When choosing welding electrodes, any novice welder has doubts. Construction stores offer a huge selection of brands and types of consumables from Russian and global manufacturers. You can agree with the advice of a sales consultant who will happily offer several options, for example, inexpensive OZS 12 electrodes for universal use. This brand was created specifically for welding carbon steels, is easy to use and ideal for beginners.

Application area

Welding electrodes OZS-12 with rutile coating can be successfully used for any work that requires joining products made of carbon steel grades:

- performing standard welding in all directions with the installation of tack welding in the workshops of industrial enterprises;

- connections of any types of pipes, regardless of the diameter and wall thickness required by the description of operating conditions;

- carrying out welding work at home.

Also, consumables are widely in demand for the manufacture of structures operated under high load conditions at particularly critical industrial facilities:

- equipment for the mining, oil and gas industries, metallurgy;

- boiler equipment;

- equipment intended for moving goods;

- lifting and transport mechanisms;

- loaded metal structures.

The technical characteristics of OZS electrodes ensure the creation of welding seams and surfacing surfaces of the highest quality, both using professional and household equipment . Inverters, transformers or electric generators are used as an arc source.

Purpose

OZS electrodes are used for manual welding, which involves joining steel products that contain carbon. The scope of application of this brand of electrodes is cutting fabrics and structures into pieces, as well as surfacing onto worn mechanisms and parts.

The ability of the electrodes to work in various positions, including in hard-to-reach places, allows complex installations to be carried out. Particularly valuable is the ability to weld surfaces coated with oxides with electrodes of this brand.

Electrodes are produced by several Russian manufacturers. For example, , which is a world leader in the production of equipment and consumables for it, produces such high-quality consumables as esab OZS-12 electrodes, which are in great demand. Also known are Bor, LEZ and other enterprises.

Electrodes from different manufacturers do not have any particular differences regarding quality, characteristics and scope of application, so you can purchase products from any of them.

Characteristics of welding electrodes OZS-12

When determining the technological characteristics of OZS-12, you should first consider the chemical composition of the rods, since other parameters of the product largely depend on it.

Welding specialists and experienced welders, when choosing an electrode, always focus on mechanical properties, which help determine the suitability of products of a particular type for forming a weld with the required operational and technological characteristics.

As mentioned above, LEZ OZS-12 electrodes are intended for welding and surfacing with carbon steel elements . The brand has special properties that set it apart from many others.

- Easy to make connections, even with pre-set tacks.

- Possibility of welding at low power currents using small cross-section rods. In this case, work can be carried out using welding transformers.

- Excellent quality T-joint, providing increased strength of concave seams. This is important when exposed to increased loads on the connection line, or when using products under other special load conditions.

- No requirements for metal purity. Welding electrodes OZS-12 are used for welding products with areas of deep corrosion when performing work in any conditions.

In such cases, specialists suggest using a long arc, which helps to further reveal the capabilities and characteristics of the electrodes.

The high quality of the formed seams is determined by the increased tensile strength. In addition, scars are characterized by plasticity and toughness.

If it is necessary to re-ignite the arc, it occurs quickly and easily; the difference with products of other brands is felt even when using OZS-12 at home.

The arc formed by an electrode with rutile coating is stable. During work, no harmful substances are released that affect the welder’s well-being.

The effectiveness of using OZS-12 does not depend on the type of current, the main thing is to maintain the required polarity. The products show excellent performance when welding in the lower, ceiling or vertical position.

Before use after long-term storage, the product should be thoroughly dried and calcined at a temperature of 150-180°C.

Welding Features

The permissible moisture content in the coating is no more than 0.7%. Exceeding the values can lead to hydrogenation of the weld metal and loss of the required toughness and ductility. Therefore, before welding, the rods are calcined for half an hour at a temperature of 150–180 °C.

- You can weld parts using both a medium and an extended arc, without fear of the formation of pores in the weld metal.

- The seam on a part can occupy any spatial position, including vertical on the descent.

- Welding with both a transformer (alternating current) and an inverter (constant reverse polarity) is acceptable.

OZS-12 electrodes are sensitive to high temperatures - when calcining, the values recommended above must be strictly observed so as not to damage the coating. The same applies to the welding mode: if the current exceeds the recommended one, pores may form in the metal of the joint.

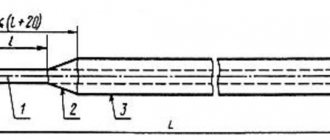

Sizes and range

OZS-12 are produced with different diameters. The products have similar characteristics and composition. The main difference is only the cross-sectional size, indicated in mm, and the length of the rod.

These values are directly proportional to each other - an increase in one leads to an increase in the other. In retail chains you can purchase electrodes of the OZS-12 brand, differing in the sizes shown in the figure.

The best manufacturers

The rating of popular OZS-12 manufacturers includes:

- domestic electrode plant “SpetsElectrod”, which owns several production sites;

- Russian branch of the Swedish company ESAB;

- the Vistek company, which packages products from various enterprises;

- Monolith company, which uses a special coating composition with reduced smoke emission during combustion;

- Sudislavsky plant of welding materials “SZSM-Invest”.

One of the best electrode manufacturers.

Special properties of welding electrodes OZS-12

The main properties and advantages of OZS-12 electrodes are:

- the possibility of high-quality welding work regardless of location in space.

