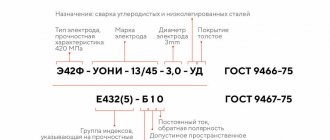

The marking of welding electrodes (SE) contains information such as type, brand, diameter and other technical characteristics.

LE3ANO-21

An example of marking and its interpretation: E46-LEZAHO-21-⌀-UD E4Z 1(Z)-RTs1Z, where

● Type. Products of this type are used to work with metal structures made of steels whose tensile strength is 46 kgf/mm2.

● Brand. The main purpose of LEZANO-21 is to create permanent connections during the installation of ordinary and critical metal structures in cases where increased requirements are placed on connections.

● Purpose of SE. The U index indicates that SEs can be used to work with structural elements made of steel with a maximum tensile strength of up to 588 MPa (60 KGS/MM2).

● Coating thickness coefficient. The letter D indicates a coating of increased thickness.

● Type of meltable coating. According to the accepted marking system, this type of coating is marked with the letter E.

● Tensile strength. Index 4З is equal to 4З0 MPa (4З KГС/MM2).

● Relative elongation. The number 1 indicates a value of 20%.

● Min.t, at which the impact strength of the connecting seams is not lower than 34 J/CM2 (3.5 KGS M/CM2). The number Z corresponds to t -20C.

● Type of coverage. Coatings based on rutile and cellulose are marked PC.

● Possible positions during welding work. Number 1 indicates the ability to work in any position, including ceiling, sub-ceiling, semi-horizontal, semi-vertical.

● Welding current. Code 3 indicates that welding of structural elements with direct current of any polarity or alternating current from energy sources with an open circuit voltage of 50±3V.

ANO-21

Decoding of marking E46-AHO-21-2,5-UD E 4З0(З)-P-11 is carried out in the following order:

● SE type. Electrodes of this type are designed to work with metal structures made of steel with a tensile strength of 46 KGS/MM2.

● Brand. ANO -21.

● Rod thickness. In this case, the specified diameter is 2.5 mm.

● Purpose. The Y marking means that the products are intended to work with steels whose tensile strength is 588 MPa (60 KGS/MM2).

● Coating thickness coefficient. Index D means that the electrodes have a thick coating.

● The presence of a melting coating is indicated by the letter E.

● Strength to tensile loads. Code 4З corresponds to 4З0 MPA (44 KГС/MM2).

● Relative elongation. The number 0 indicates a relative elongation of 20%.

● Min temperature at which the impact strength of the weld is not lower than 34 J/CM2 (3.5 KGS M/CM2). Code Z indicates t -20C.

● Coating material. Rutile is used as a type P coating for solar cells.

● Acceptable spatial positions. The number 1 is indicated in cases where welding work can be carried out in any position.

● Welding current and open circuit voltage. The next unit is indicated in cases where welding is performed with alternating or direct current with a voltage of 50V.

MP-3 PLA3MA

Example of marking E46-MP-3 PLA3MA-⌀-UD E 4З0(З)-P26 and interpretation.

● Type and brand. Electrodes of this brand are intended for arc welding of metal structures in any position in space, with the exception of vertical.

● Scope of application. Electrodes designated by code U are used to work with alloys that have tensile strength. up to 588 MPa (60 KGS/MM).

● Coating thickness. Thick coating is marked with code D.

● Type of coverage. In accordance with the international classification system, fusible coatings are designated by the index E.

● Tensile strength equal to 430 MPa (44 KGS/MM2), indicated by the digital code 43.

● A relative elongation of 20% is marked with the number 0.

● The minimum t values at which the strength of the connecting seam is maintained is -20C and is designated by the index Z.

● A coating containing 48% rutile, 25% feldspar, 10% liquid glass, 10-13% each of magnesite and ferromanganese is designated by the letter P.

● The method of applying a weld, other than vertical, is indicated by the number 2.

● The number 6 indicates that work should be carried out at a voltage of 70V.

UOHI-13/55

The marking E50A-UONI-1Z/55-Z,0-UD E514(4)-B20 is deciphered as follows:

● Type and brand. SEs of this category are used to work with carbon and low-alloy alloys, whose tensile strength is 50 KGS/MM2. The letter A denotes increased ductility and impact strength of the connecting seam.

