Application of chippers, wood crushers

Drum and disk crushers are used for processing substandard wood, large branches, organic waste and other waste generated during economic activities. The resulting fine-grained material is a valuable raw material and can be used in the production of fuel briquettes, particle boards, and building blocks. An additional advantage is the absence of the need for constant waste combustion, as well as the ability to work even in a limited space, for example, within a dense forest or woodworking workshop.

Working principle of wood chipper

The unit turns wood waste into chips or granules of the same size. By crushing, a suspension from 0.6 cm to larger pieces is obtained. Grinding produces granules smaller than 0.5 cm.

There are several principles by which grinding occurs:

- Bending and breaking of raw materials.

- Trituration.

- Grinding with a strong blow.

- Fixation of raw materials with shift.

- Compression with crushing.

- Splitting and grinding.

The processing process involves capturing wood with toothed shafts. It is transferred to the grinding chamber. Through outlet sleeves, the finished raw materials are placed into containers.

Disc crusher (chipper) for wood

The design of a wood disc crusher is relatively simple. Used for crushing branches, wood trunks with an average diameter of 16 to 25 cm, and slabs. For work, a single or double disk with a diameter of up to 100 cm made of steel is used. In different models, from 2 to 4 knives are installed in special pockets. Raw materials are supplied using manual or hydraulic feeding. When feeding manually, the raw materials fall directly under the knife. This type of machine is considered budgetary, but it has lower productivity compared to other types of crushers.

There are disc wood crushers either using a tractor power take-off shaft (the most affordable option) or with their own engine.

Description of the wood and log shredder, scope of application

When working with wood, waste always appears. Crushers are units that transform large pieces of wood into a fine mixture. The use of machines can increase labor productivity and reduce worker injuries.

Reference! Automation of raw material processing by the forestry industry has reduced the amount of waste disposal by 50%.

The tree shredder is used in production and gardening. It comes in several types:

- rotary;

- hammer;

- disk and cone;

- screw and roller;

- ball mill.

Installations can be mobile or stationary. Large amounts of waste are processed using powerful crushers. Utility farms can cope quite well with mobile units with low power.

The equipment will help grind wood waste after trimming branches, leftover building materials, and old furniture. The crushed raw materials are used for mulching or fertilizing beds.

You can use environmentally friendly types of wood for soil. Furniture waste contains harmful components. They cannot be used to fertilize plants.

Drum crushers for wood

They benefit in productivity compared to disk-type chippers. Accordingly, they require a larger engine. Drum crushers (chips) for wood can be powered by a diesel engine, a power take-off shaft, or an electric motor.

The retraction power unit is made in the form of a pair of drums with spikes. Feeding can be done manually or using a manipulator.

A more convenient scheme can also be implemented. The pressing drum with spikes is located on top, and the raw material is fed by a belt with spikes from below

Design Features

A variety of wood shredders allows you to choose the required type of installation. Design features depend on power, engine type, and working elements.

Table No. 1

| Type | Engine | Power, kWt) | Dimensions of raw materials for processing in mm |

| Household shredder | electric | 1,6 | up to 30 |

| Universal installation | petrol, electric | 2,6 | up to 40 |

| Professional unit | petrol | 8 | up to 75 |

The main indicator of equipment is its performance. These parameters depend on the power of the installation. The fuel the unit runs on determines the type of engine. Liquid fuel crushers are more powerful than electric crushers.

The industry produces plants with various crushing mechanisms. Processing of logs, trunks, and round waste is carried out using drum shredders. Several narrow knives are installed here in a checkerboard pattern, which chop the raw materials when feeding.

Disc units cope with large branches and pieces. The crushing mechanism consists of disc knives that are mounted on a shaft rotating on bearings.

Shredders crush wood waste containing metal components. They belong to the rotary type of crushing mechanism. There are single-rotor and double-rotor units. The first ones are low-speed for recycling large volumes of waste, the second ones can even process nails and staples.

Description and application of wood chipper

A wood chipper usually consists of a hopper with a collar, the chopper mechanism itself and an additional container for collecting wood parts . The tree branch is inserted into the hopper (the collar serves as a partial safety mechanism) and the chipping process begins. The chips exit through a chute and can be directed into a container on a truck or onto the ground. The typical yield is chips ranging in size from 2.5 cm to 5.1 cm.

Wood chips are medium-sized hard materials made by cutting or trimming large pieces of wood. Wood chips can be used as solid biomass fuel and are a raw material for the production of wood pulp. They can also be used as organic mulch:

- in gardening;

- in landscaping;

- restorative ecology;

- in bioreactors for denitrification;

- growing mushrooms.

According to the different chemical and mechanical properties of the masses, wood logs are mainly cleaned, and bark and wood chips are processed in different processes.

Machine structure

Most shredders rely on the power coming from a heavy flywheel to do their job (although some use drums). The grinding blades are mounted on the face of a flywheel, which is accelerated by an electric motor or internal combustion engine.

Large wood chippers often have grooves in the throat of their feed hoppers. As soon as the branch is caught by the rollers, the branch is transported to the blades at a constant speed. These rollers have a safety feature and are usually reversible for different situations.

Kinds

To produce wood chips, special equipment is used - knife and chipping machines. In woodchip production, chip uniformity has a major impact on quality.

A number of machines are capable of producing chips of excellent quality; you can choose such a machine by studying its technical characteristics.

