Metallurgy and metalworking are the basis of the existence and development of human civilization, since it was the beginning of the extraction and use of metals in everyday life that caused the evolution of society from the Stone Age to more developed forms. A special place in metallurgy is occupied by the creation of alloys, evidence of which is bronze, which became the basis for the emergence of the concept of the “Bronze Age”. An alloy is a mixture of several chemical elements that give the final product certain properties. There is a huge variety of alloys and methods for creating them. Of particular importance in this list is an alloy of zinc and copper, also called brass.

What are alloys?

Alloys are materials made from a mixture of several metals and other elements. They may contain random admixtures of natural components. One of the first known alloys was bronze. Man created products from it back in the 4th millennium BC.

Alloys are made to improve the quality of metals. For example, to make gold jewelry last longer, be stronger, or have a certain shade, a small proportion of nickel, platinum, zinc or silver is added to it.

By mixing several components, you can change the properties of the metal, increase the melting point and malleability, impart strength and hardness, and increase wear resistance. The most common alloys are bronze, brass (an alloy of copper and zinc), cast iron, steel, Babbitt, Pobedit, and duralumin.

They are used in mechanical engineering, construction, industry, aircraft manufacturing, etc. Magnets are made from a mixture of nickel, magnesium and cobalt. Tin and lead were formerly used to make cutlery, and cast iron was widely used to make household items such as frying pans and irons.

Necessary theoretical information.

Methods of expressing the composition of mixtures.

- The mass fraction of a component in a mixture

is the ratio of the mass of the component to the mass of the entire mixture. Usually the mass fraction is expressed in %, but not necessarily. ω ["omega"] = mcomponent / mmixture - Mole fraction of the component in the mixture

- the ratio of the number of moles (amount of substance) of a component to the total number of moles of all substances in the mixture. For example, if the mixture contains substances A, B and C, then:χ ["chi"] component A = ncomponent A / (n(A) + n(B) + n(C))

- Molar ratio of components.

Sometimes problems for a mixture indicate the molar ratio of its components. For example:ncomponent A : ncomponent B = 2 : 3

- Volume fraction of the component in the mixture(only for gases)

- the ratio of the volume of substance A to the total volume of the entire gas mixture.φ ["phi"] = Vcomponent / Vmixture

Electrochemical voltage series of metals.

| Li Rb K Ba Sr Ca Na Mg Al Mn Zn Cr Fe Cd Co Ni Sn Pb H Sb Bi Cu Hg Ag Pd Pt Au |

Reactions of metals with acids.

- With mineral acids, which include all soluble acids ( except for nitric and concentrated sulfuric acids

, the interaction of which with metals occurs in a special way),

only metals

up to (to the left of) hydrogen

in the electrochemical voltage series . - At the same time, metals that have several oxidation states (iron, chromium, manganese, cobalt) exhibit the minimum possible oxidation state - usually +2.

- The interaction of metals with nitric acid

leads to the formation, instead of hydrogen, of nitrogen reduction products, and with

concentrated sulfuric acid

- to the release of sulfur reduction products. Since a mixture of reduction products is actually formed, there is often a direct reference to a specific substance in the problem.

Nitric acid reduction products.

| The more active the metal and the lower the acid concentration, the further nitrogen is reduced | ||||

| NO2 | NO | N2O | N2 | NH4NO3 |

| Inactive metals (to the right of iron) + conc. acid Nonmetals + conc. acid | Inactive metals (to the right of iron) + dil. acid | Active metals (alkali, alkaline earth, zinc) + conc. acid | Active metals (alkali, alkaline earth, zinc) + medium dilution acid | Active metals (alkali, alkaline earth, zinc) + very diluted. acid |

| Passivation: the following do not react with cold concentrated nitric acid: Al, Cr, Fe, Be, Co. | ||||

| Do not react with nitric acid at any concentration : Au, Pt, Pd. | ||||

Products of the reduction of sulfuric acid.

| SO2 | S | H2S | H2 | |

| Inactive metals (to the right of iron) + conc. acid Nonmetals + conc. acid | Alkaline earth metals + conc. acid | Alkali metals and zinc + concentrated acid. | Dilute sulfuric acid behaves like ordinary mineral acid (for example, hydrochloric acid) | |

| Passivation: the following do not react with cold concentrated sulfuric acid: Al, Cr, Fe, Be, Co. | ||||

| Do not react with sulfuric acid at any concentration : Au, Pt, Pd. | ||||

Reactions of metals with water and alkalis.