● Diameter. The thickness of the rod is 3.0 mm.

● Scope of application. Electrodes marked with the letter U are used to create permanent connections during the installation of metal structures made of alloys with a tensile strength of 588.3 MPa (60 KGS/MM2).

● Thickness and characteristics of the coating. A thick non-melting coating is designated by the indices D and E.

● Mechanical properties. The combination of numbers 51 indicates a tensile strength of 510 MPa (52 KGS/MM2), and the number 4 indicates a relative elongation of the metal of 20%. The minimum temperature at which the weld metal retains the specified strength is indicated by the number 4, which corresponds to -30C.

● Type of coverage. The main type of coating is marked with the letter B.

● Position in space. The number 2 in the SE marking corresponds to any position other than vertical.

● Welding current. The number 0 indicates the possibility of carrying out work with direct current of reverse polarity.

TsL-11

Decoding of the marking code E-08X20H9G2B-TsL-⌀-BD E-2005-B20:

● Type and brand. This type of electrodes is designed to work with parts and structures made of high-alloy steels.

● Scope of application. The index B denotes SEs used to connect elements of metal structures made of alloys with special properties.

● Coating characteristics. A thick coating of a melting type is marked DE.

● Methods for testing the resistance of connecting weld metal to intercrystalline corrosion. AM and AMU methods are designated by the number 2.

● The amount of fine delta ferrite in the weld metal. The number 5 corresponds to the ferrite phase content from 2% to 10%.

● Type of coverage. Marking B indicates that a base coat is being used.

● Welding current. The number 0 indicates that welding work is carried out with direct current of reverse polarity.

Type

To work with high-strength and high-strength steels, markings are drawn up as follows:

● product name;

● subsequent numbers indicate the tensile strength;

● Code A means that the weld alloy has improved mechanical properties.

For products used to work with heat-resistant and high-alloy alloys, the marking code is as follows:

● product name;

● C content in hundredths of a percent;

● content of chemical components in percentage.

If the content of a substance does not exceed 1.5%, then it is not indicated

Table. Designation of metals.

| Nitrogen | A |

| Cobalt | K |

| Silicon | C |

| Niobium | B |

| Molybdenum | M |

| Titanium | T |

| Tungsten | B |

| Nickel | H |

| Vanadium | F |

| Manganese | G |

| Phosphorus | P |

| Chromium | X |

| Copper | D |

| Bor | P |

| Zirconium | C |

general information

What are they for? MP3 electrodes are used for welding parts made of alloys with a carbon content of up to 0.25% . They can work in the most difficult conditions, with high humidity of workpieces and even in the presence of rust. This property is especially useful when performing repair work on pipelines.

Cooking is allowed in all welding positions except vertical. Welding can be done both with close contact of parts and with some gap between them. In this case, the value of the welding current should be reduced to avoid the appearance of cracks.

What makes them different: easy ignition of the electric arc and high stability of its combustion. The splashing of melt droplets from the weld pool is minimized. The composition of the coating is selected in such a way that during welding it releases few toxic substances. The resulting slag crust can be easily separated from the weld material during cleaning.

inverters can be used as a source of operating current . They must provide a voltage of 50 volts or higher. Electrodes for welding carbon alloys MP 3 are suitable for operation with both alternating and direct current. They allow you to weld workpieces of various thicknesses.

When the edges are cut correctly, they provide high-quality deep penetration. Particular attention should be paid to the correct selection of the operating welding current. It depends both on the diameter of the electrode and on the welding position. Excessive current will not allow you to take full advantage of the product's benefits.

To obtain a strong and durable seam, the electrodes themselves must be properly dried and calcined.

Advantages and disadvantages

The advantages of MP-3 electrodes include:

- rapid formation of a stable arc;

- smooth, reliable seam;

- high connection strength;

- safety, no release of harmful substances;

- easy removal of slag;

- small range of metal spattering;

- high productivity;

- ease of operation.

Disadvantages include high price and intensive consumption of welding material.

Storage conditions and calcination

Model MP-3 electrodes must be stored under certain conditions. The room must be heated with a temperature T>15℃ and air humidity not exceeding 40%. Packages with these products should be placed on pallets or racks. This will prevent unwanted contact with load-bearing walls and floors.

