The electrode holder is included with the welding machine. Its function is to hold the electrode in the desired position during the welding process and provide current supply to the work area. The quality of the accessory will determine the reliability of the welded joint, the formation of defects, productivity and safety of work.

The designs were gradually improved, the appearance and the principle of fixation changed, but the convenience and reliability of fastening was always valued. Welders use both old and new clamp models. They can be selected at your discretion and used with any welding machine. In addition, they periodically fail because they come into contact with a melting rod. The welding holder is easy to replace and rearrange due to its versatility.

Peculiarities

The holder of the welding unit is a device that controls the electrode during welding work.

It must conscientiously hold an electrode of any cross-section and supply electric current to it, providing controlled control of the process without additional effort. The variety of designs also determines the variation in the technical and operational characteristics of the holders, however, there are also final values approved by GOST. For example, the length of the protected part of the handle must be at least 110 millimeters, and the average cross-section is in the range of 36-40 millimeters. The size of the clamp also affects the ability to work with electrodes designed for different levels of electrical current.

The initial level is 200-300 A; holders with a diameter of 36 millimeters function with similar parameters, and samples for 400-500 A, therefore, must have a cross-section of approximately 40 millimeters.

The materials used to make the device must also be taken into account. They also determine the ability to work with different limits of electric current strength, and resistance to adverse environmental conditions.

The combination of scale-resistant steel and high-strength plastic with corrugations on the surface will make it possible to protect the working base of the electrode holder from both high temperatures and cold if work takes place outdoors in winter.

What is important when choosing a holder

An electric welder holds this device in his hands for a significant part of his working time, so his choice should be approached with maximum responsibility. An experienced master will definitely pay attention to the following points:

- weight, dimensions, ergonomic qualities of the handle;

- compliance of the product labeling with the range of current used in the upcoming work;

- possibility of reliable fixation of electrodes of the required diameter;

- ease of fastening the rod at different angles;

- quality of manufacture of live parts and clamping devices;

- the degree of outer coating of the holder with insulating materials;

- model cost.

Device

Let us briefly consider the design of the electrode holder. Several important factors depend on the design of the device:

- quality of welded joints;

- master's labor productivity;

- convenience and safety of work.

inexpensive electrode holder

A standard type holder is a tool consisting of several parts: body, clamp, handle, moving parts. But different species may have some structural features . More details below.

Overview of species

On the equipment market, manufacturers offer a wide range of electrode holders. Despite this, they use several basic methods of fastening and design.

Main types of electrode holders:

- spring (lever);

- clamping (screw);

- universal;

- specialized.

A standard electrode holder consists of a housing, an insulated handle, a clamp and a movable locking mechanism. The design and operating principle of the holder may differ.

As a rule, holders are divided into multifunctional and models with a narrow specialization. They are produced in strict compliance with GOST. There are different types of devices.

The clothespin is the most common hand holder. It, like a clothespin, fixes the electrode with a spring. Equipped with serrated copper jaws, it securely holds the rod in any position, including at an angle of 180° relative to the handle. Insulating plastic covers cover all metal elements and protect against contact. The clamp makes it possible to quickly change electrodes by pressing the lever. The remains are insignificant, no more than 30 millimeters.

An electrode holder of this design (spring or lever) is the most common and simple product.

The price of the clothespin holder is the lowest in comparison with parts of other designs. The use of this type of holding device allows you to quickly and safely perform welding work, while the quality of the weld will always be at a high level.

The trident fork is the oldest design of a holder, which is made in a handicraft way. It is banned in many states. It has many exposed areas that conduct current, which pose a danger to the life of the user. The welder may suffer radiation damage while working.

The design consists of 3 pins arranged in a triangle. An electrode is inserted between them. The fixation is tight. You can use both alloyed 2 mm electrodes and bare wire with a cross section of 8-10 mm in long pieces when welding large products and welding casting defects.

Powder and carbon electrodes with low ductility cannot be inserted - they crumble.

