Tubing is used in industry to transport gas and liquid inside casing strings during the operation of gas and oil wells. They also find application in various types of hoisting and repair work.

These pipes are connected to each other by couplings with a threaded connection. These connections allow you to maintain the patency of the pipe in curved and places with a complex profile. They also maintain tightness at the joints and the ability to be easily replaced and repaired.

The plants of Pipe Metallurgical Company have adopted the ISO 9001-2000 quality system; API Q1 in accordance with post-operative control, and meets the following requirements: API Spec 5CT, Spec 5B; GOST 633-80 and consumer technical conditions. This system allows you to trace 100% quality of tubing pipes and their parts.

All pipes and couplings undergo non-destructive testing. The most modern technologies are used in their production. The pipes undergo appropriate quality control, also using modern methods.

Pipes are manufactured in accordance with the following range:

- cold-resistant;

- highly sealed;

- corrosion resistant;

- with a sealing unit made of polymer material;

- with ends set outward;

- with distinctive coupling markings;

- standard version.

At the customer's request, they can be metal, polymer or a combination.

The pipes are marked and branded in accordance with current requirements. These products are supplied with threaded connections protected with a special grease, which extends the life of the pipes.

Tubing 60.3×5.0

Parameter

| Tubing pipe 60.3x5.0 g. D, K, E GOST 633-80 steel, seamless, used for the operation and repair of oil and gas wells, as well as wells for other purposes. | |||||

| Meaning | Price per ton, rub. VAT included | ||||

| D | TO | E | L | ||

| Nominal pipe diameter, mm | 60,3 | 44000 | 45000 | 49000 | — |

| Wall thickness, mm | 5,0 | ||||

| Execution | A | ||||

| Strength groups | D, K, E | ||||

| GOST | GOST 633-80 | ||||

| Thread | tubing | ||||

| Weight of 1 meter of pipe, kg | 6,8 | ||||

| Coupling weight, kg | 1,3 | ||||

Possibility of production: - 600 tons/month

For thread "NKM" surcharge of 10% For left-hand thread on tubing surcharge of 10%

Tubing 73.0×5.5; 73.0×7.0

Parameter

| Tubing pipe 73.0x5.5; 73.0x7.0 gr. D, K, E, L GOST 633-80 steel, seamless, used in the operation and repair of oil and gas wells, as well as wells for other purposes. | |||||

| Meaning | Price per ton, rub. VAT included | ||||

| D | TO | E | L | ||

| Nominal pipe diameter, mm | 73,0 | 43000 | 45000 | 48000 | — |

| Wall thickness, mm | 5,5; 7,0 | ||||

| Execution | A | ||||

| Strength groups | D, K, E, L | ||||

| GOST | GOST 633-80 | ||||

| Thread | tubing | ||||

| Weight of 1 meter of pipe, kg | 9,2 | ||||

| Coupling weight, kg | 2,4 | ||||

Possibility of production: - 600 tons/month

For thread "NKM" surcharge of 10% For left-hand thread on tubing surcharge of 10%

Tubing 89.0×6.5; 89.0×8.0

Parameter

| Tubing pipe 89.0×6.5; 89.0×8.0 gr. D GOST 633-80 steel, seamless, used for the operation and repair of oil and gas wells, as well as wells for other purposes. | |||||

| Meaning | Price per ton, rub. VAT included | ||||

| D | TO | E | L | ||

| Nominal pipe diameter, mm | 89,0 | 43000 | 45000 | 48000 | — |

| Wall thickness, mm | 6,5; 8,0 | ||||

| Execution | A | ||||

| Strength groups | D | ||||

| GOST | GOST 633-80 | ||||

| Thread | tubing | ||||

| Weight of 1 meter of pipe, kg | 13,2 | ||||

| Coupling weight, kg | 3,6 | ||||

Possibility of production: - 600 tons/month

For thread "NKM" surcharge of 10% For left-hand thread on tubing surcharge of 10%

Tubing 102.0×6.5

Parameter

| Tubing pipe 102.0×6.5 g. To GOST 633-80 steel, seamless, used for the operation and repair of oil and gas wells, as well as wells for other purposes. | |||||

| Meaning | Price per ton, rub. VAT included | ||||

| D | TO | E | L | ||

| Nominal pipe diameter, mm | 102,0 | 48000 | 49500 | 51000 | — |

| Wall thickness, mm | 6,5 | ||||

| Execution | A | ||||

| Strength groups | TO | ||||

| GOST | GOST 633-80 | ||||

| Thread | tubing | ||||

| Weight of 1 meter of pipe, kg | 15,2 | ||||

| Coupling weight, kg | 4,5 | ||||

Possibility of production: - 600 tons/month

For thread "NKM" surcharge of 10% For left-hand thread on tubing surcharge of 10%

