We continue to consider the types of door hinges, only for metal doors. Canopies for metal entrance doors are divided into two types - hidden internal and external welded, and these types already have subtypes.

External welded ones have varieties:

- cylindrical - round;

- teardrop-shaped;

- “Bark” (related to cylindrical);

Types of hidden ones are divided into:

- lamellar;

- cylinder.

For information:

The main types of hinges for wooden interior doors.

External welded

Welded canopies are used in many places, they are installed both on metal entrance doors and on gates, gates... Drop-shaped and cylindrical have the same modifications such as:

- with an ordinary axle - already a rarity;

- an axle with a pressed ball from a bearing;

- with a regular axle with 1 bearing;

- with an open bearing - found in cylindrical bearings, used in rare cases, since it is not resource-intensive during operation;

Modifications of teardrop-shaped ones from Italian manufacturers:

- machined axle for roller bearing with thrust bearing;

- with two bearings on the axle at the top and bottom - the structure is hidden inside;

Drop-shaped and cylindrical hinges differ mainly only in appearance. But because drop-shaped ones are more modern welded canopies; they have more different modifications of the insides than cylindrical ones. We will consider the same modifications that are found in both teardrop-shaped and cylindrical ones.

Basic truths

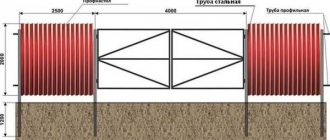

The process of installing hinges can be considered using the example of a metal gate. In order for it to properly perform its main functions, a number of conditions must be met when welding hinges:

- Provide a gap between the support post and the gate frame, which should be 3-5 mm.

- Provide a gap of several millimeters between the hinge and the gate frame by welding plates - metal plates of the required thickness - to the hinge. In total, for each loop you need two strips, the length of each of them is 2 mm less than the length of half.

- The optimal distance from the edge of the gate to the loop is 15-20 cm. If you need a middle loop, then it is located exactly in the middle between the outer loops.

First, the lower part of the fastener (with the pin) is welded to the post, then the upper part (with the groove) is welded to the sash.

A properly assembled structure should have the following parts:

- a loop;

- plate; wicket frame;

- support pillar;

- lower part (with pin);

- upper part (with groove).

This design consists of several elements.

All loops must be coaxial, that is, their centers must be on the same straight line. The alignment requirement is extremely important. It is on its compliance that it depends on how evenly the weight of the gate will be distributed on the fastenings and, accordingly, how long they will last.

To work, the master will need:

- welding machine;

- metal plate for making plates;

- Bulgarian;

- hammer;

- plumb line;

- oil for lubricating hinges;

- protective equipment - mask, gloves, overalls.

At the preparatory stage, you should mark the gate frame and sash, determining the places where the hinges will be welded. Clean them from dust, dirt, and rust. To do this, you can use a wire brush and solvents. Next, a similar treatment is performed on the surface of the hinges, and lubricant is applied to their inner part.

The traditional welding method involves the installation of plates at this stage, for which it is recommended:

- Take 2 identical plates of the required thickness and length. Place them so that there is a gap of 2-3 mm between them.

- Place the bottom part of the loop on them.

- Weld the loop to one of the plates (in this case, to the right one).

- Do the same for the top of the hinge and weld it to the left plate.

- Then you need to install the shutters in the working position and fix them.

- The plates with the lower part of each hinge are spot welded to the post, then the upper hinge elements are inserted into the lower parts and spot welded to the sash. After checking the alignment of the hinges and the operation of the gate, final welding is carried out along the contour of the plates.

For an inexperienced craftsman, vertical welding, which must be done on an already installed pole, may be too difficult a task. In addition, it is almost impossible to do the work alone: you need an assistant.

teardrop-shaped

If you look at the “droplet” canopies from above - from the end, then their name will immediately become clear. The drop-shaped shape was invented to make it easier to weld it to the workplace. The drop-shaped loop is made in both two-section and three-section.

With two bearings on the axle at the top and bottom - the structure is hidden inside.

Drop-shaped ones are more often found with a bearing; if without it, then with a ball. Either they are generally ordinary, but only with a washer, or the axle is machined as if with a washer.

A few tips for a novice master

In order for your efforts on how to weld hinges on a door to be successful, you should be careful when purchasing garage hinges. Be sure to make sure that:

- their size and length correspond to the weight and dimensions of the doors;

- the pin rotates freely in the hole;

- between it and the inner surface of the groove there is a small gap of 0.1 mm;

- There is no damage on the hinge: dents, rust, shells.