- Only

metals that correspond to soluble bases (alkalis) dissolve in water at room temperature These are alkali metals (Li, Na, K, Rb, Cs), as well as group IIA metals: Ca, Sr, Ba. This produces alkali and hydrogen. Boiling water can also dissolve magnesium. - Only amphoteric metals can dissolve in alkali: aluminum, zinc and tin. In this case, hydroxo complexes are formed and hydrogen is released.

Copper-zinc alloy

A mixture of copper and zinc is called brass. Like bronze, it appeared before our era. Since then, its manufacturing technology has changed somewhat. In the past, copper was mixed with charcoal and zinc ore to make brass. In the 18th century, Englishman James Emerson proposed mixing the metals themselves without the use of ore.

The base of brass is copper. The zinc content varies from 5 to 45 percent. Because of its yellowish color, reminiscent of gold, in ancient Rome brass was called orichalcum, which literally means “golden copper.”

The alloy of copper and zinc is not always limited to only these metals. It may contain some tin, lead, iron, manganese, nickel and other components. If you add more tin than zinc, you get a completely different material - tin bronze.

History of appearance and application

Brass has been known since the beginning of the new era and was first produced in the Roman Empire, but was also used in India and China. Later, the method of smelting zinc was lost in Europe, so for a long time the metal was imported from Asia. Zinc mining in Europe resumed in the 16th century, and brass smelting began in the 19th century. Thanks to archaeological excavations, it is known that brass was widely used for jewelry, as it has the characteristic yellow color of gold and is called “fake gold.” With the development of metallurgy, the alloy expanded its scope of application, which was ensured by regulating the characteristics of the metal by varying the ratio of its components.

Properties of brass

Depending on the amount of zinc, the color and quality of brass varies. The less it is, the more red and saturated the color of the material. If the alloy of copper and zinc does not contain other elements, it is called simple brass, which is divided into two types: tombak (zinc up to 20%) and yellow brass (zinc from 20%).

The material brass is very ductile and exhibits greater resistance to corrosion than copper. The melting point ranges from 880°C to 950°C, decreasing with larger proportions of zinc. The metal lends itself well to welding, rolling and pressure processing.

Yellow brass cracks when exposed to humid air. This can be corrected by annealing at a temperature of 250 °C. Multi-component brass resists corrosion better and is stronger. Adding tin to the composition promotes resistance to sea water.

The content of impurities in the alloy can be found on the product labeling. Capital letters indicate the names of the components. First comes the letter “L”, then the remaining additional (alloying) elements. After them, the percentage content of substances is indicated in accordance with the letter order, with the first two digits indicating the amount of copper in the alloy. Thus, the marking LAZH60-1-1 means that brass consists of 60% copper, 1% aluminum and 1% iron, the rest is zinc.

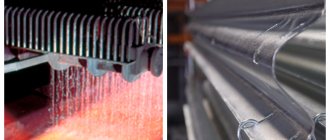

Brass production

Modern methods of producing brass are based on melting chalcopyrite (copper pyrite) in electric furnaces at a temperature of +1400 °C.

The silicate formed during the melting process floats to the surface and is removed. The base metal (matte) is poured into the converter and purged with oxygen. As a result of oxidation reactions, metallic “blister” copper is formed with a metal content of about 91%. Next, electrolytic purification occurs in an acidified solution of copper sulfate. The electrolytic copper produced at the cathode is 99.99% pure and is used in the production of wires, electrical equipment and alloys. Zinc is introduced into molten copper in portions, which gives it new properties - strength, corrosion resistance and ductility. Depending on the application of the metal, other additives may be added: nickel, iron, tin, manganese, aluminum. The copper alloy made in this way has a low coefficient of friction and is used in the manufacture of worm gears and as sliding bushings in small household electric motors.

There are many versions about what the alloy is called and where the name brass comes from. During the reign of Augustus, it was called orichalcum, which literally means golden copper. The current name came into Russian from the German latun, which, in turn, came from the Italian lattone - crown, or laton (latta) - tin. This is currently the most common version.

One type of brass is tombac (copper - 88-97%, zinc - up to 10%), which was rediscovered by London watchmaker Christopher Pinchbecker in the 18th century. Previously, this alloy was known to the Peruvian Moche civilization. Its name comes from the French tombak, which means copper.