When welding work is carried out in an open space, measures must be taken to prevent precipitation from entering the boxes with electrodes. Excessive inventories of these products should not be created. They should be enough for no more than 2 days of work. And it is necessary to replenish reserves as electrodes are consumed.

Subject to the above conditions, there is no need to ignite these products before use. In this case, the rutile coating does not lose its excellent performance characteristics. But if the MP-3 electrodes did come into contact with moisture, they must be calcined at a temperature of 100℃≤T≤150℃ for one to two hours.

Features of use

When working with MP 3, it is permissible to use both alternating and direct current . The welding source must provide an open circuit voltage of 50 volts. When operating with direct current, the connection polarity is reversed. In this case, the positive contact is connected to the holder, and the negative contact to the workpiece.

Electrodes have the following advantages:

- easy ignition and stable combustion of the electric arc;

- making a durable, well-welded seam with specified geometric parameters;

- Spattering of melt droplets is minimized;

- the fragile slag crust that forms above the suture material is easily and quickly removed during stripping;

- facilitated re-ignition of the electric arc after a break in the conduction of the electrode;

- high welding productivity.

Despite the fact that the product is optimized for difficult working conditions, in no case should you neglect the preparation of the seam area for connection. The better the workpiece is cleaned and degreased, the stronger and more durable the seam will be .

The suture material has an impact strength of 80 J/cm2, allows bending up to 150°, and the relative elongation is 18%.

The weld material has physical and mechanical parameters close to the characteristics of the metal of the part itself. Therefore, the seam does not create additional mechanical stresses that weaken the entire structure and reduce its strength and reliability.

Features of electrodes of the MP-3 and MP-3c brands

Products of both brands provide the ability to weld with short tacks, as well as perform it with a long arc. Due to their technical characteristics, there is no need for preliminary preparation of the metal to be welded. On its surface the presence of:

- traces of corrosion;

- oxide residues;

- slight dirt;

- moisture.

Electrodes of the MP-3 and MP-3c brands can be used if it is necessary to perform welding work along an existing gap. The amount of current during their course should be as minimal as possible, otherwise pores will begin to form in the seam being created.

In addition to these electrodes, consumables of the MP-3m brand are actively used today. They differ in the type of coating: they have rutile-ilmenite. MP-3c electrodes contain a coating saturated with additional ionizing impurities. The characteristics of electrodes of all three brands - MP-3, MP-3m and MP-3c - are largely similar and almost completely identical.

The coating of the latest products ensures easy ignition of the welding arc. This feature makes it possible to use low-power current sources for operation. MP-3c electrodes are more environmentally friendly. When they are welded, harmful substances are released into the environment in a volume that is smaller compared to MP-3 (MP-3 has 1.25 grams of manganese, and MP-3c has 2 times less - 0.6 grams). But the most compelling argument in favor of choosing the latter electrodes is the possibility of obtaining a better-quality weld. As a result, the formed connection will have better performance properties.

How are they different from MP-3?

Electrodes MP 3 and MP 3C are very similar. Their composition and characteristics are almost identical, with the exception of one feature. The MP 3C brand contains a number of additives, thanks to which the arc is easier to ignite and burns more stably when using a low-power household welding inverter. Also, this brand emits much less manganese during operation than MP 3. The seams are more uniform and easier to form.

From this we can conclude that the MP 3C brand is more likely intended for amateur welding at home, and MP 3 is more universal. They can be used both at home and in professional activities.

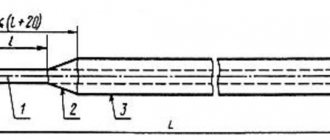

Description of electrodes

A welding electrode is a rod made of various metals and coated with a special coating. The composition of the rod, as well as the coating, will depend on their purpose. Some may be for steel, others for softer metal. For example, there are electrodes for cast iron and copper.

Rods for electric welding can differ not only in composition, but also in diameter. Typically, electrodes with a diameter of 3-4 are used for welding work. But there are cases where a rod with a thicker diameter may be required and vice versa.

There are also types that are not intended for welding parts, but, on the contrary, for cutting them. However, such electrodes require special machines and electrode holders.

Due to the fact that there are a large number of metals and alloys, there are many types of electrodes. The most common ones are:

- SSSI.

