Home / Electrodes

Back

Reading time: 3 min

0

3305

When we talk about home welding, it usually means that electrodes are used. We often hear that wire, semi-automatic welding machines or gas are used only by specialists in their field.

And novice welders use only electrodes in their work. However, this is a persistent stereotype. In fact, there are many types of electrical conductors, including those with rods for specialized applications.

E50A represents one of them. This type of electrode is used when welding structures of particular importance. Electrodes of this type include several models.

After reading this article, you will understand what the abbreviation E50A means, what functional properties these electrodes have, and what you need to consider when planning work using these rods.

- General information

- Abbreviation meaning

- Brands of electrical conductors

- Analogs

- Peculiarities

- Results

Characteristics

Domestic rod analogues of OK-46 SEOK-46, E46 are certified by the National Academy of Compliance Control (NAKS) . Used for welding carbon steels, including those with galvanic coating with a layer of zinc.

The main technical parameters are identical:

- Welding without spatial restrictions.

- Use of direct and alternating current (AC/DC) sources.

- Arc burning is stable.

- Spattering is moderate.

- The seam is not prone to fatigue deformation.

- Initial ignition, repeat after arc interruption without difficulty.

- Convenient for working with thin-walled structures, making short seams and tacks.

- Tolerant of insufficient metal cleaning and slight rust deposits.

- Available in Ø 1.6–5 mm.

- Size range 300–450 mm.

- Suitable for welding wide gaps.

- The no-load current of 50 A allows the use of household sources with voltage fluctuations.

- The inclination of the electrode is allowed within 350.

- Porosity only appears when the welder makes mistakes in selecting the current or ignoring drying.

- The vulnerability of rutile coating to dampness requires calcination at 1000 C.

- Easy slag removal.

- The rod is made of low-carbon steel SV-08, which has become a limitation in welding alloy steels.

An analogue of the OK-46 electrode for an equivalent replacement is OZS 12 . The quality of the connecting seam is lower for OZS 6. Group ANO 4 (6; 29M; 23), MR-3 for critical connections of pipelines and loaded structures have a number of limitations.

Rutile coating is technologically advanced. Coagulation of titanates in the upper layer of the weld pool accelerates the increase in slag viscosity. Magnesium and calcium bicarbonates and aluminosilicates bind silicon and oxygen, causing hot cracking and a decrease in impact strength.

Technical characteristics and welding features of different brands of the same type of electrode do not coincide.

Table for selecting operating current for electrodes E46 GOST 9467 75

| Rod Ø, mm | Average current value, A at seam position | Long size, mm | ||

| Horizontal | Vertical | Ceiling | ||

| 1,6–2 | 40–75 | 40–60 | 50–75 | 300 |

| 2,5 | 60–100 | 60–90 | 60–100 | 350 |

| 3 | 80–150 | 80–130 | 80–170 | 350 |

| 4 | 100–200 | 100–200 | 90–200 | 450 |

| 5 | 120–250 | 140–250 | 140–270 | 450 |

General information

E50A are electrical conductors for welding metal structures of special reliability, which are made of tool steel, which contains a low concentration of impurities.

The resulting seams are used in work at low and high temperatures. These seams have high ductility, which is well felt during mechanical shocks.

This type of electrode is typically used in the shipbuilding and nuclear industries.

Electrodes OZS-12 and OK-46, what is the difference?

OZS 12 forms a connection of high quality parts at low currents. With rods Ø 2–3 mm, reliable welding is carried out with the transformer connected to a 220 V household network. Many indicators of OZS 12 and E46 are the same:

- There are no restrictions on the spatial position of the seam.

- The use of direct and alternating current (AC/DC) sources is allowed.

- Polarity limitation, straight only.

- Low demands on the cleanliness of cutting.

- Resistance of the deposited metal to fatigue deformation, which contributes to the durability of the connections.

- The coating helps protect the seam, the slag crust is uneven, and individual fragments are difficult to remove.

- The suture surface tends to be concave.

- Long-term transfer of static loads.

- Uniformity and stability of maintaining arc combustion.

- Recommended for pipe and T-joints.

- No tendency to crack.

- Re-ignition without sticking.

OZS 12, in comparison with welding electrodes OK-46, requires calcination with a temperature increase of 50% . The quality of the seam increases when welding with a long arc. Up to 60% of the electrode weight goes to waste and slag formation.

The coating has an atypical increased moisture absorption in the rutile family. Large inclusions tend to get baked in, and manual cleaning of the seam is labor-intensive.

Quality certification

Electrodes intended for industrial use or for connecting critical structures are subject to mandatory certification.

Electrodes are subject to mandatory certification.

An official document on the territory of the Russian Federation is issued by the National Welding Control Agency (NAKS) to tool manufacturers and has a limited validity period (3 years).

Each certificate form has an individual number entered into the database and is certified by the signature of the NAKS President and seal.

The document states:

- type of certification (primary or periodic);

- brand and diameter of electrodes;

- testing methods and additional information.

When issuing a certificate, the controlling body receives a test batch of electrodes and carries out welding work followed by destructive testing of the seam. The results obtained confirm the product’s compliance with the standards; if the parameters deviate, a certificate is not issued. The presence of a certificate allows the use of electrodes for welding critical structures, but in the event of damage to the seam due to insufficient strength of the weld metal, the manufacturer bears financial and criminal liability in accordance with the legislation of the Russian Federation.

