Welding electrode is a rod made of electrically conductive material, which can be metallic or non-metallic, used to supply current to the surfaces being welded. Today, about two hundred brands of electrodes with different characteristics are produced; it should be noted that more than 50% of the entire produced model range are consumable electrodes for manual arc welding.

Welding electrodes are divided into consumable and non-consumable. Non-consumable electrodes are made from refractory metals, such as tungsten according to GOST 23949-80 “Tungsten welding non-consumable electrodes”, synthetic graphite or electrical coal. Consumable electrodes are made from welding wire, which, according to GOST 2246-70, is divided into carbon, alloy and high-alloy. A layer of protective coating is applied to the metal rod by pressing under pressure. The role of the coating is to metallurgically treat the weld pool, protect it from atmospheric influences and ensure more stable arc combustion.

Classification

According to GOST 9466-75, coated metal electrodes for manual arc welding are divided according to their intended purpose:

- and carbon steels of structural type - U. Temporary tensile strength does not exceed 60 kgf/mmI.

- of structural alloy steel – L. Tensile strength over 600 MPa.

- Impact on heat-resistant steels supplemented with alloy elements - T.

- Welding of high-alloy steels with special properties - B.

- Surfacing of surface coatings with modified properties - N.

Weld metal or surfacing

Surfacing is a welding operation in which a layer of molten metal (called filler material) is applied to the internal or external surface of a part. Surfacing is performed for the purpose of:

- restore the original dimensions of the worn part;

- bring the dimensions to the design ones when manufacturing a part and detecting a removable defect;

- create a coating of one metal with a layer of another in order to increase corrosion resistance or impart special physical or chemical properties;

- strengthen the surface layer.

Surfacing

The electrode is guided along the surface of the part at a given location. The top layer of metal of the part melts and, together with the metal of the electrode, forms a surfacing layer. If necessary, several layers are deposited. Despite the fact that there are special surfacing electrodes, E42 can also be used for surfacing relatively small volumes of metal.

Dimensions

Electrodes are manufactured according to nominal diametrical dimensions . When ordering in bulk, some manufacturers can produce products with custom sizes. Sometimes the coating on the edge is not cleared, but both ends must remain in contact. In the total batch, no more than 10% of electrodes have a length deviation of 4 mm.

The electrode is made of several structural elements: 1 – rod; 2 – transition zone; 3 – coating; 4 – contact end.

The cleaning area has a conical, round or combined shape. The inclination of the cone is not regulated in any way, since it does not affect operation.

Ionizing elements are applied to the contacts, which facilitates the appearance of the welding arc. Product marking: electrodes E46 GOST 9466-75 with a diameter of 4 mm.

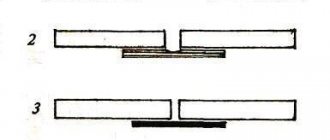

Crap. 4

1 - control weld; 2 - weld, ensuring the rigidity of the sample (performed only on a double-sided T-type sample)

Damn.4

Table 7

| Diameter of tested electrodes | Plate thickness | Seam leg |

| 1,6 | 3-5 | 2-3 |

| 2,0 | ||

| 2,5 | 6-10 | 4-5 |

| 3,0 | ||

| 3,15 | ||

| 4,0 | 10-16 | 6-8 |

| 5,0 | ||

| 6,0 | 14-20 | 8-10 |

| 6,3 | ||

| 8,0 | 20-25 | 10-12 |

| 10,0 | ||

| 12,0 | 25-30 | 12-14 |

| 12,5 |

5.11. Pipe welded butt samples are made from two pipe sections, the dimensions of which must correspond to those given in Table 8.

5.12. For pipe welded butt samples, the structural elements for preparing edges for welding must correspond to those shown in Figure 5, and for the completed seams - in Figure 6.

Table 8

mm

| Diameter of tested electrodes | Pipe outer diameter | Pipe wall thickness | Minimum length of each pipe section to be welded |

| Up to 2.5 | 32-42 | 3,5-5,0 | 100 |

| St. 2.5 | 108-133 | 8,0-10,0 | 120 |

Technical requirements

Metal consumable electrodes are manufactured in accordance with GOST 9466-75, but with modifications. The main element is made of special wire . The coating is durable, without pores, swelling, or cracks. The presence of minor irregularities is normal; deep dents and lingering scuffs are considered defective. The length of the damage does not exceed 3 times the diametrical size. The normal depth of dents is up to 50% of the total thickness of the coatings; there can be up to 4 of them with a total length of maximum 25 mm on the product.

Calcination (drying)

If the electrodes were not stored in a sealed package and could become damp, then it is recommended to calcinate them. It should be noted that calcining the electrodes immediately before use is a critical procedure that ensures the ignition of the arc.

At the same time, experts do not recommend getting too carried away with it, since excessive and frequent heating of the rod can lead to damage to the special coating.