A professional electric welder can easily use a trident fork. It is not easy for a beginner to work with a holder where the ability to adjust the angle of the electrode is limited and there are exposed conductive parts.

A simple device that makes it easy to fix an electrode of any diameter.

Great care should be taken when using a trident due to the large uninsulated area of the product.

The main advantage of a holder of this design is the possibility of self-production.

The collet holder is highly specialized. It is used in argon welding with a non-consumable rod. The tungsten electrode is inserted into the holder with the non-insulated end and pressed with a nut.

It is used exclusively when welding metal in a protective gas environment.

The device has a long service life and, when used correctly, allows you to perform work of the highest quality. Non-flammable ones provide quick fixation of the electrode. These holders are made in the form of a cylindrical handle, to which a metal pin is attached. The key advantage of this design is waste-free. The electrode is welded to the protruding rod and burns without a residue. A new electrode is then inserted. It is not possible to change the angle of inclination.

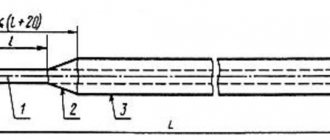

This type of device allows you to perform work using almost 100% of the length of the welding electrode. The flameless holder consists of a cylindrical handle (2), into which a metal pin (1) is mounted on one side.

The electrode is fixed by welding its end part to the contact pin.

The holder with a clamping screw is characterized by strong fixation of the electrode. The rod is inserted into a specialized hole and clamped with a screw. The downside is that it takes a lot of time to install and remove the electrode. It is not possible to change the angle of inclination.

As mentioned above, along with the presented samples, there are also highly specialized holders that are designed for the production of specific types of seams and products.

These modifications include holders for several electrodes at once or for functioning under voltage of a 3-phase electric arc. The key difference is the large mass and complex structure, which classifies such modifications as special ones that do not have much application. Each welder personally selects the necessary equipment based on his own needs and working conditions.

Screw-type electrical holders secure consumables well, have good contact and uninterrupted power supply. The contact surfaces have an anti-corrosion coating. With proper use, the device will last for many years.

Varieties

There are three main types of electrode holders.

"Fork"

The most primitive type of holder. Easy to make with your own hands at home. Simple, durable and cheap. But it is not entirely convenient, since the “fork” in some cases does not fix the electrode tightly enough.

"Collet"

The collet type holder is the most convenient and, therefore, the most expensive. It easily adjusts to any electrode diameter, holds the rod securely and allows you to arc with a high degree of accuracy.

"Clamp"

The clamp type holder is the golden mean. It is not as expensive as a collet, but it holds the electrode securely. The clamp can have different degrees of “corrugation”, so you can choose it for the type of electrodes that you use most often.

They all differ in how they work, but the essence remains the same. These devices are designed to hold the welding electrode. In this case, the type of electrodes used is not at all important. It is possible to use graphite or tungsten, steel or copper, as well as ESAB or UONI, Kobelco or LEZ electrodes. In short, neither the manufacturer nor the type of electrode is important. Therefore, when choosing a holder, electrodes can be ignored.

But something still needs to be taken into account. The welding electrode holder should be convenient for you personally. The plastic handle should be made of thick, durable plastic, preferably rubberized. However, we will talk about choosing a holder later.

How to choose the right electric holder

When selecting a holder, you should pay attention to the following characteristics:

- Size and weight of the device. The weight and dimensions of the holder are very important. When working for many hours, the extra 50 grams of the device will be felt. In this case, it is better to purchase a compact and lightweight design. If you have a choice, give preference to light and small parts, provided they have the same characteristics.

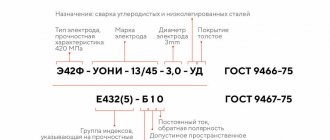

- Specifications. The holder must match the current strength. Failure to comply with this requirement will result in burnout of the contact part. If the contacts burn, further use of the device will be impossible. You can determine whether a device belongs to a category based on current strength by the markings that are applied to the non-replaceable part of the product.

