The production of rectified distillate is technologically different from the production of noble craft distillates. I will tell you how to get pure alcohol at home in the next lesson of the Craft School. Today we will discuss everything you wanted to know about home rectification. The bell rings - let's start the lesson!

To obtain a rectification, special equipment is required

Production Features

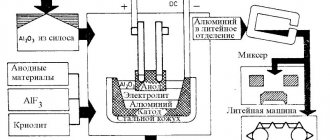

The process of making ethyl alcohol has some peculiarities. Indeed, depending on the selected raw material, such alcohol can be industrial or drinking. The production process is as follows:

- Initially, raw materials are prepared. It uses manure, oil, coal and other components of chemical production. The prepared raw materials are supplied to the corresponding distilleries.

- The factories use special technology. For example, oil undergoes a so-called hydrolysis process. And the gas formed after special processing soon turns into the necessary product.

- Then distilleries pack the resulting component into containers and send it to industrial enterprises, that is, to end consumers. Some of the modern distilleries or workshops, operating semi-legally or illegally, also use this product. It is added to various alcoholic drinks.

Drinking alcohol is used to produce strong drinks. Consequently, companies that produce alcohol care about both their own reputation and public health. They buy exclusively certified, high-quality products from distilleries.

Drinking alcohol is produced as follows:

- Initially, raw materials are prepared. For this purpose, potatoes, cereal grains, sugar cane or sugar beets or other natural ingredients are used, which are grown, collected, and then sent to the appropriate distilleries.

- To obtain high-quality products, specialized factories process grain using special technologies, add yeast to it and, through fermentation, obtain high-quality alcohol. To make it suitable for preparing alcoholic beverages, several degrees of purification are carried out, that is, rectification. In some cases, double distillation technology is used. This allows the product to become higher quality and cleaner.

- Then the products go to factories producing alcoholic beverages. There, additional purification of the alcohol is carried out and the product is saturated with all sorts of aromas. After this, alcoholic drinks are made.

Many modern manufacturers prefer cheap raw materials, because the production of ethyl alcohol from grain crops requires the use of special technology and various degrees of purification. This takes a lot of time.

Another factor is also important here. Given the high cost of raw materials, the final alcohol product cannot be cheap. The exception is if it is made of low-quality ethyl alcohol. Some manufacturers provide the opportunity to purchase inexpensive alcoholic drinks. But, as a rule, this is a sign that the product is made from cheap raw materials (for example, rotten potatoes).

Other methods for making alcohol at home

https://youtube.com/watch?v=-fi7qxeG8KY%3Ffeature%3Doembed

There are different ways to make alcohol at home, using different ingredients:

- Sugar beet. It is best to remove the juice from the beets and ferment it, but you can go the other way. The beets are washed, then grated, malt is added to it, which can be used from the recipe described above, and hot water is added. The contents must be boiled until the beets become soft, then grind them through a sieve. The wort must be cooled to room temperature and the yeast must be added without removing the grounds. To create such a mash you will need 500 grams of malt, 5 liters of water and 10-15 kg of beets. Before obtaining alcohol, you need to squeeze out the grounds. The output is 1-1.5 liters of the finished product.

- Fruits and berries. Berries or other types of fruit can be used to create alcohol. They need to be crushed, then add 5% malt, counting from the total mass, and add water. Next, water is added and everything is thoroughly mixed. The contents should be boiled over low heat, then ground using a sieve and left to cool and ferment. When creating homemade alcohol, it is recommended to use unripe fruits and it is better that they are tart, since green fruits contain a lot of starch, which will turn into sugar only at the ripening stage .

- Bread. Alcohol can be obtained from bread mash; for this you need to put 10 loaves of black bread in 10 liters of warm water and leave everything to cook until the bread is completely dissolved. Next, the contents are cooled to 60 degrees and 3.5 kg of malt is added. The ingredients must be left for 3 hours, maintaining a constant temperature of 60 degrees. Next, the mash is cooled to room temperature and 350 grams of yeast is added to it. Everything needs to be left for a week to ferment, and after distillation you should get 2 liters of alcohol.

- You can use berries or other types of fruit to create alcohol

. Sugar. Sugar mash will allow you to get up to 4 liters of alcohol. To prepare it, you will need to use 30 liters of water, about 7 kg of sugar, and 500 grams of yeast. - Jam. If the jam has already been candied and no one wants to eat it, then alcohol can be made from it. To prepare you need 6 kg of base, 30 liters of water, and 200 grams of yeast. This amount of ingredients will yield approximately 3 liters of alcohol.

- Candies. If you have candies with filling, you can also make alcohol from them. To do this, you need to dilute 1 kg of sweets in 5 liters of water and add 40 grams of yeast. This amount can yield 500 ml of alcohol, which will have a delicate and unusual taste.

- Wild pears. It is from such fruits that the maximum amount of alcohol can be obtained. To do this, it will be enough to boil 2.5 buckets of pears, then add 1.5 kg of malt and 2.5 kg of water. The prepared contents must be supplemented with 2.5 kg of sugar, as well as 100 grams of yeast. The output from the resulting raw materials will be 3 liters of alcohol.

Using such simple recipes, you can make alcohol at home and the better the distillation apparatus, the larger, stronger and better the alcohol will be.

Plum tincture with alcohol

To prepare the tincture according to this recipe, you do not need to remove the seeds from the plums - they will add interesting notes to the taste and aroma of the drink

You will need: 1 kg of plums, 1 liter of alcohol, 150 ml of water, 200 g of sugar, 4 sprigs of mint.

Preparation. Place the washed plums in a saucepan, cover with alcohol and leave for 2 weeks at room temperature in a dark place. Then pour the resulting liquid into a jar and carefully pour it into the container with the pre-prepared syrup, without ceasing to stir. Place mint in the bottle and strain the tincture into it. Close the lid and within a day you can enjoy the aromatic drink.

