Since I always deal with the arrangement of the local area on my own without the involvement of specialists and expensive materials, I decided to puzzle myself with the question of how to make crumb rubber at home. In the future I will need it for landscape design. I offer two options for manufacturing raw materials: simple and complex.

Source dorogaya-zemlya.ru

Making your own rubber coating

A troubling thought often haunts the heads of savvy craftsmen: “Is it possible to make a safety coating from crumb rubber yourself?” Yes, let's look at interesting Internet offers together. The first interesting question: “How to make crumb rubber at home?” Let's start with the fact that there are really original tips on the Internet for making crumb rubber:

“At the initial stage, it is necessary to prepare a sufficient amount of raw materials, i.e. old car inner tubes and corresponding cutting tools. To make a coating with an area of one square meter and a thickness of 10 mm, about 8 kg of crumb rubber is needed. When producing crumbs from old chambers, the loss of material by weight is minimal. Thus, it is necessary to prepare the starting material at the rate of 8 kg of old cameras per 1 square meter of coating. To grind rubber, you can use ordinary scissors or an ax. If desired, you can build special guillotine shears. As a last resort, you can organize cutting of the cameras with a fairly sharp knife. Making crumbs should be done according to the following algorithm:

According to its characteristics, rubber refers to materials that include all of the listed items and their processing is in demand:

- mass production and short service life determine a high degree of pollution;

- take a long time to decompose in the natural environment;

- limited natural rubber production;

- technologically simple and inexpensive to maintain processing;

- high demand for the material.

In this article we will tell you how to make crumb rubber with your own hands, where it is used and how rational it is.

Advantages

The advantages of rubber lie in its elastic deformation properties and chemical structure. Rubber is a polymer with the formula C5H8; synthetic reproduction of rubber is based on the use of the same polymer, but with a greater ability to obtain highly targeted characteristics. This is what determines such characteristics of the material as:

- elasticity;

- low thermal conductivity;

- low sound conductivity;

- dielectric properties;

- lack of hygroscopicity;

- lack of adhesion to gases and aggressive substances (with the exception of some acids);

- low density.

Another advantage of rubber is its ability to be recycled. Its complete restoration is possible only with a loss of strength, so it is subsequently used either for non-critical products or for secondary use.

What is crumb rubber made from?

Any rubber can be used as a raw material, previously cleared of foreign objects: reinforcing, glued, etc. But basically crumb rubber is made with your own hands from tires. The yield from this raw material is 60-70%. On an industrial scale, equipment using 3 technologies is used:

- Deep frozen with liquid nitrogen (-190 °C).

- Mechanical cord separation.

- Universal equipment using crushers.

Methods for making crumb rubber yourself

Most people who are interested in how to use crumb rubber with their own hands are not large entrepreneurs, but individuals or small companies/communities for which purchasing expensive equipment is unrealistic. Their main goal: a minimum of investments, up to self-manufacturing of the entire technical base, and making a quick profit. Even with this approach to marketing, processing can be organized by making the equipment yourself according to the drawings.

How to prepare crumb rubber at home

The business plan is drawn up in all details, taking into account the distance to the source of raw materials and the method of obtaining them (purchase, self-collection), the warehouse of raw materials and finished products, the location of the machine and the possibility of servicing it. For a small production, it is enough to use 3 workers.

Technology

Since the main raw materials for which it is designed are tires and tires, the process consists of several stages (the first and second depend on the selected production line):

- Cutting and simultaneous cleaning of mechanical impurities.

- Freezing to temperatures at which rubber loses its plasticity (-190 °C; used for industrial scale).

- Passing through a shredder.

- Calibration and screening of crumbs.

- Use of crumbs in the future.

Tool

A direct cutting machine consists of elements that you can either purchase or make yourself:

- 2 motors with a power of 5 kW;

- disc shafts in the housing;

- 2 worm gearboxes;

- shredder;

- automation (control).

- loading hopper;

- guide;

- mesh sieve;

- frame.

Material

The system for the mini-complex consists of a slicing device and a chopper. The final fraction consists of particles from 2 to 6 mm, the most popular being 2-4 mm. After screening to the desired size, the residue can be recycled.

