HOT-ROLLED STEEL FOR REINFORCEMENT OF REINFORCED CONCRETE STRUCTURES

Specifications

GOST 5781-82

II . PERIODIC PROFILES

STATE STANDARD OF THE UNION OF THE SSR

[td] STEEL FOR REINFORCEMENT OF REINFORCED CONCRETE STRUCTURES Technical conditions Hot-rolled steel for reinforcement of ferroconcrete structures. Specifications

| GOST 5781-82 |

Valid from 07/01/83 to 07/01/94

This standard applies to hot-rolled round steel of smooth and periodic profiles intended for the reinforcement of ordinary and prestressed reinforced concrete structures (reinforcing steel).

Regarding the standards for the chemical composition of low-alloy steels, the standard also applies to ingots, blooms and billets.

(Changed edition, Amendment No. 4).

CLASSIFICATION AND ASSORTMENT

1.1. Depending on the mechanical properties, reinforcing steel is divided into classes AI (A240), A-II (A300), A-III (A400), A-IV (A600), AV (A800), A-VI (A1000).

1.2. Reinforcing steel is manufactured in bars or coils. Reinforcing steel of class AI (A240) is made smooth, classes A-II (A300), A-III (A400), A-IV (A600), AV (A800) and A-VI (A1000) - periodic profile.

At the request of the consumer, steel of classes A-II (A300), A-III (A400), A-IV (A600) and AV (A1000) is made smooth.

1.1, 1.2. (Changed edition, Amendment No. 5).

1.3. Profile numbers, cross-sectional areas, weight of 1 m length of reinforcing steel of smooth and periodic profiles, as well as maximum mass deviations for periodic profiles must correspond to those indicated in the table. 1.

1.4. The nominal diameters of periodic profiles must correspond to the nominal diameters of smooth profiles of equal cross-sectional area.

Table 1

6[/td]

| Profile number (nominal rod diameter dн) | Cross-sectional area of the rod, cm2 | Weight of 1 m profile | |

| Theoretical, kg | Limit deviations, % | ||

| 0,283 | 0,222 | +9,0 -7,0 | |

| 8 | 0,503 | 0,395 | |

| 10 | 0785 | 0,617 | +5,0 -6,0 |

| 12 | 1,131 | 0,888 | |

| 14 | 1,540 | 1,210 | |

| 16 | 2,010 | 1,580 | +3,0 -5,0 |

| 18 | 2,540 | 2,000 | |

| 20 | 3,140 | 2,470 | |

| 22 | 3,800 | 2,980 | |

| 25 | 4,910 | 3,850 | |

| 28 | 6,160 | 4,830 | |

| 32 | 8,010 | 6,310 | +3,0 -4,0 |

| 36 | 10,180 | 7,990 | |

| 40 | 12,570 | 9,870 | |

| 45 | 15,000 | 12,480 | |

| 50 | 19,630 | 15,410 | +2,0 -4,0 |

| 55 | 23,760 | 18,650 | |

| 60 | 28,270 | 22,190 | |

| 70 | 38,480 | 30,210 | |

| 80 | 50,270 | 39,460 | |

(Changed edition, Amendment No. 3).

1.5. The weight of 1 m of profile is calculated based on the nominal dimensions with a steel density of 7.85 × 103 kg/m3. The probability of providing a mass of 1 m must be at least 0.9.

(Changed edition, Amendment No. 3).

1.6. The maximum deviations of the diameter of smooth profiles must comply with GOST 2590-88 for normal rolling accuracy.

1.7. Periodic profile reinforcing steel is a round profile with two longitudinal ribs and transverse projections running along a three-lead helix. For profiles with a diameter of 6 mm, protrusions running along a single-start helical line are allowed, with a diameter of 8 mm - along a double-start helical line.

1.8. Reinforcing steel of class A-II (A300), manufactured in a conventional design, with a profile shown in Fig. 1 a, and special purpose (Ac-II) (Ac300) profile shown in Fig. 2a, must have protrusions running along helical lines with the same approach on both sides of the profile.

Steel class A-III (A400), manufactured with the profile shown in Fig. 1b, and classes A-IV (A600), AV (A800), A-VI (A1000) with the profile shown in Fig. 1b, 2b, should have protrusions along helical lines that have right-hand entries on one side of the profile and left-hand entries on the other.

Crap. 1

Crap. 2

Reinforcing steel for special purposes of class Ac-II (Ac300) is made with profiles shown in Fig. 1a or 2a.

The profile shown in Fig. 2a, for special purposes is manufactured by agreement between the manufacturer and the consumer. The shape and dimensions of the profiles shown in Fig. 2a and b may be specified.

1.9. Dimensions and maximum deviations in dimensions of reinforcing steel of periodic profile, manufactured according to drawing. 1a and b must correspond to those given in table. 2, but damn. 2a and b - given in table. 3.

table 2

Dimensions, mm

| Profile number (nominal diameter dн) | d | h | d1 | h1 | t | b | b 1 | r | ||

| Nom. | Prev. off | Nom. | Prev. off | |||||||

| 6 | 5,75 | 0,5 | ±0,25 | 6,75 | 0,5 | 5 | 0,5 | 1?0 | 0,75 | |

| 8 | 7,5 | 0,73 | 9,0 | 0,75 | 5 | 0,75 | 1,25 | 1,1 | ||

| 10 | 9,3 | 1,0 | 11,3 | 1,0 | 7 | 1,0 | 1,5 | 1,5 | ||

| 12 | 11,0 | +0,3 | 1,25 | 13,5 | 1,25 | 7 | 1,0 | 2,0 | 1,9 | |

| 14 | 13,0 | -0,5 | 1,25 | 15,5 | 1,25 | 7 | 1,0 | 2,0 | 1,9 | |

| 16 | 15,0 | 1,5 | 18,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | ||

| 18 | 17,0 | 1,5 | ±0,5 | 20,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | |

| 20 | 19,0 | 1,5 | 22,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | ||

| 22 | 21,0 | +0,4 | 1,5 | 24,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | |

| 25 | 24,0 | -0,5 | 1,5 | 27,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | |

| 28 | 26,5 | 2,0 | 30,5 | 2,0 | 9 | 1,5 | 2,5 | 3,0 | ||

| 32 | 30,5 | 2,0 | 34,5 | 2,0 | 10 | 2,0 | 3,0 | 3,0 | ||

| 36 | 34,5 | +0,4 | 2,5 | ±0,7 | 39,5 | 2,5 | 12 | 2,0 | 3,0 | 3,5 |

| 40 | 38,5 | -0,7 | 2,5 | 43,5 | 2,5 | 12 | 2,0 | 3,0 | 3,5 | |

| 45 | 43,0 | 3,0 | 49,0 | 3,0 | 15 | 2,5 | 3,5 | 4,5 | ||

| 50 | 48,0 | 3,0 | 54,0 | 3,0 | 15 | 2,5 | 3,5 | 4,5 | ||

| 55 | 53,0 | +0,4 | 3,0 | 59,0 | 3,0 | 15 | 2,5 | 4,0 | 4,5 | |

| 60 | 68,0 | 1,0 | 3,0 | ±1,0 | 64,0 | 3,0 | 15 | 2,5 | 4,0 | 5,0 |

| 70 | 68,0 | +0,5 | 3,0 | 74,0 | 3,0 | 15 | 2,5 | 4,5 | 5,5 | |

| 80 | 77,5 | -1,1 | 3,0 | 83,5 | 3,0 | 15 | 2,5 | 4,6 | 5.5 | |

Note. At the request of the consumer, maximum deviations of size d 1 should not exceed maximum deviations d plus double maximum deviations h.