As you can see, in order to prepare a homemade tincture with alcohol, the most important thing is to be patient, because the longer the drink infuses, the richer its taste will be.

Selection of raw materials and sources of their supply

Another, no less important, smoothly follows from the previous question - the choice of the types of raw materials used for production and the sources of their production.

The production of alcohol by distilling mash can be carried out using a variety of raw materials. First of all, it is sugar. Its productivity is maximum: 10 kg of such raw materials gives approximately 5-5.5 kg of the finished product, that is, pure alcohol.

However, it is also the most expensive. In addition to sugar, you can use various starch-containing products: grains (rice, corn), as well as sugar beets and fruits (apples, grapes, plums, etc.). It is also possible to produce alcohol from potatoes. From wheat you can get up to 3 liters of alcohol, and from beets/potatoes and fruits only about a liter.

In any case, the choice is quite large. In addition, you can use several different sources at once, as well as mix brews obtained from different components. This is unimportant if you produce technical alcohol. But in the production of drinking alcohol, and especially of high quality (extra and higher categories), such mixing is unacceptable. The raw materials must be of high quality (and not rotten or frozen fruits, beets, etc.) and single-component.

What is needed for rectification?

I hope you know exactly why you want to get pure rectified alcohol. I'll tell you what you need for this.

Raw materials

Rectified alcohol is obtained from raw alcohol with a strength of 25–35 degrees, which is not prone to fire and is well divided into fractions. If you take a stronger raw material, then the separation into separate fractions will not work, therefore, you will not receive a rectification. So don't overdo it with raw materials.

Equipment

You will need a special column-type apparatus, at least 1.5 meters high. A prerequisite is the presence of an atmospheric fitting.

The height of the column is an important criterion for the apparatus. The smaller it is, the lower the probability of receiving a real rectification. The processes that occur in the column during rectification require a significant height of equipment. The design of columns from different manufacturers may vary, but all have a drawer, a cooler and a reflux condenser.

The distillation column can be purchased separately, the main thing is that an atmospheric fitting is installed in the basic apparatus. Then you will be able to receive the coveted rectification. If the apparatus does not have an atmospheric fitting, then even the use of a column will not ensure the production of alcohol with a strength of 96 degrees.

Distillation column "Astra"

Inside the column, in the drawer, there is a nozzle. The choice of nozzle is a matter of individual preference, since the market offers a variety of options from different materials: copper, ceramics, stainless steel.

Nozzles are divided into regular and bulk. Regular ones are a single mesh or cellular fabric. It is laid, evenly filling the diameter of the column. For example, the Panchenkov nozzle.

Bulk packings are a set of separate, unrelated elements that are poured randomly into the column. For example, spiral-prismatic nozzles made of copper or stainless steel.

Conditions

Rectification is a complex process. Its success depends on the quality of your raw materials, equipment, and atmospheric pressure. Pure alcohol can only be obtained at normal atmospheric pressure. If it is higher or lower than the norm, then the process will have to be postponed. A simple barometer will help you determine the atmospheric pressure.

Appearance of a column-type apparatus and its components

How to check the quality of alcohol at home

Once you have alcohol at home, you can test it for impurities by performing a Lang test.

Needed:

- 3 fractions of one alcohol - heads, body and tails;

- 3 flasks (clean jars will also do);

- a strong solution of potassium permanganate (per 50 ml of distilled water - 0.1 g of potassium permanganate);

- graduated pipette (syringe).

This is done like this:

- Add 0.4 ml of potassium permanganate to each of the three jars and add 20 ml of alcohol fractions: heads into the first jar, bodies into the second, tail fractions into the third.

- Literally within a minute, reactions occur: the heads become light yellow, the body remains pink, the tails remain brown.

- Immediately after breeding, time is noted and after what time the sample with the “body” acquires the color of salmon:

- 10 minutes – first grade alcohol, not very high quality;

- 15 minutes – premium;

- 20 – “Basis”;

- 22 – “Lux”.

If the alcohol has acquired the color of salmon earlier than 10 minutes, consuming it internally is dangerous to health.

The easiest way is to drop it on your hand and rub it. An unpleasant, pungent odor indicates that the alcohol is unsuitable for internal consumption.

Business plan for production

The scale of production depends on the power of the equipment. A small moonshine still allows you to produce ethanol with your own hands, without the involvement of additional workers. However, it should be understood that the lower the turnover, the lower the profit will be. Are there economic benefits in this case? After all, there are still costs for opening and registering a business, and permission to produce and sell ethanol is not cheap.

Mini production kit

But you can start small - open a mini-factory with low productivity and gradually increase momentum. The modular system allows you to replace the mash tank with a more spacious one.

Alcohol stillage

There is also the possibility of developing a side business - the production of animal feed or bioethanol - a flammable liquid used to ensure the operation of biofireplaces. Compound feed is made from mash waste after distillation (stillage) to which straw, milling waste, sugar, chalk, salt and other feed fillers are added.

To calculate the main economic indicators, the mini-plant BRU-PD.1.000850 (Ethanol-Kom) was considered. When producing 850 liters of ethanol, the following is consumed:

- raw materials (wheat, rye, flour) – 2.55 tons;

- enzyme preparations – 3 t;

- electricity – 140 kW;

- fuel for the steam generator (natural gas) – 523 m3.

Such a home moonshine still can be serviced by one person - independently, with his own hands, without the involvement of hired workers.

Alcohol mashine

Cost of raw materials:

- wheat, rye, flour - 5 rubles per 1 kg;

- enzyme preparations – 142 rubles/kg;

- electricity – 5.33 rubles/kW;

- fuel for the steam generator (natural gas) – 3.54 rubles/m3.

