Self-analysis of a chemistry lesson conducted in 9th grade on the topic “Alloys.”

For me, self-analysis of a lesson is a kind of reflection that allows me to assess my weaknesses and strengths, identify unused resources, evaluate ways of working in interaction with the class; makes it possible to compare the activities in the lesson with the tasks that were set by me. In the process of my own assessment, I can identify the level of achievement of the planned results.

So, the lesson on the topic “Alloys”, included in Chapter I of the 9th grade chemistry course, which corresponds to the work program compiled on the basis of an example program, had a goal that was mainly aimed at a meta-subject result: to develop the ability to organize educational cooperation and joint activities with teacher and peers; work individually and in a group.

Personal UUD: be able to realize the unity and integrity of the surrounding world, the possibility of its knowability and explainability based on the achievements of science.

Cognitive UUD: be able to acquire new knowledge: find answers to questions using a textbook, information received in class, convert information from one type to another.

Communicative UUD: be able to express your thoughts in written and oral form, lead a discussion, be able to prove your point of view.

Regulatory: be able to independently discover and formulate an educational problem, determine a goal, and draw up a plan for solving problems.

Lesson summary: Metal alloys

11th grade chemistry

The purpose of the lesson:

organize work to assimilate students’ knowledge of the concepts of ferrous and non-ferrous metals, alloys and their application.

Objectives:

Educational.

Generalize and deepen students’ knowledge about metal alloys and their properties. Show the differences between metals and metal alloys. Consider the classification of alloys according to various criteria. Consider the structural features, properties and application of ferrous alloys. Practice problem solving skills.

Developmental.

To develop in schoolchildren the ability to highlight the main thing in the material being studied, compare, generalize, draw conclusions, and draw diagrams.

Educational.

During the lesson, promote the formation of a worldview idea of the cause-and-effect relationship of the composition, structure and properties of metals.

Lesson type:

lesson - learning new material.

During the classes.

Org moment.

Open your notebooks, write down the date and topic of the lesson

Today we have to recall and expand knowledge about metals and alloys, their classification, the properties of ferrous alloys, their production and use. But, before we move on to studying it, let us remember the basic properties of metals as simple substances.

Updating knowledge. Frontal survey:

- Where are metals located in the periodic table?

- How do metallic properties vary across periods and groups?

- What are the peculiarities of the structure of metal atoms and their crystal lattices?

- What metals are attracted to a magnet?

- List the general physical properties of metals.

- What differences exist in the physical properties of metals?

Learning new material.

Metals and alloys .

Now that we have become familiar with the properties of the most important metals of the main and secondary subgroups, we can recall alloys. What is the difference between simple metals and alloys?

Simple metals

consist of one main element and a small amount of impurities of other elements.

For example, technically pure copper contains from 0.1 to 1% impurities of lead, bismuth, antimony, iron and other elements. Alloys

are complex metals that are a combination of a simple metal (the base of the alloy) with other metals or non-metals.

For example, brass is an alloy of copper and zinc. Here the base of the alloy is copper. Compare the physical properties of metals and alloys.

High electrical conductivity, thermal conductivity, malleability, ductility, metallic luster, opacity.

Thus, the concept of alloys can be formulated as follows (write it down in a notebook)

:

Alloys

are systems consisting of two or more metals, as well as metals and non-metals, possessing properties inherent in the metallic state.

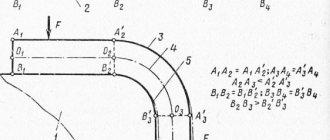

Classification of alloys .

Alloys have both common and different properties, so they can be classified according to the following criteria:

Alloy classification

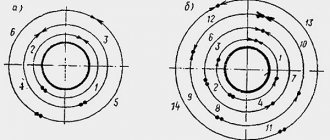

According to technological characteristics

– foundry (for the manufacture of parts by casting) and deformable (subject to forging, stamping, rolling, pressing and other types of processing)

According to the nature of the metal that is the basis of the alloy

, - black (steel, cast iron), non-ferrous (alloys of aluminum, copper, etc.)