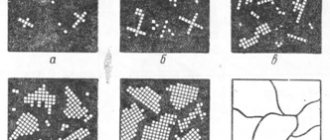

Tompak is widely used in steel cladding and the production of steel-brass bimetallic joints.

Brass is made by melting copper and steel.

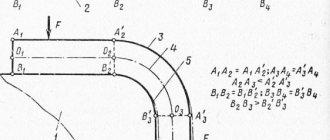

Cladding (French plaquer - to apply, cover) is a thermomechanical coating used to impart special properties to metal using other materials.

For example, the internal surface of a nuclear reactor is clad with high-alloy austenitic steel, since the base metal of the body is susceptible to corrosion when exposed to high temperatures.

Tompak is used for cladding steel in the production of coins of 10 and 50 kopecks.

Where is brass used?

Brass has good heat capacity. It is no coincidence that samovars were made from it in Ancient Rus'. In Rome, under Octavian Augustus, coins of sestertia and dupondium were minted from brass. In the Middle Ages, it was used to make jewelry, frame compasses, and decorate objects of art.

And now the material is used everywhere. Jewelry and small interior items are made from brass. A special artificial aging technique gives brass products a special charm. Figurines, door handles, and mirror frames are cast from it.

The high technological properties of brass make it possible to use the material for the production of small building parts, tubes, plates, tapes and wires. The alloy with lead is used for cars and watches, tombac is used for cladding steel and making radiator pipes. Insignia are made from a composition containing 0.5% aluminum, as it has a golden hue.

Areas of application

Brass is used in the following areas:

- Making jewelry from brass. Despite the fact that in the jewelry business only costume jewelry is made from it, the demand for such products is great.

- Due to its plasticity, furniture decorations are forged from it. Fittings are also manufactured.

- If the zinc content is 40%, the alloy is used in shipbuilding, watch movements and aircraft construction.

- Water taps, mixers, and fittings are made from it.

Brass faucet

Examples of solving problems C4 (task 33) in chemistry

Examples of problem solving.

Let's look at three examples of problems in which mixtures of metals react with hydrochloric acid

acid:

Example 1. When a mixture of copper and iron weighing 20 g was exposed to excess hydrochloric acid, 5.6 liters of gas (no.) were released. Determine the mass fractions of metals in the mixture.

In the first example, copper does not react with hydrochloric acid, that is, hydrogen is released when the acid reacts with iron. Thus, knowing the volume of hydrogen, we can immediately find the amount and mass of iron. And, accordingly, the mass fractions of substances in the mixture.

Solution to example 1.

- Find the amount of hydrogen: mole.

- According to the reaction equation:

The amount of iron is also 0.25 mol. You can find its mass:

G.

- Now you can calculate the mass fractions of metals in the mixture:

Answer: iron, copper.

Example 2. When a mixture of aluminum and iron weighing 11 g was exposed to excess hydrochloric acid, 8.96 liters of gas (no.) were released. Determine the mass fractions of metals in the mixture.

both react

metal Here, hydrogen is already released from the acid in both reactions. Therefore, direct calculation cannot be used here. In such cases, it is convenient to solve using a very simple system of equations, taking as - the number of moles of one of the metals, and as - the amount of substance of the second.

Solution to example 2.

- Find the amount of hydrogen: mole.

- Let the amount of aluminum be mole and the amount of iron mole. Then we can express through and the amount of hydrogen released:

– molar ratio

- We know the total amount of hydrogen: moles. This means (this is the first equation in the system).

- For a mixture of metals we need to express masses

through the amount of substances. This means the mass of aluminum

mass of iron

and the mass of the entire mixture

(this is the second equation in the system).

- So, we have a system of two equations: It is much more convenient to solve such systems using the subtraction method, multiplying the first equation by 18: and subtracting the first equation from the second:

mole

mole

- Next we find the masses of metals and their mass fractions in the mixture:

G

G

respectively,

Answer: iron, aluminum.

Example 3. 16 g of a mixture of zinc, aluminum and copper were treated with an excess of hydrochloric acid solution. In this case, 5.6 liters of gas (n.s.) were released and 5 g of the substance did not dissolve. Determine the mass fractions of metals in the mixture.

In the third example, two metals react, but the third metal (copper) does not react. Therefore, the remainder of 5 g is the mass of copper. The amounts of the remaining two metals - zinc and aluminum (note that their total mass is 16 - 5 = 11 g) can be found using a system of equations, as in example No. 2.