The cost of production will be:

- ethanol (96.6%) – 22 rubles/l;

- Luxury alcohol – 28 rubles/l;

Average selling price of products:

- ethanol (96.6%) – 60 rub./l;

- Luxury alcohol – 80 rub./l;

If you produce 430 liters per day (8 working hours), then the possible profit, subject to full implementation, will be - 25,800 - 9,460 = 16,340 rubles, per month - 359,48 rubles.

Obtaining a license for a mini alcohol plant

A homemade moonshine still costs 1,680,000 rubles.

If 30% of the profit is allocated to cover capital costs (equipment cost), then the payback period will be 15 months. Such economic indicators indicate that opening a mini-plant for the production of ethanol is a fairly profitable business that will bring net profit after the first year of production.

Making alcohol without sugar

https://youtube.com/watch?v=UKjogw5Cygo%3Ffeature%3Doembed

Get malt. It is obtained from grains of rye, barley or wheat. How? By germination in trays (their height is from five to ten centimeters). Treat the grains with potassium permanganate. Pour into trays (three centimeters) and irrigate them with water. Do this so that the grains float in the water. Cover the patches with film. Place in a place that is well lit. Irrigate the grains periodically as they absorb water. The malt will be ready in seven days. Peel the potatoes (one kilogram), chop them not very finely and boil for two hours. When the potatoes turn into a paste, leave it to cool.

The temperature should drop to sixty degrees. Add malt (crushed) to it. Leave to cool to twenty-two degrees. Now - adding yeast. With the yeast, place the mixture in a warm place.

At a temperature of twenty to twenty-two, the mash will be considered cooked in three days. If the temperature is fifteen degrees – in a week. Distill the mash through a special distillation apparatus. You can adjust its strength yourself during the distillation process. If you see that the alcohol turns out to be cloudy, then lighten it by adding potassium permanganate.

How to do it? Pour a small amount of it into alcohol. Stir. Leave to infuse for twenty-four hours. In the morning, carry out the process of filtering out the sediment. You, as you understand, don’t need it.

And now we will also deal with the unpleasant smell. Coal (wood) will help us in the showdown. Pour it into a container with alcohol and stir. Let it brew for fifteen days. During infusion, the charcoal sometimes needs to be shaken. After fifteen days, add a mixture of coal and alcohol and filter it.

How to distinguish drinking ethanol from technical ethanol

Unfortunately, the high price of a bottle of vodka does not guarantee its quality. Alcohol is easy to counterfeit, just get similar labels and containers, and “elite” sawdust booze (at best) is ready. Stores also do not hesitate to buy cheaper goods, so the risk of poisoning is not excluded, even if we buy alcohol in beautiful “rich” packaging.

Our readers recommend! To quickly and reliably get rid of alcoholism, our readers advise. This is a natural remedy that blocks cravings for alcohol, causing a persistent aversion to alcohol. In addition, Alcobarrier triggers restoration processes in organs that alcohol has begun to destroy. The product has no contraindications, the effectiveness and safety of the drug has been proven by clinical studies at the Research Institute of Narcology.

To reduce this risk, it is better to make such purchases in hypermarkets, chain stores or specialized stores. In a word, this should be a point of sale that values its reputation, and to which, if anything happens, you can make a claim (most importantly, keep your receipts). You should avoid stalls, market tents, and dubious private outlets. Such sales points like to disguise themselves as “confiscated goods,” thus explaining the low price of such a “good product.”

The purchased alcoholic drink should be set on fire before drinking. Just pour a little product into a tablespoon and light it. If it burns with a translucent blue flame, we have ethanol (although what it is made of remains unknown). If the flame gives off a greenish tint, it is poisonous industrial alcohol.

If you want to check the quality of your favorite brand of vodka or the one you just bought, a potato wedge will help. Place a piece of peeled potato into a glass of alcohol and leave it for a couple of hours. If the root vegetable has not changed its color, the drink is based on good food grade ethanol. The pink tint of potatoes indicates a high methanol content.

You can also check alcohol for foreign impurities using copper wire. It must be heated over a fire and lowered into a container with the product being tested, but no unpleasant odor or vapors should be released. If the liquid gives off a strong odor, you should not drink it.

The best prevention against industrial alcohol poisoning is to avoid heavy alcohol altogether. It is quite difficult to talk about the quality of ethanol, even drinking ethanol, since it is also poisonous to the body. GOST of 1972 defined ethanol as “a potent drug that first causes excitement and then paralysis of the nervous system.” Today, Russian GOST defines it as “a colorless liquid with a characteristic odor.” Despite the fact that the standards for its production have not changed. We should not forget that the alcohol industry has brought and continues to generate income for the state treasury. And the treasury is interested in the sale of alcohol, and not in the health of the nation. Ethyl alcohol was poison in 1972 and is poison today.

Sedimentation of diluted alcohol

First, try to fill the container in which the alcohol will be stored to the very neck. If alcohol interacts with oxygen, it will oxidize and form acetic acid. Dilute alcohol can be used after a couple of days, or better yet, after a week - during this time all chemical reactions should stop. The optimal settling temperature is +40 C and above; the container should be stored in a dark place.

After settling the alcohol, you can safely pour the ingredients of the tinctures with it, and then, if strong raw materials were used, dilute it to the required degrees, guided by the table above.

Now you know how to dilute alcohol with water at home, which means it has become even easier to prepare tinctures and other homemade alcohol. Subscribe to the Rum Diary - this is just a fraction of the useful information that we want to convey to you. Good luck!

