Principle of operation

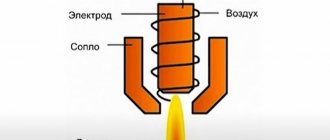

Tap water is purified from impurities. The water is then fed into a pump where it is compressed under a pressure of 4,000 bar and fed into the nozzle of the cutting head. The cutting head is mounted on a support that moves back and forth across the workbench. When the valve is open, a stream of water is drawn out of the nozzle, the diameter of which is Ø 0.10-0.5 mm. In this case, its speed reaches 900 m/s. The abrasive mixer, where the abrasive cloth is supplied, is located slightly below the nozzle. Water mixes with the abrasive and accelerates its particles up to 250 m/s over a length of 7-10 cm. The mixture at a very high speed comes into contact with the material being processed, fixed on the working plane, and cuts it. A mixture of water, abrasive and small particles of the material being cut settles under the work table at the bottom of the bath.

The bath must be filled with water before starting work to effectively dampen the flow. If a sediment removal system is used, the bath is mechanically cleaned and the equipment can therefore operate continuously. When cleaning manually, the machine must be turned off for 1-2 days. All installation mechanisms are controlled by a CNC unit, which controls the pump, opens and closes the water and abrasive valves, and is also responsible for moving the support and cutting heads. The jet cutting process is absolutely fire - and explosion-proof.

Areas of use

Rocketry and aircraft manufacturing - where carbon fiber processing of titanium alloys and high-temperature alloys is required. All areas of construction. Waterjet machines are used to cut reinforced concrete slabs, stones, hard floor clay and porcelain tiles; for creating mosaics, unique panels, inlays from natural granite and marble. Regular and figured cutting of stones of natural and artificial origin.

Cutting glass - reinforced, composite and plexiglass. Woodworking - structural or artistic cutting of hard wood (for example, oak), chipboard panels or laminite. Cutting various plastics - creating complex shapes and components. Tool production – production of parts requiring high precision for machine tools and production equipment. Food and light industry - cutting frozen briquettes and elastic materials can be done only with water and without abrasive materials.

Machine bath

The load-bearing parts of the machine are made of non-corrosion steel and can be easily replaced in case of their breakdown or failure. To base the material being processed, quick-release ribs are attached to the load-bearing supports, this makes it possible to maximally protect machine parts from the effects of waterjet.

To protect against dust and noise in the working area, the machine bath is equipped with a system for quickly filling and removing water, which allows cutting material completely immersed in water. The dust that is formed as a result of the operation of the machine settles in the liquid, while the noise level during cutting is no more than 70 dB.

Terms of supply of equipment from an official dealer

offers affordable prices for waterjet cutting installations: from the catalog you can select a complete set of equipment to equip the production complex. Take advantage of several benefits of cooperation:

- Professional advice when selecting the necessary equipment. Our specialists will help you choose everything to equip the production workshop, taking into account the planned operations.

- Supply of equipment without intermediaries and extra charges. Ordering directly from the manufacturer's official dealer will avoid overpayment.

- High quality equipment. CNC waterjet cutting equipment is designed for long-term operation without breakdowns or failures.

Order machines and auxiliary equipment with delivery in Yekaterinburg, delivery to other cities of Russia is also possible. Consult with specialists to select a complete set of equipment with the required parameters and get it at minimal cost.

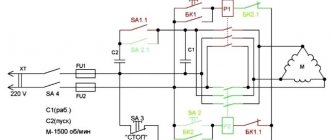

Machine drive system

The machine is equipped with a cantilever design with a belt-type drive for moving the axes. The belt drive is easy to operate, easily replaced if broken, and is ideally suited for processing on waterjet cutting machines, as it is resistant to the impact of abrasive material on the moving parts of the drive.

To increase the accuracy of movement of the cutting head, linear inductive sensors are installed on the machine, which will allow achieving positioning accuracy of ±0.001 mm. Movement occurs along linear guides, which ensures high positioning accuracy, smooth operation and reduced movement time.

High pressure pump

One of the main components of waterjet cutting is the high-pressure pump.

CNC system

The machine control is a numerical control system.

Remote control with handwheel

To operate the machine, it is convenient to use a flywheel and a remote control. This device allows you to perform corrections or adjustments as efficiently and quickly as possible.

Tank with abrasive

The design of the tank allows you to replenish the abrasive even while the waterjet equipment is operating, which can significantly save time.

The tank is equipped with sensors for the level of material used.