Tubing 114.0×7.0

Parameter

| Tubing pipe 114.0×7.0 g. E GOST 633-80 steel, seamless, used for the operation and repair of oil and gas wells, as well as wells for other purposes. | |||||

| Meaning | Price per ton, rub. VAT included | ||||

| D | TO | E | L | ||

| Nominal pipe diameter, mm | 114,0 | 47000 | 48500 | 49500 | — |

| Wall thickness, mm | 7,0 | ||||

| Execution | A | ||||

| Strength groups | E | ||||

| GOST | GOST 633-80 | ||||

| Thread | tubing | ||||

| Weight of 1 meter of pipe, kg | 18,5 | ||||

| Coupling weight, kg | 5,1 | ||||

Manufacturing capability:

— 600 tons/month

For thread "NKM" surcharge 10% For left-hand thread on tubing surcharge 10%

Casing.

Seamless hot-rolled steel pipes (drill and casing pipes).

Table 1. Theoretical weight 1 linear. m of pipe (kg), for a given wall thickness (drill and casing pipes).

| N p/p | Dн, mm | 2.5 | 2.8 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

| 1 | 25 | 1,39 | 1,53 | 1,63 | 1,86 | 2,07 | 2,28 | 2,47 | 2,64 | 2,81 | 2,97 | 3,11 | 3,24 | 3,35 |

| 2 | 28 | 1,57 | 1,74 | 1,85 | 2,11 | 2,37 | 2,61 | 2,84 | 3,05 | 3,26 | 3,45 | 3,63 | 3,79 | 3,94 |

| 3 | 32 | 1,76 | 2,02 | 2,15 | 2,46 | 2,76 | 3,05 | 3,33 | 3,59 | 3,85 | 4,09 | 4,32 | 4,53 | 4,74 |

| 4 | 38 | 2,19 | 2,43 | 2,59 | 2,98 | 3,35 | 3,72 | 4,07 | 4,41 | 4,74 | 5,05 | 5,35 | 5,64 | 5,92 |

| 5 | 42 | 2,44 | 2,70 | 2,89 | 3,32 | 3,75 | 4,16 | 4,56 | 4,95 | 5,33 | 5,69 | 6,044 | 6,38 | 6,71 |

| 6 | 45 | 2,62 | 2,91 | 3,11 | 3,58 | 4,04 | 4,49 | 4,93 | 5,36 | 5,77 | 6,17 | 6,56 | 6,94 | 7,30 |

| 7 | 50 | 2,93 | 3,25 | 3,48 | 4,01 | 4,54 | 5,05 | 5,55 | 6,04 | 6,51 | 6,97 | 7,42 | 7,86 | 8,29 |

| 8 | 54 | 3,77 | 4,36 | 4,93 | 5,49 | 6,04 | 6,58 | 7,10 | 7,61 | 8,11 | 8,60 | 9,08 | ||

| 9 | 57 | 4,00 | 4,62 | 5,23 | 5,83 | 6,41 | 6,99 | 7,51 | 8,10 | 8,63 | 9,16 | 9,67 | ||

| 10 | 60 | 4,22 | 4,88 | 5,52 | 6,16 | 6,78 | 7,39 | 7,99 | 8,58 | 9,15 | 9,71 | 10,26 | ||

| 11 | 63.5 | 4,48 | 5,18 | 5,87 | 6,55 | 7,21 | 7,87 | 8,51 | 9,14 | 9,75 | 10,36 | 10,95 | ||

| 12 | 68 | 4,81 | 5,57 | 6,31 | 7,05 | 7,77 | 8,48 | 9,17 | 9,86 | 10,53 | 11,19 | 11,84 | ||

| 13 | 70 | 4,96 | 5,74 | 6,51 | 7,27 | 8,01 | 8,75 | 9,47 | 10,18 | 10,88 | 11,56 | 12,23 | ||

| 14 | 73 | 5,18 | 6,00 | 6,81 | 7,60 | 8,38 | 9,16 | 9,91 | 70,66 | 11,39 | 12,11 | 12,82 | ||