Table 3

Dimensions, mm

| Profile number (nominal diameter d n) | d | h | d1 | h1 | hr | hB | t | b | b1 | r 1 | a, deg | ||

| Nom. | Prev. off | Nom. | Prev. off | ||||||||||

| 10 | 8,7 | 1,6 | ±0,5 | 11,9 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 1,5 | 11 | ||

| 12 | 10,6 | 1,6 | 13,8 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 2,0 | 11 | |||

| 14 | 12,5 | +0,3 | 2,0 | 16,5 | 2,0 | 0,8 | 1,2 | 12 | 1,0 | 2,0 | 12 | ||

| 16 | 14,2 | -0,5 | 2,5 | 19,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 18 | 10,2 | 2,5 | +0,65 | 21,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 20 | 18,2 | 2,5 | -0,85 | 23,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | 50 | |

| 22 | 20,3 | +0,4 | 2,5 | 25,3 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 25 | 23,3 | -0,5 | 2,5 | 28,3 | 2,5 | 1,0 | 1,5 | 14 | 1,2 | 2,0 | 14 | ||

| 28 | 25.9 | 3,0 | 31,9 | 3,0 | 1,2 | 1,8 | 14 | 1,2 | 2,5 | 14 | |||

| 32 | 29,8 | +0,4 | 3,2 | +1,0 | 36,2 | 3,2 | 1,2 | 2,0 | 16 | 1,5 | 3,0 | 14 | |

| 36 | 33,7 | -0,7 | 3,5 | -1,2 | 40,7 | 3,5 | 1,5 | 2,0 | 18 | 1,5 | 3,0 | 19 | |

| 40 | 37,6 | 3,5 | 44,6 | 3,5 | 1,5 | 2,0 | 18 | 1,5 | 3,0 | 19 | |||

1.10. Relative displacements of helical protrusions on the sides of the profile, separated by longitudinal ribs, are not standardized.

Dimensions for which maximum deviations are not established are given for caliber construction and are not checked on the finished profile.

1.11. The ovality of smooth profiles (the difference between the largest and smallest diameters in one section) should not exceed the sum of the plus and minus maximum deviations in diameter.

1.9-1.11. (Changed edition, Amendment No. 3).

1.12. Reinforcing steel of classes A-I (A240) and A-II (A300) with a diameter of up to 12 mm and class A-III (A400) with a diameter of up to 10 mm inclusive is produced in coils or rods, larger diameters in rods. Reinforcing steel of classes A-IV (A600), AV (A800) and A-VI (A1000) of all sizes is produced in rods, with a diameter of 6 and 8 mm, manufactured in coils by agreement between the manufacturer and the consumer.

1.13. The rods are made from 6 to 12 m long:

- measured length;

- measured length with unmeasured segments of at least 2 m in length, not more than 15% of the lot weight;

- of unmeasured length.

In a batch of rods of unmeasured length, the presence of rods from 3 to 6 in length and no more than 7% of the mass of the batch is allowed.

By agreement between the manufacturer and the consumer, it is possible to manufacture rods from 5 to 25 m.

1.14. Maximum deviations along the length of measuring rods must correspond to those given in table. 4.

Table 4

| Length of rods, m | Maximum deviations along the length, mm. with cutting accuracy | |

| ordinary | increased | |

| Up to 6 incl. | +50 | +25 |

| St. 6 | +70 | +35 |

High-precision rods are manufactured according to customer requirements.

1.15. The curvature of the rods should not exceed 0.6% of the measured length.

Examples of symbols

Reinforcing steel with a diameter of 20 mm, class A-II (A300):

20-A-II (A300) GOST 5781-82

Reinforcing steel with a diameter of 18 mm, class AI (A240):

18-AI (A240) GOST 5781-82.

In the designation of class A-II rods for special purposes, the index c is added: Ac-II.

(Changed edition, Amendment No. 4).

TECHNICAL REQUIREMENTS

2.1. Reinforcing steel is manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

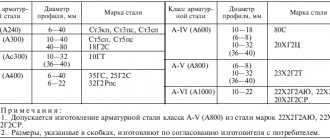

2.2. Reinforcing steel is made from carbon and low-alloy steel of the grades indicated in table. 5. The steel grade is indicated by the consumer in the order. If there is no indication, the steel grade is determined by the manufacturer. For class A-VI (A1000) rods, steel grades are established by agreement between the manufacturer and the consumer.

Table 5

| Reinforcing steel class | Profile diameter, mm | steel grade |

| AI (A240) | 6-40 | St3kp, St3ps, St3sp |

| A-II (A300) | 10-40 | St5sp, St5ps |

| 10-80 | 1NG2S | |

| Ac-II (Ac300) | 10-32 | 10GT |

| (36-40) | ||

| A-III (A400) | 6-40 | 35GS, 25G2S |

| 6-22 | 32G2Rps | |

| 10-18 | 80C | |

| A-IV (A600) | (6-8) | |

| 10-32 | 20ХГ2Ц | |

| (36-40) | ||

| (6-8) | ||

| A-V (A800) | 10-32 | 23Х2Г2Т |

| (36-40) | ||

| A-VI (A1000) | 10-22 | 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR |

Notes:

1. Production of reinforcing steel class AV (A800) is allowed. Made from steel grades 22Kh2G2AYU, 22Kh2G2R and 20Kh2G2SR.

2. The dimensions indicated in brackets are manufactured by agreement between the manufacturer and the consumer.

(Changed edition, Amendment No. 3, 4).

2.3. The chemical composition of reinforcing carbon steel must comply with GOST 380-88, low-alloy steel standards given in table. 6.