The choice of material from which the hinge is made is equally important, since different types of steel are welded differently. It will be easiest to weld fasteners cast from black steel or low-alloy alloy. For them, you can use conventional electric welding.

If you purchase hinges made of stainless steel or alloy materials, you should be prepared for the fact that carbon dioxide or argon welding will be required.

The only advantage of stainless steel is that the hinge will not rust. But, since the coefficient of friction in a hinge made of this material is much higher than in a hinge made of black steel, it will have to be lubricated and cleaned more often. This is interesting: how to properly weld hinges on garage doors.

To avoid problems when welding hinges in the future, it is better to adhere to the following recommendations:

- It is not advisable to purchase cheap hinges made from ordinary raw steel, since their service life is only 2-3 years. During this time, the hinge wears out so much that the gate leaves begin to sag.

- It is better to figure out in advance which side of the gate the hinges will be welded on, taking into account that the optimal option for opening the doors is to the street, and think through the entire welding process down to the smallest detail.

- We should not forget that the main function of the gate is to ensure security. It is not advisable to install them on the street side, as they can be easily cut off. If you cannot do without this, it is recommended to order hinges made of forged steel, which no cutter will accept.

- You need to make sure that the gate leaf cannot be removed when closed. Sometimes, in order to avoid such actions on the part of intruders, experienced craftsmen place one of the hinges on each of the doors “upside down”. However, then it will be impossible to remove the sashes for the purpose of repairs.

- If this is your first time dealing with a welding machine, you should learn how to handle it in advance. Only an absolutely even weld seam will give a reliable and durable connection. It will be difficult to redo completed work.

These simple tips will help the novice master, and the installed doors will not cause him any problems in the future.

Ball inside the axle

The same cannot be said about canopies with a ball bearing inside on the axle. This bearing ball is made of durable steel and is hardened. It is pressed into the axle with lubricant, so that when rotating in the axle, the loop does not deform and its movement is easier. Thus, welded with a ball will last longer.

With ball and adjustment

Materials

Steel, brass or stainless steel are used as materials for making hinges. Steel hinges are reliable and affordable, and can come in different sizes. Brass hinges are produced by casting, which makes it possible to obtain a product with a beautiful design and excellent galvanic properties. Stainless steel hinges are quite durable and resistant to corrosion.

On bearings

Not adjustable with bearing

And, of course, the hinges on the bearings will last much longer than the previous ones, because here the friction is transferred to a durable support bearing. If in the case of an ordinary axle and a ball on the axle, over time you will need to “collectively farm”. Place washers or replace the entire canopies as normal. Then only the bearings will need to be replaced.

Classification of loops

Of great importance for how the door will function is the possibility or not the possibility of adjusting its hinges in different planes. Adjustable hinges for metal structures have an advantage over non-adjustable ones in houses where wall shrinkage is possible if the door is in constant use and is prone to distortion and sagging or is subject to constant climatic influences.

The variety and technical features of hinges for metal structures are determined by GOST 5088-2005 “Hinges for window and door units.”

According to this GOST, according to the type of loop design:

- Classic without a ball. Such hinges are almost out of use, since they wear out very quickly, after a while they begin to creak and the structure sags. They are a fairly cheap option, but in comparison with more modernized models they no longer have any advantages;

- Classic with a ball. In such hinges, a ball is located between two rods, which contributes to less wear and smooth operation of doors on such hinges;

- Hinges with a bearing in their design have a ball bearing support, thanks to which the wear of the hinge and all the negative consequences of this are minimized: sagging, creaking, jamming. Hinges with bearings are easy to use and have a longer service life than similar hinges without them.

Related article: How to make lighting in a dressing room

Also, it is worth noting that noticeably less effort must be applied to a hinged sash with a bearing when opening or closing.

Also, in accordance with GOST, door hinges according to the installation method can be:

- screw-in;

- mounted;

- hidden;

- spring.

With a grease fitting

With oiler and open bearing.

For a longer service life of canopies and bearings, they must be lubricated regularly, at least once a year. To simplify lubrication, sheds with a grease fitting (grease fitting) have been invented. In order not to remove the canvas, but simply unscrew the oil can and pour oil inside, you can lubricate it without unscrewing it, but for this you will need a special tool that presses in a syringe.

Axleless hinges "Bark"

Welded ones also include Bark axleless hinges. They are called axleless because instead of a standard axis, such as cylinder and teardrop-shaped ones, there is a hardened ball.

"Bark" are not the same as the axial ones, they are divided into upper and lower. The upper axleless one comes with an adjusting bolt, this bolt helps when installing the blade in the box, and the lower one, without a bolt, only has one ball.