We recommend reading Which aluminum electrodes to choose

E46A, technical specifications

E46A provide a weld with increased ductility and toughness due to a decrease in the proportion of sulfur and phosphorus in the rod (S and P in the range of 0.04–0.045%). Designed to operate under variable loads, including dynamic and low temperatures. Low-alloy steels with a carbon content of up to 2%, such as 15HSND, 14G2, are welded. Heat loads above 2000 are not desirable.

Analogs similar in weld quality: OMNIA-46, OK 48.00, OK Femax 38.95, Pipeweld 6010. Type E46A includes the following brands:

- With cellulose-rutile coating – SE-46-00, SZSM 46.00;

- With the main coating of the rod and the creation of an alkaline environment in the weld pool (neutralization of hydrogen against cracking) - ANO-8, UONI-13/45A, UONI-13/55K;

- With the inclusion of iron powder VN48U and ITS-1.

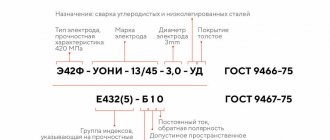

The decoding of the alphanumeric indication informs about the basic technical data in accordance with GOST 9467-75:

- E – electrode with external coating for manual electric arc welding;

- 46 – value of temporary tensile strength in kg per mm2;

- A – ductility and impact strength are designed for variable loads.

Welding process requirements include holding a short arc as a measure to eliminate porosity and lack of fusion . Calcination of electrodes for an hour at 3000 C before use.

Preference is given to direct current of reverse polarity. The requirements for surface cleanliness, especially regarding scale and rust, are high. Increasing the concentration of iron powder in the coating reduces the carbon content of the surfacing and the tendency to cracking.

Abbreviation meaning

Each abbreviation carries encrypted information, and E50A has its own meaning for each letter and number. "E" means that this type of electrical conductor is designed for manual arc welding with coated electrodes.

And the numbers “5” and “0” indicate the ultimate strength relative to ruptures. Thus, it is possible to calculate the loads that the connections can withstand, which is very important when working with load-bearing structures (trusses, etc.).

“A” means that the resulting seam will be plastic and viscous.

E50A

The scope of application has been expanded in comparison with OK-46A . In addition to pipeline and sea transport, products and structures with significant dynamic loads at low temperatures are included, including nuclear industry facilities.

Type E50A includes a number of interchangeable brands of Russian manufacturers based on Sv-08A welding wire: OZS-18, OZS-25, E-138/50N, ANO-TM, DSK-50U, TMU-21U, TMU-50, MTG-02, MTG-01K, TsU-5, TsU-5M. The coating is predominantly alkaline-basic.

The chemical composition of the overlay weld is identical. But the scope of application is different. Given the harsh operating conditions, universalization is impractical. The size of the coating layer and the variability of chemical components influence the process technology and are related to the purpose of the brand.

Foreign and domestic analogues suitable for replacing E50 electrodes, electrode brand: SE-08-00 (RF), OK 48.04 (Sweden), OK 53.70 (ESAB), Fox EV 50 (Germany), Phoenix K50 R (Germany), Garant (Germany) ), LB-52U (Japan).

The German brand Fox EV 50 compares favorably with its indifference to humidity due to water-repellent additives. TMU-21U is used primarily by oil and gas producers on Arctic pipelines.

Where to buy a welding electrode type E50 A.

From us you can purchase welding rods in packages of 1, 2.5 or 5 kilograms. We guarantee that products comply with the necessary regulations regarding production, storage and transportation. When ordering electrodes from us, you can be sure of the highest quality of the ordered products. We attach regulatory documentation and quality certificates to each order.

By calling the number indicated in the site contacts, you can leave a request, the processing speed of which will pleasantly surprise you.

Features and Limitations

The breaking load of the seam is determined to be 500 MPa with an additional margin of safety . At the same time, technological features introduce restrictions into the practice of application: for domestic brands of this type, only OZS-28 is available in a circular seam with a vertical descent from top to bottom. For others this is unacceptable.

UONI-13/55T, OZS-28, OZS-33 operate on welding machines with direct and alternating currents. Large group: UONI-13/55, UONI-13/55G, OZS-18, OZS-25, OZS-29, TMU-21U - are adapted exclusively for the use of direct current of reverse polarity.

The protective functions of alkaline coatings are based on the reaction of carbonates CaCO3, MgCO3 releasing carbon monoxide CO, which, as a reducing agent, absorbs oxygen, turning into carbon dioxide. Carbon dioxide gas protection is retained until the solidifying slag sets.

For electrodes of the E50A type, a short arc is generally recommended . An hour-long drying of the coating is considered mandatory. Use is limited to 3–4 days. Wet electrodes burn unstably. Triple calcination is the limit. Heat treatment destroys the coating.

The criterion for selecting externally coated arc electrodes for welding structural alloys should take into account network capabilities and personal skill. OZS-12 are considered easy to ignite and operate, while UONI 13/55 requires an experienced hand, especially during intermittent actions.