Answer to Example 3: 56.25% zinc, 12.5% aluminum, 31.25% copper.

The next three example problems (No. 4, 5, 6) contain reactions of metals with nitric and sulfuric acids. The main thing in such tasks is to correctly determine which metal will dissolve in it and which will not.

Ads by Browser ShopAd Options

Example

4. A mixture of iron, aluminum and copper was treated with an excess of cold concentrated sulfuric acid.

In this case, part of the mixture dissolved, and 5.6 liters of gas (n.s.) were released. The remaining mixture was treated with an excess of sodium hydroxide solution. 3.36 liters of gas were released and 3 g of undissolved residue remained. Determine the mass and composition of the initial mixture of metals. In this example, we must remember that cold concentrated

sulfuric acid does not react with iron and aluminum (passivation), but does react with copper. This releases sulfur (IV) oxide.

With alkali

Only aluminum

reacts (in addition to aluminum, zinc and tin also dissolve in alkalis, and beryllium can also be dissolved in hot concentrated alkali).

Solution to example 4.

- Only copper reacts with concentrated sulfuric acid, number of moles of gas: mol

(conc.) (do not forget that such reactions must be equalized using an electronic balance)

Since the molar ratio of copper and sulfur dioxide is , then copper is also a mole. You can find a mass of copper:

G.

- Aluminum reacts with an alkali solution, resulting in the formation of a hydroxo complex of aluminum and hydrogen:

- Number of moles of hydrogen: mole, molar ratio of aluminum and hydrogen and therefore

mole.

Aluminum weight:

G

- The remainder is iron, weighing 3 g. You can find the mass of the mixture: g.

- Mass fractions of metals:

Answer: copper, aluminum, iron.

Example 5. 21.1 g of a mixture of zinc and aluminum was dissolved in 565 ml of nitric acid solution containing 20 wt. % НNO 3 and having a density of 1.115 g/ml. The volume of the released gas, which is a simple substance and the only product of the reduction of nitric acid, was 2.912 l (n.s.). Determine the composition of the resulting solution in mass percent. (RHTU)

The text of this problem clearly indicates the product of nitrogen reduction—a “simple substance.” Since nitric acid with metals does not produce hydrogen, it is nitrogen. Both metals dissolved in the acid.

The problem asks not the composition of the initial mixture of metals, but the composition of the resulting solution after the reactions. This makes the task more difficult.

Solution to example 5.

- Determine the amount of gas substance: mole.

- Determine the mass of the nitric acid solution, the mass and amount of dissolved substance:

G

G

mole

Please note that since the metals have completely dissolved, it means there is definitely enough acid

(these metals do not react with water).

Accordingly, it will be necessary to check whether the acid is in excess

, and how much of it remains after the reaction in the resulting solution.

- We compose reaction equations (don't forget about your electronic balance

) and, for the convenience of calculations, we take for - the amount of zinc, and for - the amount of aluminum. Then, in accordance with the coefficients in the equations, nitrogen in the first reaction will be mole, and in the second - mole:

- Then, taking into account that the mass of the mixture of metals is g, their molar masses are g/mol for zinc and g/mol for aluminum, we obtain the following system of equations:

– amount of nitrogen – mass of a mixture of two metals

It is convenient to solve this system by multiplying the first equation by 90 and subtracting the first equation from the second.

means mole

means mole

Let's check the mass of the mixture:

G.

- Now let's move on to the composition of the solution. It will be convenient to rewrite the reactions again and write down above the reactions the amounts of all reacted and formed substances (except water):

- The next question is: is there nitric acid left in the solution and how much of it is left? According to the reaction equations, the amount of acid that reacted: mole,

those. the acid was in excess and you can calculate its remainder in the solution:

mole.

- So, in final solution

contains:

zinc nitrate in mole amount:

G

aluminum nitrate in moles:

G

excess nitric acid in the amount of moles:

G

- What is the mass of the final solution? Let us remember that the mass of the final solution consists of those components that we mixed (solutions and substances) minus those reaction products that left the solution (precipitates and gases):

=

Sum of masses of mixed solutions and/or substances

—

Weight of precipitation

—

Mass of gases

- Then for our task:

- = mass of acid solution + mass of metal alloy – mass of nitrogen

- G

- G

- Now you can calculate the mass fractions of substances in the resulting solution:

Answer: zinc nitrate, aluminum nitrate, nitric acid.