- performing welding on direct or alternating current;

- possibility of use for mating products without preliminary cleaning of corroded areas without pore formation and oxidation;

- the connection of wet elements using OZS-12 does not lead to a deterioration in the properties and parameters of the rumen;

- ensuring smooth coupling of the scar with the base metal of the product;

- high resistance of rumen metal to fatigue stresses, which makes it possible to use OZS-12 to create metal structures that constantly operate under conditions of significant loads along the rumen line;

- the possibility of joining metals characterized by the appearance of a pronounced oxide film, for example, aluminum and alloys based on it;

- during operation of the rods, no toxic substances are formed or released, and the arc is highly stable;

- ease of arc initiation even if it is necessary to re-form it;

- providing improved strength parameters of the scar during the formation of T-joints;

- the possibility of using OZS-12 for connecting products using small currents;

- rods of small diameter can be used for work using household current sources, including low power ones;

- ability to work using a long arc.

The use of OZS-12 electrodes can significantly increase the welder’s productivity. The slag crust formed on the scar is easily removed without the use of abrasive tools and additional mechanical impact.

In addition to standard properties, OZS-12 also has characteristics that other brands of consumables do not have.

Many experienced welders note the convenience of creating tack welds when welding pipeline elements, due to the high speed and ease of seam formation. It is also noted that the seam is fully welded to its entire thickness, even by beginners.

Novice welders note as an undeniable advantage of the OZS-12 the ability to use household power sources connected to a 220 V home network for operation.

general information

OZS-12 products can operate when supplied with direct or alternating voltage and are designed for current in the circuit up to 70 A. Thanks to this feature, the electrodes are used in domestic conditions.

Inverters or standard welding transformers with reduced power consumption and connection to a 220 V network are suitable for their use. For the welding arc, alternating or direct voltage with reverse polarity is used.

The electrodes belong to the E46 model, the seam has a tensile strength of at least 460 MPa. The rod is coated with a mineral rutile coating containing natural titanium dioxide.

The material reduces the risk of cracks in the joint metal and maintains stable combustion of the arc discharge (compared to acid-type coatings).

It is possible to use an ilmenite layer (a natural mixture of titanium dioxide and iron). The industry produces rods of the E series with a digital index from 42 to 60, which are distinguished by the strength of the weld.

Area of use

The electrodes are designed to create a permanent connection of parts made of carbon steel (up to 0.25% carbon). The rods allow welding in horizontal or vertical positions, as well as on the ceiling part of the joint.

The products are used by repair teams and private craftsmen to connect water pipes without drying the interior or metal structures for domestic use.

The resulting joint has high tensile strength. To protect the metal from corrosion, it is necessary to apply layers of primer and paint.

Electrodes are used in the manufacture of industrial structures for:

- mining industry;

- lifting mechanisms for technical purposes;

- chemical and petrochemical enterprises;

- gas industry;

- public utilities.

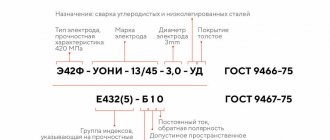

Classification according to GOST

Products are manufactured in accordance with GOST:

- 9466-75;

- 9467-75.

Markings with explanation

The basic designation of OZS-12 products is understood as:

- OZ is a pilot plant (the electrodes were created in the USSR in the laboratory of the E.O. Paton Institute of Electric Welding);

- C – intended for construction work;

- 12 – serial number of the model (several models of electrodes were developed at the same time, differing in the type of coating and chemical composition).

We recommend reading Characteristics and operation of non-consumable electrodes

The marking is applied with waterproof paint to the coating closer to the metal base (for example, the products of the Losinoostrovsky plant are designated by the letters LEZ OZS-12).

Additional information about the strength of the weld metal, the diameter of the rod and the permissible welding directions is indicated on the packaging in the form of 2 groups of symbols, separated by a horizontal line.

Properties of OZS-12 electrodes.

Welding modes for OZS-12

When using OZS-12 electrodes, a power source is used that maintains the open circuit voltage within 45-55 V. The parameters are set manually depending on the cross-section of the rod, the position of the joint in space and the thickness of the workpieces being connected.

The main values are given in the table.

| Electrode cross-section, mm | Current strength in the circuit, A |

| 2 | 30-90 |

| 2,5 | 50-110 |

| 3 | 70-130 |

| 4 | 11-180 |

| 5 | 130-220 |

Geometric dimensions and current strength

Geometric parameters and current when using electrodes with rutile coating of the OZS-12 brand in accordance with their diameters are presented in the table.

Dmitry Shestkovsky, electric and gas welder, 25 years of work experience: “Electrodes of the OZS-12 brand are the best choice for welders, both those working on a permanent basis, as well as amateurs or home craftsmen. The use of consumables of this type makes it possible to obtain a high-quality seam in any conditions and practically does not depend on the skill level of the performer and the selected manufacturer. The main thing is to try to choose only high-quality electrodes and follow the rules for their storage and operation. To obtain truly high-quality consumables, it is recommended to purchase them in specialized stores or large retail chains.”

Advantages

The advantages of this type of electrodes include:

- Lack of porosity of the material of the seam formed.

- Low probability of hot cracks.

- Small formation of slag crust, as well as ease of its removal.

- Minor spattering of hot material.

- The coating contains no harmful substances that could have a negative impact on the health of the welder.

- Possibility of welding in various positions.

- Possibility of welding wet surfaces. This is important if pipeline welding occurs, in which drying of internal surfaces is problematic.

- Ease of ignition of the arc and stability of its combustion.

- Working with welding machines powered from the mains.

One of the main advantages is the ability to weld surfaces with these electrodes that have traces of primer, rust and paint. This solves the problem when welding is carried out in a ceiling position, when it is difficult to completely remove dirt. Such advantages are the reason for the great popularity and widespread use of OZS electrodes.