Shredding tires will make it possible to quickly process rubber in a shredder, and will also prevent metal elements from getting into it. It represents:

- Stand on a supporting base and a rotating mechanism with a clamp.

- Knife located on the stand.

The basis of the unit is a box with knives - this is the place where crumb rubber is processed with your own hands at home. They are driven by 5 kW motors connected via a worm gear. This is the most expensive part of the project, which increases its cost and the use of knives according to all the rules of engineering design, i.e., made of W and Mo alloyed cutting steel.

The optimal gear ratio is selected in the range of 25-35. An increase in it will increase wear on the cutting edge, and a deficiency will increase the load on the engine and reduce product quality.

For the frame, profile pipes with a diameter of 50 x 70 or 70 x 80 mm are selected. They must ensure the load of equipment in motion and cargo for a long time.

The loading hopper is always wedge-shaped. It evenly distributes the workpiece and also directs movement towards the working body.

Application

This is a universal material that can be used to cover any type of surface. Knowing how to make crumb rubber yourself, you can use the products for:

- Own needs.

- Sales

- Organizations for the production of products based on crumbs: provision of services to the population (laying surfaces, manufacturing roofing, paths, etc. to order).

The most common uses of the products are below.

Sports and children

Athletic tracks in which the rubber surface increases traction when running and walking. Children's playgrounds are covered with crumbs to reduce the risk of injury: rubber not only does not slip, but also softens the impact of a fall.

Decor and practicality on the site

Garden paths are covered with crumbs not only because of their decorative appearance: they wash well, do not crack, and in winter they do not slip when there is ice and a small level of snow.

Reservoirs

The most practical use is to decorate surfaces near water sources: swimming pools, artificial lakes and decorative waterfalls.

Business idea

Do-it-yourself rubber crumbs, the production of which can be organized in a utility room (there are no strict requirements for temperature conditions and moisture resistance), can be an excellent basis for starting a business. Recycling waste brings good profits to enterprising owners, considering that the cost of the finished material is almost zero.

Video

How to shred tires?

The technological chain consists of several preparatory stages before the product of the required fraction is obtained.

This procedure includes:

- Inspection and removal of foreign objects from the tire cavity.

- Cord cutting.

- Cutting tires into strips measuring 50-80 mm.

- Grinding of raw materials using a shredder.

- Separation and separation of metal parts from textile parts.

- Calibration of crumbs into fractions using a vibrating sieve.

We make crumb rubber with our own hands using a homemade crusher

Every year, thousands of tires are lost in landfills and landfills, despite the fact that for an enterprising person they are a free resource from which crumb rubber can be produced.

If you need it only once, you can buy it in the required quantity from the manufacturers.

But where can you get crumb rubber if you need it on an ongoing basis and in large quantities?

It is worth considering purchasing your own tire recycling equipment.

However, not everyone can afford a full-fledged installation , and not everyone will find such an investment profitable. The solution is to create equipment with your own hands and use it to produce crumb rubber from tires at home.

Recycling small amounts of rubber at home

If you need very little raw material, you can do without equipment at all.

All you need to do this is scissors and a cutter .

The metal cord is first removed from the tire, then divided into strips and crushed into smaller fractions to the required size .

At this point the process is considered complete.

The material for decorating paths, flower beds or a separate playground is ready for use.

But in order to obtain a larger volume of raw materials or to have income from processing tires at home, you need the appropriate equipment.

Construction of a tire crusher

There are three main methods for producing crumbs:

- Crushing tires after cooling them with liquid nitrogen to –190 degrees.

- Production of crumbs using full-cycle industrial equipment with cord removal and subsequent rubber grinding.

- Processing using universal crushers, which can be done at home yourself.

The first two methods require large investments. The third option is available to everyone

who has the opportunity and desire to make a crusher at home.

The necessary units can be made independently in a workshop or at a production site - where there are metal-cutting machines (lathes, milling) and a welding machine for the manufacture of component parts.

If you cannot perform mechanical processing of the workpieces yourself and you have to order them according to your own drawings, the cost of tire processing machines will still be several times cheaper than similar purchased units.