Electrodes: marking and application

The brands of electrodes and their purposes are given in Tables 1-7.

| Table 1. Electrodes for welding carbon and low-alloy steels | ||||

| Electrode brand | Coverage type | Type of current and polarity | Deposition rate, g/Ah | Purpose |

| Type E42 | ||||

| OMA-2 | AC | Constant and variable | 7,0-9,0 | For welding structures made of thin sheet steel |

| ANO-5 | RJ | Constant and variable | 11,0 | For welding critical structures operating under static and dynamic loads |

| ANO-1 | RJ | Constant and variable, 65V | 15,0 | For welding long and multi-pass seams |

| WCC-4 | C | Constant, any polarity | 10,5 | Welding the first and second layers of low-carbon steel pipe joints |

| Type E42A | ||||

| SM-11 | B | Constant, reverse polarity | 9,5 | Welding of especially critical structures, including those operating at subzero temperatures |

| Type E46 | ||||

| ANO-3/ANO-4 | R | Constant, any polarity | 8,5 | Welding of critical structures, including those operating under dynamic loads |

| OZS-4/MR-3 | R | AC, DC, reverse polarity | 8,0-9,0 | Welding of critical metal structures |

| OZS-6 | RJ | AC, DC, reverse polarity | 8,5 | Welding of critical structures made of low-carbon steels |

| OZS-12 | R | Constant and variable | 7,5-8,5 | Welding critical structures made of low-carbon steels, most suitable for welding T-joints |

| RBU-4/RBU-5 | R | Alternating, reverse polarity | 9,5-10,5 | Welding of critical structures made of low-carbon steels |

| OZS-3 | RJ | AC, DC, reverse polarity, 65V | 15,0 | Welding of critical structures made of low-carbon steels, electrode support welding |

| OZSCh-17N | RJ | Constant and variable | 9-10 | Welding using the inclined electrode method on special installations |

| Type E46A | ||||

| SSSI 13/45 | B | Constant, reverse polarity | 8,5-10 | Welding of especially critical structures, including those operating at low temperatures |

| E138/45N | B | Constant, reverse polarity | 8,5 | Welding of underwater parts of ship hulls |

| Type E50 | ||||

| WCC-4A | C | Constant, any polarity | 10,0-10,5 | Welding the first and second layers of low-alloy steel pipe joints |

| VSN-3 | B | Constant, reverse polarity | 9,0 | Welding of pipelines made of steel 10G2, operating at temperatures down to -70°C |

| Type E50A | ||||

| UONI-13/55 | B | Constant, reverse polarity | 9,0 | Welding of critical structures made of low- and medium-carbon steels operating in northern conditions |

| DSK-50 | B | Constant, reverse polarity, alternating | 10,0 | Critical structures made of low-alloy steels 14KhGS and 15KhSND |

| OZS-18 | B | Constant, reverse polarity | 9-9,5 | Critical structures made of low-alloy steel 10KhNDP, up to 15 mm thick |

| K-5A | B | Constant, reverse polarity, alternating, 65V | 9,0 | Critical structures made of carbon and low-alloy steels |

| E-138/50N | B | Constant, reverse polarity | 9,0 | Welding of the underwater part of sea vessels |

| ANO-9 | B | Constant, reverse polarity, alternating | 9,5-10,0 | Welding of critical structures made of carbon and low-alloy steels |

| TsU-5 | B | Constant, reverse polarity | 8,0-9,0 | Welding of boiler heating surface pipes, thin-walled pipes made of steel 10 and 20 |

| TMU-21 | B | Constant, reverse polarity | 9,5-10,0 | Welding of pipelines made of carbon and silicon-manganese steels |

| E55, E60 | ||||

| UONII-13/55U | B | Constant, reverse polarity | 9,5 | Bath welding of reinforced concrete reinforcement bars made of steels St5, 18G2S, 25GS, 15GS, etc. |

| UONII-13/65 | B | Constant, reverse polarity | 9,0 | Welding of critical machine-building structures from medium-carbon, as well as chromium, chromium-molybdenum and chromium-silicon-manganese steels |

| VSF-65 | B | Constant, reverse polarity | 8,5-9,5 | Welding of critical machine-building structures from medium-carbon, as well as chromium, chromium-molybdenum and chromium-silicon-manganese steels |

| E70, E85 | ||||

| VSF-75 | B | Constant, reverse polarity | 8,5-9,5 | Welding of highly loaded engineering structures from medium-carbon and low-alloy steels of increased and high strength |

| LKZ-70 | B | Constant, reverse polarity | 9,5 | Welding of highly loaded engineering structures from medium-carbon and low-alloy steels of increased and high strength |

| UONII-13/85 | B | Constant, reverse polarity | 9,5-10,5 | Welding of highly loaded engineering structures from medium-carbon and low-alloy steels of increased and high strength |

| NIAT-3M | B | Constant, reverse polarity | 9,0-10,0 | Welding of structures made of steels with a tensile strength of 60–100 kgf/mm2 (30KhGSA, 30KhGSNA, etc.) |

| Table 2. Electrodes for welding alloy heat-resistant steels | ||||

| Electrode brand | Electrode type | Deposition rate, g/Ah | Purpose | Recommended heat treatment of parts |

