Results and discussion

Combustion of metals, their alloys, metal-containing substances, incl. Organometallic substances according to GOST 27331-87 are divided into 3 classes:

- class D1 – combustion of light metals (aluminum, magnesium and their alloys, calcium, titanium), conventionally “heavy” metals (zirconium, niobium, uranium, etc.);

- class D2 – combustion of alkali metals (lithium, sodium, potassium, etc.);

- class D3 – (organometallic compounds: aluminium, lithium, organozinc, hydrides of aluminum, lithium, etc.).

Each of the listed metals and their hydrides is a solid in its normal state, except for organometallic compounds (MOCs), which are liquids.

Of the features of metals that are directly related to their fire, explosion and combustion hazards, the following should be noted:

- tendency to spontaneous combustion under normal conditions (i.e. pyrophoricity);

- the ability to explode in a state of air suspension;

- interaction of burning metals with water, some gaseous fire extinguishing compounds: freons (chlorofluorocarbons), nitrogen (for example, magnesium), etc.

Alkali metals, shavings, metal powders with a non-oxidized active surface, metal hydrides, MOS (fire classes D2, D3) have the ability to spontaneously ignite.

The most flammable and explosive metals, the combustion of which occurs in class D1, are light metals in the form of their processing products: powders of different dispersion, shavings. It is almost impossible to ignite metals in the form of products of various configurations (sheets, profiles, etc.) if the conditions for the predominance of heat removal over heat gain are ensured.

Metal hydrides occupy an intermediate position between metals and organic compounds. This is due to the fact that during their decomposition hydrogen is released, which can be considered as an analogy to the process of release of flammable gases during the pyrolysis of organic materials burning in the gas phase [1]

.

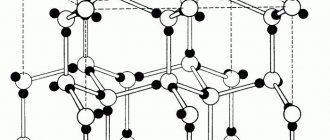

At the same time, metal hydrides differ significantly from each other in their physical and chemical properties, in the mechanism of combustion and ignition. Thus, hydrides of titanium, niobium, tantalum, etc. are essentially solutions of hydrogen in metal and have a variable composition with a metallic type of bond. They burn mainly in a smoldering mode; there is practically no flaming combustion of hydrogen.

At the same time, lithium aluminum hydride (LAH), aluminum hydrides (HA) and lithium hydrides (HL) are pronounced individual compounds with ionic (for GL - partially covalent) bonds, characterized by the presence of flame and heterogeneous combustion modes [2]

.

HA and alkali metal hydrides exhibit pyrophoric properties, actively interact with air moisture, with slight heating they actively release hydrogen and, as a result, form hybrid explosive mixtures with air in the state of air suspension.

At elevated temperatures and during combustion, nitrogen can interact with the most active hydrides, for example, HA.

A slight dilution of nitrogen with air can lead to a very “hard” explosion of the HA air suspension, so not all metal hydrides can use nitrogen as a protective atmosphere. Sometimes you have to use argon for this.

Thus, the nature of the combustion of metals and metal-containing substances excludes the use of water, water-foam extinguishing agents and a number of gas fire extinguishing compounds, since when these agents come into contact with burning metals, they interact, leading to combustion.

In Russia and world practice, special-purpose fire extinguishing powder compositions (OPSN) are used to extinguish fires of classes D1, D2, D3. When creating the formulation of such compositions, the following factors are taken into account:

- the main substance that determines this composition (from 80 to 95% vol.) should not contain an oxygen atom in the molecule (not support combustion) and not enter into a chemical reaction with the metal;

- OPSN must have a certain fractional composition (usually in the range of 50-75 microns);

- SPSN should not cake during storage, which is achieved by including anti-caking, water-repellent additives in their composition, and also have a number of other performance properties in accordance with generally accepted technical requirements;

Currently, the most common for extinguishing fires of classes D1, D2, D3 are fire protection equipment based on alkali metal chlorides (KCl - Russia and NaCl - Europe, USA). There are a number of liquid compositions (for example, based on boron ethers) as fire extinguishing compositions for metals, but they have not found widespread use in fire extinguishing practice.

The main principle of achieving a positive result when extinguishing metal-containing substances (according to classes D1, D2, D3) is the creation, with the help of fire protection equipment, of a protective complete covering of the combustion area, preventing the access of air oxygen to the combustion zone. Such a coating must be sufficiently dense and have the required thickness of the powder layer over the entire surface of the combustion site, which is achieved at a certain specific powder consumption (kg/m2).

Extinguishing metals and metal-containing substances has a number of features inherent in each group of substances in classes D1, D2, D3, including:

- to extinguish metals according to class D1, fire protection equipment must meet the criteria given above, while the powder is based on, for example, potassium chloride with a density of about 1 g/cm3);

- for extinguishing metal hydrides (D3), OPSN is used with characteristics similar to OPSN used for extinguishing class D1;

- for organometallic substances that are liquids under normal conditions, OPSN should have a density close to the density of these substances (~ 0.7-0.8 g/cm3), which is ensured by the introduction of a low-density non-flammable additive into the powder composition (perlite, vermiculite) , which also promotes the adsorption of MOC and improves the reliability of extinguishing.

When extinguishing sodium [3]

The so-called “capillary” or wick combustion effect occurs due to the growth of oxide formations growing through the layer of powder, through which liquid sodium penetrates and burns in the form of a wick. To prevent the growth of oxides, special additives are usually used.

