Metals are a generalized name for chemical elements combined according to a number of characteristics. They occupy a large part of the periodic table, but there is still no document that allows them to be divided into classes.

Metals differ primarily in their quality characteristics. Some have high thermal conductivity, others can withstand high tensile and tensile loads. Depending on these qualities, the scope of application is determined, but metals in their natural form, even purified, do not have the necessary characteristics in sufficient form, so the technology of alloys is used, that is, the combination of several elements into one molecular lattice. This allows you to significantly improve the characteristics and give the alloy the necessary qualities.

A simple example: let’s take a common industrial alloy, bronze. This is a compound where the main element is copper. Tin is used as an alloying, that is, quality-improving, component. The result of the connection is a new metal, harder and more elastic than pure copper, which is often used to make fasteners.

Signs of metals

The following basic mechanical properties are distinguished:

- Hardness - determines the ability of one material to resist the penetration of another, harder one.

- Fatigue is the amount and time of cyclic impacts that a material can withstand without changing its integrity.

- Strength. It is as follows: if you apply a dynamic, static or alternating load, this will not lead to a change in shape, structure and dimensions, or damage to the internal and external integrity of the metal.

- Plasticity is the ability to maintain integrity and the resulting shape during deformation.

- Elasticity is deformation without violating integrity under the influence of certain forces, and also, after getting rid of the load, the ability to return to its original shape.

- Resistance to cracks - under the influence of external forces they do not form in the material, and external integrity is also maintained.

- Wear resistance – the ability to maintain external and internal integrity during prolonged friction.

- Viscosity – maintaining integrity under increasing physical stress.

- Heat resistance - resistance to change in size, shape and destruction when exposed to high temperatures.

Manufacturing of metal (alloy) products

Humanity began to master metallurgy 4,000 years ago.

People have been melting steel and processing metal for 30 centuries. There is no limit to the improvement of technology, and today we have access to both traditional and innovative methods of metal processing: turning, mechanical, thermal, milling, etc. We carry out high-precision cutting, argon-arc welding and bending of rolled metal, ensuring the design shape and size. The following characteristics speak about our technological capabilities: the accuracy of gas, plasma and guillotine cutting is 0.5-16 mm, and we bend sheets up to 2 mm. We produce all factory metal products from certified rolled metal products in accordance with GOST requirements. Our trump cards are good technical equipment and highly qualified engineering and design staff. Thanks to the developed infrastructure, high-tech equipment, professionalism of employees and step-by-step quality control, the manufacturer can vouch for the manufactured metal products, providing them with a long-term guarantee. Our products are reliable, high quality, varied and inexpensive. The buyer can be confident in the timely completion of the order - at a high level and of any volume.

Metal classification

Metals include materials that have a combination of mechanical, technological, operational, physical and chemical properties:

- mechanical confirm the ability to resist deformation and destruction;

- technological indicate the ability to perform different types of processing;

- operational ones reflect the nature of changes during operation;

- chemical ones show interaction with various substances;

- physical ones indicate how the material behaves in different fields - thermal, electromagnetic, gravitational.

According to the metal classification system, all existing materials are divided into two volumetric groups: ferrous and non-ferrous.

Technological and mechanical properties are also closely related. For example, the strength of a metal can be the result of proper processing. For these purposes, so-called hardening and “aging” are used. Chemical, physical and mechanical properties are closely interrelated, since the composition of the material determines all its other parameters. For example, refractory metals are the strongest. Properties that appear at rest are called physical, and under external influence - mechanical. There are also tables for classifying metals by density - main component, manufacturing technology, melting point, and others.

Classification by crystal lattice structure

The differences in the structure of the crystal lattice for various metals in the solid state are obvious. They are characterized by the presence of one of three types of device:

- A body-centered cubic lattice with 8 equidistant atoms from the atom taken as the reference point and 6 more neighbors at a greater distance;

- Close-packed cubic lattice with 12 equidistant neighbors;

- A close-packed hexagonal lattice with 12 equally spaced neighbors.

For metals in the molten and gaseous state, these properties do not play a big role, since the crystal structure of atoms in these states becomes disordered.

Black metals

Materials belonging to this group have the same properties: impressive density, high melting point and dark gray color. The first large group of ferrous metals includes the following:

- Iron - cobalt, manganese, nickel, iron. They are used as a base or additives to alloys.

- Refractory - chromium, tungsten, molybdenum, titanium. All of them have a melting point higher than the level at which iron melts. Used as a base or additive for the production of alloy steels.

- Uranium – actinides and metals obtained as a result of synthesis. They are widely used in nuclear energy.

- Rare earths – neodymium, cerium, lanthanum. All metals have related chemical properties, but completely different physical parameters. They find their application as additives to alloys.

