The topic of the article is covering a house with corrugated sheets. This building material has been used in construction for a long time. And if earlier these were gray inexpressive sheets, which were mainly used for cladding hangars and warehouses, as well as in the formation of barrier structures, today it is one of the most popular building materials. Today we will talk about corrugated sheeting, its varieties, and the technology of cladding houses using this material.

House sheathed on the outside with corrugated sheets Source remontik.org

Features of facade finishing

Finishing the facade using profiled sheets has some features that set it apart from others. The advantages include:

- Economical. Corrugated sheets are distinguished by the low price of not only the sheets themselves, but also the installation work.

- Durability. Properly installed sheets have a long service life, from approximately five to fifty years.

- Increased resistance to corrosion, the influence of various negative weather conditions, and high humidity.

- Fire safety. The façade finishing made from this material is non-flammable and does not emit toxic substances at high temperatures.

- The appearance is very attractive. Properly installed corrugated sheeting can decorate any, even very stylish, residential building. Such sheets can be used in various shades, which will be in a checkerboard pattern or in parallel multi-colored stripes.

Installation technology

Frame diagram for covering a house with corrugated sheets.

How to cover a house with corrugated sheets? Correct installation of wall corrugated sheets must take into account the following steps:

- First, special brackets are attached to the wall.

- Now you can begin laying the insulation in the form of slabs. For this, foam or mineral wool is usually used. A special windproof film is attached to the top.

- Vertical guides must be attached to brackets that are U-shaped. This allows you to level the wall, while the necessary air gap remains between the film and the guides.

- Now let's start with our own hands.

Among the features of the technology of correctly performed installation, one can note not only the simplicity of execution, but also the minimal costs and variety of design solutions.

The main idea is that there will be air circulation between the sheet and the facade itself, which will allow regulating the temperature and removing excess humidity, that is, such houses are very comfortable and convenient for living.

How to properly sheathe a house with your own hands

If the product is installed on a wooden surface, it is important to remember that before starting work, the wood must be treated with special solutions to prevent the appearance of bark beetles, mold and fungi on the surface, leading to rotting and decomposition of the wood

If the rotting process does begin under the sheathing, then damage will occur not only to the wooden structure, but also to the top layer of the corrugated sheet. The inspection is carried out manually, by walking around the house and checking every detail.

If a house made of timber is visited by a bark beetle, its traces can be seen by the rottenness of the surface, and black spots will indicate fungus. The damaged areas are removed and all cracks and gaps are thoroughly plastered.

If the walls have not been damaged, then the owner is lucky, and work can begin on the frame of the structure. The sheathing is performed either vertically or horizontally.

Cross beams are not allowed due to insufficient ventilation penetration into the surface of the house.

The work of installing corrugated sheets on the wall surface can be divided into several stages:

- The surface of the wall is covered with lines arranged vertically. The distance between them should not be more than sixty centimeters.

- Steel brackets are attached to the wall surface for leveling.

The brackets are mounted on self-tapping screws, ensuring that they are all located on the same line.

Profiles with a U-shaped structure are attached to the installed brackets.

In order for the profiles to be installed strictly in a vertical plane, a water level is applied to them.

Heat-insulating materials are installed in the resulting gaps between the profiles.

Mineral wool slabs are most often used. The slabs must fit tightly to the wall surface, so installation can be achieved without additional fasteners.

After installing the heat-insulating material, you need to attach a vapor barrier film, which will prevent the formation of condensation on the inner surface of the profile sheet and prevent wet drops from hitting the surface of the insulating material.

After the above steps, you can begin installing the profiled sheet.

To do this, you will need self-tapping screws with round washers at the end. It is with their help that the material will be attached to the wall. When turning the screws, you need to leave a gap between the surface of the corrugated sheet and the head so that thermal expansion is compensated.