| 15 | 83 | 6,86 | 7,79 | 8,71 | 9,62 | 10,51 | 11,39 | 12,26 | 13,12 | 13,96 | 14,80 | |||

| 16 | 89 | 7,32 | 8,38 | 9,38 | 10,36 | 11,33 | 12,28 | 13,22 | 14,16 | 15,07 | 15,,98 | |||

| 17 | 95 | 7,90 | 8,98 | 10,04 | 11,10 | 12,14 | 13,17 | 14,19 | 15,19 | 16,18 | 17,16 | |||

| 18 | 102 | 8,50 | 9,67 | 10,82 | 11,96 | 13,09 | 14,21 | 15,31 | 16,40 | 17,48 | 18,55 | |||

| 19 | Dн, mm | 2.5 | 2.8 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 |

| 20 | 108 | 10,26 | 11,49 | 12,70 | 13,90 | 15,09 | 16,27 | 17,44 | 18,59 | 19,73 | ||||

| 21 | 114 | 10,85 | 12,15 | 13,44 | 14,72 | 15,98 | 17,23 | 18,47 | 19,70 | 20,91 | ||||

| 22 | 121 | 11,54 | 12,93 | 14,30 | 15,67 | 17,02 | 18,35 | 19,68 | 20,99 | 22,29 | ||||

| 23 | 127 | 12,13 | 13,59 | 15,04 | 16,48 | 17,90 | 19,32 | 20,72 | 22,10 | 23,48 | ||||

| 24 | 133 | 12,73 | 14,26 | 15,78 | 17,29 | 18,79 | 20,28 | 21,75 | 23,21 | 24,66 | ||||

| 25 | 140 | 15,04 | 16,65 | 18,24 | 19,83 | 21,40 | 22,96 | 24,51 | 26,04 | |||||

| 26 | 146 | 15,70 | 17,39 | 19,06 | 20,72 | 22,36 | 24,00 | 25,62 | 27,23 | |||||

| 27 | 152 | 16,37 | 18,13 | 19,87 | 21,60 | 23,32 | 25,03 | 26,73 | 28,41 | |||||

| 28 | 159 | 17,15 | 18,99 | 20,82 | 22,64 | 24,45 | 26,24 | 28,02 | 29,79 | |||||

| 29 | 168 | 20,10 | 22,04 | 23,97 | 25,89 | 27,79 | 29,69 | 31,57 | ||||||

| 30 | 180 | 21,59 | 23,70 | 25,75 | 27,70 | 29,87 | 31,91 | 33,93 | ||||||

| 31 | 194 | 23,31 | 25,60 | 27,82 | 30,00 | 32,28 | 34,50 | 36,70 | ||||||

| 32 | 203 | 29,14 | 31,50 | 33,83 | 36,16 | 38,47 | ||||||||

| 33 | 219 | 31,52 | 34,06 | 36,60 | 39,12 | 41,63 | ||||||||

| 34 | 245 | 38,23 | 41,09 | 43,85 | 46,76 | |||||||||

| 35 | 273 | 42,64 | 45,92 | 49,10 | 52,28 | |||||||||

| 36 | 299 | 53,91 | 57,41 | |||||||||||

| 37 | 325 | 58,74 | 62,54 | |||||||||||

| 38 | 351 | 67,67 |

Table 1. Theoretical weight 1 linear. m of pipe (kg), for a given wall thickness (drill and casing pipes, continued).

| N p/p | Dн, mm | 8,5 | 9,0 | 9,5 | 10 | 11 | 11 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

| 1 | 42 | 7,02 | 7,32 | 7,6 | 7,88 | |||||||||

| 2 | 45 | 7,65 | 7,99 | 8,32 | 8,63 | |||||||||

| 3 | 50 | 8,70 | 9,10 | 9,49 | 9,86 | |||||||||

| 4 | 54 | 9,54 | 9,99 | 10,43 | 10,85 | 11,67 | ||||||||

| 5 | 57 | 10,17 | 10,65 | 11,13 | 11,59 | 12,48 | 13,32 | 14,11 | ||||||

| 6 | 60 | 10,80 | 11,32 | 11,83 | 12,33 | 13,29 | 14,21 | 15,07 | 15,88 | |||||

| 7 | 63,5 | 11,53 | 12,10 | 12,65 | 13,19 | 14,24 | 15,24 | 16,19 | 17,09 | |||||

| 8 | 68 | 12,47 | 13,10 | 13,71 | 14,30 | 15,46 | 16,57 | 17,63 | 18,64 | 19,61 | 20,52 | |||