- Quality of insulating material. To ensure safe performance of work, you should select a holder with a high-quality insulated handle. Plastic of sufficient thickness is used as a dielectric in almost all parts to reliably protect the welding machine operator from the effects of electric current.

- Price. You can buy a holder for a welding machine from 100 rubles, but the quality of a cheap model will not differ. Branded copies sell for several hundred dollars, but for everyday work there is no need to purchase holders at that price. It is enough to purchase a product in the middle price category to provide yourself with a high-quality tool for welding metals for a long time.

An inexpensive device can be purchased as a spare part. If the main device fails, if you have an additional holder, you can continue working without a serious time delay.

Video:

Main requirements for holders

The quality of the electrode holder directly affects the result of welding work. Therefore, when choosing, you need to consider the following factors:

- The clamping part must be brass.

- The device should be light, compact and comfortable in the hand.

- The quality of the clamping jaws.

- Contact with the electrode must be tight.

- It is better to give preference to the middle price category.

- A good holder has an elongated handle with grooves that prevent slipping in the hand.

- The type and condition of the insulation on the handle, on which the safety of the welder depends.

- The electrodes must be securely attached at different angles.

- Ideally, the holder can withstand 6,000 installation and removal cycles.

The electrode holder must meet the following mandatory requirements:

- Reliability and confidence in fixing electrical conductors of any diameter in the required position.

- Possibility of quickly changing the electrode exit angle.

- Good and complete contact .

- Ensuring quick electrode replacement.

- Durability of use.

- Lightness of the device.

- Insulation of live parts.

- Possibility of welding in hard-to-reach places.

Requirements for electrode holders

The requirements for this welder's accessory are formulated as a result of generalizing long-term experience in joining metals. Ease of use, productivity, and quality of connections directly depend on compliance with the requirements.

The electrode holder must provide:

- Reliable fixation of welding rods of all diameters in any spatial orientation relative to the holder axis;

- Quick change of electrode mounting angle;

- Good electrical contact with a large contact area;

- Quick removal of underburned material, installation of a new rod;

- Long period of operation;

- Insulation of conductive parts of the structure;

Ability to create connections in places with limited access; the device should have a small mass: the lighter it is, the less tired the welder’s hand is.

How not to buy a low-quality holder for a welding machine

Live parts of a quality device must be made of copper and protected with insulating material. Some unscrupulous companies manufacture live parts from steel and then coat them with copper. Thus, the parts become very hot and burn quickly.

They look like copper and it is difficult for a non-professional to visually distinguish them from “all-copper” parts. There is one surefire way that requires a magnet. It is necessary to bring a magnet to the part being tested; if the parts are magnetic, then they are made of steel.

Copper jaws of the holder

Review of popular models

Among the wide variety of electrode holder models and brands, the following manufacturers and brands are the most popular among welders.

The electrode holder ED-40 “Kord” (Russia) works on the principle of pliers. It features the ability to install the electrode at several angles and adjust the spring pressure. Works with electrodes with a diameter of up to 6 mm in everyday life and in production.

The DE 2500 spring-type electrode holder from ABICOR BINZE (Germany) is ergonomic and reliable. Provides rigid fixation of the electrode in four positions. Cooks with current up to 500 A. Modern insulating materials of the handle can withstand heavy loads and reliably protect against electric current.

The Esab electrode holder from the leader in the welding equipment market ensures ideal current supply and strong electrode attachment.

Advantages of the device:

- ergonomic design and modern design;

- small dimensions without protruding parts;

- they are easy to work with;

- maximum contact of conductive parts;

- Thanks to the design of the handle, it can be used for a long time;

- works in all spatial positions;

- There are two holes for installing electrodes: at 45 and 90°;

- electrical safety.

The following models of Esab electrode holders are available on the market:

- Esab 200, 400 and 500;

- Optimus;

- Eco Handy;

- Eco Confort;

- Prima.

ESAB Handy 200 (200 A) - is in great demand among professional welders.