- https://therumdiary.ru/napitki/samogon/kak-pravilno-razvesti-spirt-vodoj-pryamo-u-sebya-na-kuxne.html

- https://drinkinhome.ru/raznye/kak-sdelat-spirt-v-domashnih-usloviyah/

- https://sunhi.ru/domashnee-proizvodstvo-spirta-prigotovlenie-spirta-v-domashnih-usloviyah/

- https://catarank.ru/v-domashnih-usloviyah/kak-sdelat-spirt-v-domashnih-usloviyah/

- https://catarank.ru/v-domashnih-usloviyah/kak-sdelat-spirt-v-domashnih-usloviyah/

Types of drinking alcohols

To understand what drinking alcohols are made from, it is advisable to consider the types of alcoholic products that exist today. All of them differ in strength, taste, and price. According to the current classification, drinking alcohols are divided into grain and grape alcohols, made from berries and fruits, sugar cane, agave, and also flavored.

Grain products include whiskey and vodka. Such drinks are considered the highest quality and natural. This is due to the presence of grain raw materials taken as a basis. Products manufactured under the luxury, alpha and super brands are made exclusively from grain. Highly purified alcohols are made from black molasses.

Grape varieties are used for the production of Armagnac, cognac, and French brandy. If the bottle says that it contains “Extra” alcohol, then the drink is not real.

Fruit varieties are made from berries and fruits. Their production technology is specific. For example, pears and apples are not pressed. They contain hydrocyanic acid. It should not get into alcoholic drinks. Berries such as raspberries and strawberries are pre-soaked in alcohol, after which the finished product is obtained. Brandy is obtained from fruit alcohols. As a rule, this drink is produced in Italy, France, and Spain.

In the process of processing sugar cane, sugar is obtained, from the waste of which black molasses is made. It is further processed to produce cachaça and rum.

To obtain the required product directly from black molasses, special yeast is added to it. Rum is different from cachaça because it infuses longer. Cachaça does not require aging. It goes on sale almost immediately.

Flavored types are used to make absinthe and similar drinks. For this, ethyl must undergo special processing. Natural raw materials such as wormwood are added to it. Then re-distillation is carried out, and absinthe is obtained from the finished product.

The last type is alcohol made from agave. Tequila is made from it. Such a drink should always contain a natural product. The manufacturer indicates all the details directly on the product label.

It should be understood that mixing alcoholic beverages made from different raw materials is unacceptable. After all, according to experts, it will be difficult for the body to process various alcohols. This can lead to a severe hangover. However, some alcohols harmonize perfectly with each other. When mixing them, a person does not expect a morning hangover.

Alcoholic drinks contain ethyl. Therefore, the effect on the body is always the same. This does not depend on how strong the alcohol is. To avoid hangover syndrome and various complications, it is advisable to consume alcoholic products made from high-quality ingredients that have been fully certified in accordance with state standards. A good strong drink cannot be cheap, and technical and medical alcohol must be used exclusively for their intended purpose.

Alcohol alpha and luxury which is better

The main factor that determines the merits of vodka is the alcohol used. Its quality depends on several components:

- Raw materials.

- Degree of purification.

- Processing technique.

GOST sets production standards, compliance parameters, and groups into which alcohol is divided. According to quality, the following varieties are distinguished:

- First grade.

- Highly purified alcohol.

- "Basis".

- "Extra".

- "Lux".

- "Alpha".

Alpha alcohol is produced from wheat and rye.

Mixing them is allowed. In any case, this is exclusively grain raw material, without any other additives. This is the highest quality alcohol. The content of methyl alcohol in it is allowed in a minimum amount, only 0.003%. Lux alcohol is made from a mixture of grain and potatoes. The potato starch content does not exceed 35%. The amount of methyl alcohol should not be more than 0.02%. This does not mean that vodka made from Lux alcohol is worse. Experts recommend choosing this particular vodka if you can’t buy Alpha.

The percentage of raw materials is established by the terms of the contract, especially for vodka going for export. The purer the alcohol, the better, both for the quality of the vodka and for the health of the consumer. Alcohol of the highest degree of purification, that is, Alpha and Lux, contain the least fusel oils and harmful impurities.

This vodka has a clean, pleasant taste, without any foreign odors. High-quality vodka has no sediment. If you shake vodka in a bottle, it will flow down the walls quickly and evenly. A certain degree of viscosity indicates that a large amount of glycerin is present.

In Russia, according to GOST, vodka may have the following alcohol content:

- 40,0-45,0%.

- 50,0%.

- 56,0% .

If you shake the vodka sharply, the foam bubbles in a high-quality product will disappear within a second. Alcohol is a good defoamer. Therefore, there cannot be any foam in real vodka.

Lux alcohol, based on grain, is almost always used for the preparation of modern balms and various tinctures. It is used by all distilleries.

Vodka made from Lux or Alpha alcohol belongs to the Premium and Super-premium classes. This is a class of elite drinks. This also includes whiskey, gin, and aged cognac. Such alcohol will not be cheap, as it is of the best quality and has a special mild taste.

Moreover, “premium” vodka has a greater degree of protection against counterfeiting. A special bottle shape, often with a characteristic relief pattern, a special cap, a hologram on the label.

Super-premium vodka differs from “premium” vodka in its higher price and certain production features. For example, rare ingredients, a unique manufacturing process, or more intricate and complex packaging.

Luxury products can be used:

- For fuel.

- For various coolants.

- For solvents.

- In the chemical industry (for the production of ethyl citate, triethyl ether, acetic acid, etc.)

- For the production of antiseptics, etc.

When choosing vodka based on Lux or Alpha alcohol, you are unlikely to risk getting a fake. This vodka is perfect for both a home feast and as a substantial gift. And naturally, the pricing policy will be slightly higher than that of cheap crafts.

There is an opinion that Alpha-based vodka is much more difficult to find. Actually this is not true. There are a number of organizations that take Alpha as a basis.

If you make a rating based on the quality of alcohol, “Alpha” can be put in first place, “Lux” in honorable second place. “Super” alcohol can compete with alpha alcohol; their quality is considered the highest.