| TsL-14 | E-09MH | 10,5 | Welding of boilers and pipelines made of steels 12МХ, 15ХМ, 12Х1МФ and others, operating at temperatures up to 540°С | Preheating to 200-300°C, after welding tempering 710-730°C |

| OZS-11 | E-09MH | 8,0-9,0 | Welding of structures made of steels 12МХ, 15МХ, 12ХМФ, 15Х1М1Ф and others, operating at temperatures up to 510°С | Preliminary and accompanying heating to 150-200°C, after welding tempering 710°C |

| TML-1 | E-09M1X | 9,5-10,2 | Welding of steam pipelines made of chrome-molybdenum, chrome-molybdenum-vanadium steels operating at temperatures up to 570°C | |

| TML-2 | E-09Х1МФ | 9,5-10,2 | ||

| TML-3 | E-09Х1МФ | 9,5-10,2 | ||

| TsL-20 | E-09X1M | 10,3 | Welding of steam pipelines made of chrome-molybdenum, chrome-molybdenum-vanadium steels operating at temperatures up to 570°C, except for thin-walled pipes | |

| TsL-38 | E-09X1M | 9,0-10,0 | Welding of thin-walled pipelines made of chrome-molybdenum, chrome-molybdenum-vanadium steels operating at temperatures up to 540°C | Vacation 710-730°C, 3 hours |

| TsL-39 | E-09Х1МФ | 9,0-10,0 | Welding of steam pipelines made of chrome-molybdenum, chrome-molybdenum-vanadium steels operating at temperatures up to 585°C | Vacation 730-750°C, 5 hours |

| TsL-26M | E-10Х3-М1БФ | 10,5 | Welding of steam pipelines made of chrome-molybdenum, chrome-molybdenum-vanadium steels operating at temperatures up to 600°C, welding of dissimilar steels (for example, 1Х11В2МФ and 12Х1МФ) | Vacation 740-760°C |

| TsL-17 | E-10Х5МФ | 9,5-10,5 | Welding of structures made of steels 15Kh5M, 12Kh5MA, 15Kh5MFA, operating in aggressive environments at temperatures up to 450°C | Preliminary and accompanying heating to 350-400°C |

| Table 3. Electrodes for welding corrosion-resistant steels | ||||

| Electrode brand | Electrode type | Electrode rod material | Deposition rate, g/Ah | Application |

| OZL-8 | E-07 X20N9 | Sv-04 X19N9 | 12-14 | Welding chromium-nickel steels, when the weld metal is not subject to strict requirements against intercrystalline corrosion |

| OZL-3 | E-10Х17-Н13С4 | Sv-15Х-18Н12С-4TYu | 11,5—12,5 | Welding steels of type 15Х18Н12С4ТУ, when the weld metal is not subject to strict requirements against intercrystalline corrosion |

| ZIO-8 | E-10Х25 Н13Г2 | Sv-07X-25N13 | 13,3 | Welding of structures and pipelines made of two-layer steels, when the weld metal is not subject to strict requirements against intercrystalline corrosion |

| UONII-13/NZH | E-12X13 | Sv-12X13 | 10-12 | Welding of critical structures made of chromium steels 08X13, 12X13 |

| OZL-22 | E-02Х21 Н10Г2 | Sv-01Х-18Н10 | 12-14 | Welding of structures made of steels X8N10, X18N12 and others operating in oxidizing environments such as nitric acid |

| OZL-14A | E-04 X20N9 | Sv-01 X19N9 | 10-12 | Welding chromium-nickel steels, when the weld metal is not subject to strict requirements against intercrystalline corrosion |

| OZL-36 | E-04 X20N9 | Sv-01 X19N9 | 13-14 | Welding chromium-nickel steels, when the weld metal is not subject to strict requirements against intercrystalline corrosion |

| OZL-7 | E-08Х20 Н9Г2Б | Sv-01 X19N9 | 11,5-12 | Welding chromium-nickel steels, when stringent requirements are imposed on the weld metal against intercrystalline corrosion |

| TsL-11 | E-08Х20 Н9Г2Б | Sv-07Х19-Н10Б | 1-12 | Welding chromium-nickel steels, when stringent requirements are imposed on the weld metal against intercrystalline corrosion |

| TsL-9 | E-10Х25-Н13Г2Б | Sv-07 X2513 | 10,5-11,5 | Welding chromium-nickel steels from the alloy layer side of two-layer steels, when stringent requirements are imposed on the weld metal against intercrystalline corrosion |

| OZL-20 | E-02Х20-Н14Г2М2 | Sv-01Х17-Н14М2 | 12,5-14,5 | Welding of structures made of steels 03Х16Н15Мз, 03Х17Н14М2, when stringent requirements are imposed on the weld metal against intercrystalline corrosion |

| NIAT-1 | E-08Х17 Н8М2 | Sv-04 X19N9 | 10-11 | Welding of structures made of chromium-nickel and chromium-nickel-molybdenum steels; most suitable for welding thin sheet metal |

| EA-400/10U | E-07Х19-Н11М3Г2 | Sv-01Х19-Н11М3 | 12 | Welding of power equipment housings and pipelines operating in contact with aggressive environments at temperatures up to 350°C |