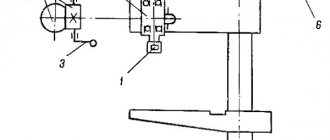

Device for controlling the constant gap of the cutting jet

This device, using a special sensor, controls the optimal distance between the material being processed and the nozzle, as a result of which the highest quality cut is obtained and does not allow the nozzle feeding the mixture to collide with the material that we are processing.

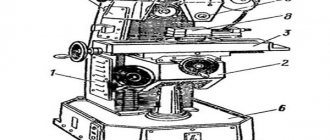

Swivel head

The head rotation angle allows rotation in 2 planes with a maximum tilt angle of up to 65 degrees, which practically allows for chamfering, curved plane, and for cone compensation during processing. When processing complex planes, the machine works with 5 coordinates.

Material scanning system

In the process of processing parts on waterjet cutting machines, a problem arises associated with the uneven surface of the material being processed.

To eliminate this problem, it is possible to install a laser or ultrasonic material scanning system on the equipment. This system scans the material before processing at a certain interval, which makes it possible to maintain a given gap during material processing and helps ensure high processing accuracy. When producing small parts, it is possible to scan only the cut-in points.

Abrasive amount control sensor

The abrasive supply control sensor allows you to check the supplied abrasive material and quantity during processing, which involves making a cut without the constant presence of a worker at the machine, and even stopping the processing process as a result of foreign objects or materials entering the cutting head, such as the remains of a bag or other material factions. The range of possible values is set by the operator from the CNC rack and can be changed during processing.

Abrasive removal device

At the GAO it is possible to install a system for removing waste material and abrasive particles, which consists of a pump and a settling tank. A characteristic feature of this system is the use of a diaphragm pump, which is extremely easy to maintain and is suitable for working in aggressive environments. For ease of operation, the container for used abrasive is equipped with quick-release connectors for connecting hoses and is adapted for movement by a crane, hoist or loader.

Material loading device

Waterjet equipment is equipped with various devices for loading the processed material. Most often, beam cranes are used with hoists, with mechanical or vacuum grips; hydraulic and pneumatic lifting mechanisms with adjustable arms that support material at critical points.

Models and specifications

WAZER

The WAZER Basic Machine is a benchtop CNC waterjet cutting machine that is compact, easy to use and versatile.

- Operating systems Windows, Mac Dimensions, mm Main module: 856 x 648 x 551; pump: 533 x 355 x 280

- Weight, kg Main module: 50; pump: 42

- Working field size 300 x 460 mm

Delivery conditions

- Price 1,438,457

Order Get a consultation

WAZER STANDUP

Wazer STANDUP is a floor-standing CNC waterjet cutting machine that does not require a workbench - it is equipped with a floor stand with a shelf, which immediately eliminates the issue of placing the machine itself, the pumping station, which can be placed down (as in the photo), and the material for cutting — the shelf has dividers for easy storage of sheet blanks.

- Power supply Machine: 100-240 V, 50/60 Hz, 2.5A; Pump: 220-240 V; 50 Hz; 10A; 2200 W Dimensions, mm Main module with rack: 856 x 648 x 1220; pump: 533 x 355 x 280

- Weight, kg Main module: 50; pump: 42 File formats DFX, SVG

- Working field size 300 x 460 mm

Delivery conditions

- Price 1,618,287

Order Get a consultation

Functions of waterjet machines

The main purpose of using the equipment is high-quality cutting of materials, drawing up complex contours or artistic patterns.

New generation waterjet machines can: cut at a speed of up to 15 m/min., rotate the cutting tool at an angle of up to 90 degrees, maintain the height of the cutting head, supply water and control the speed of its movement, work 4 times faster due to the simultaneous installation of four independent heads, compensate for lags in flow and cone when cutting, and obtain a high result, create a chamfer when processing material, distribute the abrasive absolutely accurately, perform work with a remote control, in case of an emergency power outage, finish the operation, execute a loaded program and quickly switch when changing modes, control the cutting price.

Advantages

"Weiser" is a relatively compact equipment capable of working with a huge amount of materials, while maintaining cleanliness in the room and operator safety.

Advantages of waterjet machines

Effective work with all materials: impermeable, brittle, viscous, composite, inaccessibility of high temperatures in the cutting zone (maximum - 90ºС), as a result, the design of the material is preserved, less production waste due to the cutting accuracy with a narrow part of the cut (only 1 mm), the edge of the finished product is smooth, does not require further processing, the thickness of the cut sheet reaches from 150 to 300 mm, dust and toxic compounds harmful to human well-being do not appear, to increase productivity, it is possible to cut several sheets at once in a stack, low cutting voltage allows do without clamping the sheet being processed, the highest cutting speed, quick reconfiguration of equipment for a new part.