The article described in detail the differences between alpha and luxury alcohol. What features do they have and where are they used? Now I would like to say a few words about harmfulness.

Drinking alcohol, almost all of it contains alcohol, is very harmful to human health. It has a detrimental effect on internal organs, the liver, heart, and gastrointestinal tract suffer.

If abused, various diseases are possible, the result of which can be fatal.

It also adversely affects the nervous system. It can lead not only to prolonged depression, but also to serious mental disorders.

Therefore, no matter how high-quality and wonderful alcohol and drinks based on it are, they should never be abused. The consequences will be very difficult to correct. Think about this, because nowadays alcoholism is increasingly gaining momentum.

No matter how good and pure the alcohol, or rather the alcoholic drink made from it, is, think three times before drinking it. This has a very detrimental effect on health. Even a seemingly high-quality balm can bring irreparable disaster.

Whoever likes it, we cook it ourselves

If we talk about the taste of different types of alcohol, then you need to understand that the cheaper the alcohol, the less natural substances it contains.

“Alpha” and “Lux” have an ethyl composition, which is produced on the basis of malt, fermented under natural conditions. If you add purified water or spring water and a couple of secret ingredients, the result will be a great taste. And what is also important, no hangover, but only pleasant impressions.

Alcoholic drinks based on Alpha and Lux alcohol will have different pricing policies than, for example, drinks with Extra alcohol.

They are many times more expensive.

They also have much better and higher quality packaging, original containers. Therefore, if you decide to have a good rest, relax and not have a headache in the morning, then it is better to choose an Alpha or Lux drink. If the goal is simply to forget, then you can save money.

You can prepare an elite alcoholic drink at home. We will give examples of several recipes using Lux alcohol.

Pepper. To prepare you will need:

Capsicum red pepper – 1 piece. Cloves – 2 pieces. Allspice - 6 peas is enough. Alcohol-based vodka "Alpha" - half a liter. If you put all the ingredients at the bottom of the container, the cloves and peppercorns will float. To avoid this, they can be placed in a pepper pod. It is first cut and the seeds are removed. After 5 days you can conduct a tasting.

Kedrovka. To prepare you will need:

- Pine nuts (unshelled) – 0.5 kilograms.

- Water (needed for nuts) – 2 liters.

- Vodka based on Alpha alcohol – 3 liters.

Cooking method:

- Place the nuts in a saucepan and add water, let them boil for 5 minutes, then change the water completely and boil for another 5 minutes.

- Place the nuts in a colander and wait until the water drains.

- I pour vodka over the nuts.

- The container with the future tincture is placed in a warm and dark room. Let it brew for 14 days. As a result, you will receive a high-quality and aromatic tincture that cannot be found on store shelves.

Vodka + cognac. For such an interesting recipe you will need:

- Soda - half a teaspoon.

- Cloves – 2 pieces.

- Sugar - a teaspoon.

- Bay leaf – 2 pieces.

- Vodka based on Alpha alcohol – 3 liters.

- Vanillin - on the tip of the knife.

- Oak bark powder - teaspoon.

- Black pepper – 3 peas.

- Coffee (necessarily instant) - a teaspoon.

- High quality tea infuser – teaspoon.

All ingredients are placed in one vessel and placed on the stove, simmering over low heat.

It is desirable that the lid be glass, but the hole must be sealed, for example, with bread pulp. Just before boiling, remove the container from the heat and place it in a cool place. When the drink has cooled, strain it well through a gauze cloth, bottle it and put it in the refrigerator. Lemon vodka. To prepare you will need:

- Vodka based on Alpha alcohol - 400 milliliters.

- Water – 60 milliliters.

- Lemon is a thing.

Cooking technology:

- Pour boiling water over the lemon and carefully cut off the peel.

- The zest is cut into thin slices and placed in a bottle.

- Water is mixed with vodka and allowed to steep in the refrigerator for several hours.

- Squeeze lemon juice into a separate jar.

- The water-vodka infusion is divided into 2 parts. Lemon juice is poured into one, the zest is poured into the second.

- Both containers are tightly screwed and allowed to brew for 14 days in a dry and dark place.

- Before serving, drinks should be strained.

https://o-polze.com

Determining the quality of a drink

The color level of the alcohol is determined using a regular glass: the presence of a whitish tint indicates poor purification and the presence of fusel oils. If the mash boiled too actively, the drink will have a cloudy color. Fusel oils can be removed by additional purification and distillation. To check the smell and taste, a little alcohol is poured into a bottle and diluted with cold water (1 to 3). Stir and taste.

Strong alcohol at home is stored in a closed bottle in the refrigerator. The shelf life of alcohol is no more than 5 years. Based on it, various tinctures of berries, roots, herbs, fruits and flowers, jams, fruits and root vegetables are made. It is also used to prepare such noble drinks as cognac, whiskey, absinthe, liqueurs, and gin. Many medical tinctures for hypertension, colds, indigestion and other diseases are also made based on it.

https://youtube.com/watch?v=-fi7qxeG8KY%3Ffeature%3Doembed

Purification of drinking alcohol

Rectification allows you to obtain high-quality alcohol that does not contain harmful impurities and oils. The process consists of chemical purification with substances that neutralize impurities, separating them through repeated evaporation and condensation of vapors. The drink is divided into several fractions, and the alcohol concentration increases. The process is carried out in a distillation apparatus.

They begin with the first purification - saponification of fusel oils. If there is a lot of acid in alcohol, it must be neutralized with baking soda or alkali. Then prepare a solution of potassium permanganate: per liter of alcohol, 2 g of manganese dissolved in 50 ml of distilled water. Mix everything and leave for 20 minutes. After the allotted time, add a soda solution prepared at the same percentages and clarify for 10-12 hours.

https://youtube.com/watch?v=0-Ck8l_FmwM%3Ffeature%3Doembed

As a result, the level of contamination of fusel oils is reduced by 95-97%.