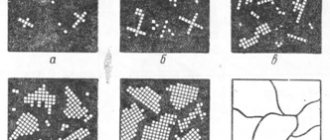

By structure

– homogeneous (single-phase) and heterogeneous (mixtures), consisting of several phases

By characteristic properties

– refractory, low-melting, heat-resistant, high-strength, hard, corrosion-resistant

By number of components

- double, triple, etc.

Each type of classification is discussed with students. Students give examples of alloys with the characteristics under consideration. During the discussion, the diagram is drawn up in a notebook.

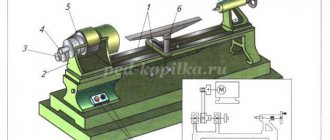

- Black metals.

Ferrous metals include iron and its alloys (steel and cast iron). page 112 tab 10

They are the most widely used in technology. This is due to the large reserves of iron ore in the earth's crust, the comparative simplicity of the technology for smelting ferrous metals, and their high strength.

The main metal materials of modern technology are alloys of iron and carbon. Alloys are divided into steels and cast irons depending on their carbon content.

What is the difference between the chemical composition of steel and cast iron?

Steel contains less than 2% carbon, cast iron contains more than 2%.

Cast iron

–

an iron-carbon alloy with a carbon content of over 2%.

Cast iron is more brittle than steel, it is less weldable, but has better casting properties.

(Consider Table 16 on page 116.)

Steel

–

an iron-carbon alloy containing up to 2% carbon.

Steel has properties that make it an irreplaceable material. It has high strength and hardness and resists shock loads well. Steel can be forged, rolled, and easily processed on metal-cutting machines. Steel products are well welded.

Carbon steels do not always meet the requirements for modern technology materials. The use of carbon steels for the manufacture of parts subjected to significant loads and operating at high speeds would cause a significant increase in the size of the parts. In addition, carbon steels have low corrosion resistance and resistance at elevated temperatures, etc.

of alloying components into their composition significantly improves the physical, mechanical and chemical properties of steels

– elements that impart special properties to steel.

Alloy steels

are steels that, in addition to conventional components, also contain alloying elements.

The following alloying components are used: chromium, nickel, tungsten, vanadium, molybdenum, cobalt, titanium, niobium, aluminum, copper, etc., as well as silicon and manganese at high contents. Let's look at some examples

- Chromium

- the cheapest alloying element. It increases hardness, strength, corrosion resistance, and somewhat reduces ductility. When the chromium content in steel is high, it becomes stainless.

- Nickel

gives steel high strength and ductility, increases impact strength, increases hardenability, and resistance to corrosion. With a high nickel content, steel becomes non-magnetic.

- Manganese

gives steel hardness, mechanical strength, resistance to impact and friction.

- Titanium

increases the strength and density of steel, increases heat resistance and mechanical strength at high temperatures, and resistance to corrosion.

- Tungsten

– an expensive and scarce metal. It forms very hard compounds with the carbon of steel - carbides, which sharply increase its hardness, heat resistance, and wear resistance.

- Molybdenum

increases the elasticity, strength, red resistance, corrosion resistance and scale resistance of steel.

- Vanadium

- also an expensive metal. It increases the density of steel, increases strength, hardness, elasticity and resistance to metals.

- Silicon

– increases resistance to acids.

Consolidation of the studied material.

Summing up the lesson. Let's return to the topic of the lesson and the purpose of the lesson.

Mutual assessment and self-assessment of students’ work in the lesson. Students evaluate their work in class based on the test results and their answers. The teacher corrects the grades and puts them in the journal.

Reflection.

Where will the knowledge gained be useful in class? What was interesting, what was difficult? What have you learned?