| HA-400/10T | E-07Х19-Н11М3Г2 | Sv-01Х19-Н11М3 | 14,5 | Welding of power equipment housings and pipelines operating in contact with aggressive environments at temperatures up to 350°C |

| Table 4. Electrodes for welding heat-resistant steels | ||||

| Electrode brand | Electrode type | Electrode rod material | Deposition rate, g/Ah | Application |

| OZL-6 | E-10Х25-Н13Г2 | Sv-07X-25N13 | 11-12 | Welding of lightly loaded structures operating in oxidizing environments at temperatures up to 1000°C |

| OZL-5 | E-12Х24-Н14С2 | Sv-10Х20-Н15 | 12,5 | Welding of structures made of steel Х25Н2С2 and others, operating at a temperature of 900–1100°С, also welding of corrosion-resistant steels, operating at a temperature of 350°С |

| OZL-9A | E-28Х-24Н16Г6 | Sv-30Х-25Н16Г7 | 13-14 | Welding chromium-nickel-manganese and chromium-nickel-silicon steels operating in oxidizing environments at temperatures up to 1050°C |

| OZL-29 | E-10Х17-Н13С4 | Sv-02Х17-Н14С4 | 14,5-16 | Welding of structures made of steel 20Х20Н14С2, operating in oxidizing environments at temperatures up to 1100°С |

| OZL-25 | E-10Х-20Н70-Г2М2В | Sv-KhN78T | 10,5-11,5 | Welding of thin-sheet structures and heating elements made of KhN78T alloy and alloys of the KhN70Yu type |

| NIAT-5 | E-11Х-15Н25-М6AG2 | Sv-10X16-N25AM6 | 12,5 | Welding of steam pipelines and boiler superheaters, welding of 30GSA steel in a hardened state |

| 032L | (TU14-4-237-72) | Sv-10Х20-Н15 | 11,5-12,5 | Welding of steels type 20Х23Н13, operating at temperatures up to 900°С in gas environments containing sulfur compounds |

| GS1 | (TU14-4-222-72) | Sv-08Х21-Н10Г6 | 10-11 | Welding of thin steels operating in carburizing environments at temperatures up to 1000°C |

| OZL-35 | (TU14-4-168-21-77) | ХН70У | 13,2 | Welding of nickel-based alloys operating at temperatures up to 1200°C |

| OZL-31 | (TU14-4-395-73) | Sv-30Х15-Н35В3Б3Т | 9-11 | Welding of steels type 20Х25Н20С2, working in carburizing media |

| TsT-1 | E-09Х19-Н11Г3-М2Ф | Sv-04-X19N9 | 13 | Welding of components of ultra-high pressure installations, turbines, pipelines made of steels 12Х18Н9Т, 1Х14Н14В2М, operating at temperatures up to 620°С |

| TsT-7-1 | E-09Х19-Н11Г3-М2Ф | Sv-06-Х19Н9Т | 10,5 | Welding of components of ultra-high pressure installations, turbines, pipelines made of steels 12Х18Н9Т, 1Х14Н14В2М, operating at temperatures up to 620°С |

| TsT-7 | E-09Х19-Н11Г3-М2Ф | Sv-08Х19-Н12М3 | 13 | Welding of components of ultra-high pressure installations, turbines, pipelines made of steels 12Х18Н9Т, 1Х14Н14В2М, operating at temperatures up to 620°С |

| TsT-15-1 | E-08Х20-Н9Г2Б | Sv-07Х19-Н10Б | 12 | Welding of structures and steam pipelines made of heat-resistant steels operating at temperatures up to 650°C |

| TsT-15 | E-08Х20-Н9Г2Б | Sv-08Х19-Н10Т | 12 | Welding of structures and steam pipelines made of heat-resistant steels operating at temperatures up to 650°C |

| TsT-26-1 | E-08Х16-Н8М2 | Sv-0Х15-Н8М2 | 10,5 | Welding of steam pipeline assemblies and heat exchangers made of heat-resistant and heat-resistant steels operating at temperatures up to 850°C |

| TsT-26 | E-08Х16-Н8М2 | Sv-Kh16-N9M2 (EP-377) | 10,5 | Welding of steam pipeline assemblies and heat exchangers made of heat-resistant and heat-resistant steels operating at temperatures up to 850°C |

| TsT-28 | E-08Х14-Н65М15-В4Г2 | Sv-H15-N60M15 (EP-367) | 10,5 | Welding of power plant components from dissimilar steels, welding of steels with nickel-based alloys |

| KTI-7A | E-27Х15-Н35В3-Г2Б2Т | Sv-30Х15-Н353Б3Т | 9-11 | Welding of reaction pipes made of steels operating at temperatures up to 900°C |

| VI-IM-1 | (TU14-4-358-73) | Sv-06Х15-Н60М15 | 12 | Welding of heat-resistant steels and alloys such as VZhL-8, EI-435, etc. |

| IM-ET-10 | E-04Х10-Н60М24 | 67N26M (NIMO-25. EI-639) | 14-16 | Welding of heat-resistant steels and alloys such as VZhL-8, EI-435, etc. |