| 9 | 70 | 12,89 | 13,54 | 14,17 | 14,80 | 16,01 | 17,16 | 18,27 | 19,33 | 20,35 | 21,31 | |||

| 10 | 73 | 13,52 | 14,21 | 14,88 | 15,54 | 16,82 | 18,05 | 19,24 | 20,37 | 21,46 | 22,49 | 23,48 | 24,41 | 25,30 |

| 11 | 76 | 14,15 | 14,87 | 15,58 | 16,28 | 17,63 | 18,94 | 20,20 | 21,41 | 22,57 | 25,68 | 24,74 | 25,75 | 26,71 |

| 12 | 83 | 15,62 | 16,42 | 17,22 | 18,00 | 19,53 | 21,01 | 22,44 | 23,82 | 25,15 | 26,44 | 27,67 | 28,85 | 29,99 |

| 13 | 89 | 16,87 | 17,76 | 18,63 | 19,48 | 21,16 | 22,79 | 24,37 | 25,89 | 27,37 | 28,80 | 30,19 | 31,52 | 32,80 |

| 14 | 95 | 18,13 | 19,09 | 20,03 | 20,96 | 22,79 | 24,56 | 26,29 | 27,97 | 29,59 | 31,17 | 32,70 | 34,18 | 35,61 |

| 15 | 102 | 19,60 | 20,64 | 21,67 | 22,69 | 24,69 | 26,63 | 28,53 | 30,38 | 32,18 | 33,93 | 35,64 | 37,29 | 38,89 |

| 16 | 108 | 20,86 | 21,97 | 23,08 | 24,17 | 26,31 | 28,41 | 30,46 | 32,45 | 34,40 | 36,30 | 38,15 | 39,95 | 41,70 |

| 17 | Dн, mm | 8,5 | 9,0 | 9,5 | 10 | 11 | 11 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 18 | 114 | 22,12 | 23,31 | 24,48 | 25,65 | 27,94 | 30,19 | 32,38 | 34,53 | 36,62 | 38,67 | 40,67 | 42,62 | 44,51 |

| 19 | 121 | 23,58 | 24,86 | 26,12 | 27,37 | 29,84 | 32,26 | 34,62 | 36,94 | 39,21 | 41,43 | 43,60 | 45,72 | 47,79 |

| 20 | 127 | 24,84 | 26,19 | 27,53 | 28,85 | 31,47 | 34,03 | 36,55 | 39,01 | 41,43 | 43,80 | 46,12 | 48,39 | 50,61 |

| 21 | 133 | 26,10 | 27,52 | 28,93 | 30,33 | 33,10 | 35,81 | 38,41 | 41,00 | 43,65 | 46,17 | 48,63 | 51,65 | 53,42 |

| 22 | 140 | 27,57 | 29,08 | 30,57 | 32,06 | 34,99 | 37,88 | 40,72 | 43,50 | 46,24 | 48,93 | 51,57 | 54,16 | 56,70 |

| 23 | 146 | 28,82 | 30,41 | 31,98 | 33,54 | 36,62 | 39,66 | 42,64 | 45,57 | 48,46 | 51,30 | 54,08 | 56,82 | 59,51 |

| 24 | 152 | 30,08 | 31,74 | 33,39 | 35,02 | 38,25 | 41,43 | 44,56 | 47,65 | 50,68 | 53,66 | 56,60 | 59,48 | 62,32 |

| 25 | 159 | 31,55 | 33,29 | 35,03 | 36,75 | 40,15 | 43,50 | 46,81 | 50,06 | 53,27 | 56,43 | 59,53 | 62,59 | 65,60 |

| 26 | 168 | 33,43 | 35,29 | 37,13 | 38,97 | 42,59 | 46,17 | 49,69 | 53,17 | 56,60 | 59,98 | 63,31 | 66,59 | 69,82 |

| 27 | 180 | 35,95 | 37,95 | 39,95 | 41,92 | 45,85 | 49,72 | 53,54 | 57,31 | 61,04 | 64,71 | 68,34 | 71,91 | 75,44 |

| 28 | 194 | 38,89 | 41,06 | 43,23 | 45,38 | 49,64 | 53,86 | 58,03 | 62,15 | 66,22 | 70,24 | 74,21 | 78,13 | 82,00 |

| 29 | 203 | 40,77 | 43,05 | 45,33 | 47,59 | 52,08 | 56,52 | 60,91 | 65,94 | 69,54 | 73,78 | 77,97 | 82,12 | 86,21 |