The first sheet is fastened from the bottom of the building. The sheet following the first and subsequent ones are overlapped. This method will ensure reliability and prevent moisture from getting under the skin. If we sheathe with imitation, the work will be delayed, and this is explained by the fact that it will be difficult for the craftsman to adjust the material. Therefore, it is recommended to carry out façade cladding from corrugated sheets under a log or wooden surface. It is important to monitor the accuracy of the pattern on the surface. It should not have any breaks. This composition is laid across, and not along, the structure, and with obligatory overlap. After attaching the profile sheet to the wall, you need to hide the gaps at the joints of the surface using additional materials.

You may be interested in an article on how to make a garage from a metal profile with your own hands.

The entire installation is contained in these stages. A novice master and several assistants from among his friends or household members can handle it

It is important for craftsmen to monitor the level when drawing angles and lines, and to work efficiently with a screwdriver

How to sheathe the outside of a house with corrugated sheeting - installation instructions in the video:

Features of the material

Considering that corrugated sheeting is a metal product, it has all the characteristics of this material. In fact, it is a product made of thin sheet steel. Although the corrugated sheet has a slight thickness, it is very durable because it has a profiled surface. The presence of trapezoidal waves on the surface of the sheet, which are used here as stiffening ribs, allows the material to demonstrate increased rigidity during operation.

Considering that the metal suffers greatly from corrosion, the appearance of which can be provoked by negative environmental factors, the product in question is made of stainless steel. In addition to this, it has an additional protective layer, presented in the form of a polymer coating located on the front side of the material. It is noteworthy that this coating not only protects from external conditions, but also gives the corrugated sheeting improved aesthetic properties. It provides this opportunity due to the fact that it can be made in any color option.

Advantages

The main advantages that ensured the popularity of corrugated sheeting are the following:

- reasonable price;

- the possibility of using even a wooden house for cladding;

- a wide selection of color options for polymer coating gives confidence that any owner will be able to find among the variety of materials offered one that suits him in color and design style;

- a significant area of corrugated sheets significantly reduces the time required for its installation, and this makes it a more preferable option than covering the facade with siding or brick cladding;

- covering the facade with corrugated sheeting provides a high level of protection from mechanical damage and atmospheric moisture;

- The polymer layer that galvanized steel sheets have protects them from corrosion. But the material can demonstrate this property only if the cuts are processed correctly during its installation.

Flaws

But corrugated sheeting also has a number of disadvantages that the buyer should be aware of. Chief among them is the low noise absorption coefficient.

If you've ever been in a building when it rains, then you know the noise created by drops falling on the eaves. What can we say about the façade, which will be lined with corrugated board.

Conclusion

From the article you learned that the process of covering a facade with corrugated sheets is within the capabilities of any person. This work is no more difficult than finishing siding, and due to the large size of the sheets, the process is even faster. Watch the video in this article to understand the technology even better, and if you have questions, write them in the comments under the review.

Did you like the article? Subscribe to our Yandex.Zen channel

December 4, 2016

Materials for finishing facades, Profile sheets, Corrugated sheets, Walls

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

What is corrugated sheeting

The production process of profiled sheets is quite simple. So, the raw material is galvanized sheet in a roll with a thickness of 0.35 to 1.2 mm. Profile forming technology – cold rolling. That is, a roll of steel sheet is untwisted by inserting the end into a rolling mill. The equipment system has rollers of different sizes. They are located sequentially. And the further you go, the larger their diameter.

That is, the sheet is rolled between rollers. Profiles are obtained on it. And in this way rolling continues until the required wave parameters of the corrugated sheet are formed. After which the sheet is cut on a special machine. The maximum sheet length is 13 m, the minimum is 0.5 m. In this case, trimming can be adjusted to any size in increments of 0.5 m.

Corrugated sheet production technology

Today, corrugated sheets are not just galvanized panels, although these are also available for sale. These are sheets painted or treated with polymer compounds with a long service life. Manufacturers are gradually stopping using paint, because the material with a polymer layer has higher performance characteristics. For example, a painted sheet will last no more than 15 years, with a polymer coating - up to 50 years. It should be noted that the finished corrugated sheeting is not painted or polymerized. This ready-made raw material in the form of sheets in rolls leaves the factory in this form. That is, they paint it or apply polymer in a factory using special equipment.

