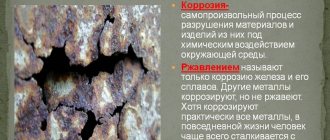

Aluminum corrosion is the destruction of metal under the influence of the environment.

For the reaction Al3+ +3e → Al, the standard electrode potential of aluminum is -1.66 V.

The melting point of aluminum is 660 °C.

The density of aluminum is 2.6989 g/cm3 (under normal conditions).

Aluminum, although an active metal, has fairly good corrosion properties. This can be explained by the ability to passivate in many aggressive environments.

The corrosion resistance of aluminum depends on many factors: the purity of the metal, the corrosive environment, the concentration of aggressive impurities in the environment, temperature, etc. The pH of solutions has a strong influence. Aluminum oxide forms on the metal surface only in the pH range from 3 to 9!

The corrosion resistance of Al is greatly influenced by its purity. For the manufacture of chemical units and equipment, only high-purity metal (without impurities), for example, AB1 and AB2 aluminum, is used.

Corrosion of aluminum is not observed only in those environments where a protective oxide film is formed on the surface of the metal.

When heated, aluminum can react with some non-metals:

2Al + N2 → 2AlN – interaction of aluminum and nitrogen with the formation of aluminum nitride;

4Al + 3С → Al4С3 – reaction of interaction of aluminum with carbon with the formation of aluminum carbide;

2Al + 3S → Al2S3 – interaction of aluminum and sulfur with the formation of aluminum sulfide.

Nitric acid

Nitric acid is one of the strongest mineral acids; in concentrated form it emits yellow vapors with a pungent odor.

With the exception of gold and platinum, it dissolves all metals. Nitric acid is used to produce dyes, fertilizers, organic nitroproducts, sulfuric and phosphoric acids. As a result of a burn with nitric acid, a dry scab of yellow-green color is formed.

In industry, nitric acid is produced by the oxidation of ammonia on platinum-rhodium catalysts.

Pure nitric acid was first obtained by treating nitrate with concentrated sulfuric acid:

It is a monobasic strong acid and reacts with basic oxides and bases. Reacts with salts under the condition of precipitation, gas evolution, or the formation of a weak electrolyte.

When heated, nitric acid decomposes. A similar reaction also occurs in light (hv), so nitric acid should be stored in a dark place.

Nitric acid is capable of oxidizing all non-metals, and if the acid is concentrated, nitrogen is usually reduced to NO2, if diluted, to NO.

At any concentration, nitric acid exhibits the properties of an oxidizing agent, with nitrogen being reduced to an oxidation state of +5 to -3. At what degree of oxidation nitrogen will stop depends on the activity of the metal and the concentration of nitric acid.

For low-active metals (standing in the voltage series after hydrogen), the reaction with concentrated nitric acid occurs with the formation of nitrate and predominantly NO2.

With dilute nitric acid, the gaseous product is predominantly NO.

In reactions with metals to the left of hydrogen in the voltage series, a variety of gaseous (and non-gaseous) products are possible: brown gas NO2, NO, N2O, atmospheric gas N2, NH4NO3.

Remember the pattern: the more dilute the acid and the more active the metal, the more nitrogen is reduced. Below are the reactions of zinc with nitric acid in various concentrations.

Look at the table below, which also reflects the patterns we have studied.

Concentrated cold nitric acid passivates chromium, iron, aluminum, nickel, lead and beryllium. This occurs due to the oxide film that covers these metals.

Al + HNO3(conc.) ⇸ (reaction does not occur)

When heating or amalgamating (coating with mercury) the listed metals, a reaction with nitric acid occurs, since the oxide film on the surface of the metals is destroyed.

Nitric acid salts - NO3 nitrates -

Nitrates are obtained through the reaction of nitric acid with metals, their oxides and bases.

In reactions with oxides and bases, a gaseous product is usually not released.

Ammonium nitrate is prepared by reacting ammonia with nitric acid.

Metal passivation

One of the effective methods of protecting the metal surface from corrosion is surface treatment using special chemical solutions.

When they interact with metal, a chemical reaction occurs, as a result of which a neutral (passive) compound is formed on the surface that can resist the occurrence of corrosive processes. This treatment is called metal passivation.