The main component on the tire conversion line is a shredder (rubber shredder). Let us consider in more detail the purpose of the components of this machine.

Unit design

The machine consists of the following main components:

- electric motor 5 kW – 2 pcs;

- housing with disk shafts;

- lattice;

- worm gearbox – 2 pcs.;

- shredder frame;

- loading hopper;

- guide tray;

- control cabinet.

The installation parts are mounted on a powerful frame welded from channels.

Box with cutting discs

The main unit of a rubber crusher is a housing with milling rolls.

At the same time, the cutting knives are made of high-strength steel and heat-treated, which significantly reduces their wear. They practically do not require sharpening during operation .

The calculation of the box openings, shafts and cutting elements must be accurate, so it must be done by a specialist in this field (designer).

Grid for calibrating crumbs

In order to obtain a calibrated fraction of tire raw materials, shredders are equipped with a special grid, which is installed under the rolls.

Worm gearbox

The rotation of shafts with disk cutters is carried out separately, directly from worm gearboxes connected to electric motors through couplings.

The gear ratio is selected from 25 to 35 so that cutting occurs without jamming and at sufficient speed .

Unit frame

The frame is welded from profile elements, ensuring the reliability and stability of the unit during operation, as well as loading and unloading operations.

Loading hopper

The tire recycling plant is equipped with a tire loading hopper and a tray for removing finished crumb rubber.

Thanks to its design, the hopper eliminates the formation of jams from the raw material and guarantees directed movement of the mass towards the rotating rolls.

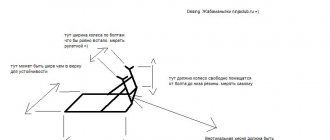

Tire cutting device

The tire cutting and cord removal installation consists of a supporting frame and a stand .

The frame contains a tire clamping mechanism that rotates with the tire during cutting. Engine speed is reduced due to different pulley diameters. The stand has a built-in wedge cutter, which is adjusted to a specific size by moving the quill.

How to shred tires?

The technological chain consists of several preparatory stages before the product of the required fraction is obtained.

This procedure includes:

- Inspection and removal of foreign objects from the tire cavity.

- Cord cutting.

- Cutting tires into strips measuring 50-80 mm.

- Grinding of raw materials using a shredder.

- Separation and separation of metal parts from textile parts.

- Calibration of crumbs into fractions using a vibrating sieve.

Equipment performance

The operation of these two main units when processing tires is done in a semi-automatic mode .

For normal operation of this line, a room of about 150-200 sq. m is required. meters. This is due to the fact that you need a place to locate not only equipment, but also to store used tires, finished tire products and metal waste.

The production of crumb rubber on this equipment per hour will be approximately 200-800 kg and up to 100 kg of metal scrap; 2-3 unqualified workers will be needed to service the machines.

In addition to tires, this equipment can process other rubber (conveyor belt, inner tubes, gas masks). The output is crumbs with dimensions from 0.7 to 4 mm, while it makes up 65-85% of the total mass of raw materials.

Where to use the resulting raw materials?

Rubber crumbs can be:

- apply for your own needs;

- sell wholesale and retail to the population and enterprises;

- use for the production of goods or open a custom rubber coating business.

The price of the crumbs will depend mainly on the quality of the raw materials, and secondarily on the fraction.

The most popular is crumb, the fraction of which is 2-4 mm .

It's great for creating:

The popularity of such crumbs is due to the fact that a minimal amount of glue is used to glue these granules together. And a polyurethane binder is sometimes 5-8 times more expensive than crumbs.

Video on the topic

In this video you can see how to grind rubber and make crumbs at home.

Conclusion

Making your own tire crusher is a good idea for those who want to make their own crumb rubber, but are not ready to spend tens of thousands of dollars on equipment.

You can create a chopper if you have a carpentry workshop, as well as certain skills and materials, or use the services of people who specialize in this.

The crumbs obtained at home can be used for your own needs or sold to businesses and the public .

Recycling small amounts of rubber at home

If you need very little raw material, you can do without equipment at all.

All you need to do this is scissors and a cutter .