| AN-ZHR-1 | (TU14-4-568-74) | Sv-08Х25-Н60М10 (EI-606) | Welding of dissimilar steels (high-alloy with medium- and low-alloy heat-resistant): hardenable steels without subsequent heat treatment, operating at a temperature of 450-600°C | |

| AN-ZHR-2 | (TU14-4-568-75) | Sv-H25-N40M7 (EP-675) | Welding of dissimilar steels (high-alloy with medium- and low-alloy heat-resistant): hardenable steels without subsequent heat treatment, operating at temperatures of 450-600°C | |

| KTI-10 | E-12Х11-NVMF | Sv-10Х11-ВМФН | 9,2 | Welding of nitrided and cast turbine elements made of high-chromium steels operating at temperatures of 535–585°C |

| OZL-19 | (TU14-4-560-74) | Sv-07Х25-Н13 | 12-13 | Welding of high-manganese steel 110G13L and its combinations with steels of type 30KhGSA |

| ANV-20 | (TU14-4-597-75) | Sv-01Х19-Н15Г6-М2АВ2 | 10,5-11 | Welding of critical structures made of steels used in low-temperature technology (cryogenic engineering) |

| Table 5. Electrodes for surfacing surface layers with special properties | ||||

| Electrode brand | Electrode type | Deposition rate, g/Ah | Hardness of deposited metal, HRG | Purpose |

| OZN-250u | E-10G2 | 7-8 | 20-28 | Surfacing by direct and alternating current of rapidly wearing parts made of carbon and low-alloy steels subject to shock loads (axles, shafts, automatic couplers, railway crosses, rails, components of agricultural machines) |

| OZN-300u | E-11G3 | 7-8 | 28-35 | Surfacing by direct and alternating current of rapidly wearing parts made of carbon and low-alloy steels subject to shock loads (axles, shafts, automatic couplers, railway crosses, rails, components of agricultural machines) |

| OZN-350u | E-12G4 | 7-8 | 35-40 | Surfacing by direct and alternating current of rapidly wearing parts made of carbon and low-alloy steels subject to shock loads (axles, shafts, automatic couplers, railway crosses, rails, components of agricultural machines) |

| OZN-400u | E-15G5 | 7-8 | 40-44 | Surfacing by direct and alternating current of rapidly wearing parts made of carbon and low-alloy steels subject to shock loads (axles, shafts, automatic couplers, railway crosses, rails, components of agricultural machines) |

| OZSh-1 | E-16-G2ХМ | 8-8,5 | 35-39 | Surfacing of dies for cold stamping |

| OZSh-2 | (TU14-4-317-73) | 9-10 | At least 56 | For surfacing in the lower and vertical positions of hot stamping dies and cutting tools |

| OZSh-3 | E-70X3-SMT | 9-10 | 25-58 | Surfacing in the lower position of cutting and cutting dies and wearing parts of machines |

| EN-60M | E-37 X9S2 | 8-9 | 25-60 | Surfacing of dies operating with heating of contact surfaces up to 400°C, machine parts: guides, gears, eccentrics, etc. |

| UONII-13/NZH | E-20X13 | 10-12 | 33-48 | Surfacing of dies operating with heating of contact surfaces up to 400°C, machine parts: guides, gears, eccentrics, etc. |

| TsN-6L | E-08Х17-Н8С6Г | — | 28-37 | Surfacing of sealing surfaces of boiler fittings operating at temperatures up to 570°C and specific pressure up to 800 kgf/cm2 |

| TsN-12M-67 | E-13Х-16Н8-М5С5Г4Б | 13-14 | 38-50 | Surfacing of sealing surfaces of boiler fittings operating at temperatures up to 600°C and high pressure |

| OZI-3 | E-90Х4-М4ВФ | 9-10 | 58-63 | Surfacing of hot and cold stamping dies and wear parts of machine tools and mining and metallurgical equipment |

| OZSh-4 | E-10M9N8K8-H2SF | 10-12 | 55-60 | Surfacing of hot and cold stamping dies and parts of machine tools and metallurgical equipment (cones and valves of blast furnaces, rolling rolls, knives for cutting metal, etc.) |

| OZI-4 | E-10K15-V7M5-H3SF | 10-11 | 52-58 | Surfacing of dies and metal-cutting tools and parts operating under particularly severe temperature and power conditions |

| OZI-5 | E-10K18-V11M10-H3SF | 10-11 | 62-65 | Surfacing of dies and metal-cutting tools and parts operating under particularly severe temperature and power conditions |

| VSN-6 | E-110-X14-V13F2 | 9-10 | 50-55 | Surfacing of wear parts operating under significant shock loads under conditions of abrasive wear |

| VSN-8 | (TU14-4-779-76) | 9-10 | At least 57 | Surfacing of wear parts operating under significant shock loads under conditions of abrasive wear |

| ENU-2 | (TU14-4-633-75) | 8,5-9,5 | At least 57 | Surfacing of fast-wearing steel and cast iron parts operating under moderate shock loads under conditions of abrasive wear |

| 12AN/LIVT | E-95Х7-G5S | 8,3 | 25-32 | Surfacing of parts of excavators and earth-moving machines operating under moderate shock loads |