After this process is completed, an oxide film forms on the surface. It has the chemical properties not to enter into an oxidation reaction and thereby prevents the destruction of not only the surface layer, but also the entire part.

This type of processing is most common for steel, aluminum, nickel, copper and their alloys. In addition to the tasks of protection against corrosion, passivation is used to carry out decorative treatment of the surface of the finished product and reduce the resistivity of contacts in electrical connections.

Description of technology

Passivation is based on the principles of chemical interaction of the surface layer of a metal with various solutions of other metals, as a result of which a surface layer with new physical and chemical properties is formed on the surface. The passivation process involves the creation of absorption (phase) layers that change the structure of the original metal. The passivation layer creates a reliable barrier that prevents the oxidation process and serves as reliable protection against corrosion.

To carry out such chemical reactions, various metals are used. This depends on the composition of the original metal from which the part is made. To give it specific properties, the following can be used: chromium, nickel, cobalt, manganese, molybdenum and other rare earth metals. Depending on their percentage, a passivation solution is prepared and the necessary equipment is selected.

When passivating stainless steel during its production, various alloying metals are added to its composition. They provide better interaction with the chemical elements included in the passivation solution.

For example, chromium oxide is used to create a reliable anti-corrosion film on the surface of steel. A chrome plating operation is performed. It completely changes the physical and chemical properties of the surface layer.

When the processing is carried out correctly, an even layer of equal density is obtained. Various acids are used to carry out passivation. Most often, a solution is created based on nitric acid.

It is the created salts based on this acid that create a protective film on the surface of the steel with high protective characteristics.

After completion of the technological process, the quality of the resulting layer is checked. This is necessary to evaluate the surface of the machined part. In practice, various verification methods are used. For example, a chemical method is used: the surface is treated with a solution of potassium ferrocyanide in nitric acid.

This impact allows you to visually identify areas of poor quality processing. In places where the layer is thin enough or absent, that is, there is a large amount of free iron, a characteristic blue color will appear. This method is used in factory laboratories.

They check selected parts from the finished batch.

A simpler, but more time-consuming method is to place the finished product in ordinary water. After a long stay in water, poorly treated areas become covered with rust.

The technology for passivation of non-ferrous metals is practically no different from the technology for processing steel. The main difference is the composition of the solutions used. For example, potassium and sodium chromates or chromic anhydride are used to process aluminum, copper, and nickel.

The processing process is accelerated by adding various salts and acids to the solution.

Passivation of copper is carried out in solutions of sulfuric acid, surface treatment of copper is carried out in a solution of phosphoric acid, zinc and cadmium in solutions of hydrochloric and nitric acid.

In some cases, the process of interaction of a solution with metal is used to solve other important technical problems. The process of metal decomposition under the influence of oxides is used for the manufacture of printed circuit boards in radio engineering. This procedure is called etching.

In this case, a pattern of future conductive strips and locations for placement of radio components is applied to the surface of the metallized textolite plate using paint.

Then the plate with the applied pattern is lowered into a bath of solution, under the influence of which the metal layer is chemically removed from the surface of the PCB. As a result of passivation, only metal protected by paint remains on the surface.

After this, the plate is washed in running water and the applied paint layer is removed using solvents. The result of such passivation (etching) is a finished printed circuit board for a specific radio-electronic device.

The technology of applying a decorative layer to the main layer of the product does not differ from the general passivation process. When creating jewelry, a thin layer of gold film is applied to the surface of a silver blank. It is formed in a similar way. Thus, a product with a characteristic golden color is obtained.

An important point in obtaining a high-quality film during passivation is finishing processing. In all cases, after removing the part from the solution bath, it is necessary to rinse it thoroughly. This is necessary in order to stop the passivation process.

If you leave part of the active solution or even its diluted components, the technology will be disrupted and the quality of the resulting film will be significantly reduced. After thorough washing, it is recommended to dry the finished part.

This can be done by natural drying or using special hair dryers. In production, drying chambers are used that provide a uniform flow of warm air.

High-quality surface preparation, compliance with all processing modes, observance of passivation time, high-quality washing and drying make it possible to obtain a high-quality, uniform protective layer that can last quite a long time.