Corrugated sheeting is a certified material, that is, a state standard has been created for it under the number 24045-2010. But it should be noted that not all manufacturers adhere to this document and produce their products according to technical specifications (TU), but this does not contradict current legislation.

Trapezoidal wave corrugated sheet

So, according to the presented GOST, profiled sheets are divided into three groups:

- wall;

- carrier;

- roofing

Since the topic of the article is covering a house with corrugated board, we will be mainly interested in the wall option. Although it should be noted that the other two can be used to decorate the walls of houses. They just cost more, so there is no point in resorting to their use.

So, the wall corrugated sheeting is marked with the letter “C” with the addition of digital parameters of the sheet, where the main one is the height of the wave. For a wall one, this size varies from 8 to 44 cm. It is the height of the profile that determines the strength characteristics of the material. The larger it is, the higher the strength.

Most often, the C-8 brand is used to decorate a house with corrugated sheets. Firstly, this is the cheapest option. Secondly, it has excellent strength characteristics. But when choosing a brand, it is necessary to take into account the loads acting on the building. For example, if the wind loads acting on the building are large, then it is better to carry out the cladding with sheets of grade C-15 (20 or 21). They have higher strength and are practically not prone to bending.

Profiled sheet of grade C-8 On our website you can get acquainted with the most popular sites in the Moscow region for the construction of a country house. In the filters you can set the desired direction, the presence of gas, water, electricity and other communications.

And just a few words about the decorative design of profiled sheets. Let's start with the fact that today manufacturers offer almost the entire color palette. But, as experts say, this is already the last century. Because the market sells panels decorated to look like different building materials: wood, brick, stone, sand, etc. At the same time, you can order sheet material with various designs: nature, landscapes, drawings, patterns, etc.

And one moment. Manufacturers today offer corrugated sheets with a double-sided decorated coating. That is, the sheets are decorated on both sides. They are usually used to build fences. For house cladding, it is optimal to use panels with one-sided coating. They are cheaper, and there is no need to use double-sided sheets in this situation.

Profiled sheet on the facade of a house with imitation of natural stone

Main manufacturers

Corrugated steel panels are a successful combination of affordable cost, technical information, simple installation and a simple production process. Consumer demand for the material is growing daily, which leads to the need to increase production capacity and modernize technologies for the production of rolled metal products.

Corrugated segments are manufactured by a huge number of production associations. The only annoying fact is that in pursuit of profit, manufacturers skimp on quality. Under these conditions, only the giants manage to unshakably and firmly maintain leading positions in the commodity turnover market. The products of such companies are certified in accordance with the regulations of world quality standards and are able to cover the supply of material throughout the entire territory of the Russian Federation.

- LLC "Royal corrugated sheet plant"

The Royal Corrugated Plant, as the largest manufacturer of rolled metal products, sets standards for the production of building materials. The product line from the company includes 8 types of products. The production process involves 2 automated lines.

A distinctive feature of the products from this plant is their high quality, as well as the use of decorative powder-type paints and varnishes, which provide protective functions and resistance of the products to corrosion processes.

To provide additional protection for shipped products, special packaging is used. It is in this form that the goods arrive at the point of sale.

- Queen LLC

The company operates on the principle of doing quality work, even when no one is looking. The Perm rolled steel plant is one of the enterprises of the Queen concern. The plant's production facilities produce 6 types of products. Despite little experience in the field of corrugated sheet production (12 years), the company is included in the list of one hundred best domestic manufacturers. The plant received honorary awards several times.

- LLC "Klimovskiy corrugated sheet"

The company's products are known to every second representative of the construction industry and the common man. Their production lines have recently been modernized with the latest technology and received European-made equipment. The plant's products are supplied to the Novolipetsk Iron and Steel Works and PJSC Severstal.