Example 6. When a mixture of copper, iron and aluminum was treated with an excess of concentrated nitric acid, liters of gas (n.s.) were released, and when this mixture was exposed to the same mass of excess hydrochloric acid, liters of gas (n.s.) were released. Determine the composition of the initial mixture. (RHTU)

When solving this problem, we must remember, firstly, that concentrated nitric acid with an inactive metal (copper) gives, but iron and aluminum do not react with it. Hydrochloric acid, on the contrary, does not react with copper.

Answer to example 6: copper, iron, aluminum.

Problems for independent solution.

1. Simple problems with two mixture components.

1-1.

A mixture of copper and aluminum weighing g was treated with a solution of nitric acid, and l of gas (n.o.) was released. Determine the mass fraction of aluminum in the mixture.

1-2.

A mixture of copper and zinc weighing 1 g was treated with a concentrated alkali solution. At the same time, liters of gas (n.y.) were released. Calculate the mass fraction of zinc in the initial mixture.

1-3.

A mixture of magnesium and magnesium oxide weighing g was treated with a sufficient amount of dilute sulfuric acid. At the same time, liters of gas (n.s.) were released. Find the mass fraction of magnesium in the mixture.

1-4.

A mixture of zinc and zinc oxide, weighing g, was dissolved in dilute sulfuric acid. We have obtained zinc sulfate weighing g. Calculate the mass fraction of zinc in the original mixture.

1-5.

When a mixture of iron and zinc powders weighing g reacted with an excess solution of copper (II) chloride, g of copper was formed. Determine the composition of the initial mixture.

1-6.

What mass of hydrochloric acid solution will be required to completely dissolve g of a mixture of zinc and zinc oxide, if hydrogen is released with a volume of l (n.s.)?

1-7.

When a mixture of iron and copper is dissolved in dilute nitric acid, nitrogen oxide (II) is released in a volume of l (n.s.). Determine the composition of the initial mixture.

1-8.

When g of a mixture of iron and aluminum filings was dissolved in a solution of hydrochloric acid (g/ml), l of hydrogen (n.s.) was released. Find the mass fractions of metals in the mixture and determine the volume of hydrochloric acid consumed.

2. The tasks are more complex.

2-1.

A mixture of calcium and aluminum weighing g was calcined without air with an excess of graphite powder. The reaction product was treated with dilute hydrochloric acid, and a liter of gas (n.o.) was released. Determine the mass fractions of metals in the mixture.

2-2.

To dissolve magnesium alloy with aluminum, ml of sulfuric acid solution (g/ml) was used. Excess acid reacted with ml of mol/l potassium bicarbonate solution. Determine the mass fractions of metals in the alloy and the volume of gas (no.) released during the dissolution of the alloy.

2-3.

When g of a mixture of iron and iron (II) oxide was dissolved in sulfuric acid and the solution was evaporated to dryness, g of iron sulfate was formed - iron (II) sulfate heptahydrate. Determine the quantitative composition of the initial mixture.

2-4.

The interaction of iron weighing g with chlorine resulted in the formation of a mixture of iron (II) and (III) chlorides weighing g. Calculate the mass of iron (III) chloride in the resulting mixture.

2-5.

What was the mass fraction of potassium in its mixture with lithium, if as a result of treating this mixture with excess chlorine, a mixture was formed in which the mass fraction of potassium chloride was ?

2-6.

After treating a mixture of potassium and magnesium with a total mass of g with excess bromine, the mass of the resulting mixture of solids turned out to be equal to g. This mixture was treated with an excess of sodium hydroxide solution, after which the precipitate was separated and calcined to constant weight. Calculate the mass of the resulting residue.

2-7.

A mixture of lithium and sodium with a total mass of g was oxidized with excess oxygen, a total of l (n.s.) was consumed. The resulting mixture was dissolved in g sulfuric acid solution. Calculate the mass fractions of substances in the resulting solution.

2-8.

An aluminum-silver alloy was treated with an excess of a concentrated solution of nitric acid, and the residue was dissolved in acetic acid. The volumes of gases released in both reactions, measured under the same conditions, turned out to be equal. Calculate the mass fractions of metals in the alloy.

3. Three metals and complex problems.

3-1.

When a mixture of copper, iron and aluminum was treated with an excess of concentrated nitric acid, a liter of gas was released. The same volume of gas is released when the same mixture of the same mass is treated with an excess of dilute sulfuric acid (DS). Determine the composition of the initial mixture in mass percent.