Application of passivation

The main objectives of passivation include:

- prevention of corrosion processes occurring in the upper layers of metal;

- protection from destruction of newly created connections, for example, at the site of a weld (passivation of welds);

- increased electrical conductivity at the point of electrical contact;

- creation of printed circuit boards using prepared templates (etching);

- processing of the finished product in order to impart new decorative and consumer properties.

The first problem is solved for a large number of metals and their alloys. One option for such protection is bluing. In the second case, to create a strong welded joint, passivation of the anodes and final processing of the resulting joint after welding are used. Carrying out passivation can significantly increase the tightness of the resulting connections.

This is especially important when laying pipelines. This treatment is very useful when welding difficult-to-weld metals such as aluminum. Passivation of copper or brass is carried out to create temporary protection against tarnishing of the surface of the product for a certain period of time (usually about a month).

Sometimes it is used as a temporary preservation of prepared parts for storage between further processing or assembly operations.

This type of processing is necessary when using metal products in the following cases:

- the use of fasteners, especially in aggressive environments and high mechanical loads;

- when assembling pipelines, especially in places of welds;

- to protect boiler equipment;

- machine parts and mechanisms in contact with sea water;

- structural elements operating under changing temperature conditions;

- individual elements of hand and mechanical tools;

- finished products used in everyday life (door handles, furniture fittings, etc.);

- decorative crafts for the interior;

- in radio electronics to improve the quality of contacts;

- Jewelry.

The problem of increasing electrical conductivity is solved by applying a thin layer of metal with increased electrical conductivity, such as gold or silver, to the surface of the manufactured contacts.

Types of passivation

The main and most well-developed types of passivation are:

- chemical;

- electrochemical.

Chemical

Chemical passivation involves the use of solutions of salts of various metals. The most effective passivation is carried out with nitric acid. In addition, sulfuric acid or citric acid is used to form a solution.

To improve the quality of the process, a small amount of sodium bichromate is added to the solution. Its amount does not exceed 6% of the total mass. The composition of the solution is selected individually and largely depends on the type of metal being processed.

For example, to passivate iron, metal salts dissolved in high concentration sulfuric acid are used.

The essence of chemical passivation is the active attraction of negative ions that are present in the solution to metal atoms. This occurs due to the presence of a positive charge. As a result of such diffusion, a surface layer is formed.

For passivation, it is necessary to carry out preliminary preparation of the surface of the product. It is thoroughly cleaned using mechanical and chemical methods. The final result and the reliability of the formed film depend on the quality of this procedure. This is of great importance when passivating non-ferrous metals: brass, copper, bronze.

Electrochemical

This type of passivation is based on the principles laid down in the technique of galvanic processing of products. Acceleration of processing is carried out due to the influence of direct current, which flows through the solution, accelerating the chemical reaction. This passivation is called electrochemical.

In addition to the bath in which the electrolyte is placed, such an installation uses a direct current source, connecting wires and one electrode. The second electrode is the part itself.

Another option for contacts is one electrode and a bath body (it must be made of metal that is resistant to electrolyte and electric current).

In practice, electrical installations with a relatively low voltage level are used. Its value does not exceed 12V.

In both cases, when the installation is turned on, an electric current is passed through the solution. It stimulates the passivation process on the surface of the workpiece. In practice, I distinguish between anodic and cathodic passivation.

With this passivation, a positive potential is applied to the workpiece, and a negative potential is applied to the bath body. When using the electrochemical method, the protective film is formed faster and is more even. But this technology is more expensive than chemical passivation, because

it uses more complex equipment and consumes electricity. Under its action, the protective film is uniform. This is how a film is formed on the surface of copper blanks. Current is passed through solutions with chromium salts dissolved in them.

It is in them that copper acquires the greatest resistance to corrosion.

Important parameters in this process are the passivation time, the density and composition of the electrolyte, and the critical value of the passivation current. These parameters are calculated for various metals and are given in special tables. Based on these data, the allowable processing time is calculated.