- Chelyabinsk corrugated sheet plant

The Chelyabinsk plant began operating as a manufacturer of certified corrugated sheets in 1974. We are talking about a large production area with adjacent territories, where innovative foreign-made equipment, work areas, and a vehicle fleet are located.

The plant demonstrates the production and sale of high-quality rolled metal products and a balanced pricing policy. One of the few in the Russian Federation that uses a line for applying decorative coatings, developed jointly by English engineers and qualified programmers.

Technology of house cladding with profiled sheets

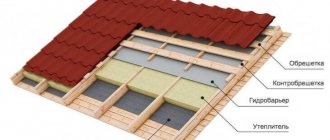

Let’s immediately make a reservation that finishing a house with corrugated sheets is the construction of a ventilated facade. That is, a frame made of metal profiles is installed on the outer walls of the building. And then the profiled sheets themselves are mounted on it. Metal profiles for the facade of a house are either special elements or profiles that are used for installing plasterboard sheets.

Let us add that a ventilated facade is an opportunity to insulate the walls of the house from the outside. That is, thermal insulation material is placed between the cladding and the walls of the building. The design is really great. It turns out, as they say, two in one: thermal insulation plus decorative cladding.

Calculation of required material

In order not to increase the budget, it is necessary to accurately calculate the amount of corrugated sheeting required. To do this, the area of window and door openings is subtracted from the total area of the wall, which is the height times the width. Here you can add the area of the gables if they are sheathed with corrugated sheets.

How to calculate wall area

Now you need to find out the usable area of the profiled panels you are purchasing.

Please note that each sheet has a total width and a usable width, so to calculate the area, the latter is taken. And now the total sheathed area must be divided by the area of one sheet, we get the number of required panels

In addition to corrugated sheets, manufacturers today also produce additional elements. There are few of them:

- external corner for decorating the external corner of the house;

- inner corner;

- a joining strip, which is used to close the joints formed between two adjacent sheets laid in the same direction;

- end and slope strips;

- window sill;

- plinth strips.

All additions are selected in size in accordance with the dimensions of the house and its structural elements.

Preparing the walls

First of all, the following are dismantled from the wall surfaces: platbands, flashings, drainage system, decorative items, lamps, etc. Then repairs are carried out. There is no need to level the surfaces, but it is necessary to repair cracks, holes, chips and gouges, as well as clean them from mold and fungi.

If a wooden house is finished with corrugated sheets, then all wooden surfaces are first treated with an antiseptic compound that will fight fungi and mold, and after drying, it is treated with a fire retardant compound. The latter increases the fire resistance of wood.

Laying corrugated sheets on the pediment

In the case of a pediment, everything is much simpler. To begin with, a sheathing of wood or metal profiles is also erected. The easiest way to work is with wooden blocks, since they can be sawed even with an ordinary hacksaw and you don’t have to bother with additional brackets on the bottom and top.

A water-slope underlay is installed at the bottom of the gable. It is important to install it in advance. This will be much more difficult to do in the future. Now measurements are taken on sheets, all using the same formula for the area of a triangle. The sheets are cut to the required length.

The installation is also carried out with an overlap. The difference is that the overlap can be vertical. The location doesn't matter.

It should be screwed with the same screws that were used to screw the sheets on the wall.

How to fasten corrugated sheets

Installation of a profiled sheet involves fixing it to the frame.

A galvanized self-tapping screw with a rubber gasket is used to secure the corrugation in increments of 35 cm. Self-tapping screws for corrugated sheets have a thread and a special tip in the form of a drill. They are usually made from high-strength alloy carbon steel grade C1022 with a finishing zinc coating. The design of the self-tapping screw with such a tip allows them to be attached to the frame without pre-drilling holes.

So, self-tapping screws for corrugated sheets with a diameter of 4.8 mm can drill through metal 2.5 mm thick.