| T-590 | E-320-H25S2GR | 8,5 | 57-65 | Surfacing of steel and cast iron parts subject to abrasive wear |

| T-620 | E-320-H25S2GR | 8,5 | 55-62 | Surfacing of steel and cast iron parts subject to abrasive wear |

| EN-60M | E-70-H3SMT | 9 | 56-62 | Surfacing of dies for cold stamping |

| OMG-N | E-65-X11N3 | 9,2 | 25-33 | Surfacing of crusher jaws, railway crosspieces and other parts made of G13L steel |

| TsN-2 | E-190-K62X-29V5S2 | 12,2 | 59-65 | Surfacing of sealing surfaces of fittings for boilers and steam pipelines operating at a temperature of 450–580°C and a specific pressure of up to 800 kgf/cm2 |

| TsN-3 | E-200-Х29Н6Г2 | — | At least 40 | Surfacing of steel and cast iron parts subject to abrasive wear |

| Table 6. Electrodes for welding and surfacing of cast iron | |||

| Electrode brand | Type of current and polarity | Position in space | Application |

| OMCH-1 | Constant, reverse polarity, alternating | Lower | Repair of cast iron products by hot welding; cracks, chips; welding with partial heating when repairing large products |

| HF-3 | Constant, reverse polarity, alternating | Lower | Correction of defects in cast iron by hot welding |

| EHR | Constant, reverse polarity, alternating | Lower | Correction of defects in cast iron by hot welding |

| MPCh-1 | Constant, reverse polarity | Lower | Welding and surfacing of products without heating, when it is necessary to obtain tough, well-worked seams. Correction of defects on treated surfaces |

| OZCH-1 | Constant, reverse polarity | Bottom and vertical | Welding without heating cracks on products that require tight seams and are subject to mechanical processing |

| OZCH-3 | Constant, reverse polarity | Bottom and vertical | Welding without heating cracks on products that require tight seams and are subject to mechanical processing |

| TsCh-4 | Constant, reverse polarity | Lower | Welding of high-strength cast iron products, welding of defects. Welding cast iron with steel |

| ANCH-1 | Constant, reverse polarity | Bottom and vertical | Welding without heating cracks on products that require tight seams and are subject to mechanical processing |

| OZZHN-1 | Constant, reverse polarity | Bottom and vertical | Welding of high-strength cast iron products, welding of defects. Welding cast iron with steel |

| TsCh-3A | Constant, reverse polarity | Lower | Welding without heating damaged parts made of gray and high-strength magnesium cast iron |

| Table 7. Electrodes for welding non-ferrous metals | |||||

| Electrode brand | Rod metal type | Deposition rate, g/Ah | Consumption of electrodes per 1 kg of deposited metal | Temporary resistance of deposited metal, kgf/mm2 | Note |

| Electrodes for welding aluminum and its alloys | |||||

| OZA-1 | SvA5 | 6,32 | 2,3 | 6,5-8,5 | Welding and surfacing in the manufacture and repair of aluminum products of grades A6, AD0, AD1, Ad |

| Af-4akr | SvA5 | 7,5-7,8 | 2,5 | 6,5-8,5 | Welding and surfacing in the manufacture and repair of aluminum products of grades A6, AD0, AD1, Ad |

| A2 | SvAMts or SvAK5 | 7,5-7,8 | 2,5 | 11,0 | Welding in the manufacture and repair of products made from Amts and AL-9 alloys |

| OZA-2 | SvAK5 | 6,25-6,5 | 2,3 | At least 10 | Welding and surfacing of parts made of cast alloys AL-2, AL-4, AL-5, AL-9, AL-11 |

| Electrodes for welding nickel alloys | |||||

| "Komsomolets-100" | Copper | 14,0 | 1,4 | 27,0 | Welding copper sheets containing not more than 0.01% oxygen and copper to low carbon steel |

| MH-5 | MH-5 | 12,0 | 1,4 | 25,0 | Welding of copper-nickel pipes from MNZh5-1 alloy and welding of these pipes with L90 brass and BrAMts9-2 bronze |

| ANMts LKZ-AB | BrANMTs 8-5-1.5 | 16,5 | 1,2 | 50,0 | Correction of defects in bronze castings of type BrAMts9 and AN |

| Electrodes for welding copper and its alloys | |||||

| M30K | NMZh-Mts28-2.5-1.5 | 13,0 | 1,4 | Not less than 40.0 | Welding of parts made of Monel metal and other copper-nickel alloys |

| KhN-1 | NIMO-25 | 14,0 | — | 65,0 | Welding of products made of nickel-molybdenum alloy (25-30% molybdenum) operating in aggressive environments (hydrochloric and sulfuric acid) |

Electrodes used in welding steels must provide high mechanical properties of the welded joint and high productivity of the welding process.

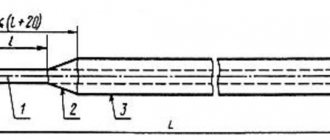

Electrode wire.

