The hydraulic cylinder is a fundamental hydraulic component. It is used as a hydraulic drive that converts the energy of the working fluid into useful work. The incoming hydraulic fluid under pressure acts on the surface of the piston of the hydraulic cylinder. This causes translational movement of the piston and, thus, the piston connected to the hydraulic cylinder rod creates the required load. The hydraulic cylinder uses hydraulic mineral oil, synthetic oil or emulsions and in certain cases water is used. Hydraulic cylinders basically consist of two elements: a body and a rod with a piston attached to it. The hydraulic cylinder sleeve is equipped with a bottom on one side and a ground bush on the other. The rod exits through a hole equipped with a wiper in the ground bushing. A piston equipped with seals and sliding rings connected to a rod “divides” the internal volume of the hydraulic cylinder liner into two areas. When hydraulic fluid is supplied to the piston area of the hydraulic cylinder, pressure is created and, with the help of the piston, the rod moves in a linear direction. If you perform the opposite action and supply working fluid to the rod cavity of the hydraulic cylinder, the rod also moves linearly, but in the opposite direction. This type of hydraulic cylinder is called double acting and is the most common of hydraulic cylinders.

Hydraulic cylinders are used in the nuclear industry, metallurgical equipment, general mechanical engineering, shipbuilding, mobile equipment, oil production equipment, chemical industry, mining equipment, construction and road equipment, lifting and earth-moving machines, aviation, turbine construction. The industrial equipment plant manufactures and sells hydraulic cylinders according to customer drawings, the markings selected below or the completed QUESTIONNAIRE . According to the technical characteristics, the hydraulic cylinder is equipped with a rod with a stroke of up to 5000 mm (5 meters) and reaches a diameter of 160 mm, with a piston up to 250 mm in diameter. The working pressure of the produced hydraulic cylinder does not exceed 700 Atm. (70 MPa). The basic parameter of a hydraulic cylinder is fastening - it is carried out according to certain standards or according to technical requirements specified by the customer. The hydraulic cylinder body is made both in a welded cylindrical structure and in a version with tie rods. The industrial equipment plant produces hydraulic cylinders according to the customer’s drawings or sketches, or develops and manufactures hydraulic cylinders compiled according to the structural designation drawn up by the customer or with the help of the company’s technical specialists.

GC .1 – 100 – 80 – 200 – 20 – 04 / X 2 / D – A1 / A2. A

Designation of the hydraulic cylinder type and its operating principle:

GC - (general purpose hydraulic cylinder)

GT - (telescopic hydraulic cylinder)

.1 — double-acting piston hydraulic cylinder with one-sided rod;

.2 — double-acting piston hydraulic cylinders with a double-sided rod;

.3 — single-acting piston hydraulic cylinders;

.4 — plunger hydraulic cylinder;

100 – designation of the diameter of the piston (plunger) of the hydraulic cylinder from 40 mm to 250 mm

80 – designation of the diameter of the hydraulic cylinder rod from 25 mm to 160 mm

200 – designation of the hydraulic cylinder rod stroke from 10 mm to 5000 mm

20 – nominal (working) pressure of the hydraulic cylinder from 10 MPa to 70 MPa

04 / X 2 / D – type of hydraulic cylinder

A1 – placement of the front boom (fluid supply to the rod end) on the hydraulic cylinder

A2 - placement of the rear boom (supplying fluid to the piston cavity) on the hydraulic cylinder

X – additional options

. D — presence of damping;

. A - made of light alloy materials;

. T – presence of inhibition

. UHL - Climatic modification and placement category according to GOST 15150

The manufacturing process of hydraulic cylinders.

Specifications

The effectiveness of their use in a particular area and the service life during which the units can be used effectively depend on the parameters and characteristics of hydraulic cylinders. In order to quickly select a replacement part in case of repair, you need to understand the structure of the hydraulic cylinder and have an idea of its main operating parameters. These are the parameters:

- Rod diameter. The scope of use depends on it: products of different diameters are installed in different mechanisms. The specific diameter of the rod is selected when calculating the load on the mechanisms and the load-carrying capacity of the device. If these calculations are carried out correctly, then the rod will not deform during operation. The rod diameter is no more than 500 mm;

- The diameter of a cylindrical rod - a device with which the pushing and pulling force is determined;

- Characteristics of the stroke of a cylindrical rod. The dimensions of the mechanism in working condition and the characteristics of the piston movement depend on them. Maximum stroke value – 10,000 mm;

- Design features that determine the methods of fastening the hydraulic cylinder and calculating the load on the fastener;

- Pulling and pushing force on the rod (in kilograms);

- Nominal pressure (in megapascals);

- Distance on centers (in non-operating condition). Thanks to this, it is possible to effectively calculate the connecting dimensions;

- Weight, length and width of the product itself.