Table 6

| Steel grades | Mass fraction of elements, % | |||

| Carbon | Manganese | Silicon | Chromium | |

| 10GT | No more than 0.13 | 1,00-1,40 | 0,45-0,65 | No more than 0.30 |

| 18G2S | 0,14-0,23 | 1,20-1,60 | 0,60-0,90 | No more than 0.30 |

| 32G2Rps | 0,28-0,37 | 1,30-1,75 | No more than 0.17 | No more than 0.30 |

| 35GS | 0,30-0,37 | 0,80-1,20 | 0,60-0,90 | No more than 0.30 |

| 25G2S | 0,20-0,29 | 1,20-1,60 | 0,60-0,90 | No more than 0.30 |

| 20ХГ2Ц | 0,19-0,26 | 1,50-1,90 | 0,40-0,70 | 0,90-1,20 |

| 800 | 0,74-0,82 | 0,50-0,90 | 0,60-1,10 | No more than 0.30 |

| 23Х2Г2Т | 0,19-0,26 | 1,40-1,70 | 0,40-0,70 | 1,35-1,70 |

| 22Х2Г2АУ | 0,19-0,26 | 1,40-1,70 | 0,40-0,70 | 1,50-2,10 |

| 22Х2Г2Р | 0,19-0,26 | 1,50-1,90 | 0,40-0,70 | 1,50-1,90 |

| 20X2G2SR | 0,16-0,26 | 1,40-1,80 | 0,75-1,55 | 1,40-1,80 |

Continuation of the table. 6

| Steel grades | Mass fraction of elements, % | ||||||

| Titanium | Zirconium | Aluminum | Nickel | Sulfur | Phosphorus | Copper | |

| no more | |||||||

| 10GT | 0,015-0,035 | — | 0,02-0,05 | 0,0-10 | 0,030 | 0,30 | |

| 18G2S | — | — | — | 0,30 | 0,045 | 0,040 | 0,30 |

| 32G2Rps | — | — | 0,001-0,015 | 0,30 | 0,050 | 0,045 | 0,30 |

| 35GS | — | — | — | 0,30 | 0,045 | 0,040 | 0,30 |

| 25G2S | — | — | — | 0,30 | 0,045 | 0,040 | 0,30 |

| 20ХГ2Ц | — | 0,05-0,14 | — | 0,30 | 0,045 | 0,045 | 0,30 |

| 80C | 0,015-0,040 | — | — | 0,30 | 0,045 | 0,040 | 0,30 |

| 23Х2Г2Т | 0,02-0,08 | — | 0,015-0,050 | 0,30 | 0,045 | 0,045 | 0,30 |

| 22Х2Г2АУ | 0,005-0,030 | — | 0,02-0,07 | 0,30 | 0,040 | 0,040 | 0,30 |

| 22Х2Г2Р | 0,02-0,08 | — | 0,015-0,050 | 0,30 | 0,040 | 0,040 | 0,30 |

| 20X2G2SR | 0,02-0,08 | — | 0,05-0,050 | 0,30 | 0,040 | 0,040 | 0,30 |

2.3.1. In steel grade 20KhG2Ts, it is allowed to increase the mass fraction of chromium to 1.7% and replace zirconium with 0.02-0.08% titanium. In steel grade 23Х2Г2Т it is allowed to replace titanium with 0.05-0.10% zirconium. In this case, in the designation of steel grade 20KhG2Ts, the letter T is used instead of the letter C; steel grade 23Kh2G2T is marked with the letter T instead of the letter T.

In steel grade 32G2Rps, aluminum can be replaced with titanium or zirconium in equal units.

2.3.2. The mass fraction of nitrogen in steel grade 22Х2Г2А10 should be 0.015-0.030%, the mass fraction of residual nitrogen in steel grade 10GT should be more than 0.008%.

2.3.3. The mass fraction of boron in steel grades 22Kh2G2R, 20Kh2G2SR and 32G2Rps should be 0.001-0.007%. In steel grade 22Х2Г2АУ, the addition of 0.001-0.008% boron is allowed.

2.3.4. It is allowed to add titanium to steel grades 18G2S, 25G2S, 35GS based on its mass fraction in finished rolled products of 0.01-0.03%, to steel grade 35GS based on its mass fraction in finished rolled products produced in coils of 0.01-0 .06%.

2.4. Deviations in the chemical composition in finished rolled products from carbon steels are in accordance with GOST 380-88, from low-alloy steels, subject to compliance with the standards of mechanical properties - according to Table. 7. Minus deviations in the content of elements (except for titanium and zirconium, and for the steel grade 20Kh2G2SR silicon) are not limited.

Table 7

| Elements | Maximum deviations, % |

| Carbon | +0,020 |

| Silicon | +0,050 |

| Manganese | +0,100 |

| Chromium | +0,050 |

| Copper | +0,050 |

| Sulfur | +0,005 |

| Phosphorus | +0,005 |

| +0,010 | |

| Zirconium | -0,020 |

| Titanium | ±0,010 |

Note. By agreement between the manufacturer and the consumer, steel can be manufactured with other deviations in the content of chromium, silicon and manganese.

(Changed edition, Amendment No. 3).

2.5. Reinforcing steel of classes A-I (A240), A-II (A300), A-III (A400), A-IV (A600) is made hot-rolled, class AV (A800) - with low-temperature tempering, class A-VI (A1000) — with low-temperature tempering or thermomechanical treatment in the flow of a rolling mill.

It is allowed not to carry out low-temperature tempering of steel classes AV (A800) and A-VI (A1000) provided that a relative elongation of at least 9% and a uniform elongation of at least 2% are obtained when tested within 12 hours after rolling.

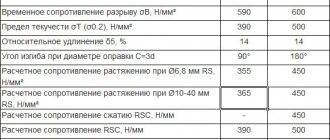

2.6. The mechanical properties of reinforcing steel must comply with the standards specified in table. 8.

Table 8

| Reinforcing steel class | Yield strength st | Temporary tensile strength sв | Relative elongation d5, % | Uniform elongation dr, % | Impact strength at -60°C | Bending and cold test (c - thickness of the post, d - diameter of the rod) | ||||

| N/mm2 | kgf/mm2 | N/mm2 | kgf/mm2 | MJ/m2 | kgf × m/cm2 | |||||

| No less | ||||||||||

| AI (A240) | 235 | 24 | 373 | 38 | 25 | — | — | — | 180°; c = d | |

| A-II (A300) | 295 | 30 | 490 | 50 | 19 | — | — | — | 180°; c = 3d | |

| Ac-II (Ac300) | 295 | 30 | 441 | 45 | 25 | — | 0,5 | 5 | 180°; c = d | |

| A-III (A400) | 390 | 40 | 590 | 60 | 14 | — | — | — | 90°; c = 3d | |

| A-IV (A600) | 590 | 60 | 883 | 90 | 6 | 2 | — | — | 45°; c = 5 d | |

| AV (A800) | 785 | 80 | 1030 | 105 | 7 | 2 | — | — | 45°; c = 5d | |

| A-VI (A1000) | 980 | 100 | 1230 | 125 | 6 | 2 | — | — | 45°; c = 5d | |

Notes:

1. By agreement between the manufacturer and the consumer, it is allowed not to test the impact strength of reinforcing steel of class Ac-II (Ac300).

2. (Deleted, Amendment No. 3).

3. For reinforcing steel of class A-IV (A600) with a diameter of 18 mm, grade 80C steel, the cold bending rate is set to at least 30°.

4. For reinforcing steel of class AI (A240) with a diameter of over 20 mm when bending in a cold state at 180° c = 2d, class A-II (A300) with a diameter of over 20 mm c = 4d.

5. Symbols for the yield strength are indicated in parentheses.

(Changed edition, Amendment No. 1, 3).

For class A-II (A300) steel with a diameter of over 40 mm, a reduction in elongation of 0.25% is allowed for each millimeter increase in diameter, but not more than 3%.

For steel class Ac-II (Ac300), a reduction in tensile strength to 426 MPa (43.5 kgf/mm2) is allowed with a relative elongation of: d 5 30% or more.

For steel grade 25G2S class A-III (A400), a reduction in tensile strength to 560 MPa (57 kgf/mm2) is allowed with a yield strength of at least 405 MPa (41 kgf/mm2), relative elongation: d 5 of at least 20%.

2.7. Statistical indicators of the mechanical properties of periodic reinforcing steel must comply with Appendix 1, with increased uniformity of mechanical properties - mandatory Appendix and Table. 9.

Table 9

| Reinforcing steel class | Profile number | S | So | ||||||

| For st (s0.2) | For sв | For st (s0.2) | For sв | For st (s0.2) | For sв | For st (s0.2) | For sв | ||

| MPa (kgf/mm2) | MPa (kgf/mm2) | ||||||||

| No more | |||||||||

| A-II (A300) | 10-10 | 29(3) | 29(3) | 15(1,5) | 15(1,5) | 0,08 | 0,06 | 0,05 | 0,03 |

| A-III (A400) | 6-40 | 39(4) | 39(4) | 20(2,0) | 20(2,0) | 0,08 | 0,07 | 0,05 | 0,03 |

| A-IV (A600) | 10-32 | 69(7) | 69(7) | 39(4) | 39(4) | 0,09 | 0,07 | 0,06 | 0,05 |

| AV (A800) | 10-32 | 78(8) | 78(8) | 49(5) | 49(5) | 0,09 | 0,07 | 0,06 | 0,05 |

| A-VI (A1000) | 10-22 | 88(9) | 88(9) | 49(5) | 49(5) | 0,08 | 0,07 | 0,05 | 0,04 |

Notes:

1. S - standard deviation in the general population of tests;

So is the standard deviation in the melting batch;

-average value in the population of tests;

-minimum average value in the melting batch.

