Manufacturing of square steel pipes

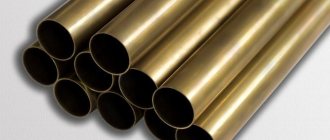

Large-scale production of steel profile pipes must comply with the standards. But there are other ways to obtain square pipes, the so-called artisanal ones. For example, rolling a round pipe. This method does not guarantee reliable operation of the product in the future and does not comply with GOST, so it is used only by craftsmen in their subsidiary plots.

Square steel pipe manufacturing factories

In Russia, large metallurgical plants are engaged in large-scale production of square pipes. Products are manufactured to order from a standard range of standard sizes. The customer chooses the method of obtaining and processing steel depending on the purpose of the future rolled product. There are more than 50 factories in the Russian Federation supplying pipe products.

Suppliers of profile square pipes in the Russian Federation are:

- "Agrisovgaz" Kaluga region.

- Almetyevsk Pipe Plant (Tatarstan).

- Amurmetal (Khabarovsk Territory).

- Barnaul mechanical press plant.

- Bor Pipe Plant (Nizhny Novgorod region).

- Brock-Invest-Service (Moscow).

- Wilsey-Plus (Kaluga).

- Volgatruboprofil (Kostroma region).

- Volzhsky Mechanical Plant.

- VTPZ (Volgograd region).

- Vyksa Metallurgical Plant.

- DZMT (Republic of Dagestan).

- Stroy-Profil LLC (Oryol region).

- ZSMK (Kemerovo region).

- LLC "Oktan" (Stavropol region).

- Isaevsky Machine-Building Plant (Kolomna).

- Royal Pipe Factory.

- Metallurg (Moscow).

- OJSC MTZ "Filit"

- Neftekamsk Pipe Plant.

- Metallinvest (Nizhny Tagil)

- NMZ named after Kuzmina (Novosibirsk).

- LLC "New Kuban Profile" (Krasnodar region).

- Pervouralsk New Pipe Plant

- Ryazan Pipe Plant and others.

The production of profile steel products is carried out in the Urals, Chelyabinsk, Yaroslavl, Ryazan, Bashkiria, and Altai Territory. There are many factories in the Moscow, Volgograd, Novosibirsk, and Sverdlovsk regions. The range of products varies - some companies sell pipes with a small cross-section (from 10x10 to 60x60), others - cross-sections over 80x80 mm.

Technology for rolling square profile pipes

The raw materials for seamless square pipes are round steel products with a wall thickness of 4 to 14 mm. Cold deformation produces products of lower quality, but this production method is less expensive and does not require powerful, expensive and large equipment.

During hot deformation of seamless profile pipes, the metal structure does not change, which is important for maintaining the strength properties of the product. Therefore, such products are of higher quality and are used in areas where heavy loads are applied.

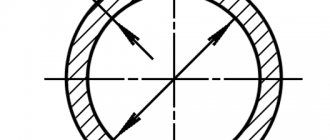

During cold and hot deformation, different equipment is used, but the rolling method is similar: round pipes pass through rolls, as a result of which they are deformed, resulting in a square-section blank.

How electric-welded square steel pipes are produced

Strips are prepared from a flat metal sheet, which are converted by bending into a round pipe. Then the seam is welded and cleaned. The workpiece is rolled on rollers, which produces a square-shaped product. But this is not enough for further operation - the profile workpiece undergoes the necessary processing and hardening procedure. This is important to relieve excess stress on the metal after bending.

Square Pipe Steel

The main material for the manufacture of square profile pipes is unalloyed carbon steel according to GOST standards 380, 1050, 9045. But there are products that are made from alloy steel grades 09G2, 09G2S, 10HSND (in accordance with GOST 19281), grades 10G2, 30KhGSA (according to GOST 4543).

Technical requirements for profile pipes are regulated by GOST 13663-86. Here are the requirements for appearance, heat treatment of pipes, steel grades, standards for the mechanical characteristics of steel products, etc.

Standard sizes of square steel pipes

The regulatory document defines the main standard sizes of square pipes:

- Seamless cold-deformed products occupy 17 standard sizes with sides from 10 to 120 mm. Within this type, products can be divided into 2-3 types of assortment depending on the wall thickness (from 1 to 8 mm).

- Seamless hot-deformed square products occupy a niche of dimensions from 30 to 160 mm, which makes up almost the entire table of GOST standard sizes. Wall thickness ranges from 4 to 14 mm.

- Electric-welded square-section pipes come in 15 standard sizes, within which variations can be distinguished with wall thicknesses from 1 to 5 mm. The section side varies from 10 to 100 mm.

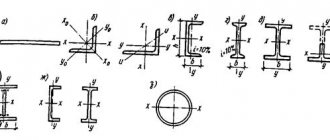

The figure shows the main parameters of a square steel profile pipe, where S is the wall thickness, R is the bending radius of the metal, A is the width of the profile along the outer walls.