| 30 | 219 | 44,12 | 46,61 | 49,08 | 51,54 | 56,43 | 61,26 | 66,04 | 70,78 | 75,46 | 80,10 | 84,69 | 89,23 | 93,71 |

| 31 | 245 | 49,56 | 52,38 | 55,17 | 57,95 | 63,48 | 68,95 | 74,38 | 79,76 | 85,08 | 90,36 | 95,59 | 100,77 | 105,90 |

| 32 | 273 | 55,45 | 58,60 | 61,73 | 64,86 | 71,07 | 77,24 | 83,36 | 89,42 | 95,44 | 101,41 | 107,33 | 113,20 | 119,02 |

| 33 | 299 | 60,89 | 64,37 | 67,83 | 71,27 | 78,13 | 84,93 | 91,69 | 98,40 | 105,06 | 111,67 | 118,23 | 124,74 | 131,20 |

| 34 | 325 | 66,35 | 70,14 | 73,92 | 77,68 | 85,18 | 92,63 | 100,03 | 107,38 | 114,68 | 121,93 | 129,13 | 136,28 | 143,38 |

| 35 | 351 | 71,80 | 75,91 | 80,01 | 84,10 | 92,23 | 100,32 | 108,36 | 116,35 | 124,29 | 132,19 | 140,03 | 147,82 | 155,56 |

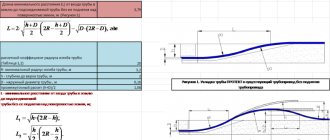

Computer program GEOFPRO Fluid

Calculation of well hydraulics

The computer program will calculate the pressure loss due to friction in the drilling fluid over the well intervals, calculate the EDS, and the wellbore cleaning index:

— inside sections of drill pipes and BHAs,

— between the walls of the well and the drilling tool,

— between the string of casing and drill pipes.

The hydraulic calculation of the well is presented in the form of a graphic report, with clear and simple diagrams and graphs.

On our website you can download a FREE computer program - a calculator for calculating the mass and weight of casing and drill pipes, tubing tubing.

Geofpro Calculator (link to site section)

Specifications

The pipe can be welded or seamless. In the first case, for the production of rolled metal, sheet steel and strips are used, which are joined at the joint by welding. The length of the pipe can vary from 1.5 to 20 meters; the material used is different grades of steel, including stainless steel.

Seamless pipes are produced by drawing, pressing, forging or rolling. Such products are characterized by versatility, durability, and wear resistance. Seamless pipe is able to withstand constant heavy loads, therefore it is used in the food, chemical and automotive industries. This assortment comes in thick-walled and thin-walled. The latter is used if high demands are placed on geometry accuracy and quality of material processing.

Pipes can be cold-formed or hot-formed. At the initial stage, the workpiece is heated to a soft state, after which it passes through the press. The required shape is obtained by rolling at the melting temperature of the metal (for hot-deformed), or below it (for cold-deformed). The diameter of the former varies from 20 to 550 mm, the latter – from 5 to 250 mm. The wall thickness also differs - 2.5 - 75 mm, 0.3 - 24 mm.

Depending on the purpose of the pipe, all products are classified into 6 classes: large-diameter pipes are mainly used for the installation of gas pipelines, oil pipelines and the arrangement of protection of utility lines.

- Class 1 – used as fences, supports, local gas supply systems. Manufactured from high-carbon steel grades.

- Class 2 – designed to work with high and low pressure, used in supply systems for gas, fuel, and petrochemical products.

- Class 3 - characterized by resistance to elevated temperatures, they are used in heating boilers, chemical and nuclear industries.

- Class 4 – pipes for drilling wells, casing, etc.

- Class 5 - used for the manufacture of supports, masts, structural elements and other equipment.

Drill pipes.