Rubberized gaskets protect the cavities of the building material from moisture.

The sheets are always laid with an overlap of 5 cm. When cutting metal, the burr is removed so as not to cut yourself.

Additional elements are fixed along the entire perimeter of the house (corners, doors, windows). Then the building receives a complete and neat appearance.

Attention! Do not use a punch or nails.

Fastening corrugated sheets with self-tapping screws

Tips and tricks

- Profiled sheets are not universal; they are divided into roofing, load-bearing and wall. Each type has its own characteristics and, therefore, its own cost.

- The thickness of the metal from which the profiled sheet is made is the most important feature of this material; it directly affects the service life and cost. The metal is selected by the customer himself in accordance with his needs.

- It is better to choose sheets with zinc, aluminum-zinc or polyester coating. Profiled sheets coated with this composition retain their original color longer. They are also more resistant to aggressive substances, frost and heat, corrosion and most mechanical damage.

- During installation, it is customary to lay profiled sheets overlapping, with the length of overlap of one sheet on another from 1 cm.

- To make the fixation of the material stronger and more reliable, direct fastening to the sheathing is carried out only in the lower part of the profile.

- When installing a roof made of corrugated sheets, it is necessary to plan for free air movement. This can be done by installing thermal insulation and a vapor barrier layer.

- Drawing up an estimate is a mandatory stage of any construction. Preliminary cost calculations will allow you to plan the project budget and adjust it. Any estimate includes calculation of the cost of the material (it is advisable to “split this part” into several separate subsections) and calculation of construction work.

Advantages of facade finishing with corrugated sheets

Of course, you can use absolutely any materials that are suitable for this as cladding. However, corrugated sheeting in this case has a number of undeniable advantages.

Characteristics of facing corrugated sheeting

- Corrugated sheeting is an economical building material. You will save not only on the material itself, but also on installation work if you want to use the services of professional builders.

- Durable design. Provided that the corrugated sheeting is installed correctly, it will last long enough and will not require additional maintenance or repairs. The service life of this building material is at least 50 years.

- Profiled sheets are quite resistant to corrosion; they are not particularly affected by negative external factors, such as the scorching sun, precipitation or low temperatures.

- The building material is absolutely fireproof.

- Attractiveness. If corrugated sheeting is installed correctly, and you also choose a building material of an unusual color, it will have not only practical, but also aesthetic functions.

- Easy to install. This is an undoubted advantage that sets corrugated sheets apart from other materials. The work will be completed in the shortest possible time, auxiliary building materials are simple and inexpensive.

Main characteristics

The ventilation facade system made of corrugated sheets has a number of positive characteristics and advantages over other types of facing materials. And this fact is difficult to dispute.

Incentives for corrugated sheeting are determined by visual presentation and low cost. A number of characteristics can be supplemented with the following points:

- high sound insulation properties, the ability to use an additional layer of thermal insulation and adjust its thickness;

- corrugated sheeting is resistant to temperature fluctuations and high humidity levels;

- small amount of preparatory work;

- the corrugated panel used as cladding for the outer part of the ventilation façade has an incredible number of possibilities for implementing non-standard design ideas;

- finishing with corrugated sheets is relevant for the transformation of industrial, administrative, commercial facilities, private residential real estate, garages;

- ease of installation;

- Corrugated sheet decor is the epitome of aesthetics with minimal investment.

Advantages of profile flooring

The profile decking is a sheet of galvanized steel covered with a reliable paint and varnish coating. Its shape may vary. There are sheets with rectangular and trapezoidal lines, and a coating that imitates natural tiles is also available. Coloring is limited only by the imagination of the designer and the demand of builders.

A house sheathed with corrugated sheets takes on a beautiful appearance, and at the same time

its performance characteristics are significantly increased. The thickness of the sheets can be from 0.3 to 1 millimeter, and the height of the wave depends on the purpose and material used.