The purified alcohol is filtered through a thick cloth. Start fractional distillation. It is carried out in a distillation cube with a drop catcher. Crude alcohol is diluted with soft water to a maximum strength of 51° and poured into a moonshine still. The temperature is quickly brought to 60°C, then the heating intensity is gradually reduced and brought to a boil (82-84°C). The resulting alcohol is purified with charcoal. Pour crushed linden or birch charcoal into a glass or ceramic container at the rate of 50 g per liter of drink. Alcohol is poured. Mix everything thoroughly and leave for 20-22 days. After the allotted time, the alcohol is filtered daily through cheesecloth for another 14 days.

Distillation of mash

To distill alcohol, homemade or purchased distillation apparatuses are used. Regardless of the model or manufacturer, their operating principle is the same. When heated, the alcohol from the mash transforms into a gaseous state. The alcohol moves through the pipes and enters the cooling chamber, where it condenses on the walls and flows into the receiver.

In the moonshine still, the mash is heated to a temperature of 82-93°C. To obtain raw material with a strength of 80 degrees, the distillation process is repeated several times. If only one distillation of moonshine has been carried out, then it is not necessary to neutralize the alcoholic undertone. To do this, use soda at the rate of 10 g per liter.

Repeated distillation is carried out under constant monitoring of the amount of alcohol in the receipt using an alcohol meter. When the concentration of secondary alcohol reaches 55-61°, it is poured out. The next fraction is drinking alcohol. It is distilled to a temperature of 98.4 °C. Repeat the distillation if the alcohol concentration in it is less than 30°.

Ethyl alcohol and its use in medicine

The described drug has antiseptic, disinfectant and tanning properties (depending on the concentration). Alcohol 95% is used when treating the hands of surgical personnel as a tanning agent. Closes skin pores. Alcohol 70% has excellent antiseptic properties. It is used, for example, to treat injection sites.

Alcohol 40% can serve as a warming agent for inflammatory diseases. For example, for applying a compress for otitis media, tonsillitis, arthritis, etc. Alcohol 35% cools the skin, expanding pores and helping to increase heat transfer, so it is excellent as a rubbing agent for fever.

Pure alcohol is added to the Bobrov apparatus for pulmonary edema and serves as an antifoam in the event of this emergency.

Ethyl alcohol is a volatile, flammable and transparent liquid with a characteristic odor and scalding taste. It is a representative of monohydric alcohols. Produced by fermentation or hydration of ethylene.