2. For reinforcing steel in coils with a diameter of 6 and 8 mm, it is allowed to increase the standards for S and So by 4.9 MPa (0.5 kgf/mm2).

3. (Deleted, Amendment No. 5).

The probability of achieving the mechanical properties indicated in table. 8, must be at least 0.95.

(Changed edition, Amendment No. 3, 5).

2.8. On the surface of the profile, including the surface of the ribs and protrusions, there should be no rolled cracks, stress cracks, flaws, rolled films or sunsets.

Minor damage to the ribs and protrusions is allowed, in the amount of no more than three per 1 m of length, as well as minor rust, individual rolled out stains, prints, sagging, traces of rolled out bubbles, rippling and scaliness within the permissible deviations in size.

(Changed edition, Amendment No. 2).

2.9. The weldability of reinforcing steel of all grades, except 80C, is ensured by the chemical composition and manufacturing technology.

2.10. The carbon equivalent for welded rod reinforcement made of low-alloy steel of class A-III (A400) should be no more than 0.62.

Hot-rolled steel for reinforcement of ferroconcrete structures. Specifications

MKS 77.140.15

OKP 09 3004; 09 3005; 09 3006; 09 3007; 09 3008

Date of introduction 1983-07-01

Information data

1. DEVELOPED AND INTRODUCED by the Ministry of Ferrous Metallurgy of the USSR, Gosstroy of the USSR

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated December 17, 1982 N 4800

3. INSTEAD GOST 5.1459-72, GOST 5781-75

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 380-2005 | 2.3, 2.4 |

| GOST 2590-2006 | 1.6 |

| GOST 7564-97 | 4.5 |

| GOST 7565-81 | 3.4 |

| GOST 7566-94 | 3.2, 3.6, 5.1 |

| GOST 9454-78 | 4.8 |

| GOST 12004-81 | 4.6 |

| GOST 12344-2003 | 4.1 |

| GOST 12348-78 | 4.1 |

| GOST 12350-78 | 4.1 |

| GOST 12352-81 | 4.1 |

| GOST 12355-78 | 4.1 |

| GOST 12356-81 | 4.1 |

| GOST 14019-2003 | 4.7 |

| GOST 18895-97 | 4.1 |

| OST 14-34-78 | Appendix 2 |

5. The validity period was lifted according to Protocol No. 3-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 5-6-93)

6. EDITION (September 2009) with Amendments No. 1, 2, 3, 4, 5, approved in February 1984, June 1987, December 1987, October 1989, December 1990 (5 -84, 11-87, 3-88, 1-90, 3-91)

This standard applies to hot-rolled round steel of smooth and periodic profiles intended for the reinforcement of ordinary and prestressed reinforced concrete structures (reinforcing steel).

Regarding the standards for the chemical composition of low-alloy steels, the standard also applies to ingots, blooms and billets.

(Changed edition, Amendment No. 4).

Classification and assortment

1.1. Depending on the mechanical properties, reinforcing steel is divided into classes A-I (A240), A-II (A300), A-III (A400); A-IV (A600), A-V (A800), A-VI (A1000).

1.2. Reinforcing steel is produced in bars or coils. Reinforcing steel of class A-I (A240) is made smooth, classes A-II (A300), A-III (A400), A-IV (A600), A-V (A800) and A-VI (A1000) - periodic profile .

At the request of the consumer, steel of classes A-II (A300), A-III (A400), A-IV (A600) and A-V (A800) is made smooth.

1.1, 1.2. (Changed edition, Amendment No. 5).

1.3. Profile numbers, cross-sectional areas, weight of 1 m length of reinforcing steel of smooth and periodic profiles, as well as maximum mass deviations for periodic profiles must correspond to those indicated in Table 1.

Table 1

| Profile number (nominal rod diameter dK) | Cross-sectional area of the rod, cm² | Weight of 1 m profile | |

| Theoretical, kg | Limit. off, % | ||

| 6 | 0,283 | 0,222 | +9,0 |

| 8 | 0,503 | 0,395 | -7,0 |

| 10 | 0,785 | 0,617 | +5,0 -6,0 |

| 12 | 1,131 | 0,888 | |

| 14 | 1,540 | 1,210 | |

| 16 | 2,010 | 1,580 | +3,0 -5,0 |

| 18 | 2,540 | 2,000 | |

| 20 | 3,140 | 2,470 | |

| 22 | 3,800 | 2,980 | |

| 25 | 4,910 | 3,850 | |

| 28 | 6,160 | 4,830 | |

| 32 | 8,040 | 6,310 | +3,0 -4,0 |

| 36 | 10,180 | 7,990 | |

| 40 | 12,570 | 9,870 | |

| 45 | 15,000 | 12,480 | |

| 50 | 19,630 | 15,410 | +2,0 -4,0 |

| 55 | 23,760 | 18,650 | |

| 60 | 28,270 | 22,190 | |

| 70 | 38,480 | 30,210 | |

| 80 | 50,270 | 39,460 | |

(Changed edition, Amendment No. 3).

1.4. The nominal diameters of periodic profiles must correspond to the nominal diameters of smooth profiles of equal cross-sectional area.

1.5. The weight of 1 m of profile is calculated based on the nominal dimensions with a steel density of 7.85·10³ kg/m³. The probability of providing a mass of 1 m must be at least 0.9.

(Changed edition, Amendment No. 3).

1.6. Maximum deviations of the diameter of smooth profiles must comply with GOST 2590 for normal rolling accuracy.

1.7. Periodic profile reinforcing steel is a round profile with two longitudinal ribs and transverse projections running along a three-lead helix. For profiles with a diameter of 6 mm, protrusions running along a single-start helical line are allowed, with a diameter of 8 mm - along a double-start helical line.

1.8. Reinforcing steel of class A-II (A300), made in the usual version, with the profile shown in Fig. 1a, and for special purpose Ac-II (Ac300) with the profile shown in Fig. 2a, must have protrusions running along helical lines with the same approach on both sides of the profile.

Steel of class A-III (A400), manufactured with the profile shown in Fig. 1b, and classes A-IV (A600), A-V (A800), A-VI (A1000) with the profile shown in Fig. 1b, 2b, must have protrusions along helical lines that have right-hand entries on one side of the profile and left-hand entries on the other.

Special-purpose reinforcing steel of class Ac-II (Ac300) is made with profiles shown in Figure 1a or 2a.

The profile shown in Fig. 2a for special purposes is manufactured by agreement between the manufacturer and the consumer. The shape and dimensions of the profiles shown in Fig. 2a, b can be specified.

1.9. The dimensions and maximum deviations of the dimensions of reinforcing steel of periodic profile, manufactured according to Fig. 1a, b, must correspond to those given in Table 2, and for Fig. 2a, b - given in Table 3.

1.10. Relative displacements of helical projections on the sides of the profile, separated by longitudinal ribs, are not standardized.

Dimensions for which maximum deviations are not established are given for caliber construction and are not checked on the finished profile.

1.11. The ovality of smooth profiles (the difference between the largest and smallest diameters in one section) should not exceed the sum of the plus and minus maximum deviations in diameter.

1.9-1.11. (Changed edition, Amendment No. 3).

1.12. Reinforcing steel of classes A-I (A240) and A-II (A300) with a diameter of up to 12 mm and class A-III (A400) with a diameter of up to 10 mm inclusive. manufactured in coils or rods, large diameters - in rods. Reinforcing steel of classes A-IV (A600), A-V (A800) and A-VI (A1000) of all sizes is manufactured in rods with a diameter of 6 and 8 mm - by agreement between the manufacturer and the consumer, in coils.

1.13. The rods are made from 6 to 12 m long:

- measured length;

- measured length with unmeasured segments of at least 2 m in length, not more than 15% of the lot weight;

- of unmeasured length.