- Alkaline earth - calcium, sodium, lithium. In their free form they have no practical use.

Inert (noble) gases

Group VIII(18). Atoms of elements of this group have a fully “complete” outer electron layer. Therefore, they “don’t” need to accept electrons. And they “don’t want to give them away.” Hence, the elements of this group are very “reluctant” to enter into chemical reactions. For a long time it was believed that they do not react at all (hence the name “inert”, i.e. “inactive”). But chemist Neil Bartlett discovered that some of these gases can still react with other elements under certain conditions.

Electronic configurations:

- Ne - 1s22s22p6;

- Ar —1s22s22p63s23p6;

- Kr - 1s22s22p63s23p64s23d104p6

For more information about inert (noble) gases, see Atoms of group 0 elements: general characteristics...

Non-ferrous metals

The second largest group has low density, good ductility, low melting point, predominant colors (white, yellow, red) and consists of the following metals:

- Lungs – magnesium, strontium, cesium, calcium. In nature they are found only in strong compounds. They are used to produce light alloys for various purposes.

- Noble ones. Examples of metals: platinum, gold, silver. They have increased resistance to corrosion.

- Low-melting materials - cadmium, mercury, tin, zinc. They have a low melting point and are used in the production of various alloys.

The low strength of non-ferrous metals does not allow them to be used in their pure form, so in industry they are used in the form of alloys.

Interior design and architecture

To successfully create decorative products, you need to know the basic properties of the source material, as well as the technology for working with it.

Nowadays, both pure metals and their alloys can be used to make dishes, jewelry and various interior design items.

Artwork - silver vase

All metals and alloys created on their basis are divided into two large groups with different properties:

- Ferrous metals - steel

- Non-ferrous metals - copper, bronze, brass, zinc, tin, aluminum, lead and silver.

It is these types of metals that are most often used to make decorative items, dishes and much more. Therefore, let's look at their properties and features of metal processing.

Steel

Steel belongs to ferrous metals. Carbon steel, which is an alloy of iron with carbon and other elements, is best suited for artistic processing. Steel has high quality characteristics, including the following:

- Elasticity

- Strength

- Hardening ability - a piece of steel is heated at a high temperature until red-hot and then dipped in water. Thanks to this, the metal acquires varying degrees of hardness and elasticity.

- Possibility of “releasing” by heating to red heat and then slowly cooling.

- Ability to be processed with a forging hammer in a heated state, since the steel is perfectly forged.

- Possibility of cutting metal into thin strips.

The softness of steel is directly proportional to the amount of carbon in its composition. The less carbon there is in a metal, the softer and easier it is to process. The softness of steel increases during annealing, that is, “releasing” the metal. To do this, the steel is heated red-hot and then subjected to a slow cooling procedure.

Steel for the manufacture of various products and artistic processing is produced in the form of graded material. For engraving and minting, U8 and U10 steels are most often used, where the letter “U” indicates the amount of carbon in the alloy.

The blade of the knives is made of stainless carbon steel

Non-ferrous metals

Non-ferrous metals are much more expensive than ferrous metals because they have many unique properties. The main one is the lack of reaction with a magnet, that is, non-ferrous metals are not attracted and are not magnetized. In addition, most of them are practically resistant to oxidation, so the products are characterized by a long service life.

The production of non-ferrous metals for artistic processing is carried out in various forms:

- Ribbons

- Stripes

- Chushki

- Tubes

- Wire

- Rods

- Sheets

Let's look at the characteristic features of the most popular non-ferrous metals among craftsmen:

- Copper is a fairly soft metal of a beautiful red-orange hue, characterized by increased ability to forge and has high electrical conductivity and the ability to conduct heat. Processing copper is not particularly difficult, but the craftsman must keep in mind the high viscosity of this metal.

Copper can be soldered using tin and braze. Copper sheet is the main material for chasing and engraving work. Copper wire is used to make decorative items and openwork sculptures.

Copper sink

- Bronze is an alloy of copper and tin. The quantitative tin content affects the color of the alloy, which can take on pink, red, yellow or gray shades. If a bronze product is covered with a layer of patina (a decorative coating of copper oxide), then it acquires a noble smoky-greenish tint and looks ancient and truly expensive. Bronze is most often used for inlay and foundry work.

Sheet bronze

- Brass is an alloy of copper and zinc. The shade of the metal depends on the amount of zinc. According to its qualitative characteristics, brass is a harder alloy than pure red copper, therefore its degree of malleability is much lower. Compared to copper, brass has some brittleness, but at the same time it is more elastic.

Brass can easily be processed in various ways; in particular, it can be used for the manufacture of thin parts in inlays, as well as jewelry of various configurations. For embossing work it is used in sheet form.