Homework:

Composition of some alloys

| Name | Compound (%) |

| Alumel | Mn – 2, Al – 2, Si – 1, Fe – 0.5, the rest Ni |

| Babbitt lead | Pb – 80, Sb – 17, Cu – 1.5 |

| Aluminum bronze | Al – 4.5-5.5, the rest Cu |

| Beryllium bronze | Be – 2.0-2.5, the rest Cu |

| Silicon bronze | Cu – 96-98, Si – 2-3.5 |

| Tin bronze | Cu – 89-91, Sn – 9-11 |

| Phosphor bronze | Cu – 93-94, Sn – 6-7, P – 0.3-0.4 |

| Wood's alloy | Bi – 50, Pb – 25, Sn – 12.5, Cd – 12.5 |

| Duralumin | Al – 93-96, Cu – 3.5-5, Mg – 0.3-1, Mn – 0.3-1 |

| Brass | Cu – 57-60, Zn – 40-43 |

| Constantan | Ni – 39-41, Mn – 0.4-0.6, the rest Cu |

| Manganin | Cu – 85, Mn – 11-13, Ni – 2.5-3.5 |

| Cupronickel | Ni – 18-20, the rest Cu |

| Nickel silver | Ni – 15, Zn – 20, Cu – 65 |

| Nichrome | Ni – 64-71, Cr – 14-16, Fe – 14-17, Mn – 1-1.8 |

| Lead-tin solder | Sn – 14-90, the rest Pb |

| Silumin | Al – 85-90, Si – 10-15 |

| Shot alloy | Sb – 0.5-1.5, the rest Pb |

| Steel | C up to 2, additives Si, S, P, O, N up to 1, the rest Fe |

| Vidia carbide | Co – 6, WC – 94 |

| Carbide will “win” | Co – 10, WC – 90 |

| Hard alloy “alpha” | Co – 8, 6 or 8, TiC – 21, 15 or 5, the rest WC |

| Typographic alloy | Pb – 75, Sb – 20-24, Sn – 1.8-4.3, Cu – 1 |

| Red brass | Cu – 89-91, Zn – 9-11 |

| Chromel | Cr – 9.5, Fe – 0.3, the rest Ni |

| Chrome stainless steel | Cr – 13-30, C up to 2, the rest Fe |

| Cast iron | C – 2-5, Fe – 95-98 |

The most important metal alloys: properties and applications

| Name | Compound | Properties | Application |

| Aluminum alloys | Al, Mg, Si, Cu, Zn, Mn, Li, Be | Lightweight, high electrical and thermal conductivity, corrosion resistance, high specific strength | Structural materials in aviation, construction, mechanical engineering, etc.; electrical devices and materials |

| Amalgam | Hg and other metals | Depending on the ratio of mercury and other metals, it can be (at room temperature) liquid, semi-liquid or solid | Gilding of metal products, production of mirrors, dentistry, reducing agent in chemistry and metallurgy |

| Tungsten alloys | Mo, Re, Cu, Ni, Ag, oxides (ThO2), carbides (TaC), etc. | Plasticity, heat resistance and high thermal emf | Parts of electric vacuum devices, high-temperature thermocouples, parts of rocket and aircraft engines |

| Iron-carbon alloys (cast iron, steel, ferroalloys) | Fe, C, P, S, Mn, Si, N, Cr, Ni, Mo, W, V, Ti, Co, Cu etc. | Mechanical strength, hardness, elasticity, corrosion resistance, viscosity, etc. | Construction materials for all areas of engineering, technology, farming, machinery, tools |

| Gold alloys | Au, Ag, Cu, Pt, Pd, Sb, Bi, Pb, Hg | The alloy with Ag at 20-40% Ag is greenish-yellow, at 50% Ag it is pale yellow; soft and malleable; alloys of Au with Cu are reddish-yellow; harder and more resilient than pure gold | Gilding of metal products, making coins, jewelry, dentures, electrical contacts |

| Low-melting alloys | Sn, Bi, In, Pb, Cd, Zn, Sb, Ga, Hg, etc. | Low melting temperatures (not higher than 232 °C); with a Bi content of more than 55%, they expand upon solidification | Production of solders, fuses in electrical equipment, molds and models for the production of castings of complex shapes from metals and plastics, metal putties |

| Magnesium alloys | Mg, Al, Zn, Mn, Zr, Th, Li, La, Nd, Y, Ag, Cd, Be | Lightness, strength, corrosion resistance | Highly loaded parts from pressed semi-finished products, stampings and forgings in the automotive industry, panels, stampings of complex shapes, welded structures |