The advantages of profile flooring include:

- high strength and reliability;

- beautiful appearance;

- ample opportunities for creating various design solutions;

- resistance to corrosion and fading due to the use of modern paint and varnish coatings;

- cheapness.

Creating a suspended ventilated façade on a building provides additional insulation. Therefore, corrugated sheeting is performed not only in new buildings. Currently, this material is used for cladding old houses, which acquire a new look, and their service life is significantly extended. The house becomes beautiful, modern and warm.

And covering a wooden house with corrugated sheets allows you to significantly save money. This procedure is very simple and convenient when installing on wooden walls.

The ease of installation of profile flooring allows you to do it yourself without the involvement of expensive specialists.

Choosing material for house cladding

Before purchasing corrugated sheeting, you need to decide not only on the color, but also choose the thickness of the sheets and wave height, which depends on the type of coating.

For house cladding, materials C8, C10, C20 or C21 are more often used, where the numbers

indicate the wave height of the corrugated sheet. To produce the material, smooth painted sheets with a width of 1250 millimeters are used. After rolling metal sheets, their width decreases depending on the type of corrugated sheet.

Cladding a house with corrugated sheets can be done in the horizontal or vertical direction of the profile. It is not recommended to calculate corrugated sheets yourself. Any manager of a trading organization can easily calculate and make a schematic drawing of the arrangement of sheets using a special program on a computer. To do this, you just need to carefully measure the parameters of the house, not forgetting the openings for windows and doors.

When deciding how to sheathe a house with corrugated sheets efficiently and quickly, you need to take care of additional additional elements.

These include:

- special corner elements;

- connecting strips;

- starting and finishing bars;

- window and door frame elements;

- ebb tides on the base.

To install the frame, you will need guide profiles made of galvanized metal, hangers for them, dowels, nails and screws.

If a wooden house is covered with corrugated sheets, then some elements may be superfluous. Attaching profiles to wood is much easier and simpler.

We make a frame

Guide profiles

Initially install the wall hangers using a hammer drill. To reduce vibration and noise, secure them through isolon gaskets. Then fix the vertical profile guides on the hangers.

To make the frame as rigid as possible, horizontal jumpers should be installed between the vertical guides. Such an event is advisable only if the finished structure is excessively heavy. If you decide to insulate the walls, then after installing the frame, lay the thermal insulation material. This can be polystyrene foam or mineral wool. To protect the thermal insulation layer from aggressive external influences, cover it with a waterproofing, vapor-permeable film.

After installing the frame and carrying out thermal and waterproofing, install the shaped elements and accessories. These include various connections, special corner profiles, base drains, etc.

Execution of house cladding

Before sheathing a house with a metal profile, developers pay attention to several parameters of this material, including:

- preventing the impact of negative external factors on the walls of the building;

- Due to the air gap, timely airing and ventilation of the interprofile space is guaranteed, so that mold does not appear and condensation does not form.

In addition, the layer acts as a kind of heat and sound insulation.

The presence of these qualities allows you to use corrugated sheeting for cladding a balcony or attic, which can later be used as full-fledged living quarters, where it will be warm and cozy in cold weather, and cool in hot weather. With the correct organization of the air “corridor”, reliable protection of the walls and the material itself is guaranteed.

For those who still doubt whether it is possible to sheathe a house with corrugated sheets, experts offer two installation methods:

- fastening sheets to a ready-made surface, in this case, a wall;

- covering each prefabricated element of the future wall with sheets.

High-quality cladding is guaranteed if the following instructions are followed:

- Installation of a metal frame on the wall, assembled from mounting brackets. The structure is leveled and checked for level, then fixed with dowels. Wooden slats can be used as frame elements, but a metal frame still has the best performance qualities. To sheathe a house with corrugated sheets, both vertical and horizontal arrangement of sheets is allowed. Some developers are experimenting with diagonal orientation of the material.

- Laying insulation, on top of which a vapor barrier film is attached.