In a batch of rods of unmeasured length, the presence of rods with a length of 3 to 6 m is allowed, no more than 7% of the mass of the batch.

table 2

Dimensions in mm

| Profile number (nominal diameter dK) | d | h | d1 | h1 | l | b | b1 | r | ||

| Nom. | Prev. off | Nom. | Prev. off | |||||||

| 6 | 5,75 | +0,3 -0,5 | 0,5 | ±0,25 | 6,75 | 0,5 | 5 | 0,5 | 1,0 | 0,75 |

| 8 | 7,5 | 0,75 | 9,0 | 0,75 | 0,75 | 1,25 | 1,1 | |||

| 10 | 9,3 | 1,0 | ±0,5 | 11,3 | 1,0 | 7 | 1,0 | 1,5 | 1,5 | |

| 12 | 11,0 | 1,25 | 13,5 | 1,25 | 2,0 | 1,9 | ||||

| 14 | 13,0 | 15,5 | ||||||||

| 16 | 15,0 | 1,5 | 18,0 | 1,5 | 8 | 1,5 | 2,2 | |||

| 18 | 17,0 | 20,0 | ||||||||

| 20 | 19,0 | 22,0 | ||||||||

| 22 | 21,0 | +0,4 -0,5 | 24,0 | |||||||

| 25 | 24,0 | 27,0 | ||||||||

| 28 | 26,5 | +0,4 -0,7 | 2,0 | ±0,7 | 30,5 | 2,0 | 9 | 2,5 | 3,0 | |

| 32 | 30,5 | 34,5 | 10 | 2,0 | 3,0 | |||||

| 36 | 34,5 | 2,5 | 39,5 | 2,5 | 12 | 3,5 | ||||

| 40 | 38,5 | 43,5 | ||||||||

| 45 | 43,0 | 3,0 | 49,0 | 3,0 | 15 | 2,5 | 3,5 | 4,5 | ||

| 50 | 48,0 | 54,0 | ||||||||

| 55 | 53,0 | +0,4 -1,0 | ±1,0 | 59,0 | 4,0 | |||||

| 60 | 58,0 | 64,0 | 5,0 | |||||||

| 70 | 68,0 | +0,5 -1,1 | 74,0 | 4,5 | 5,5 | |||||

| 80 | 77,5 | 83,5 | ||||||||

Note. At the request of the consumer, maximum deviations of size d1 should not exceed maximum deviations d plus double maximum deviations h.

By agreement between the manufacturer and the consumer, it is possible to manufacture rods from 5 to 25 m.

1.14. The maximum deviations along the length of the measuring rods must correspond to those given in Table 4.

Table 3

Dimensions in mm

| Profile number (nominal diameter dK) | d | h | d1 | h1 | hT | hB | t | b | b1 | r1 | α | ||

| Nom. | Prev. off | Nom. | Prev. off | ||||||||||

| 10 | 8,7 | +0,3 -0,5 | 1,6 | ±0,5 | 11,9 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 1,5 | 11 | 50° |

| 12 | 10,6 | 13,8 | 2,0 | ||||||||||

| 14 | 12,5 | 2,0 | +0,65 -0,85 | 16,5 | 2,0 | 0,8 | 1,2 | 12 | 1,0 | 2,0 | 12 | ||

| 16 | 14,2 | 2,5 | 19,2 | 2,5 | 1,0 | 1,5 | |||||||

| 18 | 16,2 | 21,2 | |||||||||||

| 20 | 18,2 | 23,2 | |||||||||||

| 22 | 20,3 | +0,4 -0,5 | 25,3 | ||||||||||

| 25 | 23,3 | 28,3 | 14 | 1,2 | 14 | ||||||||

| 28 | 25,9 | +0,4 -0,7 | 3,0 | +1,0 -1,2 | 31,9 | 3,0 | 1,2 | 1,8 | 2,5 | ||||

| 32 | 29,8 | 3,2 | 36,2 | 3,2 | 2,0 | 16 | 1,5 | 3,0 | 19 | ||||

| 36 | 33,7 | 3,5 | 40,7 | 3,5 | 1,5 | 18 | |||||||

| 40 | 37,6 | 44,6 | |||||||||||

Table 4

| Length of rods, m | Prev. off along the length with cutting accuracy, mm | |

| ordinary | increased | |

| Up to 6 incl. | +50 | +25 |

| St. 6 | +70 | +35 |

High-precision rods are manufactured according to customer requirements.

1.15. The curvature of the rods should not exceed 0.6% of the measured length.

Examples of symbols

Reinforcing steel with a diameter of 20 mm, class A-II (A300):

20-A-II GOST 5781-82

The same, with a diameter of 18 mm, class A-I (A240):

18-A-I GOST 5781-82

The index “c” is added to the designation of class A-II (A300) rods for special purposes: Ac-II (Ac300).

(Changed edition, Amendment No. 4).

Technical requirements

2.1. Reinforcing steel is manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Reinforcing steel is made from carbon and low-alloy steel of the grades indicated in Table 5. The steel grade is indicated by the consumer in the order. If there is no indication, the steel grade is determined by the manufacturer. For class A-IV (A600) rods, steel grades are established by agreement between the manufacturer and the consumer.

Table 5

| Reinforcing steel class | Profile diameter, mm | steel grade |

| A-I (A240) | 6-40 | St3kp, St3ps, St3sp |

| A-II (A300) | 10-40 | St5sp, St5ps |

| 40-80 | 18G2S | |

| Ac-II (Ac300) | 10-32 (36-40) | 10GT |

| A-III (A400) | 6-40 | 35GS, 25G2S |

| 6-22 | 32G2Rps | |

| A-IV (A600) | 10-18 (6-8) | 80C |

| 10-32 (36-40) | 20ХГ2Ц | |

| A-V (A800) | (6-8) 10-32 (36-40) | 23Х2Г2Т |

| A-VI (A1000) | 10-22 | 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR |

Notes:

1. It is allowed to manufacture reinforcing steel of class A-V (A800) from steel grades 22Х2Г2АУ, 22Х2Г2Р and 20Х2Г2СС.

2. The dimensions indicated in brackets are manufactured by agreement between the manufacturer and the consumer.

(Changed edition, Amendment No. 3, 4).

2.3. The chemical composition of reinforcing carbon steel must comply with GOST 380, low-alloy steel - with the standards given in Table 6.

Table 6

| steel grade | Mass fraction of elements, % | ||||||||||

| Carbon | Manganese | Silicon | Chromium | Titanium | Zirconium | Aluminum | Nickel | Sulfur | Phosphorus | Copper | |

| no more | |||||||||||

| 10GT | No more than 0.13 | 1,00-1,40 | 0,45-0,65 | No more than 0.30 | 0,015- 0,035 | — | 0,02- 0,05 | — | 0,040 | 0,030 | 0,30 |

| 18G2S | 0,14-0,23 | 1,20-1,60 | 0,60-0,90 | — | — | 0,30 | 0,045 | 0,040 | |||

| 32G2Rps | 0,28-0,37 | 1,30-1,75 | No more than 0.17 | 0,001- 0,015 | 0,050 | 0,045 | |||||

| 35GS | 0,30-0,37 | 0,80-1,20 | 0,60-0,90 | — | 0,045 | 0,040 | |||||

| 25G2S | 0,20-0,29 | 1,20-1,60 | |||||||||

| 20ХГ2Ц | 0,19-0,26 | 1,50-1,90 | 0,40-0,70 | 0,90-1,20 | 0,05-0,14 | 0,045 | |||||

| 80C | 0,74-0,82 | 0,50-0,90 | 0,60-1,10 | No more than 0.30 | 0,015- 0,040 | — | 0,040 | ||||

| 23Х2Г2Т | 0,19-0,26 | 1,40-1,70 | 0,40-0,70 | 1,35-1,70 | 0,02- 0,08 | 0,015- 0,050 | 0,045 | ||||

| 22Х2Г2АУ | 1,50-2,10 | 0,005- 0,030 | 0,02- 0,07 | 0,040 | 0,040 | ||||||

| 22Х2Г2Р | 1,50-1,90 | 1,50-1,90 | 0,02- 0,08 | 0,015- 0,050 | |||||||

| 20X2G2SR | 0,16-0,26 | 1,40-1,80 | 0,75-1,55 | 1,40-1,80 | |||||||

2.3.1. In steel grade 20ХГ2Ц, it is allowed to increase the mass fraction of chromium to 1.7% and replace zirconium with 0.02-0.08% titanium. In steel grade 23Х2Г2Т it is allowed to replace titanium with 0.05-0.10% zirconium. In this case, in the designation of steel grade 20KhG2Ts, the letter T is used instead of the letter C; steel grade 23Kh2G2T is marked with the letter T instead of the letter T.