- Ambient temperature during hydraulic cylinder operation. The minimum is minus 40 degrees Celsius, the maximum is +40.

The manufacturing process of hydraulic cylinders.

For the production of hydraulic cylinders, at the first stage, the drawings are agreed upon with the customer.

The hydraulic cylinders of the Industrial Equipment Plant use rod rings, wipers, piston seals and support rings from global manufacturers such as Simrit, Forsheda Polipac, Merkel, Busak Shamban, Hallite, which will increase the service life of the hydraulic cylinder at least twice, due to increased wear resistance and increased strength, but at the customer’s request, hydraulic cylinders are equipped with sealing elements made in Russia or from another manufacturer of rubber products. After approval of the hydraulic cylinder drawings, metal parts and blanks are processed on machines and CNC machine centers, depending on the complexity of manufacturing the hydraulic cylinder. Next, the hydraulic cylinder enters the assembly point. The rod with the piston with installed sealing connections is placed in the sleeve, after which the rear and front covers of the hydraulic cylinder are welded or connected with tie rods. After assembly, the manufactured hydraulic cylinder is tested in accordance with GOST standards. The hydraulic cylinder enters the painting booth after the above steps. Special primers are applied to the hydraulic cylinder and, after drying, painted in at least two layers. YOU CAN FIND OUT THE PRICE, ORDER, PURCHASE AND BUY A HYDRAULIC CYLINDER BY CLICKING ON LINK E

Components

Hydraulic cylinder components

The hydraulic cylinder consists of the following parts:

- Stock

- Piston

- Sleeve (is the body)

- Piston seals

- Books

- Back cover

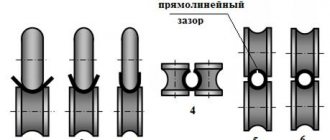

The chambers in the hydraulic cylinder must be sealed. To achieve this goal, special seals are installed on the piston - cuffs that prevent fluid from flowing through the piston. Also, the cuffs are placed on the axle box, here they act as seals. The axle box is also equipped with a wiper to prevent particles from the external environment of the device from getting into the inside of the cylinder.

Important: The seals on the piston do not work if there are roughness and scratches inside the liner. The inside of the liner is ground by special machines at the factory to achieve a relatively perfectly smooth state.

FEATURES OF POWER HYDRAULIC CYLINDERS

Let us note the features characteristic of power hydraulic cylinders

1) hydraulic cylinders are capable of functioning as a hydraulic motor and as a hydraulic pump;

2) high tightness of the device;

3) and efficiency close to 100%;

4) smooth stroke of the rod;

5) low noise level;

6) long service life;

7) high operational reliability.

Currently, a number of manufacturers are offering new approaches to the production of cylinders.

The new process produces cylinders from seamless, cold-drawn, honed or polished tubing and chrome-plated rods with final-machined running surfaces, which opens the door to high-quality, custom-designed cylinders with minimal labor costs. Apparently, this is the only example in drive technology. In any case, the facts of similar design of electric motors are unknown.

Where are they used?

Hydraulic cylinder for turning the bucket of the 702EM backhoe loader

In devices that have hydraulic motors in their design, operate under heavy loads and require increased functionality. These are, for example, construction and repair, road and earth-moving equipment, cleaning units. Modern cranes and dump trucks, bulldozers and heavy-duty vehicles cannot be imagined without hydraulic cylinders. In addition, they are used in production: they are equipped with machines that cut metal, forging units, and presses.

Hydraulic cylinders

Hydraulic cylinders are an important component in the field of hydraulics, a specialized form of power transmission that takes the energy transferred by moving fluids under pressure and converts it into mechanical energy.

Energy transfer, as a general term, refers to the process of using technology to convert energy into practical, usable forms. In the category of power transmission, hydraulics falls into the subcategory of hydraulic power, which depends on moving fluids (both gases and liquids) to produce energy.

History of hydraulic drive and cylinders

The history of hydraulic cylinders is inextricably linked with the history of hydropower as a whole. From a technical point of view, hydraulics can be traced back to ancient times, when the power of moving water was used for various purposes. The main use of hydraulics was to use moving water to move wheels. Ancient Rome used such hydraulics to operate mills producing a wide variety of products (e.g. flour, wood, etc.).

The history of modern hydraulics dates back to 1648, when French scientist Blaise Pascal discovered that pressure in a confined fluid must remain constant and act equally in all directions. However, this theoretical principle (known as "Pascal's Law" or "Pascal's Principle") did not find practical application until the next century.

In 1738, Daniel Bernoulli built on the work of Pascal, describing the behavior of fluids under various conditions of flow and height (Bernoulli's principle) and using his ideas to work with pumps and mills. In 1795, Englishman Joseph Bramah patented the first practical hydraulic machine: a hydraulic press.