Extinguishing metals and metal-containing compounds of fire-fighting equipment is fundamentally different from extinguishing, for example, hydrocarbon flammable liquids, gas liquids (fire classes A, B, C) with general-purpose powders. In the case of extinguishing fires of class D (D1, D2, D3), the main task when supplying fire protection equipment is to create a layer of powder coating on the surface of the combustion site, preferably equal in height, which is achieved by using so-called dampers attached to the supply device (at the outlet of the supply barrel ) fire extinguishers, powder vehicles. The use of a dampening nozzle when supplying fire extinguishing equipment is necessary when extinguishing metal powders and their hydrides, while the formation of an aerosol suspension of fire extinguishing powder is practically prevented. To extinguish fires of classes A, B, C, a “pistol” type spray device is used, which creates a powder cloud over the combustion source, which helps to achieve extinguishing.

OPSN can be used to extinguish radioactive metals. When using, for example, a fire extinguishing agent based on potassium chloride, the release of radioactive aerosols is significantly reduced.

However, the use of powder fire extinguishing also has its disadvantages:

- The fire extinguishing powder composition, unlike water, does not have a cooling effect. Reliable extinguishing can be achieved by cooling metals to a temperature below their auto-ignition temperature. And the temperature of burning metals, as a rule, is significantly higher than the self-ignition temperature, so the process of extinguishing metals and their hydrides is lengthy;

- Almost all powder extinguishing vehicles produced have limited technical capabilities and cannot provide reliable extinguishing in rooms with a volume of more than 300-600 m3. The maximum height for supplying fire extinguishing equipment, depending on the type of powder extinguishing vehicle and the pressure in the tank, is 10-25 m, while the maximum distance for supplying powder horizontally is 40-60 m, which in some cases is insufficient to ensure delivery of the powder to the site sunbathing

Fire hazard of liquid flammable substances

The fire hazard of flammable liquids is determined by the flash point of the vapors of the evaporating liquid when a heat source is introduced. The flash point is the lowest temperature at which vapors of a flammable substance create a vapor-air mixture above its surface that ignites when a heat source is introduced (for example, an open fire).

During the flash, the surface of the flammable liquid does not warm up to a temperature sufficient for intensive evaporation of the liquid, and further combustion stops. If the temperature of the liquid at the moment of the flash is sufficient for the flash to be followed by combustion, then this temperature is called the ignition temperature of the flammable liquid.

The lower the flash point of a flammable liquid, the greater the fire hazard. According to the existing classification, all flammable liquids are divided into two classes. Class I includes liquids with a flash point of less than 45°C (for example, gasoline, alcohol, ether, kerosene, etc.), and class II includes liquids with a flash point of more than 450°C (for example, oils, fuel oils, etc.). Class I flammable liquids are classified as flammable liquids, and class II liquids are classified as flammable.

It should be noted that the fire hazard of a number of solid substances (for example, naphthalene, phosphorus, camphor, etc., which evaporate at normal temperatures) is also characterized by a flash point.

For flammable liquids there is a small (1-2°C) difference between the flash point of the vapor and the ignition temperature. For flammable liquids this difference reaches 30 0C or more.

The fire hazard of liquids increases with a decrease in the flash point, ignition temperature and auto-ignition temperature, as well as with an increase in the evaporation rate and a decrease in the lower limit of the concentration of an explosive mixture of liquid vapor and air.

Literature:

- Chibisov A.L., Soina E.A., Gabrielyan S.G., Smirnova T.M., Gabrielyan G.S. Limiting conditions and features of ignition, combustion and extinguishing of various metals // Hydrogen materials science and chemistry of metal hydrides: Collection of abstracts of the VII international conference. - Ukraine, Yalta, 2001. - P. 416.

- Chibisov A.L., Smirnova T.M., Gromov A.D., Akinin N.I. Determination of the safe specific rate of hydrogen evolution in a technological process // Hydrogen materials science and chemistry of metal hydrides: Collection of abstracts of the VIII international conference. - Ukraine, Yalta, 2003. P.356-357.

- Gabrielyan S. G., Gabrielyan G. S. Recommendations for quenching liquid sodium and pyrophoric organoaluminum catalysts M.: Izd. VNIIPO, 2000, 19 p.

Other related articles:

- Basic suspension and steering problems - part 1

- Safety precautions and basic safety requirements during disassembly

- Sharpening and straightening cutting tools

- Basic suspension and steering problems - part 2

- Main elements of the ignition system. Ignition coil. Part 2

- Main elements of the ignition system. Ignition coil. Part 1

- Safety precautions when operating washing equipment and using detergents

- Workplace. Features of the organization and safety

- Safety precautions when using benzene and antifreeze

- Safety precautions when working on the line

Fire hazard of dust

Dust of flammable substances in the airgel state (in the form of dust deposits) can smolder and burn, and being in the form of an aerosol, i.e., being suspended in the air, it can explode, forming explosive dust-air mixtures. Dust combustion is greatly facilitated by the adsorption of air oxygen by dust. The explosiveness of dust increases with a decrease in dust particles due to an increase in its specific surface area. The auto-ignition temperature of combustible dust usually ranges from 700-900°C, but some types of dust have a relatively low auto-ignition temperature (for example, soot explodes at 360°C).

Similar to flammable gases and vapors, dust has lower and upper limits for explosive concentrations. The lower limit of explosive concentration (heat source is a hot body) for sulfur dust is 7, sugar 10.3, aluminum 7 and coal dust 17.2 g/m3.

The limits of explosive dust concentration depend on humidity, dispersion, temperature and power of the heat source and other factors. The pressure developed during dust explosions usually does not exceed 0.4–0.6 mN/m2 (4–6 atm).