Embossing on brass

- Zinc is perfect for casting both in its pure form and in alloys with other metals. Pure zinc is difficult to forge, but it is easy to solder, engrave, and machine with a variety of tools. The melting point is 419* C.

Sheet zinc

- Tin is a non- ferrous metal, known for a long time for its softness and ductility. Its melting point is only 252* C. As a component, tin is included in various types of bronze. When broken, tin produces a characteristic, recognizable crunch. Pure tin and its alloys are ideal for making inlays. Tin is also used for tinning and soldering dishes, both in its pure form and in alloys with lead. At the same time, its oxidation products are harmless.

Set of tin soldiers

- Aluminum is a silvery-white non-ferrous metal that melts at a temperature of about 658* C. A characteristic feature of aluminum is its lightness and ease of metal processing. Cast aluminum is quite brittle, but when rolled (annealed) it acquires the desired ductility.

Aluminum crafts from Madagascar

- Lead is a soft non-ferrous metal with a bluish-gray tint. It melts at a temperature of 327* C and resists corrosion well. However, it should be noted that lead oxides are poisonous. Lead is suitable for foundry work and the manufacture of molded products.

Lead (standard)

- Silver is also a non-ferrous metal, but it is also a precious metal. Pure silver is too soft and therefore difficult to work with. For the manufacture of products it is used in the form of alloys with copper. Silver inserts are used in inlays, engraving, embossing and niello.

Antique silver items

Properties of metals

Let's consider some properties of metals that affect the quality of artistic products:

- Malleability of the metal - Malleable ductile metals require greater cutting force, but their toughness must be taken into account. A piece of copper or lead needs to be chopped to the end, but brass, zinc or steel can be chipped with a chisel and then simply broken. Harder brass gives a smooth surface when turned, while aluminum or copper seems to drag on the cutter.

- Brittleness is the ability of solid materials to fracture due to mechanical stress without noticeable plastic deformation. This property is the opposite of plasticity. Heavily hardened steel, as well as many types of brass and bronze, are very brittle and will break into pieces under strong impacts. The brittleness of a metal is not always a sign of its hardness; for example, a zinc casting is brittle but not hard. A hardened steel knife is both hard and brittle.

- Elasticity is the property of metals to restore their shape and volume after the cessation of external forces or heating that caused the deformation. To a large extent, special grades of steel have this property.

- Melting when heated - the ability of a metal to melt when heated is an important quality, since melting is considered one of the most accessible and cheapest ways to produce metal products. Parts of huge machines and small metal sculptures are made in the same way.

If there is a need to harden a part while maintaining the viscosity of the metal, craftsmen use high-frequency currents. In this case, the part is hardened to a depth of several millimeters. However, the rest of the metal mass inside the product remains unchanged. And finally, metal parts can be processed without heating - for example, by engraving and metal carving.

Silver products

Copper and copper alloys

In its pure form it has a pinkish-red color, low resistivity, low density, good thermal conductivity, excellent ductility, and is resistant to corrosion. It is widely used as a conductor of electric current. For technical needs, two types of copper alloys are used: brass (copper with zinc) and bronze (copper with aluminum, tin, nickel and other metals). Brass is used for the manufacture of sheets, strips, pipes, wires, fittings, bushings, and bearings. Flat and round springs, membranes, various fittings, and worm pairs are made from bronze.

Magnesium, titanium and their alloys

Magnesium is not resistant to corrosion, but there is no lighter metal used for technical needs. Basically, it is added to alloys with other materials: zinc, manganese, aluminum, which are perfectly cut and are quite strong. Alloys with light metal magnesium are used to make housings for cameras, various devices and engines. Titanium has found its application in the rocket industry, as well as mechanical engineering for the chemical industry. Titanium-containing alloys have low density, excellent mechanical properties and corrosion resistance. They lend themselves well to pressure treatment.

Anti-friction alloys

Such alloys are specified to increase the service life of surfaces subject to friction. They combine the following characteristics of the metal - good thermal conductivity, low melting point, microporosity, low coefficient of friction. Antifriction alloys include those based on lead, aluminum, copper or tin. The most used include:

- babbitt. It is made from lead and tin. Used in the production of liners for bearings that operate at high speeds and under shock loads;

- aluminum alloys;

- bronze;

- metal-ceramic materials;

- cast iron.

Soft metals

According to the metal classification system, these are gold, copper, silver, aluminum, but among the softest are cesium, sodium, potassium, rubidium and others. Gold is highly dispersed in nature. It is found in sea water, the human body, and can also be found in almost any fragment of granite. In its pure form, gold has a yellow color with a hint of red, since the metal is soft - it can even be scratched with a fingernail. Under the influence of the environment, gold is destroyed quite quickly. This metal is indispensable for electrical contacts. Although silver is twenty times more abundant than gold, it is also rare.