Drum

The drum chipper has very high productivity, so it is often used in industrial enterprises. This type of shredder produces thin slices of wood, cutting them from a single piece of wood. The working tool of this machine is a rotating drum with several sharp knives.

The resulting chips are used for:

- obtaining pyrolysis gas;

- sprinkles for garden paths;

- heating;

- smoking;

- mulching the garden.

Disk

The disk machine is also highly productive and is common in large industries. But its operation is based on a different mechanism: tree trunks are fed at an angle onto a rotating disk, the knives of which gradually cut off small pieces of wood.

This type is used for the production of large chips suitable for the production of:

- OSB;

- heating;

- obtaining pyrolysis gas;

- smoking

Conical

The conical chipper is suitable for all types of wood, its versatility and high productivity are its main advantages. The working tool of the machine is a conical screw knife that cuts wood without breaking it.

Chip machine

The chips produced by such a unit are suitable for:

- pulp and paper production;

- preparing mulch;

- gardening work;

- heating.

Wood chipper

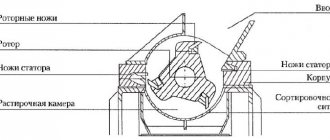

A chipper is a crusher that is used in semi-industrial production. The mechanism of operation of the chip cutter is close to the mechanism of a disk machine. The difference is that the wood chipper has a chamber with rotating hammers inside. There, additional grinding of wood chips takes place, which are screened by size through a chamber sieve.

This type of chips is used in:

- smoking;

- production of argolite blocks;

- making mulch;

- crushing plastic waste.

Garden wood shredders

Branches, bushes, and dried grass are collected at the dacha and garden plot. They need to be disposed of. A wood chipper can make your work easier. The advantages of the equipment are:

- Small dimensions.

- The finished raw materials can be used as fertilizer.

- Efficiency.

- Low energy or fuel consumption.

The choice of unit depends on the size of the site and the volume of work. Equipment for recycling wood waste is produced by manufacturers from different countries. One of the disadvantages is the high cost.

Russian industry produces shredders at affordable prices. If the installation is needed for seasonal use at a summer cottage, it can be rented.

Technical capabilities

The garden unit can be equipped with an electric or gasoline engine. Equipment that consumes electrical energy is silent in operation, light in weight, and small in size. But the need to have a power source on hand makes it not always convenient to use.

A gasoline shredder is more bulky and noisy during operation, but it can be used in any corner of the garden. It is more powerful than electrical equipment and processes a larger volume of wood.

Device types

Shredders using high-speed, low-torque grinding rollers are becoming increasingly popular for indoor use. These machines are driven by an electric motor and have a low noise level. Some of these machines are equipped with an anti-jam feature.

Disc shredders

The original design uses a steel disk with knives mounted on it as a grinding mechanism. This technology dates back to the invention of Heinrich Wigger , for which he received a patent in 1922. In this design, (usually) hydraulically driven reversible wheels pull material out of the hopper toward a disc that is mounted perpendicular to the incoming material.

As the disc rotates, the knives cut the material into chips. They eject the tray with flanges on the drum. This operating principle is not as energy efficient as the drum principle, but produces chips that are more uniform in shape and size. Most chippers currently used by commercial tree care companies are disc chippers.

Consumer disk machines typically have disk diameters ranging from 15 to 46 cm . Industrial crushers are available with discs up to 4.1 m in diameter, requiring 4 thousand to 5 thousand horsepower (3 thousand to 3700 kW). One of the applications of industrial disk cuttings is to obtain wood chips used in the production of chipboards.

Drum machines

Newer chippers use mechanisms consisting of a large steel drum driven by a motor, usually by a belt. The drum is mounted parallel to the hopper and rotates towards the output tray. The drum also serves as a feed mechanism, pulling out the material.

These types of shredders have many disadvantages and safety issues . If the operator somehow becomes entangled with the material being fed into the machine, the potential for injury or death is very high.

New models have overcome many of these shortcomings with Auto-Feed Plus, invented by Kurt Snyder. Auto's digitally controlled tachometer reverses the hydraulic feed wheels. The reversible feed system allows the newer, stylish drums to handle larger diameter materials.

Units for processing large diameter wood

There are much larger wood processing machines that can process material diameters greater than 180 cm and use:

- drums;

- disks;

- their combination.

The largest woodworking machines, often called "grinders", can handle material with a diameter of 240 cm or more , and also use carbide hammers to crush the wood instead of cutting it. These machines have power from 200 to 1 thousand horsepower. Some are so heavy that they need to be transported on semi-trailers. Smaller models can be towed by a medium-duty truck.

Although shredders vary greatly in size, type, and power, the blades that process wood are similar in design. They have a rectangular shape and a thickness of 3.8 cm to 5.1 cm. The blades are made of high quality steel and contain at least 8% chromium for hardness.

Requirements for wood chippers

To ensure that the installation meets the owner’s wishes, when choosing, you need to pay attention to the following parameters:

- power and performance level;

- degree of noise;

- operational purpose;

- equipment weight;

- design of working elements;

- dimensions of the opening for loading raw materials.

In a small area where professional tree shredders are not needed, a household installation is used. If areas where mature plants grow are being processed, then using a device with high power is justified.

Equipment size is related to power. The more powerful, the more cumbersome the unit will be.

The variety of types allows you to choose the installation. Taking into account all the parameters, you can find a unit for processing thin branches or thick logs into wood chips, sawdust or shavings.

By using a wood shredder, you will be able to avoid the loss of valuable raw materials needed for recycling in the form of paper, cardboard or furniture boards.