The metal cord is first removed from the tire, then divided into strips and crushed into smaller fractions to the required size .

At this point the process is considered complete.

The material for decorating paths, flower beds or a separate playground is ready for use.

But in order to obtain a larger volume of raw materials or to have income from processing tires at home, you need the appropriate equipment.

Do-it-yourself rubber crumbs - manufacturing methods and methods

A fashionable trend has become the design of areas with crumb rubber and materials based on it. This is a reliable material for covering paths and roofs of houses. It is also used for waterproofing when laying foundations for building construction.

Construction companies offer professional services for decorating sites with this material. But crumb rubber does not require special knowledge and skills, and you can prepare it yourself. Therefore, you can work with this material yourself.

Methods for making crumb rubber yourself

There are two ways to prepare the material at home:

- The first way is difficult and it is not always possible to implement it at home. But it's cheaper than just buying crumb rubber. It consists of cooling the source material to -80 degrees Celsius. In this case, the rubber becomes brittle and crumbles easily. This method uses any material.

- The second method involves the initial selection of rubber. Since the method involves grinding with improvised tools. Here it is better to use old tires as the starting material. They are easy to cut, so getting crumbs out of them will not be difficult. But it’s better not to use car cameras. They are much tougher and more difficult to cut. In addition, after grinding, it is necessary to remove the metal cord from the chamber crumbs, which is difficult to do.

- metal elements are removed from the old material, tube or tire;

- rubber is cut into thin strips;

- then the strips are cut into small squares. The smaller the particles, the more aesthetically pleasing the coating looks.

Having decided on the method of making crumbs and the material, you can begin the actual preparation.

How to prepare crumb rubber at home

First of all, you should stock up on a sufficient amount of starting material. It is easy to calculate: for 1 square meter of covered area 10 cm thick you will need at least 8 kg of rubber. It is also worth choosing a convenient cutting tool. A sharp knife, ax or scissors is suitable for this.

After everything is ready, we begin to create the crumbs. Its production takes place in several steps:

That's all, the crumb rubber is ready

Now it is suitable for use for the necessary purposes: you can fill paths or the area around the playground, provide waterproofing. The material will last a long time, and it will be cheap.

Where to use the resulting raw materials?

Rubber crumbs can be:

- apply for your own needs;

- sell wholesale and retail to the population and enterprises;

- use for the production of goods or open a custom rubber coating business.

The price of the crumbs will depend mainly on the quality of the raw materials, and secondarily on the fraction.

The most popular is crumb, the fraction of which is 2-4 mm .

It's great for creating:

The popularity of such crumbs is due to the fact that a minimal amount of glue is used to glue these granules together. And a polyurethane binder is sometimes 5-8 times more expensive than crumbs.

Technology for laying crumb rubber coating: step by step

Seamless crumb rubber floors can be laid on almost any substrate. This can be either a hard covering made of cement screed, asphalt concrete or boardwalk, or a compacted sand-crushed stone cushion or natural soil.

For a solid base, a thinner layer of crumb rubber (from 10 mm) is sufficient. When laid on a shock-absorbing pad, the thickness of the coating must be at least 30-40 mm to ensure its indestructibility during operation from vibration. Therefore, it is more expedient to prepare a rigid base, reducing the consumption of expensive components.

The construction of a seamless coating from crumb rubber can be done in two ways: “dry” or using a binder. In the first case, the granules are simply spread over the base in a fairly thick layer (more than 80 mm). But this method is used only for quickly creating temporary coatings - they are short-lived, but the financial costs are minimal.

The technology of laying seamless rubber floors using binding adhesive components allows you to obtain a reliable, durable and injury-proof coating for indoor and outdoor areas.

Preparing the base

There are no special requirements for the base under the rubber coating; it is enough to remove weak points and repair large cracks using special compounds (depending on the type of base).

The base should be cleared of debris and dust. It should be free of oil and chemical contamination.

When laying crumb rubber on a sand-crushed stone bed or natural soil, it is recommended to use a rolled rubber backing, which will not only reduce material consumption, but also increase the damping properties of the coating.

To strengthen the soil base and prevent it from being washed away by drainage water during operation, a layer of geotextile should be laid on it, thus separating the crumb rubber coating and the soil.