| Copper alloys | Cu, Zn, Sn, Al, Ni, Be, P | Strength, high electrical conductivity, corrosion resistance, ductility | Pipes, heating equipment, bearings, gears, bushings, springs, parts of precision mechanics instruments, thermocouples, shaped parts, decorative and applied products and sculpture |

| Nickel alloys | Cu, Co, Fe, | Ferromagnetism, high ductility and corrosion resistance, absence of allotropic transformations, chemical resistance | Structural materials with high resistance to aggressive environments, ferromagnetic products, magnetostrictive materials |

| Tin alloys | Sn, Pb, Sb, Cu, Zn, Cd, etc. | low melting point, softness, corrosion resistance; anti-friction properties | Low-melting alloys (solder, poluda) and bearing materials (babbitt) |

| Platinum alloys | Pt, Rh, Ir, Pd, Ru, Ni, Co, Cu, W, Mo | High melting point, corrosion resistance, mechanical strength, catalytic properties | production of thermocouples, electrical contacts, potentiometers, permanent magnets, high-temperature solders, catalysts, laboratory glassware |

| Lead alloys | Pb, Fe, Cu, Sb, Sn, Cd, Ca, Ca, Mg, Li, K, Na | Strength, hardness, anti-friction properties, low melting point of lead, corrosion resistance, good adhesion to many metals and alloys | Manufacturing or lining of acid-resistant equipment and pipelines, manufacturing of low-voltage and power cable sheaths, solders and half-soles, bearings, printing alloys, weights, ballasts, casting shot, bullet cores, manufacturing of grids for lead batteries |

| Hard alloys | WC, TiC, TaC; binder metals: Co, Ni, Mo, steel | High hardness, refractoriness, wear resistance, corrosion resistance | Solid carbide products (tools) for processing metals, alloys and non-metallic materials, for equipping working parts of drilling tools and as structural materials |

| Printing alloys (hart) | Pb, Sb, Sn, etc. | low melting point (240-350 °C), good casting properties | production of cast stereotypes (printing industry) and typesetting elements (fonts, etc.). |

| Titanium alloys | Al, V, Mo, Mn, Sn, Zr, Cr, Cu, Fe, W, Ni, Si; Nb and Ta | Lightweight, high strength in a wide temperature range from -250 °C to 300-600 °C, corrosion resistance | Structural materials in aviation, rocketry, chemical equipment |

| Zinc alloys | Zn, Al, Cu, Mg | Low melting point, ease of processing by pressure and cutting, welding and soldering, possibility of applying coatings by electrochemical and chemical methods, satisfactory corrosion resistance | Structural and structural-decorative parts in the automotive industry, electrical engineering, office equipment, bearing shells, household products, souvenirs |

| Alloy name | Compound | Application |

| Brass | Zinc 35-10%, copper 65-90% | Mechanical engineering, decorative products |

| Ordinary bronze (tin) | Zinc 2% tin 6%, copper 92% | Mechanical engineering, decorative products |

| Aluminum bronze | Aluminum 10% copper 90% | Mechanical engineering, decorative casting |

| Bronze coin | Zinc 1% tin 4% copper 95% | Minting of coins, medals |

| Dental amalgam | Copper 30% mercury 70% | Dental fillings |

| Duralumin | Magnesium 0.5% manganese 0.5% copper 5% aluminum 94% | Aircraft industry |

| Coin gold | Copper 10% gold 90% | Coinage |

| Gold dental | Silver 28-14% copper 14-28% gold 58% | Dentures |

| Lead battery | Antimony 6% lead 94% | Battery plates |

| Manganin | Nickel 1.5% manganese 16% copper 82.5% | Wire and tapes for the electrical industry |

| Nichrome | Chrome 20% nickel 80% | Heating elements, wire for the electrical industry |

| Dish tin | Tin 80% Lead 20% | Kitchenware |

| Coin silver | Copper 10% silver 90% | Coinage |

| Solder | Tin 50% Lead 50% | Soldering iron objects |

| Stainless steel | Nickel 8-20% chromium 10-20% iron 80-60% | Kitchenware |

| Reinforcing steel | Nickel 1-4% chromium 0.5-2% iron 98-95% | Reinforced concrete |

| Tool steel | Chromium 2-4% molybdenum 6-7% iron 95-90% | Tools |