Properties of metal after processing

The main objective of passivation is to improve the physicochemical and mechanical characteristics of the surface layer of the material from which the part is made. The remaining characteristics of the deeper layers remain unchanged. Therefore, after passivation is completed, the following properties and characteristics change in the surface layer:

- a layer with a new chemical composition appears;

- anti-corrosion activity changes (it slows down significantly);

- the physical characteristics of the material are improved (only the surface layer);

- in some cases, the mechanical strength of the product increases;

- the color of the part changes (it takes on a more aesthetic shape);

- consumer properties increase and presentation improves.

Passivation of stainless steel can significantly improve anti-corrosion properties and give the finished part a completely different color. The use of chromium or nickel in the passivation solution produces a shiny metallic color.

Passivation of iron with chemical elements close to it makes it possible to create an outer layer that is sufficiently resistant to corrosion. In this way, the scope of application of such products expands. They can be used even in active and aggressive environments. In addition to various grades of steel, cast iron is subjected to passivation.

The main task is to create a protective film against corrosion. In some cases, when thickened sodium nitrate is used, the surface layer acquires some elasticity. In this case, the fragility of the entire part is reduced. One type of steel is the so-called blued finish.

The result of processing is a reliable outer layer of black color.

The properties of the surface layer of non-ferrous metals change in a similar way. As a result of passivation, adsorption or phase layers of a certain thickness are formed. Placing an aluminum workpiece stimulates the process of natural passivation of the surface layer of this metal. When exposed to acidic solutions, the protective properties of the surface layer of aluminum increase.

, please select a piece of text and press Ctrl+Enter.

Passivation of stainless steel to protect it

When stainless steel products are made, they are typically immersed in a nitric acid bath at the end of the manufacturing process to remove contaminants.

The acid also activates the oxidation process of chromium in the air called passivation, where a protective layer of chromium oxide is formed when oxygen reacts with chromium.

Passivation occurs very quickly - usually within 20 minutes.

Now some stainless brewing equipment, particularly lower cost stainless materials, were likely machined, stamped, pickled, polished and welded only after the stainless steel had been fabricated and acid washed.

As a result, it may contain oils, polishes, welding compounds and other contaminants that protect the steel but should be washed away the first time you clean your parts. Plus, you probably don't want to find these oils and compounds in your beer.

Reaction of aluminum with concentrated nitric acid when heated

Aluminum is a reactive metal, but a strong oxide film determines its resistance under normal conditions. In almost all chemical reactions, aluminum exhibits reducing properties.

- Interaction with non-metals

It interacts with oxygen only in a finely divided state at high temperatures:

the reaction is accompanied by a large release of heat.

Above 200°C it reacts with sulfur to form aluminum sulfide:

At 500°C – with phosphorus, forming aluminum phosphide:

At 800°C it reacts with nitrogen, and at 2000°C – with carbon, forming nitride and carbide:

It reacts with chlorine and bromine under normal conditions, and with iodine when heated, in the presence of water as a catalyst:

Does not interact directly with hydrogen.

With metals it forms alloys that contain intermetallic compounds - aluminides, for example, CuAl2, CrAl7, FeAl3, etc.

Aluminum purified from the oxide film vigorously interacts with water:

As a result of the reaction, slightly soluble aluminum hydroxide is formed and hydrogen is released.

Interaction with acids

Easily reacts with dilute acids, forming salts:

8Al + 30HNO3 = 8Al(NO3)3 + 3N2O + 15H2O (nitrogen and ammonium nitrate can also be the product of nitric acid reduction).

It does not react with concentrated nitric and sulfuric acids at room temperature; when heated, it reacts to form a salt and the acid reduction product:

Interaction with alkalis

Aluminum is an amphoteric metal; it reacts easily with alkalis:

in solution to form sodium tetrahydroxodiaquaaluminate:

when fused to form aluminates:

Recovery of metals from oxides and salts

Corrosion of aluminum in water

Aluminum corrosion is almost not observed when interacting with clean, fresh, distilled water. Increasing the temperature to 180 °C does not have any special effect. Hot water vapor also has no effect on aluminum corrosion. If you add a little alkali to water, even at room temperature, the corrosion rate of aluminum in such an environment will increase slightly.

The interaction of pure aluminum (not covered with an oxide film) with water can be described using the reaction equation:

2Al + 6H2O = 2Al(OH)3 + 3H2↑.