Calculated route Garden-dacha Alcohol Plant by car

| Tomylovo | ||

| Tomylovo - Chapaevsk (0 km; 0:00) | ||

| Chapaevsk | 1 km | 0:00 |

| Chapaevsk - Tomylovo (0 km; 0:00) | ||

| Tomylovo | 1 km | 0:00 |

| Tomylovo - Voskresenka (22 km; 0:16) | ||

| Voskresenka | 23 km | 0:17 |

| Voskresenka - Podstepnovka (6 km; 0:03) | ||

| Podstepnovka | 29 km | 0:21 |

| Podstepnovka - Verkhnyaya Podstepnovka (0 km; 0:00) | ||

| Verkhnyaya Podstepnovka | 29 km | 0:21 |

| Verkhnyaya Podstepnovka - Preobrazhenka (2 km; 0:01) | ||

| Preobrazhenka | 32 km | 0:23 |

| Preobrazhenka - Southern City (8 km; 0:06) | ||

| Southern City | 39 km | 0:29 |

| Southern City - Samara (1 km; 0:00) | ||

| Samara | 40 km | 0:30 |

| Samara - Novosemeykino (30 km; 0:30) | ||

| Novosemeykino | 70 km | 1:00 |

| Novosemeykino - Radio Center (0 km; 0:00) | ||

| Radio center | 71 km | 1:01 |

| Radio Center - Zvezdny (4 km; 0:03) | ||

| Star | 75 km | 1:04 |

| Zvezdny - Krasny Yar (10 km; 0:06) | ||

| Krasny Yar | 84 km | 1:10 |

| Krasny Yar - Izluchina (7 km; 0:07) | ||

| Bend | 92 km | 1:18 |

| Bend – Fried Bugor (2 km; 0:01) | ||

| Fried Hillock | 94 km | 1:20 |

| Fried Bugor - Ekaterinivka (4 km; 0:03) | ||

| Ekaterinivka | 99 km | 1:23 |

| Ekaterinivka - Zaglyadovka (2 km; 0:01) | ||

| Peek | 102 km | 1:24 |

| Zagladovka - Old Buyan (4 km; 0:02) | ||

| Old Buyan | 106 km | 1:27 |

| Old Buyan - Elkhovka (30 km; 0:20) | ||

| Elkhovka | 136 km | 1:47 |

| Elkhovka – Proleyka (4 km; 0:02) | ||

| Spilling water | 140 km | 1:50 |

| Proleika – Borma (10 km; 0:07) | ||

| Borma | 150 km | 1:58 |

| Borma - Vysokyi Kolok (13 km; 0:08) | Samara region - Ulyanovsk region | |

| High Kolok | 163 km | 2:06 |

| Vysoky Kolok – Srednyaya Yakushka (20 km; 0:12) | ||

| Middle Yakushka | 182 km | 2:18 |

| Srednyaya Yakushka - Chernaya Rechka (5 km; 0:02) | ||

| Black River | 186 km | 2:21 |

| Chernaya Rechka - Worker (5 km; 0:02) | ||

| hard worker | 191 km | 2:23 |

| Truzhenik - Dimitrovgrad (5 km; 0:02) | ||

| Dimitrovgrad | 195 km | 2:25 |

| Dimitrovgrad - Mullovka (20 km; 0:13) | ||

| Mullovka | 215 km | 2:39 |

| Mullovka - Lesnoy (17 km; 0:11) | ||

| Forest | 231 km | 2:50 |

| Lesnoy - Ozerki (7 km; 0:03) | ||

| Ozerki | 238 km | 2:54 |

| Ozerki - Malaevka (6 km; 0:03) | ||

| Malaevka | 245 km | 2:57 |

| Malaevka - Old Urenbash (5 km; 0:02) | ||

| Old Urenbash | 249 km | 3:00 |

| Old Urenbash - Cherdakly (6 km; 0:03) | ||

| Attics | 255 km | 3:03 |

| Cherdakly - Mirny (9 km; 0:06) | ||

| Peaceful | 265 km | 3:09 |

| Mirny - Ulyanovsk (2 km; 0:02) | ||

| Ulyanovsk | 267 km | 3:12 |

| Ulyanovsk - Laishevka (31 km; 0:22) | ||

| Laishevka | 298 km | 3:35 |

| Laishevka - Laishevka (5 km; 0:02) | ||

| Laishevka | 303 km | 3:37 |

| Laishevka - Peat bog (1 km; 0:01) | ||

| Peat bog | 304 km | 3:39 |

| Peat bog – Timiryazevsky (1 km; 0:00) | ||

| Timiryazevsky | 306 km | 3:40 |

| Timiryazevsky - Bolshoye Nagatkino (17 km; 0:09) | ||

| Bolshoye Nagatkino | 323 km | 3:49 |

| Bolshoye Nagatkino - Middle Algashi (25 km; 0:13) | ||

| Middle Algashi | 348 km | 4:03 |

| Middle Algashi - New Algashi (5 km; 0:02) | ||

| New Algashi | 352 km | 4:05 |

| New Algashi - Aleshkin-Saplyk (6 km; 0:03) | Ulyanovsk region - Tatarstan | |

| Aleshkin-Saplyk | 358 km | 4:08 |

| Aleshkin-Saplyk - Trekhizb-Shemursha (10 km; 0:05) | Tatarstan - Chuvashia | |

| Trekhizb-Shemursha | 369 km | 4:14 |

| Trekhizb-Shemursha - Old Shemursha (4 km; 0:02) | ||

| Old Shemursha | 373 km | 4:16 |

| Old Shemursha - New Shemursha (1 km; 0:00) | ||

| New Shemursha | 374 km | 4:17 |

| New Shemursha - Shemursha (1 km; 0:00) | ||

| Shemursha | 375 km | 4:18 |

| Shemursha - Karabay-Shemursha (8 km; 0:04) | ||

| Karabay-Shemursha | 383 km | 4:22 |

| Karabay-Shemursha - Shygyrdan (8 km; 0:06) | ||

| Shygyrdan | 391 km | 4:28 |

| Shygyrdan - Turunovo (4 km; 0:02) | ||

| Turunovo | 395 km | 4:30 |

| Turunovo - Batyrevo (0 km; 0:00) | ||

| Batyrevo | 396 km | 4:31 |

| Batyrevo - Maloye Batyrevo (0 km; 0:00) | ||

| Maloe Batyrevo | 396 km | 4:31 |

| Maloe Batyrevo - Turunovo (0 km; 0:00) | ||

| Turunovo | 397 km | 4:31 |

| Turunovo - New Kotyakovo (2 km; 0:01) | ||

| New Kotyakovo | 398 km | 4:32 |

| New Kotyakovo - Dolgiy Island (1 km; 0:01) | ||

| Long Island | 400 km | 4:33 |

| Dolgiy Ostrov - Komsomolskoye (17 km; 0:11) | ||

| Komsomolskoe | 417 km | 4:45 |

| Komsomolskoe - Mayak (12 km; 0:10) | ||

| Lighthouse | 429 km | 4:55 |

| Lighthouse - Askhva (19 km; 0:11) | ||

| Askhva | 448 km | 5:06 |

| Askhva – Bolshie Bikshikhi (2 km; 0:01) | ||

| Big Bikshikha | 450 km | 5:07 |

| Bolshie Bikshikhi - Shikhazany (3 km; 0:02) | ||

| Shihazan | 454 km | 5:10 |

| Shikhazany - Shibylgi (6 km; 0:03) | ||

| Shibylgi | 460 km | 5:13 |

| Shibylgi - Dalnie Sormy (4 km; 0:02) | ||

| Dalnie Sorma | 464 km | 5:16 |

| Far Sormy - Koshnoruy (4 km; 0:02) | ||

| Koshnorui | 468 km | 5:18 |

| Koshnorui - Churaciki (5 km; 0:05) | ||

| Churaciki | 473 km | 5:23 |

| Churaciki - Ryndino (15 km; 0:08) | ||

| Ryndino | 489 km | 5:31 |

| Ryndino - Tsivilsk (0 km; 0:00) | ||

| Tsivilsk | 489 km | 5:32 |

| Tsivilsk - Opytny (2 km; 0:01) | ||

| Experienced | 491 km | 5:33 |

| Experienced – Tauskasy (6 km; 0:03) | ||

| Tauskasy | 497 km | 5:37 |

| Tauskasy – Tingovatovo (6 km; 0:04) | ||

| Tingovatovo | 503 km | 5:41 |

| Tingovatovo - Buldeevo (1 km; 0:00) | ||

| Buldeevo | 504 km | 5:42 |

| Buldeevo - Sutchevo (20 km; 0:16) | ||

| Sutčevo | 524 km | 5:58 |

| Sutchevo - Mariinsky Posad (3 km; 0:03) | ||

| Mariinsky Posad | 528 km | 6:01 |

| Mariinsky Posad - Spirit Factory (6 km; 0:06) | ||

| AlcoholPlant | 535 km | 6:08 |

Popular articles Guilloche

Choosing a room

As for the premises, its choice must be approached with all responsibility. Let's look at the main parameters that it must meet. We hope you are not planning to produce alcohol at home? This option is quite acceptable if you make it for personal needs, but we are going to do business. But here everything is already serious, and the appropriate premises are required to organize a fully functioning workshop in it.