- The frame is ready, and corrugated sheeting can be mounted to it, as shown in the photo. In this case, galvanized steel screws should be used as fasteners, each of which is equipped with a moisture-proof gasket.

- The work is completed with the installation of additional elements.

If a prefabricated insulated panel is sheathed with corrugated sheets, then an important step will be to perform high-quality waterproofing of the foundation with a two-layer roofing felt as follows:

- The guide profile is fixed to the foundation of the building using anchors.

- Racks with an upper lintel are mounted on top of the profile - this creates a wall frame.

- Each cell of the frame is filled with heat-insulating boards.

- The corrugated board strips are attached to the side of the frame.

- Sheets of corrugated sheets are fixed according to the same principle as conventional wall cladding.

The example of wall cladding presented above proves the simplicity and speed of the work, but there are also important points that should be considered in more detail.

Video description

The video shows how to assemble a frame for a corrugated metal sheet:

As for the metal profile for drywall, that can also be used. To do this, choose a rack or ceiling profile as the most durable. And direct hangers are used as fasteners to the walls. The photo below shows just such an option.

Frame made of metal profiles for sheathing with corrugated sheets Source oooarsenal.ru

House cladding

The frame guides are fastened not to the walls, but to special brackets fixed to the wall

Before sheathing the house with metal profiles, it is necessary to apply markings to the walls to which the guides will be attached. The installation step of the guide elements of the fastening frame depends on the selected brand of corrugated sheet and can be within 40-80 cm. It is best to mark from the corner of the building. Load-bearing elements must be installed along the edges of door and window openings. To control the vertical installation of load-bearing elements, a level and plumb line are used when marking.

The frame guides are fastened not to the walls, but to special brackets fixed to the wall. When installing brackets, adhere to the following recommendations:

- The pitch of the brackets on one marking line should be 60 cm.

- On adjacent marking strips, the brackets are mounted in a checkerboard pattern. This is necessary to evenly distribute the load and increase the strength of the entire structure.

Frame installation

Installation of the supporting frame is carried out according to certain rules

Installation of the supporting frame is carried out in the following sequence:

- Using a hammer drill, holes are made in the walls of the house for fasteners.

- Next, brackets are installed in the holes. In this case, an isolon gasket must be used. This is necessary to increase the sound insulation of the walls.

- Next, the guide elements of the frame are attached to the brackets using metal screws. In this case, you need to ensure that all fastening profiles are located in the same plane. This will ensure a smooth vertical surface of the facade. To facilitate installation in one plane, the outer guide elements are first mounted. Then a fishing line or cord is stretched between them, along which the intermediate profiles are aligned.

- To increase the rigidity of the structure, horizontal jumpers can be installed between the vertical fasteners. To connect profiles, you can use special “crabs” or profile trims with cut and bent side walls.

- Regardless of what material your house is made of, be it wood or brick, it is better to put thermal insulation under the cladding. This way you will reduce the cost of heating your home and increase its sound insulation. To do this, after installing the guide profiles, heat-insulating material (foam or mineral wool) is laid between them. It is attached to the walls using special plastic dowels with caps. The top of the insulation is covered with a vapor barrier film. This will prevent the formation of condensation in the insulating material.

Installation of additional elements

Installation of additional panels is carried out precisely at this stage, since after installing the profiled sheets this will not be possible. To do this, using a screwdriver and self-tapping screws, you need to secure the frames of door and window openings, base ebbs, guide strips, corners and other elements.

Video description

The video shows how to properly repair the facade of a house:

Frame installation

The next stage is covering the house with metal profiles. It should be noted right away that corrugated sheeting can be laid on walls horizontally and vertically. Accordingly, the frame elements will be mounted vertically or horizontally. In this case, the cladding, both in the first and second cases, will be a structure with high protective functions. She is not afraid of heavy slanting rain, snow, or strong wind.

Vertical cladding of a house with corrugated sheets Source pinterest.co.uk