But students need to remember that these are complex compounds that contain hydrogen atoms that are replaced by metal atoms and acidic residues. The chemical elements being studied are endowed with certain properties. For example, they can interact with oxides, salts and metals.

5.2. Corrosion in various environments

Some corrosive environments and the destruction they cause are so characteristic that the corrosion processes occurring in them are also classified by the name of these environments. So, they release gas

corrosion, i.e. chemical corrosion under the influence of hot gases (at temperatures well above the dew point).

Some cases of electrochemical corrosion (mainly with cathodic reduction of oxygen) in natural environments are characteristic: atmospheric

- in clean or polluted atmospheric air, with humidity sufficient to form an electrolyte film on the metal surface (especially in the presence of aggressive gases, for example, or aerosols of acids, salts and etc.);

marine

- under the influence of sea water, and

underground

- in soils and soils.

Corrosion under the influence of additional factors (impacts).

Stress corrosion develops in the area of tensile or bending mechanical loads, as well as residual deformations or thermal stresses, and usually leads to

corrosion cracking

, to which, for example, steel cables and springs are subject to atmospheric conditions, carbon and stainless steels in steam power plants, high-strength titanium alloys in sea water, etc. Under alternating loads,

corrosion fatigue

, expressed in a more or less sharp decrease in the fatigue limit of the metal in the presence of a corrosive environment. Corrosion erosion is the accelerated wear of metal under the simultaneous influence of mutually reinforcing corrosive and abrasive factors (sliding friction, flow of abrasive particles, etc.).

Electrical corrosion (electrocorrosion)

is a consequence of stray currents.

Such currents arise in the ground during the operation of grounded electrical installations operating in direct current mode (including electric vehicles). When such installations operate, part of the electric current passes through the ground and through underground metal structures, and at the latter there appear areas of DC input and output, i.e., cathode and anode sections. The anodic areas of a metal structure (rails, piles, etc.) are subject to corrosion. Similar destruction, localized near the contact, can be caused by contact in the electrolyte of two dissimilar metals forming a galvanic cell. In this case, contact corrosion

.

In narrow gaps between parts, as well as under a loose coating or build-up, where the electrolyte flows, but the access of oxygen necessary for passivation of the metal is difficult, crevice corrosion

, in which the dissolution of the metal mainly occurs in the crack, and cathodic reactions are partially or completely leak next to it, on an open surface.

It is also customary to distinguish biological

corrosion (biocorrosion), which occurs under the influence of waste products of bacteria and other microorganisms, and

radiation corrosion

- when exposed to radioactive radiation.

Quantifying Corrosion.

The rate of general corrosion is estimated by the loss of metal per unit area (

K

), for example in g/m2×h, or by the rate of corrosion penetration, i.e. by a one-sided decrease in the thickness of the intact metal (

P

), for example in mm/year.

When selecting materials that are resistant to various aggressive environments under specific conditions, use reference tables of corrosion and chemical resistance of materials or carry out laboratory and natural (directly on site and in conditions of future use) corrosion tests of samples, as well as industrial components and apparatus.

Reactions of metals with concentrated sulfuric acid

When the content of sulfuric acid in a solution is more than 68%, it is considered concentrated and interacts with metals to the left and to the right of hydrogen. The principle of the reaction with metals of varying activity is shown in the photo below. Here the oxidizing agent is the sulfur atom in the sulfate anion. It is reduced to hydrogen sulfide, tetravalent oxide or molecular sulfur.

Reactions with concentrated nitric acid

In this case, nitrogen also acts as an oxidizing agent. All reactions end with the formation of salt and the release of nitric oxide. Schemes for the occurrence of redox reactions are proposed in the graphical appendix. At the same time, the reaction of aqua regia with low-active elements deserves special attention. This interaction of acids with metals is nonspecific.

Reactions with dilute nitric acid

Dilute nitric acid reacts with metals located to the left and to the right of hydrogen. During the reaction with active metals, ammonia is formed, which immediately dissolves and reacts with the nitrate anion, forming another salt. The acid reacts with metals of medium activity to release molecular nitrogen. With low-active ones, the reaction proceeds with the release of divalent nitrogen oxide. Most often, several sulfur reduction products are formed in one reaction. Examples of reactions are provided in the graphical appendix below.