It is advisable to accurately calculate the required number of products and dry them in such a way that upon completion of the work there are none left at all or only a minimum remains.

The next time you turn to welding operations, the previously dried electrodes should be worked out first.

Calcination is also necessary in order to slightly raise the temperature of the consumable immediately before using it for welding pipes, for example. Few product samples are able to immediately provide the required operating conditions due to too large a temperature difference in the welding zone.

Additional heating of the rods also ensures the tightness of the connection formed during the so-called “pressure welding”. However, this requires gradual heating to allow the accumulated moisture to evaporate to avoid the appearance of limescale.

The issue of calcination is closely related to the maximum time and storage conditions. According to current regulations, the shelf life of these products is approximately five years. But, according to a number of experts, they can be used for some time after the warranty period expires.

Acceptance rules

Acceptance testing in accordance with the requirements of the current standard is mandatory. The inspector analyzes the condition of the electrodes for compliance with technical specifications, checks the appearance and the absence of moisture in the packaging.

All products from a batch are manufactured according to a single technical process, on identical machines, using the same brand of wire.

From 1 ton of batch, 0.5% of electrodes are selected from various packing places. If the study shows an unsatisfactory result, then it is repeated, but with a double number of products. The result of the second analysis is final and applies to the entire batch. In the event of a defect, you must act immediately by contacting the supplier.

The presence of moisture, deviations in the size and number of pores are eliminated by calcination, followed by diagnostics for compliance with welding and technological qualities.

For what metal: stainless steel and not only, areas of application, purpose

Electrodes of the OZL brand are used mainly by professional welders in the construction of metal structures with increased requirements for the corrosion resistance of welds to increase the reliability of the structure. In addition, the welding seam of such electrodes has the qualities of heat resistance and heat resistance , which allows these objects to be operated at elevated temperatures without fear of destruction.

In the energy, food, chemical, oil and gas industries, parts operating in aggressive environments made of stainless alloys, welded using OZL electrodes, are successfully used. Some types of such consumables, on the contrary, are used in structures where it is necessary to ensure the cold resistance of the welding joint.

Sometimes it becomes necessary to weld carbon or low-alloy steels with high-alloy steels. Among the brands of OZL consumables you can find those that will perform such welding efficiently.

Test methods

Linear dimensions are examined with an error of 1 mm. The depth of the dents and the length of the exposed part of the rod are measured with an error of 10 times less, that is, with 0.1 mm. To determine the thickness, measurements are carried out on three sections of the product, between which a distance of 5-10 cm is maintained. To measure this value, a micrometer is used, as well as high-precision magnetic devices.

Welding and technological indicators are checked by creating branded products . On double-sided products, the likelihood of cracks in the seam is checked. The quality of the weld is checked for cracks using a 5x magnifying glass.

Crap. 3

1 — electrode coating; 2 — electrode rod

Damn.3

(400±10) °C - for the main coating; (180±10) °C - for acidic and rutile coatings; (110±5) °C - for cellulose coating. For other and mixed types of coatings, as well as for acidic and rutile coatings containing cellulose, the temperature is taken in accordance with the instructions of the standards or technical specifications for electrodes of the controlled brand. The moisture content in the coating () as a percentage is calculated with an error of 0.1% using the formula

,

where is the initial mass of the coating, g; — constant mass of the coating, g. The mass is determined by weighing with an error of 0.01 g. It is possible to determine the moisture content in the coating by other methods that provide the required accuracy. (Changed edition, Amendment No. 1).

5.6. The coating mass coefficient () in percent is calculated with an error of 0.1% using the formula

,

where is the mass of the coated part of the electrode, g; — mass of the rod of the same part of the electrode, g. The mass is determined by weighing with an error of 0.1 g.

5.7. When checking the welding and technological properties of electrodes intended for welding steels, one single-sided welded T-sample and one double-sided welded T-sample are made with the electrodes of the controlled batch. In cases established by standards or technical specifications for electrodes of a specific brand, instead of a one-sided welded T-type sample, a pipe welded butt sample is made. Notes:

1. On double-sided welded T-type samples, the tendency of the seams to form cracks is checked.

2. If the standard or technical specifications for electrodes of a controlled brand provide for a more stringent test to check the tendency of seams to form cracks, performing double-sided welded T-type samples is not mandatory.

3. In cases established by the standard or technical conditions for electrodes of a controlled brand, it is allowed not to make double-sided welded T-type samples, however, the manufacturer is obliged to ensure that there is no tendency to form cracks in the welds made by the electrodes of this batch, in accordance with the requirements of this standard. (Changed edition, Amendment No. 1, 2).