- TsU-5.

- MR-3 and MR-3S (E46).

SSSIs are one of the most versatile types. They have a good and durable alloy, which gives strength to the parts. However, they are best used by people who have good knowledge of electric welding.

TsU-5 welds parts perfectly. However, due to their cost and rapid combustion, they are used in rare and especially important cases . For example, such rods are used to weld the root of a pipe under pressure.

MP-3 and MP-3S have more practical rods. They do not have an increased tensile or fracture load, however, they are well suited for simple types of electric welding.

Decent analogues in comparison

In addition to MP-3 electrodes, modifications such as ANO and UONI are popular among welders. They are often compared with each other to choose the best option, but this is not entirely correct. These rods differ not only in coating, but also in structure. The main difference lies in the composition and method of coating.

SSSI electrodes

Unlike the MP-3 brand, UONI rods have a base coating rather than rutile. They are designed to operate from DC devices with reverse polarity. Before welding the SSSI, the surface must be thoroughly cleaned. Spraying is also sensitive to moisture.

Brief characteristics of this brand:

- surfacing coefficient - 9.5 g/Ah;

- consumption per 1 kg of metal - 1.7 kg;

- productivity - 1.4 kg/h;

- safety factor - 540 MPa;

- fluidity - up to 420 MPa;

- relative elongation - up to 22%.

ANO electrodes

ANO rods are distinguished by the variety of rods and specific parameters. It is inappropriate to compare them directly with the MP-3 brand. This is due to the fact that these elements are designed for welding metal up to 4 mm and are not suitable where MR modifications are needed.

Short description:

| Diameter, mm | Length, mm | Package capacity 1 kg (pcs.) | Limit operating current, A |

| 2,0 | 300 | 95 | 100 |

| 3,0 | 350 | 40 | 140 |

| 4,0 | 350 | 40 | 180 |

Colors: blue, red (brown), green

The color of the electrodes depends on the type of coating. MP-3 rods most often have a rutile coating, which is sometimes red in color. It is also important to know that the shade depends on the manufacturer . Thus, welders have the opportunity to buy electrodes with green, blue, and gray coating colors.

Features of MP-3 brand products

Electrodes of the MP-3 brand have the following technological characteristics:

- easy ignition of the welding arc. It is characterized by stable combustion;

- forming a weld seam is not particularly difficult even for a novice welder;

- the degree of spattering of molten metal is minimal;

- the crust of frozen slag on the surface of the created seam is easily separated;

- re-ignition of the electric arc does not cause difficulties;

- high level of productivity of work related to welding, without compromising the quality of the formed seam.

Setting the welding current requires a special approach. The value of this parameter (designation Ist.) is determined by two factors: the spatial location of the seam being formed and the diameter of the electrode (designation De.). So, for products with

- De.= 6.0 mm at a current varying within 300.0 A≤Ist.≤360.0 A, exclusively lower seams are performed;

- De.= 5.0 mm: the lower seams are formed at a current of 180.0 A≤Ist.≤260 A; vertical seams at current 160.0 A≤Ist.≤200.0 A;

- De.= 4.0 mm: the formation of ceiling seams is carried out at a current of 140.0 A≤Ist.≤180.0 A; lower ones - at a current of 160.0 A≤Ist.≤220.0 A; vertical seams - 140.0 A≤Ist.≤180.0 A;

- De.= 3.0 mm: ceiling seams are made at a current of 100.0 A≤Ist.≤120.0 A; bottom seams at current 100.0 A≤Ist.≤140.0 A; vertical - 90.0 A≤Ist.≤110.0 A;

Important characteristics of electrodes include their total weight required to deposit a certain volume of metal in the weld being formed. For example, for products with a diameter of D = 4.0 mm of the MP-3 brand, these figures look like this: to surfacing 1 kilogram of metal, 1.7 kilograms of such electrodes are required. The work productivity is ensured at the level of 1.7 kilograms per hour with a deposition rate of 8.50 grams/Ah. You should know that the deposition rate is usually less than this indicator of the electrode melting process. This phenomenon is caused by metal loss during welding work.

Specifications

The technical conditions for the production of MP 3 are regulated by GOST 9466 and 9467. These documents also contain a description of the procedure for quality control and acceptance testing and the applicability of the product.