When interacting with sea water, pure aluminum begins to corrode, because... sensitive to dissolved salts. To use aluminum in seawater, a small amount of magnesium and silicon is added to its composition. The corrosion resistance of aluminum and its alloys when exposed to sea water is significantly reduced if the metal contains copper.

Aluminum

Aluminum is the most abundant metal in the earth's crust. The properties of aluminum allow it to be actively used in metal structures: it is light, soft, stampable, and has high corrosion resistance.

Aluminum is characterized by high chemical activity and is also characterized by high electrical and thermal conductivity.

Ground and excited state

When an aluminum atom transitions to an excited state, two electrons of the s-sublevel are paired off, and one electron moves to the p-sublevel.

Natural compounds

Receipt

Aluminum is produced by electrolysis of Al2O3 melt in cryolite (Na3[AlF6]). Gallium, indium and thallium are obtained in a similar way - by electrolysis of their oxides and salts.

Chemical properties

At room temperature, it reacts with halogens (except fluorine) and oxygen, becoming covered with an oxide film.

Al + Br2 → AlBr3 (aluminum bromide)

When heated, aluminum reacts with fluorine, sulfur, nitrogen and carbon.

Al + F2 → (t) AlF3 (aluminum fluoride)

Al + S → (t) Al2S3 (aluminum sulfide)

Al + N2 → (t) AlN (aluminum nitride)

Al + C → (t) Al4C3 (aluminum carbide)

Aluminum exhibits amphoteric properties (Greek ἀμφότεροι - dual), reacts with both acids and bases.

Al + NaOH + H2O → Na[Al(OH)4] + H2↑ (sodium tetrahydroxyaluminate; since aluminum is given in its pure form, hydrogen is released)

During calcination, complex salts are not formed, so the water evaporates - instead of them, intermediate salts are formed (within the Unified State Examination) - aluminates (academically - complex oxides):

At room temperature it does not work due to the formation of an oxide film - Al2O3 - in air. If you destroy the oxide film by heating an alkali solution or by amalgamation (coating the metal with a layer of mercury), the reaction occurs.

Aluminothermy (Latin Aluminum + Greek therme - heat) is a method of producing metals and non-metals, which consists in reducing their oxides with aluminum. Temperatures during this process can reach 2400°C.

Using aluminothermy, Fe, Cr, Mn, Ca, Ti, V, W are obtained.

Aluminium oxide

Aluminum oxide is produced by reacting with oxygen - in air, aluminum is covered with an oxide film. When heated, aluminum hydroxide, as an insoluble base, easily decomposes into oxide and water.

It exhibits amphoteric properties: it reacts with both acids and bases.

Al2O3 + NaOH + H2O → Na[Al(OH)4] (sodium tetrahydroxyaluminate)

Aluminum hydroxide

Aluminum hydroxide is obtained through exchange reactions between soluble aluminum salts and alkalis. As a result of the hydrolysis of aluminum salts, a white precipitate often forms - aluminum hydroxide.

Corrosion of aluminum in air (atmospheric corrosion of aluminum)

Aluminum, when interacting with air, becomes passive. When pure metal comes into contact with air, a thin protective film of aluminum oxide instantly appears on the aluminum surface. Further, film growth slows down. The formula of aluminum oxide is Al2O3 or Al2O3•H2O.

The reaction of aluminum with oxygen:

4Al + 3O2 → 2Al2O3.

The thickness of this oxide film ranges from 5 to 100 nm (depending on operating conditions). Aluminum oxide has good adhesion to the surface and satisfies the condition of continuity of oxide films. When stored in a warehouse, the thickness of aluminum oxide on the metal surface is about 0.01 - 0.02 microns. When interacting with dry oxygen – 0.02 – 0.04 microns. When heat treating aluminum, the thickness of the oxide film can reach 0.1 microns.

Aluminum is quite resistant both in clean rural air and in an industrial atmosphere (containing sulfur vapor, hydrogen sulfide, ammonia gas, dry hydrogen chloride, etc.). Because sulfur compounds do not have any effect on the corrosion of aluminum in gas environments - it is used for the manufacture of sour crude oil processing plants and rubber vulcanization devices.