In steel grade 32G2Rps, aluminum can be replaced with titanium or zirconium in equal units.

2.3.2. The mass fraction of nitrogen in steel grade 22Х2Г2АУ should be 0.015-0.030%, the mass fraction of residual nitrogen in steel grade 10GT should be no more than 0.008%.

2.3.3. The mass fraction of boron in steel grades 22Kh2G2R, 20Kh2G2SR and 32G2Rps should be 0.001-0.007%. In steel grade 22Х2Г2АУ, the addition of 0.001-0.008% boron is allowed.

2.3.4. It is allowed to add titanium to steel grades 18G2S, 25G2S, 35GS based on its mass fraction in finished rolled products of 0.01-0.03%, to steel grade 35GS based on its mass fraction in finished rolled products produced in coils of 0.01-0 .06%.

2.4. Deviations in the chemical composition in finished rolled products from carbon steels - according to GOST 380, from low-alloy steels, subject to compliance with the standards of mechanical properties - according to Table 7. Minus deviations in the content of elements (except for titanium and zirconium, and for steel grade 20Kh2G2SR - silicon) are not limited.

Table 7

| Elements | Prev. off, % |

| Carbon | +0,020 |

| Silicon | +0,050 |

| Manganese | +0,100 |

| Chromium | +0,050 |

| Copper | +0,050 |

| Sulfur | +0,005 |

| Phosphorus | +0,005 |

| Zirconium | +0,010 -0,020 |

| Titanium | ±0,010 |

Note. By agreement between the manufacturer and the consumer, steel can be manufactured with other deviations in the content of chromium, silicon and manganese.

(Changed edition, Amendment No. 3).

2.5. Reinforcing steel of classes A-I (A240), A-II (A300), A-III (A400), A-IV (A600) is made hot-rolled, class A-V (A800) - with low-temperature tempering, class A-VI ( A1000) - with low-temperature tempering or thermomechanical treatment in the flow of a rolling mill.

It is allowed not to carry out low-temperature tempering of steel of classes A-V (A800) and A-VI (A1000) provided that a relative elongation of at least 9% and a uniform elongation of at least 2% are obtained when tested within 12 hours after rolling.

2.6. The mechanical properties of reinforcing steel must comply with the standards specified in Table 8.

For steel class A-II (A300) with a diameter of St. 40 mm, it is allowed to reduce the relative elongation by 0.25% for each millimeter increase in diameter, but not more than 3%.

For steel class Ac-II (Ac300), a reduction in tensile strength to 426 MPa (43.5 kgf/mm²) is allowed with a relative elongation δ5 of 30% or more.

For steel grade 25G2S class A-III (A400), a reduction in tensile strength to 560 MPa (57 kgf/mm²) is allowed with a yield strength of at least 405 MPa (41 kgf/mm²), relative elongation δ5 of at least 20%.

Table 8

| Reinforcing steel class | Yield strength σT | Tensile strength σB | Relative elongation δ5, % | Uniform elongation δp, % | Impact strength at minus 60 °C | Cold bending test (c - mandrel thickness, d - rod diameter) | |||

| N/mm² | kgf/mm² | N/mm² | kgf/mm² | MJ/m² | kgf m/cm² | ||||

| no less | |||||||||

| A-I (A240) | 235 | 24 | 373 | 38 | 25 | — | — | — | 180°; c=d |

| A-II (A300) | 295 | 30 | 490 | 50 | 19 | 180°; c=3d | |||

| Ac-II (Ac300) | 441 | 45 | 25 | 0,5 | 5 | 180°; c=d | |||

| A-III (A400) | 390 | 40 | 590 | 60 | 14 | — | — | 90°; c=3d | |

| A-IV (A600) | 590 | 60 | 883 | 90 | 6 | 2 | 45°; c=5d | ||

| A-V (A800) | 785 | 80 | 1030 | 105 | 7 | ||||

| A-VI (A1000) | 980 | 100 | 1230 | 125 | 6 | ||||

Notes:

1. By agreement between the manufacturer and the consumer, it is allowed not to test the impact strength of class Ac-II reinforcing steel.

2. (Deleted, Amendment No. 3).

3. For reinforcing steel of class A-IV with a diameter of 18 mm and steel grade 80C, the cold bending rate is set to at least 30°.

4. For reinforcing steel class A-I (A240) with a diameter of St. 20 mm when bending in a cold state by 180°, c=2d, class A-II (A300) with a diameter of St. 20 mm - c=4d.

5. Symbols for the class of reinforcing steel according to yield strength are indicated in brackets.

(Changed edition, Amendment No. 1, 3, 5).

2.7. Statistical indicators of the mechanical properties of reinforcing steel bars of periodic profile must correspond to Appendix 1, with increased uniformity of mechanical properties - Appendix 1 and Table 9.

The probability of achieving the mechanical properties indicated in Table 8 must be at least 0.95.

(Changed edition, Amendment No. 3).

2.8. On the surface of the profile, including the surface of the ribs and protrusions, there should be no rolled cracks, stress cracks, flaws, rolled films or sunsets.

Minor damage to the ribs and protrusions is allowed, in the amount of no more than three per 1 m of length, as well as minor rust, individual rolled out stains, prints, sagging, traces of rolled out bubbles, rippling and scaliness within the permissible deviations in size.

(Changed edition, Amendment No. 2).

2.9. The weldability of reinforcing steel of all grades, except 80C, is ensured by the chemical composition and manufacturing technology.

2.10. The carbon equivalent Ceq≤C+Mn/6+Si/10 for welded rod reinforcement made of low-alloy steel of class A-III (A400) should be no more than 0.62.

(Introduced additionally, Amendment No. 5).

Table 9

| Reinforcing steel class | Profile number | S | S0 | S/X | S0/X | ||||

| For σT(σ0,2) | For σB | For σT(σ0,2) | For σB | For σT(σ0,2) | For σB | For σT(σ0,2) | For σB | ||

| MPa (kgf/mm²) | MPa (kgf/mm²) | ||||||||

| no more | |||||||||

| A-II (A300) | 10-40 | 29 (3) | 29 (3) | 15 (1,5) | 15 (1,5) | 0,08 | 0,06 | 0,05 | 0,03 |

| A-III (A400) | 6-40 | 39 (4) | 39 (4) | 20 (2,0) | 20 (2,0) | 0,07 | |||

| A-IV (A600) | 10-32 | 69 (7) | 69 (7) | 39 (4,0) | 39 (4,0) | 0,09 | 0,06 | 0,05 | |

| A-V (A800) | 78 (8) | 78 (8) | 49 (5,0) | 49 (5,0) | |||||

| A-VI (A1000) | 88 (9) | 88 (9) | 0,08 | 0,05 | 0,04 | ||||

Notes:

1. S - standard deviation in the general population of tests;

S0 is the standard deviation in the melting batch;

X is the average value in the population of tests;

X is the minimum average value in the melting batch.