The table shows the main geometric characteristics and weight of drill pipes.

| Pipe | coupling | Weight, kg | Stiffness, kN m2 | |||||||

| Diameter, mm | Wall thickness, mm | Outer diameter, mm | Length, mm | 1 m smooth pipe | two landings | couplings | when bending EJ | at shear GJ0 | ||

| conditional | outer | interior | ||||||||

| Drill pipes with upset ends | ||||||||||

| 60 | 60,3 | 46,3 | 7 | 80 | 140 | 9,15 | 1,5 | 2,7 | 89 | 68 |

| 42,3 | 9 | 11,3 | 103 | 78 | ||||||

| 73 | 73 | 59 | 7 | 95 | 166 | 11,4 | 2,0 | 4,2 | 168 | 128 |

| 55 | 9 | 14,2 | 198 | 151 | ||||||

| 51 | 11 | 16,8 | 223 | 170 | ||||||

| 89 | 89 | 75 | 7 | 108 | 166 | 14,2 | 3,2 | 4,4 | 320 | 244 |

| 71 | 9 | 17,8 | 385 | 293 | ||||||

| 67 | 11 | 21,2 | 439 | 334 | ||||||

| 102 | 101,6 | 87,6 | 7 | 127 | 184 | 16,4 | 5,0 | 7,0 | 491 | 374 |

| 85,6 | 8 | 18,5 | 545 | 415 | ||||||

| 83,6 | 9 | 20,4 | 595 | 453 | ||||||

| 81,6 | 10 | 22,4 | 641 | 488 | ||||||

| 114 | 114,3 | 100,3 | 7 | 140 | 204 | 18,5 | 6,0 | 9,0 | 716 | 546 |

| 98,3 | 8 | 20,9 | 797 | 607 | ||||||

| 96,3 | 9 | 23,3 | 872 | 664 | ||||||

| 94,3 | 10 | 25,7 | 944 | 719 | ||||||

| 92,3 | 11 | 28,0 | 1011 | 770 | ||||||

| 127 | 127 | 113 | 7 | 152 | 204 | 20,7 | 6,5 | 10,0 | 1000 | 762 |

| 111 | 8 | 23,5 | 1116 | 850 | ||||||

| 109 | 9 | 26,2 | 1226 | 934 | ||||||

| 107 | 10 | 28,9 | 1330 | 1013 | ||||||

| 140 | 139,7 | 123,7 | 8 | 171 | 215 | 26 | 7,5 | 14 | 1512 | 1152 |

| 121,7 | 9 | 29 | 1664 | 1268 | ||||||

| 119,7 | 10 | 32 | 1909 | 1378 | ||||||

| 117,7 | 11 | 35 | 1947 | 1483 | ||||||

| 168 | 168,3 | 150,3 | 9 | 197 | 229 | 35,3 | 9,5 | 16,7 | 3008 | 2292 |

| 148,3 | 10 | 39,0 | 3283 | 2501 | ||||||

| 60 | 60,3 | 46,3 | 7 | 86 | 140 | 9,15 | 1,5 | 2,7 | 89 | 68 |

| 42,3 | 9 | 11,3 | 103 | 78 | ||||||

| 73 | 73 | 59 | 7 | 105 | 165 | 11,4 | 2,5 | 4,7 | 168 | 128 |

| 55 | 9 | 14,2 | 198 | 151 | ||||||

| 51 | 11 | 16,8 | 223 | 170 | ||||||

| Drill pipes with upset ends | ||||||||||

| 89 | 89 | 75 | 7 | 118 | 165 | 14,2 | 3,5 | 5,2 | 320 | 244 |

| 71 | 9 | 17,8 | 385 | 293 | ||||||

| 67 | 11 | 21,2 | 439 | 334 | ||||||

| 102 | 101,6 | 85,6 | 8 | 140 | 204 | 18,5 | 4,5 | 9,0 | 545 | 415 |

| 83,6 | 9 | 20,4 | 595 | 453 | ||||||

| 81,6 | 10 | 22,4 | 641 | 488 | ||||||

| 114 | 114,3 | 98,3 | 8 | 152 | 204 | 20,9 | 5,0 | 11,0 | 797 | 607 |

| 96,3 | 9 | 23,3 | 872 | 664 | ||||||

| 94,3 | 10 | 25,7 | 944 | 719 | ||||||

| 92,3 | 11 | 28,0 | 1011 | 770 | ||||||

| 140 | 139,7 | 123,7 | 8 | 185 | 215 | 26,0 | 7,0 | 15,0 | 1512 | 1152 |

| 121,7 | 9 | 29,0 | 1664 | 1268 | ||||||

| 117,7 | 11 | 35,0 | 1947 | 1483 | ||||||

| Project GEOFPRO computer programs for well drilling | |

| GEOFPRO 2D digital drilling |

| +79261429641 | https://vk.com/drilling_rig | https://www.facebook.com | ||

3d modeling of drilling tools

| Chisels |

| PDC bits |

| BHA |

| Support centering tool |

| Crowns |

| Drilling rigs for drilling deep wells |

| Drilling wells in a given direction |

| Drilling wells in seas and oceans |

| Drilling equipment |

| Drilling with simultaneous casing |

| Drilling water wells |

| Well filters |

| Methods for decolmatization of hydrogeological wells |

| video |

| Superdeep drilling |

| Drilling rigs |

| Hydrogeological modeling |

| Sections of the site |

Weight and range of large-diameter metal pipes according to GOST 10704-91

Electric-welded straight-seam steel pipes - GOST 10704-91.