Table 1. Standard sizes of square steel pipes

| Outer diameter A, mm | Wall thickness S, mm | Cross-sectional area, cm2 | Weight 1 m, kg |

| 10 | 1,0 | 0,343 | 0,269 |

| 15 | 1,0 | 0,543 | 0,426 |

| 1,5 | 0,771 | 0,605 | |

| 20 | 1,0 | 0,743 | 0,583 |

| 1,5 | 1,071 | 0,841 | |

| 2,0 | 1,37 | 1,075 | |

| 25 | 1,0 | 0,943 | 0,740 |

| 1,5 | 1,37 | 1,07 | |

| 2,0 | 1,77 | 1,39 | |

| 2,5 | 2,14 | 1,68 | |

| 3,0 | 2,48 | 1,95 | |

| 30 | 2,0 | 2,17 | 1,70 |

| 2,5 | 2,64 | 2,07 | |

| 3,0 | 3,08 | 2,42 | |

| 3,5 | 3,50 | 2,75 | |

| 4,0 | 3,88 | 3,04 | |

| 35 | 2,0 | 2,57 | 2,02 |

| 2,5 | 3,14 | 2,46 | |

| 3,0 | 3,68 | 2,89 | |

| 3,5 | 4,20 | 3,30 | |

| 4,0 | 4,68 | 3,67 | |

| 5,0 | 5,57 | 4,37 | |

| 40 | 2,0 | 2,97 | 2,33 |

| 2,5 | 3,64 | 2,85 | |

| 3,0 | 4,28 | 3,36 | |

| 3,5 | 4,90 | 3,85 | |

| 4,0 | 5,48 | 4,30 | |

| 5,0 | 6,57 | 5,16 | |

| 6,0 | 7,54 | 5,92 | |

| 42 | 3,0 | 4,52 | 3,55 |

| 3,5 | 5,18 | 4,07 | |

| 4,0 | 5,80 | 4,56 | |

| 5,0 | 6,97 | 5,47 | |

| 6,0 | 8,02 | 6,30 | |

| 45 | 3,0 | 4,88 | 3,83 |

| 3,5 | 5,60 | 4,40 | |

| 4,0 | 6,28 | 4,93 | |

| 5,0 | 7,57 | 5,94 | |

| 6,0 | 8,74 | 6,86 | |

| 7,0 | 9,80 | 7,69 | |

| 8,0 | 10,74 | 8,43 | |

| 50 | 3,0 | 5,48 | 4,31 |

| 3,5 | 6,30 | 4,94 | |

| 4,0 | 7,08 | 5,56 | |

| 5,0 | 8,57 | 6,73 | |

| 6,0 | 9,94 | 7,80 | |

| 7,0 | 11,20 | 8,79 | |

| 8,0 | 12,34 | 9,69 | |

| 60 | 3,5 | 7,70 | 6,04 |

| 4,0 | 8,68 | 6,82 | |

| 5,0 | 10,57 | 8,30 | |

| 6,0 | 12,34 | 9,69 | |

| 7,0 | 14,00 | 11,00 | |

| 8,0 | 15,54 | 12,20 | |

| 70 | 4,0 | 10,28 | 8,07 |

| 5,0 | 12,57 | 9,87 | |

| 6,0 | 14,74 | 11,57 | |

| 7,0 | 16,80 | 13,19 | |

| 8,0 | 18,74 | 14,71 | |

| 80 | 4,0 | 11,88 | 9,33 |

| 5,0 | 14,57 | 11,44 | |

| 6,0 | 17,14 | 13,46 | |

| 7,0 | 19,60 | 15,38 | |

| 8,0 | 21,94 | 17,22 | |

| 90 | 5,0 | 16,57 | 13,00 |

| 6,0 | 19,54 | 15,34 | |

| 7,0 | 22,40 | 17,58 | |

| 8,0 | 25,14 | 19,73 | |

| 100 | 6,0 | 21,94 | 17,22 |

| 7,0 | 25,20 | 19,78 | |

| 8,0 | 28,34 | 22,25 | |

| 9,0 | 31,37 | 24,62 | |

| 110 | 6,0 | 24,34 | 19,11 |

| 7,0 | 28,00 | 21,98 | |

| 8,0 | 31,54 | 24,79 | |

| 9,0 | 34,97 | 27,45 | |

| 120 | 6,0 | 26,74 | 20,99 |

| 7,0 | 30,80 | 24,18 | |

| 8,0 | 34,74 | 27,27 | |

| 9,0 | 38,57 | 30,28 | |

| 140 | 6,0 | 31,54 | 24,76 |

| 7,0 | 36,40 | 28,57 | |

| 8,0 | 41,14 | 32,29 | |

| 9,0 | 45,77 | 35,93 | |

| 150 | 7,0 | 39,20 | 30,77 |

| 8,0 | 44,34 | 34,81 | |

| 9,0 | 49,37 | 38,75 | |

| 10,0 | 54,28 | 42,61 | |

| 180 | 8,0 | 53,94 | 42,34 |

| 9,0 | 60,17 | 47,23 | |

| 10,0 | 66,28 | 52,03 | |

| 12,0 | 78,17 | 61,36 | |

| 14,0 | 89,59 | 70,33 | |

| 32 | 4,0 | 4,20 | 3,30 |

| 36 | 4,0 | 4,84 | 3,80 |

| 40 | 2,0 | 2,97 | 2,33 |

| 65 | 6,0 | 13,54 | 10,63 |

The customer can submit an application for the production of profile pipes of various lengths. But GOST also regulates this indicator:

- Unmeasured length:

- hot-deformed seamless – 4…12.5 m;

- cold deformation, seamless and welded - 1.5...9 m.