The part has high performance characteristics that do not decrease throughout the entire period recommended by the manufacturer. The product was made in Sweden, so you can count on European quality.

The Handy 200 weighs 550 grams, but given the good insulating coating and high-quality clamp, the slight increase in the weight of the holder compared to other models is quite justified. Handy 200 is a screw holder, which allows you to perform welding work efficiently and safely.

When using the device, you can weld metal with electrodes with a diameter of 2.0 to 4.0 mm. The cost of the product on the Russian market is about 500 rubles.

ESAB Eco Handy 300 electrode holders are designed for use with all types of welding current for surfacing and manual arc welding. Rated load current – 300 A.

A powerful threaded rod forms the basis of the clamp. It is made of brass for the best current transmission. Contact areas with anti-corrosion coating. The design and selection of materials prevent contacts from burning. The handle is made of high-strength insulating material for safety. To connect a welding cable with a cross-section of 50 mm², a screw connection is used.

The Esab Handy 300 electrode holder is characterized by convenient and reliable operation. Indispensable when welding in hard-to-reach places where spring fixation is unacceptable.

The clamp-type electrode holder Esab PRIMA 300 is a reliable installation of the electrode in any position, eliminating bending. The accessory is used for MMA mode. Rated current load is 300 A. The diameter of the consumables used is 2.5–6 mm.

The head of the holder has a cast, closed shape. The head and handle are completely insulated. To install and replace the rod, simply press the handle. Insert the bare end of the electrode into the hole and release the handle. There can be a left, right or straight position of the rod. To connect the cable, the handle is screwed together. A cord is passed through it and inserted into the holder. The position is fixed with a screw and a copper plate.

ESAB 500 is a holder from a well-known Swedish company that has been producing high-quality products for over 100 years. The esab electrode holder can be used for welding work with currents up to 500 A.

The main advantage of ESAB 500 products is their ultra-light weight, which is only 200 grams. The cost of the product on the Russian market is about 3,000 rubles.

Electrode holder SIBRTECH ED-500 A is designed for welding operations of all degrees of complexity. It is easy to use and holds the electrode firmly. The device is durable and reliable in operation.

Electrode holder SIBRTECH ED is a universal option for beginners and professionals.

The holder uses the principle of clothespins. Installation and replacement of the electrode occurs quickly, without additional effort. The body and handle are made of impact-resistant plastic with insulating properties.

The holder is designed for use with electrodes with a cross section of 2–6 mm. Maximum current – 500 A. Core of the connected welding cable – 50–70 mm².

Electrode holder “Cedar” type 200A is universal, durable and convenient. The holder rigidly fixes and holds the electrode in 4 positions. The insulating material of the oval handle can withstand high loads.

Rated welding current – 200 A.

In addition to universal devices, special electrode holders are produced. They allow you to cook with several rods or a three-phase arc at once.

Germany type 300 A - ideal for welding with currents up to 300 A and electrode diameter 2 - 4 mm. Thanks to the special corrugated design of the device’s handle, it is possible to achieve a reliable hold in the hand. The model is distinguished by high-quality plastic insulation and relatively low weight.

The current-carrying part has a low resistance coefficient and high corrosion resistance due to the use of brass as the main material. The electrode can be fixed in the device in four positions, which makes performing complex work more comfortable and precise. You can purchase Germany 300 A for only 300 rubles.

It’s hard to say which electrode holders are most widespread among professional welders! It is safe to say that any of the samples described above can be used when performing complex welding work.

PS If welding holders for manual arc welding are selected correctly, the connection of metal structures will be comfortable.

Sources

- https://stroy-podskazka.ru/svarka/svarochnyj-derzhak/

- https://WeldElec.com/svarka/post/osnastka/derzhatel/

- https://plavitmetall.ru/oborudovanie/derzhak-dlya-svarochnogo-apparata.html

- https://WikiMetall.ru/oborudovanie/elektrododerzhatel.html