5.8. To produce welded samples when checking according to clause 5.7 of electrodes for welding carbon structural steels, plates made of steel grade St3sp in accordance with GOST 380 and pipes made of steel grade 20 in accordance with GOST 1050 should be used. If the electrodes are intended for welding both carbon and low-alloy structural steels, The steel grades of plates and pipes must correspond to those specified in the standard or technical specifications for electrodes of the controlled grade.

5.9. To make welded samples when checking electrodes for welding low-alloy, alloy and high-alloy steels according to clause 5.7, you should use plates and pipes made of steel for which electrodes of the controlled grade are intended for welding. If the electrodes are intended for welding several grades of steel or for welding steel from which rolled sheets and pipes are not made, the steel grades of the plates and pipes must correspond to those specified in the standard or technical specifications for the electrodes of the controlled grade.

It is allowed to replace plates made of low-alloy and alloy steels with plates made of steel grade St3sp according to GOST 380 and plates made of high-alloy steels with plates made of other steels of the same structural class, provided that the plates are pre-fabricated with controlled electrodes in at least three layers at the places where welds are applied and at adjacent to them in areas with a width of at least 25 mm with mechanical processing of the deposited surfaces. Note. Surfacing with electrodes of other batches of the same brand (including a different diameter) is allowed.

5.8, 5.9. (Changed edition, Amendment No. 1).

5.10. The shape and dimensions of welded T-type samples must correspond to those indicated in Figure 4 and Table 7.

Packaging, labeling, transportation and storage

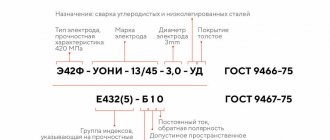

To determine the varieties and characteristics, the labeling should be analyzed. The packaging contains information about 9 main indicators of welding electrodes according to GOST:

- Type . The designation begins with the value “E”, which indicates the electrode, followed by numbers that show the permissible tensile force, followed by the index A, which describes the resistance of the seam to impact stresses.

- Brand . The parameter is regulated by the policy of the manufacturer.

- Diameter _ The thickness of the internal zone of the electrode is in the range of 1.6 – 12 mm. For domestic use, devices with a thickness of no more than 5 millimeters are used. Electrodes with a diameter of no more than 2 mm are common in enterprises involved in the production of small-sized devices.

- Purpose . According to this parameter, products are designated by letter values - U, L, T, V, N.

- Thickness _ The parameter is characterized by the ratio of the inner part of the rod to the size of the coating.

- Seam properties . The characteristic indicates the percentage of chemical elements of the alloy and the operating temperature of the weld. Detailed decoding can be seen in special tables.

- Type of welding current and connection method.

- A type of electronic coating.

- Location markings.

There are several types of electrodes. Correct decoding of the marking allows you to choose the most appropriate product for a specific task. Products are packaged in packs or boxes:

- sealed plastic cases;

- packages in wrapping paper placed in metal containers;

- boxes with a minimum cardboard thickness of 0.7 mm, wrapped in polyethylene;

- cardboard boxes with a thickness of more than 0.8 mm;

- packs with a sealed shell and wrapping paper;

- packaging made from two-layer special paper or a moisture-resistant analogue.

Deputy General Director of NPO Spetselektrod LLC Bystrov V.I.: “Transportation and storage conditions have a huge impact on the quality of electrodes. Therefore, several complete checks are carried out before dispatch. The boxes are placed in medium-sized containers, the loading must be carried out to the fullest extent, and shelves are installed between the tiers. Each tier cannot exceed 60 cm in height.”

Each batch is supported by a quality certificate. Electrodes are stored in rooms with minimal humidity and temperatures above 15 degrees.

Coverage options

The working qualities of the electrode and the features of its use are largely determined by the material of the flux coating. There are several options:

- Sour. Based on silicon and iron oxides, manganese oxide is used as an additive. A connection made using such a coating is prone to the formation of hot microcracks.

- Rutile. Based on titanium dioxide. Compared to the previous option, the likelihood of the formation of hot microcracks is significantly reduced. Allows you to obtain a more stable and powerful electric arc. Reduces melt spattering and associated metal losses. Improves the formation and uniformity of the seam, forms an easily removable slag crust, which reduces the labor intensity of subsequent cleaning operations.

- Basics. It is based on bases - fluorine compounds mixed with carbonates. According to the degree of deoxidation, it corresponds to calm type steels. The suture material acquires high ductility and impact strength, both at room and at low temperatures. The likelihood of hot microcracks appearing is also reduced.

Electrodes "Tien Shan" type E42

For any type of coating, the requirement for use only in dry form remains. If you try to use wet electrodes, manufacturers disclaim their warranty on the quality of the seam. The products are supplied in hermetically sealed boxes with cellophane; they should be printed immediately before starting work. If the electrodes do become wet, they must be dried and calcined in a muffle furnace.

Also, regardless of the coating option, it is necessary to carefully follow the technology and welding modes.