- Measured length:

- hot deformation seamless – 4…12.5 m;

- cold deformation seamless – 4.5...11 m;

- welded - 5...9 m.

Profile pipe sizes

Depending on the shape, there may be the following sizes:

Square

- cross section: 1010 mm - 180180 mm.

- wall thickness: 0.8 mm - 14.0 mm.

Rectangular

- cross section: 1510 mm - 180150 mm.

- wall thickness: 0.8 mm - 12.0 mm.

Oval

- cross-section: 63 mm - 7222 mm.

- wall thickness: 0.5 mm - 2.5 mm.

Marking of square steel pipes

Square steel products are stamped by manufacturing plants to confirm quality and compliance with GOST. How to read the label correctly?

The designation must indicate the cross-sectional size - for square pipes the value will be duplicated, since the sides of the square are the same. The length of the product is indicated - according to GOST, pipes can be of measured or unmeasured length, as well as the wall thickness of the profile pipe. Also in the numerator at the end there is a corresponding regulatory document - in this case GOST 8639-82 for square steel pipes.

Yulia Petrichenko, expert

The denominator of the marking indicates the steel grade and GOST to which the metal corresponds. An example of marking a 40x40 steel square pipe with a length of 1.25 m and a wall thickness of 3 mm. Steel grade 10 group B.

For pipes of unmeasured length, the corresponding value is not indicated in the marking.

Range of rectangular profile pipes: GOST 8645-68

The most clear information about the range of steel rectangular pipes is presented in the corresponding GOST, which is presented below.

Scope of application of square steel pipes

The main advantage of a square pipe is its ability to withstand loads: static and bending. This is an indispensable material for the construction of frame structures, farms, greenhouses, warehouses, overpasses, lifts, bridge structures, etc. Square profile products are part of advertising structures, roofing structures, and arched vaults.

The pipe is used in the production of furniture, including school furniture, household items and interior design. For these purposes, the workpiece is subjected to careful processing - grinding, painting, etc. The hollow square pipe in interior items ensures high reliability of the structure and its low weight. Unbending profiled pipe is a durable frame for tables, chairs, beds, shelves, benches and other household items.

The secret of a square pipe is the uniform distribution of the load on the sides, which generally gives high values of the radius of gyration along the perimeter, and accordingly, over the cross-sectional area. In global construction, it is practiced to fill profile rectangular and square pipes with concrete (in compressed and curved rods), which in general significantly increases not only the reliability of the structure, but also the fire resistance of the structure. This allows you to avoid expensive treatment of buildings with fire-retardant coatings, or significantly reduce the costs of this work.

Unlike round pipes, profile pipes do not have rolling inertia, therefore they are successfully used in roof structures instead of load-bearing beams. Their light weight ensures the reliability and durability of the structure, reducing the load on walls, foundations and other elements.

What profiled products do you use in construction? Share your experience with square steel pipe in the comments.

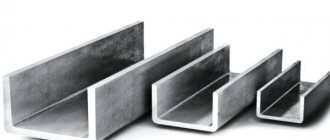

Rectangular

Rectangular profile pipes are produced with a range in accordance with GOST 8645-68. The length and maximum deviations in size correspond to GOST 8639-82.

Profile pipes of this section are most often used in construction as metal beams. Four stiffening ribs, low specific gravity and high bending strength allow them to withstand increased loads. Profile rectangular steel pipes are fastened by electric arc welding. In addition to high strength, such products are more economical (up to 25% compared to round ones) and easier to install, allowing the creation of more complex engineering structures. Fits well on flat surfaces. They are also used to create durable frames in furniture production, the automotive industry, for the construction of durable structures, supports, where the low weight of the profile is a decisive factor, for example, in outdoor advertising.

Dimensions:

- width: 10, 20, 25, 30, 35, 40, 42, 45, 50, 60, 70, 80, 90, 100, 110, 120, 140, 150, 180 mm;

- height: 10, 15, 20, 25, 30, 40, 50, 60, 70, 80, 100, 120, 150 mm;

- thickness: 1, 1.5, 2, 2.5, 3, 3.5, 4, 5, 6, 7, 8, 9, 10, 12 mm.

The most popular sizes of this profile are 40×80 and 40×100 mm; rectangular profiles of large diameter are also available.

An example of the designation of a rectangular profile pipe 40 mm x 25 mm x 3 mm, wall thickness 3.0 mm, length multiple of 1250 mm, made of steel 10, with a chemical composition according to group B (GOST 13663-86):

| Pipe | 40×25×3×1250 cr GOST 8645-68 ———————— B 10 GOST13663-86 |