Nearly half a century later (1840), William Armstrong developed more efficient applications of hydraulic power than water mills, including the hydraulically driven crane. Together,

Cylinders played a fundamental role in the work of Brahma and Armstrong. Brahma's practical breakthrough came when he discovered how to drive the moving plate of his press through the flow of fluid between the smaller and larger cylinders.

Hydraulic cylinder parts

The hydraulic cylinder contains some of the most important mechanical components of the hydraulic system. Despite their impressive role in converting kinetic energy into mechanical energy, basic hydraulic cylinders are relatively simple devices. The main components of hydraulic cylinders are included in the following list:

Types of hydraulic cylinders

How does hydraulic power work?

The essence of hydraulics is that liquids are incompressible (unlike gases). Thanks to this fact and Pascal's principle, a force applied at one point in a confined fluid can be effectively transferred to another point in that fluid and used to drive various mechanisms.

How do hydraulic cylinders work?

"Pascal's Law" applies to confined liquids. Thus, for a fluid to act hydraulically, it must operate within some type of closed system.

A closed mechanical system that uses fluid hydraulically is known as a hydraulic power unit or hydraulic power unit. These units consist of a reservoir (to store unused hydraulic fluid), a pump (to supply fluid to the rest of the hydraulic system), various types of tubing (to transport hydraulic fluid), and actuators (devices). which actually convert the energy produced by the flow of hydraulic fluid into mechanical energy.)

Hydraulic cylinders form the basic type of hydraulic drive . The other main type of drive is a hydraulic motor. The main difference between hydraulic cylinders and hydraulic motors is that hydraulic cylinders primarily produce linear mechanical motion, whereas hydraulic motors primarily produce rotary mechanical motion.

Although a hydraulic power unit is generally designed to harness the energy of fluid transmission, the cylinders are the part of the unit where the energy conversion actually occurs. Inside the cylinder (or cylinders, of which there are sometimes several) there is a gear train and two valves next to the piston.

There is an inlet check valve at one end and an outlet check valve at the opposite end. (As with the cylinder, some systems have only one piston or gear, while others have several.)

A hydraulic system requires pipes and a pressure vessel (or hydraulic pump) to store and transport fluid. When pressurized hydraulic fluid is introduced into the vessel, it pushes against the piston and engages the rod attached to it.

When the pump is running, the piston is retracted. This creates a vacuum that draws hydraulic fluid from the reservoir through the hose and intake valve and finally into the cylinder. When the piston returns to its original position and the check valve closes, the fluid is under pressure.

This pumping action is repeated at variable speeds until sufficient pressure is built up in the cylinder to force the fluid through the release valve. This creates the energy needed to operate the attachment and move the intended load.

The direction is determined by which side the piston meets the pressurized fluid. The fluid above the piston retracts the rod, and the fluid below it causes it to expand. Injecting varying amounts of pressurized hydraulic fluid at both ends controls the movement of the piston, rod, and attached load.

Application of hydraulic cylinders

Hydraulic systems and their uses are widely used in a wide variety of applications, including construction, agricultural, industrial, transportation (e.g., automotive, aerospace), various marine work environments, etc.

Hydraulic cylinders are extremely versatile, allowing them to be used in various industries.

As industries continue to grow, so do the required capabilities of hydraulic cylinders, industrial equipment and the machines they are part of.

Maintenance of hydraulic cylinders

Although hydraulic systems are simpler than electrical or mechanical systems, they are still complex systems that should only be handled with care. It is especially important for hydraulic cylinders that they are used for their intended purpose, such as linear pushing or pulling operations.

Generally speaking, it is unwise to make extensive use of hydraulic cylinders in situations involving bending movements and lateral pressure. Even when equipped with appropriate accessories that provide more than just linear motion (such as a fork), best practice involves using a hydraulic cylinder for non-linear motion only in selected cases.

It was previously emphasized that hydraulic cylinders must be made of durable materials due to the heavy loads to which they are subjected. However, even cylinders such as stainless steel hydraulic cylinders can corrode or fail over time.

Features of the production of hydraulic cylinders

Although hydraulic power transmission is extremely useful in a wide range of professional applications, it is generally never a good idea to rely on one form of power transmission.

Each type of power transmission (electrical, mechanical and hydraulic) works best when it is integrated into an overall power transmission strategy.

When it comes to hydraulic cylinders, it is important to note that all cylinder components must be made of durable materials that can withstand the friction and heat generated when using a hydraulic cylinder.

The above components must also be compatible with the hydraulic fluid, which is usually a composite material based on minerals, oils, ether or water. However, selecting the right hydraulic cylinder for a specific application requires more than just manufacturing technology, body material and fluid.

Additional considerations include, but are not limited to, maximum operating pressure, stroke, bore size, and rod diameter. Because the work force produced by pressurized hydraulics can vary significantly, it is important to understand the system requirements before choosing a specific model.