2. For reinforcing steel in coils with a diameter of 6 and 8 mm, it is allowed to increase the standards for S and S0 by 4.9 MPa (0.5 kgf/mm²).

3. (Deleted, Amendment No. 5).

Acceptance rules

3.1. Reinforcing steel is accepted in batches consisting of profiles of the same diameter, one class, one melt-ladle and issued with one quality document.

The batch weight should be up to 70 tons.

It is allowed to increase the mass of the batch to the mass of the melting ladle.

3.2. Each batch is accompanied by a quality document in accordance with GOST 7566 with additional data:

- profile number;

- Class;

- minimum average value X and standard deviations S0 in a batch of values σT(σ0.2) and σB;

- results of cold bending tests;

- values of uniform elongation for steel classes A-IV (A600), A-V (800), A-VI (A1000).

3.3. To check the size and quality of the surface, select:

- in the manufacture of reinforcing steel in rods - at least 5% of the batch;

- when produced in skeins - two skeins from each batch.

(Changed edition, Amendment No. 3).

3.4. To check the chemical composition, samples are taken according to GOST 7565.

The manufacturer determines the mass fraction of aluminum periodically, but at least once a quarter.

3.5. To test for tensile, bending and impact strength, two rods are selected from the batch.

For the manufacturer, the interval for selecting rods must be at least half the time spent on rolling one profile size of one batch.

(Changed edition, Amendment No. 3).

3.6. If unsatisfactory test results are obtained for at least one of the indicators, repeated tests are carried out in accordance with GOST 7566.

Test methods

4.1. Chemical analysis of steel is carried out according to GOST 12344, GOST 12348, GOST 12350, GOST 12352, GOST 12355, GOST 12356, GOST 18895 or other methods that provide the required accuracy.

4.2. The diameter and ovality of the profiles are measured at a distance of at least 150 mm from the end of the rod or at a distance of at least 1500 mm from the end of the skein with a skein weight of up to 250 kg and at least 3000 mm with a skein weight of more than 250 kg.

4.3. Dimensions are checked with a measuring tool of the required accuracy.

4.4. One sample is cut from each selected rod for tensile, bending and impact strength testing.

4.5. Sampling for testing tensile, bending and impact strength is carried out in accordance with GOST 7564.

4.6. The tensile test is carried out according to GOST 12004.

4.7. The bending test is carried out according to GOST 14019 on samples with a cross-section equal to the cross-section of the rod.

For rods with a diameter of St. 40 mm, it is allowed to test samples cut along the axis of the rod on a mandrel with a diameter reduced by half compared to that indicated in Table 4, with a bending force applied from the side of the cut.

4.8. Determination of impact strength is carried out according to GOST 9454 on samples with a type U type 3 concentrator for rods with a diameter of 12-14 mm and type I samples for rods with a diameter of 16 mm or more. Samples are manufactured in accordance with the requirements of GOST 9454.

4.9. It is allowed to use statistical and non-destructive methods for monitoring the mechanical properties and mass of profiles.

4.10. The curvature of the rods is measured along the length of the supplied profile, but not shorter than 1 m.

4.11. Determination of statistical indicators of mechanical properties - in accordance with Appendix 2.

4.12. The quality of the surface is checked without the use of magnifying devices.

4.10-4.12. (Introduced additionally, Amendment No. 3).

4.13. The height of the transverse projections of a periodic profile should be measured along the vertical axis of the cross-section of the reinforcing bars.

(Introduced additionally, Amendment No. 4).

Packaging, labeling, transportation and storage

5.1. Packaging, labeling, transportation and storage - in accordance with GOST 7566 with the following additions:

- the ends of rods made of low-alloy steels of class A-IV (A600) must be painted with red paint, class A-V - red and green, class A-VI (A1000) - red and blue. It is allowed to paint the ligaments at a distance of 0.5 m from the ends;

- the rods are packaged in bundles weighing up to 15 tons, tied with wire or wire rod. At the consumer's request, the rods are packaged in bundles weighing up to 3 and 5 tons.

On the ties, paint is applied in strips no less than 20 mm wide on the side surface around the circumference (at least 1/2 the length of the circumference) at a distance of no more than 500 mm from the end.

Paint is applied to the skeins in strips no less than 20 mm wide across the turns on the outside of the skein.

For unpackaged products, paint is applied to the end or side surface at a distance of no more than 500 mm from the end.

The label attached to each bundle of rods is marked with the accepted designation of the reinforcing steel class (for example, A-III) or the symbol of the yield strength class (A400).

(Changed edition, Amendment No. 3, 5).

Appendix 1 (mandatory). Requirements for statistical indicators of mechanical properties

APPENDIX 1 Mandatory

1. The manufacturer guarantees to the consumer the average values of tensile strength σB and yield strength (physical σT and conditional σ0.2) in the general population - Xi and the minimum average values of these same indicators in each batch-melt - Xi, the values of which are determined from the conditions:

where Xibr are the rejection values of σB, σ0.2, indicated in Table 8 of this standard;

t is the quantile value taken equal to 2 for classes A-II (A300) and A-III (A400) and 1.64 for classes A-IV (A600), A-V (A800) and A-VI (A1000) .

2. Quality control of indicators of mechanical properties of products at the manufacturer

2.1. The required quality indicators of profiles are ensured by compliance with production technology and controlled by testing in accordance with the requirements of clause 3.5, clauses 4.4-4.8.

2.2. The values of Xi, Xi, S and S0 are set in accordance with the test results and the provisions of Appendix 2.

3. Quality control of indicators of mechanical properties of products at the consumer enterprise

3.1. The consumer, if he has a quality document for products of the highest quality category, may not test the mechanical properties.

3.2. If it is necessary to check the mechanical properties of each batch, six samples taken from different bags or skeins and from different profiles are tested, and based on the results, the fulfillment of the conditions is checked:

where X6 is the average value of mechanical properties based on the test results of six samples;

Xmin is the minimum value of the test results of six samples.

3.3. The minimum values of relative elongation δ5 and uniform elongation δp must be no less than the values given in Table 8.

(Changed edition, Amendment No. 3, 5).

ACCEPTANCE RULES

3.1. Reinforcing steel is accepted in batches consisting of profiles of the same diameter, one class, one melt-ladle and issued with one quality document.

The batch weight should be up to 70 tons.

It is allowed to increase the mass of the batch to the mass of the melting ladle.

3.2. Each batch is accompanied by a quality document in accordance with GOST 7566-81 with additional data:

- profile number;

- Class;

- minimum average value and standard deviations So in a batch of values sт (s0.2) and sв;

- results of cold bending tests;

- values of uniform elongation for steel classes A-IV (A600), AV (A800), A-VI (A1000).

3.3. To check the size and quality of the surface, select:

- in the manufacture of reinforcing steel in rods - at least 5% of the batch;

- when making and skeins, two skeins from each batch.

(Changed edition, Amendment No. 3).

3.4. To check the chemical composition, samples are taken according to GOST 7565-81.

The manufacturer determines the mass fraction of aluminum periodically, but at least once a quarter.

3.5. To test for tensile, bending and impact strength, two rods are selected from the batch.

For the manufacturer, the interval for selecting rods must be at least half the time spent on rolling one profile size of one batch.

(Changed edition, Amendment No. 3).

3.6. If unsatisfactory test results are obtained for at least one of the indicators, repeated tests are carried out in accordance with GOST 7566-81.