Electrode wire is made with a diameter of 1-12 mm. The length of electrodes cut from wire with a diameter of up to 3 mm is usually 350 mm, and with a diameter over 3 mm - 450 mm. In practice, electrodes with a diameter of 2–7 mm are predominantly used. Electrodes with a diameter of 2 mm are used to weld metal up to 2 mm thick, and with a diameter of 3 mm - metal with a thickness of 2 mm and above. For welding metal with a thickness of 5–10 mm, electrodes with a diameter of 4–5 mm are used, and for thicknesses over 10 mm, electrodes with a diameter of 5–7 mm are used. The chemical composition of the metal of steel electrode wire is established by GOST and has 19 grades. For welding low-carbon steel and many types of structural steels, three grades of wire are most widely used in production: Sv-I, Sv-IA and Sv-II.

These wire grades differ in the content of carbon, silicon and phosphorus. The best Sv-IA wire contains up to 0.10% C; 0.35—0.6% Mn; 0.15-0.25% Si; 0.03—0.04% S; up to 0.03% R. Mark Sv-II contains carbon up to 0.18%.

For manual arc welding, the electrode wire is coated with special coatings to protect the molten metal bath from absorbing oxygen and nitrogen from the air. The oxygen content in the weld metal above 0.2% and nitrogen above 0.15% sharply reduces the plastic properties of the weld metal: relative elongation, bend angle, impact strength. The absorption of nitrogen and oxygen by the molten metal during the welding process occurs both during the transition of metal drops from the electrode to the bath and in the bath itself and continues until the metal solidifies. Oxygen, which has great chemical activity, enters into compounds with iron: FeO, Fe3O4 and Fe2O3.

The lower oxide - oxide FeO - is formed earlier than others on the surface of a drop of molten metal and immediately dissolves in it. Higher oxides of iron at the moment of transferring a drop of metal into the bath are deoxidized by carbon, manganese, and silicon contained in the electrode wire. Burnout of these impurities reduces their content in the weld metal. On the surface of the weld pool, oxidation reactions continue and, despite the deoxidation processes occurring inside the pool, the metal is saturated with oxygen in the form of a solid solution of FeO in iron or oxide inclusions.

Saturation of the molten metal with air nitrogen can occur either through the formation of manganese nitrides MnN and silicon SiN or oxide NO at high temperatures. At a metal temperature of about 1000°C, this oxide precipitates from the solid solution and dissociates into atomic nitrogen and oxygen. Atomic nitrogen forms nitrides Fe4N and Fe2N with iron in the temperature range 500-800°C. To reduce the nitrogen and oxygen content in the weld metal, a number of measures are used: the content of deoxidizing agents (Mn, Si) in the electrode metal is increased, and a special electrode coating containing deoxidizing agents is applied. A good protection of the molten metal from oxygen and nitrogen in the air during manual arc welding is the use of coated electrodes, which, when melted, produce slags that protect the metal both during its transition from the electrode to the bath and in the bath itself. Depending on the thickness of the coating, electrodes are divided into thin-coated, with a coating layer thickness of 0.1-0.3 mm, and thick-coated, with a coating layer thickness of up to 2 mm. The weight of a thin coating is about 1%, and a thick one is about 20-35% of the weight of the electrode. Thin coatings are designed to increase arc stability and are therefore often called ionizing coatings. The most common ionizing coating is chalk, consisting by weight of 80-85% finely sifted chalk CaCO3 and 15-20% liquid soluble glass NaOSiO2.

Welds made by these electrodes, due to the lack of protection of the molten metal, have low tensile strength and low ductility. To obtain welds with high strength and ductility, thickly coated electrodes are used. The composition of the thick coating includes gas-forming, slag-forming and alloying substances and deoxidizers.

The gas-forming substances in coatings, such as wood flour, starch, food flour, cellulose, etc., are intended to create a protective gaseous environment (around the arc and the liquid metal pool) during the melting process of the electrode, consisting mainly of hydrogen and carbon monoxide. As a result of this protection, it is possible to eliminate the harmful effects of air on the liquid metal. Slag-forming substances included in thick coatings, such as feldspar, manganese ore, titanium ore, chalk, kaolin, etc., form slags when melting the electrode, protecting the molten metal from exposure to air and improving the conditions for the formation of weld metal.

Ferroalloys in the form of ferromanganese, ferrotitanium, ferrosilicon, etc. are introduced into coatings to deoxidize the weld metal and slag, convert ferrous oxide in the metal into other compounds, as well as to alloy the weld metal by increasing the content of certain elements in it, such as Mn, Si, Ti and etc.

For welding steels with a low content of alloying impurities, electrodes with rods made of low-carbon steel are used, but with the introduction of alloying elements in the form of ferroalloys (ferromanganese, ferrosilicon, ferrovanadium, ferrotitanium, etc.) into the coating along with the corresponding gas and slag-forming components.

Alloying elements from the coating, partially burning out, pass into the deposited weld metal and make it possible to obtain mechanical properties of the weld close to the properties of the metal being welded.

When welding high-alloy steels (stainless and heat-resistant), electrodes are used whose rods are identical in chemical composition to the metal being welded. To compensate for burnout during welding of the alloying elements contained in the wire, the corresponding components in the form of ferroalloys are introduced into the coating composition for these electrodes, in addition to gas and slag protective substances. In all coatings, liquid glass is used as a binder. In some cases, dextrin and organic glue are used.