When installing the canvas in the box, first place it on the lower hinge, then push in the upper one and secure it with the adjusting bolt. The loops themselves are attached to the corners of the canvas. Almost like heels for wooden interior doors.

For strong burglary resistance of a type like the Bark, a box with a protrusion is required. In such a box they will perform all the functions provided by the manufacturer. They will be more difficult to cut down than in an ordinary box.

People who are not familiar with this type of canopy may think that it is easy to remove the canvas simply by unscrewing the adjusting bolt of the top hinge. Not so simple. Firstly, for the adjusting bolt, a bolt is made to fix it, which is unscrewed only when the blade is open. And secondly, it is unlikely to be possible to remove the canvas from the axleless ones when closed.

As for Bark lubricant. Rubbing elements, especially under load, must be lubricated, so do not listen to anyone if they tell you that they do not need to be lubricated. At a minimum for ease of movement, at a maximum for less wear of parts.

Welding without plates

If the weight of the gate is light, you can do without plates. The welding technology will be slightly changed:

- The support and frame of the gate are laid horizontally so that their surfaces are in the same plane. A gap of 3-5 mm is left between them.

- 20 cm is measured from the top edge of the frame and a loop is placed in the gap. To raise it a little, you can use two matches, placing them perpendicular to the gap and installing a hinge on them.

- The hinge is fixed by spot welding: the lower element with the pin is welded to the support, the upper element with the groove is welded to the frame.

- To check how well the hinges work, it is not at all necessary to lift the sash: it is much easier to turn the support. If everything is normal, final welding is performed along the entire length of the fastener<./li>

These methods are suitable for installing new gates, doors or gates. If it is necessary, for example, to replace old hinges on an already installed gate, experienced craftsmen suggest proceeding as follows:

- Secure the plaits to the loop.

- Laying the sash horizontally, weld the top part of the hinge.

- Place the sash in the opening and secure it.

- Insert the bottom of the loop into the top. Mark on the support the place where the bottom plate should be.

- Weld the lower part to the support.

After welding the door hinges, the seams are cleaned, primed and painted. Further care of the hinges comes down to regular lubrication, which will prevent rust and reduce friction.

Lubrication should be carried out only in the warm season, otherwise the hinges may freeze. Before applying lubricant, it is recommended to remove the door from the hinge, remove the remains of the previous composition, dirt, rust from the pin, and clean the groove.

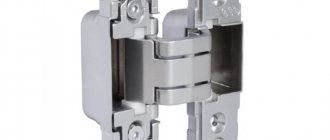

Hidden hinges for metal doors

As mentioned above, hidden loops are divided into two subtypes.

Lamellar

Plate doors are used for relatively lightweight entrance doors. They are adjustable in several planes and consist of plates rotating on an axis. More often found in lightweight doors from Chinese manufacturers.

Hidden cylindrical

Hidden cylindrical ones are external welded ones. Installed inside the box and connected to a canvas, angle or “U” shaped channel, depending on the design. Such hinges are used for heavy fabrics; they are adjustable only up and down, and only if they have adjusting bolts. And by and large, doors with cylindrical internal hinges are made to order. So, the necessary adjustments are made during manufacturing.

Opening 90-100 degrees

Hidden door hinges are so named because they are located inside the frame. They are good for high burglary resistance, since there is no open access to them for cutting. With their secrecy, they give the door an interesting and aesthetic appearance. Hidden hinges are best used on doors that are installed outdoors. Since they are hidden inside the box, they are not affected by weather conditions such as rain, snow, etc.

Concealed opening 90-100°

Some small nuances:

- Opening of the canvas.

There are hidden hinges for metal entrance doors that open the door at 90-100° degrees, and there are those that open at 180° degrees.

- Removing the fabric from the hinges

To remove the canvas from the internal plates, you need to unscrew each loop. And, in order to remove it from the external welded ones, you need to lift the blade up in the open position and move it to the side.

- Price

The cost of hidden ones is an order of magnitude higher than the cost of external welded ones.

Opening 180° degrees

For heavy doors, adjustable in three planes.

For light doors

Conclusion

To summarize, we can note that if your budget is limited and you don’t have a lot of tools, then take butterflies or screw-in hinges. Mortise door hinges are better suited for wooden panels. It is advisable to install hidden canopy models on iron and expensive wooden doors. The video in this article shows the nuances of selection and installation. If the information was useful, then there are social network buttons below, perhaps your like will help one of your friends decide.

The simplest hidden canopy for a heavy metal door.