TEST METHODS

4.1 Chemical analysis of steel is carried out according to GOST 12344-88, GOST 12348-78, GOST 12350-78, GOST 12352-81, GOST 12355-78, GOST 12356-81, GOST 18895-81 or other methods that provide the required accuracy.

4.2. The diameter and ovality of the profiles are measured at a distance of at least 150 mm from the end of the rod or at a distance of at least 1500 mm from the end of the skein with a skein weight of up to 250 kg and at least 3000 mm with a skein weight of more than 250 kg.

4.3. Dimensions are checked with a measuring tool of the required accuracy.

4.4. One sample is cut from each selected rod for tensile, bending and impact strength testing.

4.5. Sampling for tensile, bending and impact strength testing is carried out in accordance with GOST 7564-73.

4.6. The tensile test is carried out according to GOST 12004-81.

4.7. The bending test is carried out according to GOST 14019-80 on samples with a cross-section equal to the cross-section of the rod.

For rods with a diameter over 40 mm, it is allowed to test samples cut along the axis of the rod on a mandrel with a diameter reduced by half compared to that indicated in the table. 4, with bending force applied from the side of the cut.

4.8. Determination of impact strength is carried out according to GOST 9454-78 on samples with a concentrator type U type 3 for rods with a diameter of 12-14 mm and samples of type 1 for rods with a diameter of 16 mm or more. Samples are manufactured in accordance with the requirements of GOST 9454-78.

4.9. It is allowed to use statistical and non-destructive methods for monitoring the mechanical properties and mass of profiles.

4.10. The curvature of the rods is measured along the length of the supplied profile, but not shorter than 1 m.

4.11. Determination of statistical indicators of mechanical properties in accordance with mandatory Appendix 2.

4.12. The quality of the surface is checked without the use of magnifying devices.

4.10-4.12. (Introduced additionally, Amendment No. 3).

4.13. The height of the transverse projections of a periodic profile should be measured along the vertical axis of the cross-section of the reinforcing bars.

(Introduced additionally, Amendment No. 4).

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Ferrous Metallurgy of the USSR, Gosstroy of the USSR

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated December 17, 1982 N 4800

3. INSTEAD GOST 5.1459-72, GOST 5781-75

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 380-2005 | 2.3, 2.4 |

| GOST 2590-2006 | 1.6 |

| GOST 7564-97 | 4.5 |

| GOST 7565-81 | 3.4 |

| GOST 7566-94 | 3.2, 3.6, 5.1 |

| GOST 9454-78 | 4.8 |

| GOST 12004-81 | 4.6 |

| GOST 12344-2003 | 4.1 |

| GOST 12348-78 | 4.1 |

| GOST 12350-78 | 4.1 |

| GOST 12352-81 | 4.1 |

| GOST 12355-78 | 4.1 |

| GOST 12356-81 | 4.1 |

| GOST 14019-2003 | 4.7 |

| GOST 18895-97 | 4.1 |

| OST 14-34-78 | Appendix 2 |

5. The validity period was lifted according to Protocol No. 3-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 5-6-93)

6. EDITION (September 2009) with Amendments No. 1, 2, 3, 4, 5, approved in February 1984, June 1987, December 1987, October 1989, December 1990 (5 -84, 11-87, 3-88, 1-90, 3-91)

This standard applies to hot-rolled round steel of smooth and periodic profiles intended for the reinforcement of ordinary and prestressed reinforced concrete structures (reinforcing steel). Regarding the standards for the chemical composition of low-alloy steels, the standard also applies to ingots, blooms and billets. (Changed edition, Amendment No. 4).

PACKAGING, LABELING, TRANSPORTATION AND STORAGE

5.1. Packaging, labeling, transportation and storage - in accordance with GOST 7500-81 with additions:

- the ends of rods made of low-alloy steels of class A-IV (A600) must be painted with red paint, class AV (A800) - red and green, class A-VI (A1000) - red and blue. It is allowed to paint the ligaments at a distance of 0.5 m from the ends;

- the rods are packaged in bundles weighing up to 15 tons, tied with wire or wire rod. At the consumer's request, the rods are packaged in bundles weighing up to 3 and 5 tons;

- on the label attached to each bundle of rods, the accepted designation of the reinforcing steel class (for example, A-III) or the symbol of the yield strength class (A400) is applied.

On ties, paint is applied in strips no less than 20 mm wide on the side surface around the circumference (at least 1/2 the length of the circumference) at a distance of no more than 500 mm from the end.

Paint is applied to skeins in strips no less than 20 mm wide across the turns on the outside of the skein.

For unpackaged products, paint is applied to the end or side surface at a distance of no more than 500 mm from the end.

(Changed edition, Amendment No. 3, 5).

REQUIREMENTS FOR STATISTICAL INDICATORS OF MECHANICAL PROPERTIES

1. The manufacturer guarantees to the consumer the average values of tensile strength sв and yield strength (physical st and conditional s0.2) in the general population-i and the minimum average values of these same indicators in each batch-i; the values of which are set from the conditions:

where x i b p are the rejection values of s in, s 0.2, indicated in the table. 8 of this standard;

t is the quantile value, taken equal to 2 for classes A-II (A300) and A-III (A400) and 1.64 for rods of classes A-IV (A600), AV (A800) and A-VI (A1000).

2. Quality control of indicators of mechanical properties of products at the manufacturer.

2.1. The required quality indicators of profiles are ensured by compliance with production technology and are controlled by testing in accordance with the requirements of clause 3.5, clauses. 4.4-4.8.

2.2. The values of , , S and S o are established in accordance with the test results and the provisions of Appendix 2.

3. Quality control of indicators of mechanical properties of products at the consumer enterprise.

3.1. The consumer, if he has a quality document for products of the highest quality category, may not test the mechanical properties.

3.2. If it is necessary to check the mechanical properties of each batch, six samples taken from different bags or skeins and from different profiles are tested, and based on the results, the fulfillment of the conditions is checked

where b is the average value of mechanical properties based on the test results of six samples;

tmin is the minimum value of the test results of six samples.

3.3. The minimum values of relative elongation d 5 and uniform elongation dr must be no less than the values given in table. 8 .

(Changed edition, Amendment No. 3).

APPENDIX 1 Mandatory

REQUIREMENTS FOR STATISTICAL INDICATORS OF MECHANICAL PROPERTIES

1. The manufacturer guarantees to the consumer the average values of tensile strength and yield strength (physical and conditional) in the general population - and the minimum average values of these same indicators in each batch - , the values of which are determined from the conditions:

;

;

,

where are the rejection values of , , specified in Table 8 of this standard;

— quantile value taken equal to 2 for classes A-II (A300) and A-III (A400) and 1.64 for classes A-IV (A600), A-V (A800) and A-VI (A1000).

2. Quality control of indicators of mechanical properties of products at the manufacturing plant

2.1. The required quality indicators of profiles are ensured by compliance with production technology and controlled by testing in accordance with the requirements of clause 3.5, clauses 4.4-4.8.

2.2. The values of , , and are set in accordance with the test results and the provisions of Appendix 2.

3. Quality control of indicators of mechanical properties of products at the consumer enterprise

3.1. The consumer, if he has a quality document for products of the highest quality category, may not test the mechanical properties.

3.2. If it is necessary to check the mechanical properties of each batch, six samples taken from different bags or skeins and from different profiles are tested, and based on the results, the fulfillment of the conditions is checked:

;

,

where is the average value of mechanical properties based on the test results of six samples;

— the minimum value of the test results of six samples.

3.3. The minimum values of relative elongation and uniform elongation must be no less than the values given in Table 8.

(Changed edition, Amendment No. 3, 5).