Used for the production of tableware and jewelry. The light metal sodium has also become widespread and is in demand in almost every industry, including the chemical industry for the production of fertilizers and antiseptics.

The metal is mercury, although it is in a liquid state, therefore it is considered one of the softest in the world. This material is used in the defense and chemical industries, agriculture, and electrical engineering.

Nonmetals (reactive)

Under normal conditions, boron, carbon, phosphorus, sulfur, and selenium are solids of various colors. Each of them has different forms of crystal lattice (allotropic modifications), for example red, yellow, black, white phosphorus, which greatly affects their chemical activity (for example, graphite is much less active than ordinary coal) and physical properties (diamond is the hardest substance in nature and is a transparent material, while graphite is brittle, soft, opaque).

Nitrogen and oxygen are gases. At the same time, nitrogen is quite chemically inert, oxygen, on the contrary, is a very active oxidizing agent.

Halides have different physical properties (fluorine, chlorine are gases, bromine is a liquid, iodine is a solid). Astatine is obtained only in extremely small quantities, like tennessine, their properties are poorly studied. Chemically, halides are very strong oxidizing agents (fluorine is the strongest on the periodic table). With metals they usually form salts with an ionic lattice, and with hydrogen they form very strong acids. With nonmetals they also form many polyatomic compounds, usually with covalent bonds.

Hard metals

The hardest metals practically do not exist in nature, so it is very difficult to obtain them. In most cases they are found in fallen meteorites. Chrome belongs to the refractory metals and is the hardest of the purest on our planet, and it is also easy to machine.

Tungsten is a chemical element. It is considered the hardest when compared with other metals. Has an extremely high melting point. Despite its hardness, any necessary parts can be forged from it. Due to its heat resistance and flexibility, it is the most suitable material for smelting small elements used in lighting fixtures. The refractory metal tungsten is the main substance of heavy alloys.

Comparison of properties

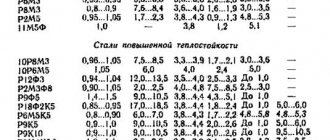

The second part of the elements in the periodic table is characterized by a variety of characteristics, so it is almost impossible to provide a complete summary table. We offer a table that shows 4 distinctive features:

| Signs | Metals | Nonmetals |

| Position in P.S. | Under the diagonal boron-astatine | Above her |

| Atomic structure | Large atomic radius, pure electrons in the last layer - from 1 to 3 | Small, from 4 to 7 - respectively |

| Physical properties | Electrical conductivity, thermal conductivity, gloss, malleability, plasticity, in terms of state of aggregation, mostly solid | Dielectrics, non-shiny, brittle, gases, liquids and volatile solids |

| Crystal lattices | Metal | Molecular, atomic |

| Chemical properties | Restorers | Oxidative (sometimes reduced) |

We talked about metal, what kind of material it is, how it is used. If you need metalworking machines, order them from. We have manual and semi-automatic band saws in stock and on order, as well as pendulum, vertical and two-post units. The price of goods has been reduced by 1.5 - 2 times compared to foreign analogues. To clarify the information you are interested in, contact our managers, we will be happy to help you select equipment.

Metals in energy

Metals, which contain free electrons and positive ions, are considered good conductors. This is a rather popular material, characterized by plasticity, high electrical conductivity and the ability to easily donate electrons.

They are used to make power, radio frequency and special wires, parts for electrical installations, machines, and household electrical appliances. The leaders in the use of metals for the manufacture of cable products are:

- lead - for greater resistance to corrosion;

- copper - for high electrical conductivity, ease of processing, corrosion resistance and sufficient mechanical strength;

- aluminum - for low weight, vibration resistance, strength and melting point.

Categories of Ferrous Secondary Metals

There are certain requirements for ferrous metal waste. To send alloys to steel furnaces, certain processing operations will be required. Before submitting an application for waste transportation, you must familiarize yourself with the GOST ferrous metals to determine its cost. Black secondary scrap is classified into steel and cast iron. If the composition contains alloying additives, then it is classified as category “B”. Category “A” includes carbon materials: steel, cast iron, additives.

Metallurgists and foundry workers, due to the limited primary raw material base, are showing an active interest in secondary raw materials. Using scrap ferrous metals instead of metal ore is a resource-saving as well as energy-saving solution. Recycled ferrous metal is used as a coolant for converter smelting.

The range of applications of metals is incredibly wide. Black and colored are used indefinitely in the construction and machinery industries. The energy industry cannot do without non-ferrous metals. Rare and precious ones are used to make jewelry. Both non-ferrous and ferrous metals are used in art and medicine. It is impossible to imagine a person’s life without them, from household supplies to unique instruments and apparatus.