Similar measures must be taken when installing a sand-crushed stone cushion, but in this case, the layers of the cushion should also be separated with geotextile fabric.

Before laying crumb rubber in an open area, it is necessary to install fencing elements. These can be either concrete or rubber curbs. The second option better meets the safety requirements and is suitable for sports and children's playgrounds. If necessary, “beacons” should be installed along which the crumb rubber will be laid.

To impart higher adhesion, the rigid base must first be primed with special compounds (you can prepare the primer yourself by diluting the polyurethane binder with an organic solvent to a liquid consistency). This will also help to hold together small dust particles that cannot be removed mechanically.

Preparing the mixture

The components for a seamless coating are:

minimum temperature of running cold water

- SBR crumb rubber, which is a product of recycling used car tires;

- adhesive binder based on polyurethane resins;

- a dye for rubber crumbs that gives the coating a certain color (red, green, yellow, blue, etc.).

Two types of pigments are used: organic and inorganic, the former are more resistant to ultraviolet radiation and do not fade under sunlight, but their cost is much higher.

- EPDM granules and inclusions of ethylene propylene rubber can be added to the mixture to give the coating additional elasticity, strength and elasticity;

- water is added in small quantities, as it serves as a catalyst for the polymerization reaction of the polyurethane binder.

To prepare the working composition, a screw and rotary mixer for rubber crumb is used, which is similar to a vertical-loading concrete mixer, but has wider blades for thoroughly mixing the components.

The proportions for preparing the mixture depend primarily on the size of the rubber granule fraction and the type of polyurethane binder. The smaller the size of the crumbs, the greater their total surface area, which requires greater consumption of adhesive and dye.

The recipe should be selected experimentally, based on the recommendations of the manufacturer of the polyurethane binder. The approximate consumption of crumb rubber per 1 m2 with a layer thickness of 10 mm and a granule size of 2.5-5 mm is 6-7 kg. In this case, 1.2-1.5 kg of polyurethane binder and 0.2-0.3 kg of dye are required. The water content in the mixture should be up to 3-4% of the total mass of crumb rubber.

Having selected the required percentage of components, all batches should be made using this recipe, since only in this case will it be possible to achieve a rubber coating that is uniform in density and color over the entire surface of the site.

It is necessary to take into account that the pigment for crumb rubber in the prepared mixture has a darker shade, which will lighten by 1-2 tones when the coating dries.

First, granules and paint are poured into the crumb rubber mixer and mixed until smooth. Then water is added to wet the surface of the crumbs and after mixing, the polyurethane binder is added. The output should be a mixture of viscous consistency, with a uniform color.

Technology for laying crumb rubber coating

Laying a seamless coating of crumb rubber can be done in one layer or in several. In the first case, the prepared mixture is laid out on the prepared base and leveled with the required layer using a rule, a trowel or a squeegee soaked in an anti-adhesive composition.

As such, you can use soapy water, white spirit or turpentine. After smoothing, the surface of the mixture must be rolled using a roller for laying crumb rubber. As a result of this operation, the coating is compacted and a smooth texture is formed.

It is not recommended to press too hard on the roller; this will reduce the elasticity, water permeability and frost resistance of the rubber coating.

To increase work productivity, a crumb rubber stacker is used, which can also serve as a mixer for preparing the composition. When moving along the guides, which are beacons, the finished mixture is evenly supplied from its hopper to the surface of the base.

Depending on the design, such equipment for laying crumb rubber is capable of covering a surface with a width of 1.5-3 m in one pass, while maintaining high accuracy of the layer thickness. Leveling and rolling are carried out automatically under the control of the operator. You only have to correct minor flaws with your own hands, which are possible when laying rubber coating over large areas.

When laying two layers of coating, there is no need to add pigment for the rubber crumb to the bottom one, so the mixture for it is made without paint. To increase the elasticity of the coating, crumb rubber of a finer fraction (0.5-2.5 mm) can be used. This increases the specific gravity (reduces porosity) and makes the bottom layer more rigid.