Criteria for choosing production areas:

- Dimensions - your workshop should be two or even three times larger than the area occupied by all the equipment for the production of alcohol (in particular, fermentation tanks). The same applies to ceiling heights.

- Temperature - the room where production is planned should be warm enough. That is, there are two options - a well-organized heating system or good thermal insulation. This is essential to maintain fermentation processes on a continuous basis.

- Ventilation is also a very important point. It can be either forced or natural (only if a water seal is used).

- A separate room must be intended for the installation of distillation equipment (distillation part).

- Other important parameters. The workshop itself must have a sewerage system, floors with equipped drains, and also running water.

As you can see, it is important to take into account various nuances before deciding whether the premises are suitable for organizing a distillery in it. Keep in mind that the larger production volumes you plan, the larger the dimensions of the equipment (as well as its quantity), and the larger the area required for the workshop or plant

Application of biofuel

Compared to gasoline, biofuels (alcohol made from recycled waste) have both advantages and disadvantages.

Here are the main advantages:

- high (105–113) octane number;

- lower combustion temperature;

- lack of sulfur;

- lower price.

Thanks to the high octane number, you can increase the compression ratio , increasing the power and efficiency of the engine.

Lower combustion temperature:

- increases the service life of valves and pistons;

- reduces engine heating in maximum power mode.

Due to the absence of sulfur, biofuel does not pollute the air and does not shorten the service life of motor oil , because sulfur oxide oxidizes the oil, worsening its characteristics and reducing its resource.

Due to its significantly lower price (not counting excise taxes), biofuel seriously saves the family budget.

Biofuel also has disadvantages:

- aggressiveness towards rubber parts;

- low fuel/air mass ratio (1:9);

- low volatility.

Biofuel damages rubber seals , so when converting an engine to run on alcohol, all rubber seals are replaced with polyurethane parts.

Due to the lower fuel-to-air ratio, normal operation on biofuel requires reconfiguring the fuel system, that is, installing larger cross-section jets in the carburetor or reflashing the injector controller.

Due to poor evaporation, it is difficult to start a cold engine at temperatures below plus 10 degrees.

To solve this problem, biofuel is diluted with gasoline in a ratio of 7:1 or 8:1.

To operate on a mixture of gasoline and biofuel in a 1:1 ratio, no modifications to the engine are required.

If there is more alcohol, then it is advisable:

- replace all rubber seals with polyurethane ones;

- grind the cylinder head.

Grinding is necessary to increase the compression ratio, which will allow higher octane rating to be realized . Without such modifications, the engine will lose power when alcohol is added to gasoline.

If biofuel is used for electric generators or household gasoline appliances, then it is desirable to replace rubber parts with polyurethane ones.

In such devices, you can do without grinding the head, because the slight loss of power is compensated by an increase in fuel supply. In addition, you will need to reconfigure the carburetor or injector ; this can be done by any fuel systems specialist.

For more information about the use of biofuel and converting engines to run on it, read this article (Use of biofuel).

How to make malt and malted milk

Begin preparation by sifting and washing the raw materials. This is needed to remove debris, empty and chipped grains, and dust. After cleaning and sorting the grain, the wheat is soaked in a wooden or ceramic container for 6-8 hours. When the first sprouts hatch, the grains are washed in running water and transferred to a flat surface (this can be a bowl with low sides, a baking sheet, or a baking board). After soaking, the seeds are germinated in a well-ventilated area at a temperature not exceeding +20°C. To prevent drying out, the raw materials are covered with a damp cloth or gauze. Stir every 4-6 hours.

When the first roots appear, the seeds are placed in a glass bottle. The layer of grains should be from 15 to 25 cm.

The room temperature is increased by 2-4°. This is necessary for the activation of grain and the active accumulation of malt enzymes. Malt is ready for use when the length of the sprouts has reached 13-15 mm.

Green malt is used to make milk: for pure wheat malted milk, only wheat is used. But many winemakers recommend a mixture of 2 parts of sprouted wheat and 1 part of sprouted barley and oats (grain is sprouted in the same way). The mixture is washed three times, then poured into a bottle, filled with hot water and left for 8-10 hours.

From wheat you need to grind 2 kg of flour, add about 200 grams of malt mixture and add a liter of water. Mix well. The resulting malted milk is necessary for saccharification of starch raw materials in the main mash during the preparation of alcohol.

How to dilute ethyl alcohol with juice: proportions

When preparing vodka using this “cold” method, the alcohol can be diluted not only with water, but also with juice. This results in exquisite cocktails.

- “Screwdriver” cocktail is a mixture of orange juice (2.5 parts) and alcohol (1 part). Add a slice of lemon and ice cubes and the drink is ready.

- “Bloody Mary” is a combination of tomato juice (2 parts) and alcohol (1 part) with the addition of salt, pepper, and lemon juice. Although you can limit it exclusively to juice and alcohol.

- Cranberry cocktail is a 2:1 combination of juice and alcohol. The drink has some astringency.

- Apple cocktail - juice and alcohol are mixed in a 3:1 ratio. Juice from green apples is best suited.

- When making a cherry cocktail, you can use 2 or 3 parts of vodka for 1 part vodka. The sweetness of the drink depends on the type of cherries.

- For a pomegranate alcoholic drink, a ratio of 3:1 is suitable, where 1 part of alcohol is added to 3 parts of juice.

- Grapefruit cocktail has a sweetish taste. Its proportion is the same as that of pomegranate: 3:1.

Based on these proportions, you can combine alcohol with any other juice.

Lemon vodka