3-2.

g of a mixture of iron, copper and aluminum, interacting with an excess of dilute sulfuric acid, releases l of hydrogen (n.s.). Determine the composition of the mixture in mass percent if chlorination of the same sample of the mixture requires liters of chlorine (n.s.).

3-3.

Iron, zinc and aluminum filings are mixed in molar ratio (in the order listed). g of this mixture was treated with excess chlorine. The resulting mixture of chlorides was dissolved in ml of water. Determine the concentrations of substances in the resulting solution.

3-4.

An alloy of copper, iron and zinc weighing g (the masses of all components are equal) was placed in a solution of hydrochloric acid weighing g. Calculate the mass fractions of substances in the resulting solution.

3-5.

g of a mixture consisting of silicon, aluminum and iron was treated with excess sodium hydroxide when heated, and l of gas (n.s.) was released. When such a mass of mixture is exposed to excess hydrochloric acid, liters of gas (n.s.) are released. Determine the masses of substances in the original mixture.

3-6.

When a mixture of zinc, copper and iron was treated with an excess of concentrated alkali solution, gas was released, and the mass of the undissolved residue turned out to be several times less than the mass of the original mixture. This residue was treated with an excess of hydrochloric acid, the volume of gas released turned out to be equal to the volume of gas released in the first case (the volumes were measured under the same conditions). Calculate the mass fractions of metals in the initial mixture.

3-7.

There is a mixture of calcium, calcium oxide and calcium carbide with the molar ratio of the components (in the order listed). What is the minimum volume of water that can enter into a chemical reaction with such a mixture of mass g?

3-8.

A mixture of chromium, zinc and silver with a total mass of g was treated with dilute hydrochloric acid, the mass of the undissolved residue turned out to be equal to g. After separating the precipitate, the solution was treated with bromine in an alkaline medium, and at the end of the reaction it was treated with an excess of barium nitrate. The mass of the formed precipitate turned out to be equal to g. Calculate the mass fractions of metals in the initial mixture.

Answers and comments to problems for independent solution.

1-1. (aluminum does not react with concentrated nitric acid);

1-2. (only the amphoteric metal, zinc, dissolves in alkali);

1-3. ;

1-4. ;

1-5. (iron, displacing copper, goes into oxidation state);

1-6. G;

1-7. (iron in nitric acid goes into);

1-8. (iron reacts with hydrochloric acid into); ml of solution.

2-1. (calcium and aluminum with graphite (carbon) form carbides and; when they are hydrolyzed with water or are released, acetylene and methane, respectively);

2-2. ;

2-3. (ferrous sulfate heptahydrate - );

2-4. G;

2-5. ;

2-6. G;

2-7. (when lithium is oxidized with oxygen, its oxide is formed, and when sodium is oxidized, peroxide is formed, which hydrolyzes in water to hydrogen peroxide and alkali);

2-8. ;

3-1. ;

3-2. ;

3-3. (iron reacts with chlorine to an oxidation state);

3-4. (don’t forget that copper does not react with hydrochloric acid, so its mass is not included in the mass of the new solution);

3-5. g g g (silicon is a non-metal; it reacts with an alkali solution, forming sodium silicate and hydrogen; it does not react with hydrochloric acid);

3-6. ;

3-7. ml;

3-8. (chromium, when dissolved in hydrochloric acid, turns into chromium (II) chloride, which, when exposed to bromine in an alkaline medium, turns into chromate; when barium salt is added, insoluble barium chromate is formed)

Advantages and disadvantages

Most zinc alloys have the following advantages:

- they are very durable and are not damaged by mechanical stress;

- resistant to corrosion;

- have good casting qualities and can be used to create even small elements;

- Over time, they practically do not age.

However, even small amounts of impurities worsen the characteristics of the alloy. They lead to a decrease in melting point, swelling, and contribute to the appearance of cracks. Therefore, zinc alloys must be created in compliance with all technologies, and the amount of impurities in them should not exceed 0.005%.

Many people ask whether zinc alloys darken or not? This is another drawback of the material. Zinc alloys may darken over time. Moreover, the darkening usually spreads over the entire surface of the material. This is caused by the formation of an oxide film on the surface of the material. It forms at room temperature after contact with air or water. Therefore, to avoid this, electroplating is required.