MP-3 belongs to the group of welding materials E46 . They are recommended for joining low-alloy, carbon and structural alloys whose mechanical tensile strength is less than 50 kgf/mm2. The thickness of the parts can range from 3 to 20 mm.

The tensile strength of the seam material should be 46 kgf/mm2. The deposition rate of the welded joint is determined to be 8.5 g/A*h. Surfacing productivity is approximately 1.7 kg per hour. To obtain 1 kg of deposited material, up to 1.7 kg of electrodes are required.

To weld metal structures of large thickness in the lower welding position, the electrode should be tilted in the direction of movement of the holder . Welding with high currents requires special attention from the welder and strict adherence to technological instructions, since in these modes there is a high risk of porosity in the suture material and other weld defects.

The products are packaged in boxes with the following parameters (for a length of 30 cm):

| Diameter, mm | Weight of one electrode, g | Quantity in box, pcs. | Box weight, kg |

| 3 | 30 | 83 | 2,5 |

| 4 | 60 | 41 | 2,5 |

| 5 | 92 | 54 | 5,0 |

For a length of 45 cm, the weight is one and a half times more.

Products should be stored in a dry, warm warehouse; the temperature should not fall below +15°C . Storage conditions must exclude the possibility of damage to the packaging and moistening of the rods.

It is unacceptable to use moistened products for welding; they must be calcined in a special cabinet or muffle furnace at a temperature of 170 ° C for at least one hour.

GOST and other requirements

Electrodes of the MP-3 brand are produced in accordance with the requirements of state standards (GOST 9467/9466). According to the standards, the filler material of the consumable welding element is classified as type E46. Similar rods are used when welding low-alloy low-carbon steels with a carbon content of 0.25%.

Powdered rutile concentrate is applied to a metal core. The active substance is titanium dioxide. The coating consists of a carbonate or aluminosilicate mixture, which increases the viscosity of the workpiece. This reduces the occurrence of cracks and deformations in the resulting seam.

The electrode core material is low-carbon wire of the Sv-08 configuration, manufactured by cold rolling. The diameter of the product is from 2 to 6 mm. The thickness of the welded workpieces is 3-20 mm. Temporary mechanical tensile strength reaches 500 MPa.

Manufacturers and brands

Buyers have the opportunity to purchase MP-3 electrodes of various brands, Russian and foreign manufacturers. When purchasing, you should choose rods from proven and reliable companies. Large companies that value their reputation produce high-quality rods that have the appropriate certificates, passports and other documents.

The greatest attention should be paid to the following class=”aligncenter” width=”644″ height=”362″[/img]

- LEZ (Losinoostrovsky Electrode Plant);

- Resanta;

- HOBEX;

- SZSM;

- Lincoln Electric (Lincoln);

- Spetselectrode (Moscow);

- ESAB (Esab);

- Tantalum;

- Arsenal (Ars);

- Prestige;

- Luxury;

- Premium

Flaws

- The connection obtained by welding is characterized by high strength.

- The arc is distinguished by easy ignition and combustion stability, especially at low current strength.

- Re-ignition is achieved without difficulty.

- The resulting seam has no joints, it is even and has a good presentation.

- There are no pronounced transition zones between the weld metal and the part.

- Thanks to the rutile type of coating, the seam is reliably protected from slag and oxidation.

- The electrode is characterized by very little metal spattering.

- The work is characterized by high productivity.

- MP-3 is equally suitable for both welding and tack welding.

There are relatively few disadvantages to electrodes of this brand, and some of them are quite conventional.

- Relatively high price - the cost of this consumable is slightly higher than many other electrodes.

- The impossibility of welding vertically from top to bottom - however, many other brands cannot “boast” of this.

- Not the lowest material consumption - 1.7 kg per 1 kg of seam (MR-3R has slightly less - 1.62 kg).

- During the welding process, the electrode must be held at an acute angle relative to the surface being made. If you weld at a right angle, a large amount of slag will inevitably be released, which will penetrate into the seam.

- It is extremely important to set the required current strength - otherwise there is a risk of pores forming in the weld metal.

And one more feature - intermittent sutures must be applied quickly enough, which requires certain skills. However, even beginners can master this technique in a short time, without much experience or special education.