When installing a seamless rubber coating on a soft base, it is recommended to lay a fiberglass mesh between the layers, first securing it with a construction stapler. Such reinforcement significantly increases the strength of the rubber coating. These works can only be carried out after the first layer has hardened.

The second layer of seamless coating is made thinner (10-15 mm) and can either include a certain amount of EPDM granules or consist entirely of ethylene propylene rubber. In the second case, adding a dye is not required, since the EPDM chips already have color applied during its production.

The technology of rubber coating allows you to create patterns, designs and sports markings of various colors on it. To do this, use a stencil to cut out an area with the outline of the future design or marking on the finished hardened surface using a stencil using a sharp knife. The edges are covered with masking tape to prevent staining of the main coating, and the cut out area is filled with a mixture of a different color. Due to the high adhesion of the polyurethane binder, such a pattern will be monolithic with the overall coating.

To reduce financial costs when creating a seamless coating, a combined method of applying the mixture is used. The main layer of unpainted rubber crumb is applied manually or using a mechanized layer, and the top decorative and protective coating is made from very fine EPDM granules (0.5-1.5 mm) and is applied by spraying using compressor-based spray units in a layer in 3 mm.

Since ethylene propylene rubber has higher performance characteristics, the abrasion resistance of such a coating is much higher, and therefore its durability increases. In addition, during the production process, pigments are not used to color the bottom layer, and the speed of applying such a seamless coating increases.

The rate of hardening of the rubber coating composition depends on the temperature and humidity conditions. It is allowed to carry out work at air humidity of 60-80%, and temperatures from +5 to +30 °C. The optimal conditions for polymerization of the polyurethane binder are +25 °C and 70% humidity. The same requirements apply not only to air, but also to the base.

When working in an open area during the hardening of the mixture, atmospheric moisture is not allowed to enter the surface of the coating. Partial strength gains, after which pedestrian loads on the coating are allowed, occur after 12 hours. Full use of the coating is allowed after 24-48 hours.

Precautionary measures

The components for making a seamless crumb rubber coating do not contain harmful or flammable substances. But the polyurethane binder, when interacting with water during the polymerization process, releases carbon dioxide.

Therefore, when laying a seamless coating in a room, it is necessary to ensure good forced ventilation in it, since an increased concentration of carbon dioxide can cause drowsiness and weakness.

All personnel must be provided with special clothing and personal protective equipment (shoe covers, protective overalls, gloves and goggles, and when using dyes, respirators). The effect of the polyurethane binder on exposed skin does not pose any risk to health, but it must be immediately removed with warm water and soapy water if it comes into contact with the mucous membranes of the eyes and mouth. After treating the affected area, it is recommended to consult a doctor.

Tool for laying seamless coating

- Mixer mixer for preparing the working composition.

- Scales for dosing components are best electronic.

- Buckets or wheelbarrow for transporting the mixture to the installation site.

- Graters, squeegees or rules for leveling the mixture.

- Smooth rollers for compacting the laid composition.

At the end of the work, the entire tool can be easily cleaned a few hours after the mixture has set. It easily lags behind plastic and polyurethane tools. Additionally, you can use turpentine or white spirit for cleaning. The metal blades of the mixer can be burned with a gas torch.

Video

Construction of a tire crusher

There are three main methods for producing crumbs:

According to its characteristics, rubber refers to materials that include all of the listed items and their processing is in demand:

- mass production and short service life determine a high degree of pollution;

- take a long time to decompose in the natural environment;

- limited natural rubber production;

- technologically simple and inexpensive to maintain processing;

- high demand for the material.

Making crumb rubber with your own hands

In recent years, the use of crumb rubber and materials made on its basis for decorating areas, organizing paths, and covering the roofs of houses has become fashionable. Crumb rubber can also be used to create waterproofing for building foundations. In order to use elements made from crumb rubber on your site, you can contact a company that professionally works with crumb rubber. However, working with this material is not so difficult. If you wish and have free time, you can make crumb rubber at home with your own hands.

What is DIY crumb rubber made from?