| Pipe outer diameter, mm | Wall thickness, mm | Weight of 1 linear meter, kg | Linear meters in 1 ton |

| 530 | 6 | 77,54 | 12,9 |

| 7 | 90,29 | 11,08 | |

| 8 | 102,99 | 9,71 | |

| 9 | 115,64 | 8,65 | |

| 10 | 128,24 | 7,8 | |

| 11 | 140,79 | 7,1 | |

| 12 | 153,3 | 6,52 | |

| 13 | 165,75 | 6,03 | |

| 14 | 178,15 | 5,61 | |

| 16 | 202,82 | 4,93 | |

| 17 | 215,07 | 4,65 | |

| 17,5 | 221,18 | 4,52 | |

| 18 | 227,28 | 4,4 | |

| 19 | 239,44 | 4,18 | |

| 20 | 251,55 | 3,98 | |

| 21 | 263,61 | 3,79 | |

| 22 | 275,62 | 3,63 | |

| 23 | 287,58 | 3,48 | |

| 24 | 299,49 | 3,34 | |

| 630 | 5 | 64,74 | 15,45 |

| 5,5 | 71,14 | 14,06 | |

| 7 | 107,55 | 9,3 | |

| 8 | 122,72 | 8,15 | |

| 9 | 137,83 | 7,26 | |

| 10 | 152,9 | 6,54 | |

| 11 | 167,92 | 5,96 | |

| 12 | 182,89 | 5,47 | |

| 13 | 197,81 | 5,06 | |

| 14 | 212,68 | 4,7 | |

| 16 | 242,27 | 4,13 | |

| 17 | 257 | 3,89 | |

| 17,5 | 264,34 | 3,78 | |

| 18 | 271,67 | 3,68 | |

| 19 | 286,3 | 3,49 | |

| 20 | 300,87 | 3,32 | |

| 720 | 7 | 123,09 | 8,12 |

| 8 | 140,47 | 7,12 | |

| 9 | 157,81 | 6,34 | |

| 10 | 175,1 | 5,71 | |

| 11 | 192,33 | 5,2 | |

| 12 | 209,52 | 4,77 | |

| 13 | 226,66 | 4,41 | |

| 14 | 243,75 | 4,1 | |

| 16 | 277,79 | 3,6 | |

| 17 | 294,73 | 3,39 | |

| 17,5 | 303,18 | 3,3 | |

| 18 | 311,62 | 3,21 | |

| 19 | 328,47 | 3,04 | |

| 20 | 345,26 | 2,9 | |

| 21 | 362,01 | 2,76 | |

| 22 | 378,7 | 2,64 | |

| 23 | 395,35 | 2,53 | |

| 24 | 411,95 | 2,43 | |

| 25 | 411,95 | 2,43 | |

| 26 | 428,49 | 2,33 | |

| 27 | 444,99 | 2,25 | |

| 28 | 461,44 | 2,17 | |

| 29 | 477,84 | 2,09 | |

| 30 | 510,49 | 1,96 | |

| 820 | 7 | 140,35 | 7,13 |

| 8 | 160,2 | 6,24 | |

| 9 | 180 | 5,56 | |

| 10 | 199,76 | 5,01 | |

| 11 | 219,46 | 4,56 | |

| 12 | 239,12 | 4,18 | |

| 13 | 258,72 | 3,87 | |

| 14 | 278,28 | 3,59 | |

| 16 | 317,25 | 3,15 | |

| 17 | 336,65 | 2,97 | |

| 17,5 | 346,34 | 2,89 | |

| 18 | 356,01 | 2,81 | |

| 19 | 375,32 | 2,66 | |

| 20 | 394,58 | 2,53 | |

| 21 | 413,79 | 2,42 | |

| 22 | 432,96 | 2,31 | |

| 23 | 452,07 | 2,21 | |

| 24 | 471,13 | 2,12 | |

| 25 | 490,15 | 2,04 | |

| 26 | 509,11 | 1,96 | |

| 27 | 528,03 | 1,89 | |

| 28 | 546,89 | 1,83 | |

| 29 | 565,71 | 1,77 | |

| 30 | 584,48 | 1,71 | |

| 920 | 7 | 157,61 | 6,34 |

| 8 | 179,93 | 5,56 | |

| 9 | 202,2 | 4,95 | |

| 10 | 224,42 | 4,46 | |

| 11 | 246,59 | 4,06 | |

| 12 | 268,71 | 3,72 | |