When solving this issue, you can go in two ways. Path number one relies on the transition of rubber to a brittle state at low temperatures. If at home it is possible to cool the source material for preparing crumbs to a temperature of -70 ... -80 degrees Celsius, then it will be possible to obtain crumbs from any type of source materials. However, solving this problem at home is not so easy.

Path number two is to competently select the source material. As we know, crumbs can be obtained from tires and tubes from car wheels. But tires are very difficult to grind under normal conditions, and it is also difficult to extract the metal cord from them later. For this reason, to obtain crumb rubber at home, it is better to use old worn-out tubes as raw materials. This material can be cut quite easily using improvised tools available in any home.

How to make crumb rubber at home?

At the initial stage, it is necessary to prepare a sufficient amount of raw materials, i.e. old car inner tubes and corresponding cutting tools. To make a coating with an area of one square meter and a thickness of 10 mm, about 8 kg of rubber crumb is required. When producing crumbs from old chambers, the loss of material by weight is minimal. Thus, it is necessary to prepare the starting material at the rate of 8 kg of old cameras per 1 square meter of coating.

To grind rubber, you can use ordinary scissors or an ax. If desired, you can build special guillotine shears. As a last resort, you can organize cutting of the cameras with a fairly sharp knife.

Making crumbs should be done according to the following algorithm:

- Remove all metal elements from the old camera

- Cut the camera into thin strips

- Grind the thin strips obtained in step 2

Sources: https://stop-othod.ru/oborudovanie/rezinovaya-kroshka-svoimi-rukami.html https://punktpriema.ru/articles/kak-sdelat-rezinovuyu-kroshku-svoimi-rukami.html https:// rcycle.net/rezina/kroshka/samodelnaya-drobilka-dlya-shin-svoimi-rukami https://yvision.kz/post/699880 https://sportkv.com/rezinovye-pokrytiya/besshovnye/tehnologiya-ukladki-pokryitiya- iz-rezinovoy-kroshki-po-shagam.html https://rezinovaja-kroshka.ru/stati/rezinovoj-kroshki-svoimi-rukami https://www.krovlyakrysh.ru/dobornye-elementy/vodostoki/iz-kanalizatsionnyh- trub/

Complex method using equipment

This manufacturing option is reliable, but requires the preparation of special equipment. I did not buy equipment for grinding, since I also decided to assemble a structure from parts available on the farm. I'll tell you step by step what followed.

Detailed design of the unit

At this stage, I will explain what parts a homemade crusher should consist of and where I got them from. If you still have to buy something from the components, then believe me it will be much cheaper than purchasing an industrial device. So, the design should consist of:

- two electric motors (I took them from two old home mills, power 5 kW each);

- a housing in which disc shafts are built in (the latter had to be ordered to fit your dimensions);

- regular grille;

- worm gearbox (at least two pieces are required);

- do-it-yourself shredder frame for rubber crumbs;

- bunker for loading material for processing;

- guide channel;

- cabinet with control buttons;

- device for preparing tires for shredding;

- powerful frame for installing equipment.

The last structural element will also have to be ordered from professional welders. The frame must be made from channels. But, if you have skill in this matter, then you can think through the support yourself. Next, I propose to consider the main components of the device in more detail.

Box with built-in cutting discs

This element includes a housing equipped with small milling shafts. The knives themselves, which are used for chopping, are made of high-strength steel. They also have high thermal stability, as they can become very hot during operation. Thanks to heat treatment, cutting structures last longer and do not require periodic maintenance.

Calibration grid

This DIY tire shredder design is installed directly under the rollers. It serves to obtain a calibrated fraction from processed raw materials. This element is mandatory, as it allows you to obtain a uniform mixture.

Worm gear

It serves for separate rotation of disk cutters. The gearbox itself is connected using couplings to the provided electric motors. To cut rubber at a sufficient speed, you will need to select the correct gear ratio - from 25 to 35.

Let me sum it up

Do-it-yourself rubber crumbs can be made at home in two ways. Small volumes can be obtained quite simply, but if you need a lot of crumbs, then additional equipment will be required. Accordingly, the first question that needs to be decided is what volume of output raw materials is required.

Write in the comments whether you used one of the methods given or are you still inclined to buy crumbs from an industrial manufacturer?

Source