| 13 | 290,78 | 3,44 | |

| 14 | 312,81 | 3,2 | |

| 16 | 356,7 | 2,8 | |

| 17 | 378,58 | 2,64 | |

| 17,5 | 389,5 | 2,57 | |

| 18 | 400,4 | 2,5 | |

| 19 | 422,18 | 2,37 | |

| 20 | 443,91 | 2,25 | |

| 1020 | 8 | 199,66 | 5,01 |

| 9 | 224,39 | 4,46 | |

| 10 | 249,08 | 4,01 | |

| 11 | 273,72 | 3,65 | |

| 12 | 298,31 | 3,35 | |

| 13 | 322,84 | 3,1 | |

| 14 | 347,33 | 2,88 | |

| 16 | 396,16 | 2,52 | |

| 17 | 420,5 | 2,38 | |

| 17,5 | 432,65 | 2,31 | |

| 18 | 444,79 | 2,25 | |

| 19 | 469,04 | 2,13 | |

| 20 | 493,23 | 2,03 | |

| 21 | 517,37 | 1,93 | |

| 22 | 541,47 | 1,85 | |

| 23 | 565,51 | 1,77 | |

| 24 | 589,51 | 1,7 | |

| 25 | 613,45 | 1,63 | |

| 26 | 637,35 | 1,57 | |

| 27 | 661,2 | 1,51 | |

| 28 | 685 | 1,46 | |

| 29 | 708,75 | 1,41 | |

| 30 | 732,45 | 1,37 | |

| 31 | 756,1 | 1,32 | |

| 32 | 779,7 | 1,28 | |

| 1120 | 8 | 219,39 | 4,56 |

| 9 | 246,59 | 4,06 | |

| 10 | 273,74 | 3,65 | |

| 11 | 300,85 | 3,32 | |

| 12 | 327,9 | 3,05 | |

| 13 | 354,9 | 2,82 | |

| 14 | 381,86 | 2,62 | |

| 16 | 435,62 | 2,3 | |

| 17 | 462,43 | 2,16 | |

| 17,5 | 475,81 | 2,1 | |

| 18 | 481,19 | 2,08 | |

| 19 | 515,89 | 1,94 | |

| 20 | 542,55 | 1,84 | |

| 1220 | 9 | 268,79 | 3,72 |

| 10 | 298,4 | 3,35 | |

| 11 | 327,97 | 3,05 | |

| 12 | 357,49 | 2,8 | |

| 13 | 386,96 | 2,58 | |

| 14 | 416,38 | 2,4 | |

| 16 | 475,08 | 2,1 | |

| 17 | 504,35 | 1,98 | |

| 17,5 | 518,97 | 1,93 | |

| 18 | 533,58 | 1,87 | |

| 19 | 562,75 | 1,78 | |

| 20 | 591,88 | 1,69 | |

| 1420 | 10 | 347,73 | 2,88 |

| 11 | 382,23 | 2,62 | |

| 12 | 416,68 | 2,4 | |

| 13 | 451,08 | 2,22 | |

| 14 | 485,44 | 2,06 | |

| 16 | 554 | 1,81 | |

| 17 | 588,2 | 1,7 | |

| 17,5 | 605,29 | 1,65 | |

| 18 | 622,36 | 1,61 | |

| 19 | 656,46 | 1,52 | |

| 20 | 690,52 | 1,45 |

How much do large-diameter electric-welded steel pipes and main pipes weigh? You will find answers to these questions in the above tables for calculating the weight of large-diameter pipes depending on their diameter and wall thickness. Weight of main pipe and large diameter pipe: theoretical weight of 1 linear meter, number of meters in 1 ton.

At the metal warehouse in Minsk you can buy wholesale and retail from a warehouse or order metal main pipes or large-diameter pipes 159, 168, 219, 245, 273, 325, 377, 426, 530, 630, 720, 820, 920, 1020, 1120, 1220, 1420 mm.

See also: Rolled metal by size and type.