Inverter welding involves the use of IIST - an inverter source of welding current. This is a welding unit, one of the power supply options for a welding arc, which is formed by a discharge in gas. It provides a permanent connection due to established interatomic bonds between the parts being welded under conditions of heating and/or plastic deformation. How to choose the right electrodes for welding with an inverter?

Welding Equipment Options

Different welding options can be performed by one type of machine; the universal IIST works in different modes, with different materials. The main goal is a constant stable burning process of the welding arc; easy ignition is also necessary.

Welding arc power sources:

- Transformers. Specially designed for welding work, by converting the mains voltage to low voltage, it converts the current from low to high. Indicators reach thousands of amperes. The parameters are changed by sectioning the turns of the device winding, primary or secondary.

- Electric generators running on diesel, gasoline or electricity. Otherwise called welding units, essentially mobile power plants capable of generating electric current for welding and electric arc cutting.

- Rectifiers. AC to DC energy converters, unidirectional, output type.

- Inverters. Devices for converting direct current into alternating current, changing the voltage according to the type of discrete signal. They are used as separate devices or in uninterruptible power supply systems.

Rectifiers and inverters are variants of the same electrical machine. This is due to the rule of reversibility of electric machines, which consists in converting electricity into mechanical energy and converting it back.

Advantages of popular brands of electrodes

Many modern types of electrodes for welding using an inverter have the following advantages.

- Easy to weld. Difficulties when welding with such electrodes can arise if you incorrectly select them according to the composition of the core material.

- High quality seam. This parameter is the most important during welding work, and the electrodes of the indicated brands make it possible to ensure it. Using such electrodes for the inverter, you can obtain high-quality internal and external connections, welds of convex and concave shapes.

- Easy slag separation. The slag obtained when welding using such electrodes is easily separated, which makes it possible to immediately see what quality of weld they provide.

- Corroded parts can be welded. Of course, products covered with a layer of rust are cooked very rarely, but these electrodes make it possible to obtain a high-quality and reliable seam even in this case.

- The welding process is safe for the welder in terms of sanitary and hygienic standards.

Electrodes of the ANO brand from the famous manufacturer ESAB

Device and method of operation of the device

Structurally, the inverter is assembled as a unit of several devices:

- Transformer providing voltage reduction.

- A block of circuits based on metal-oxide-semiconductor type transistors - MOS, in English - MOSFET - metal-oxide-semiconductor field effect transistor, or IGBT - in English, IGBT - Insulated-gate bipolar transistor.

- Choke for stabilizing current ripples.

The device operates as follows:

The mains voltage is supplied to the rectifier, the direct current is converted into alternating current, which has a high frequency. It is transmitted to the welding transformer, from which the voltage goes to the welding arc.

A special feature of the inverter apparatus is its compactness and improved quality of arc operation. Thanks to this, efficiency increases, spatter during operation decreases, and welding parameters can be adjusted. This has led to their popularity and widespread use not only by professionals, but also by amateur craftsmen.

Direct or alternating current

In order to correctly select electrode products, you need to know what type of current the welding process is possible with. In other words, what is better - “constant” or “change”? There are also universal brands that work on both types of current.

Electric welding with inverters using direct current has its own characteristics and advantages:

- There is practically no metal spattering (this saves electrodes);

- ease of use;

- high productivity due to reduced labor intensity;

- persistent and stable arc even in the presence of external negative influences: voltage fluctuations or gusts of wind;

- neat and high quality seam. There are no uncooked areas;

- ability to work with thin metal products.

There are also disadvantages:

- work is possible only with the use of expensive inverter technology;

- unstable arc in difficult places. For example, in the corners.

Two operating modes are possible: with direct or reverse polarity. The first option is used when working with thick metal and when high temperatures are required. Reverse polarity currents are convenient for connecting thin and low-melting metals, as well as dissimilar alloy and stainless steels.

Electric welding with alternating current does not require a rectifier. In addition, such electrodes are universal: they also work with direct current.

Minuses:

- worse connection quality than when using “permanent”;

- low impact strength;

- uneven seam;

- metal splashing.

How to choose electrodes for welding with an inverter

To ensure a high level of skill in the process of welding metals and to obtain an even, reliable seam, it is worth concentrating not only on the characteristics of the inverter, but also on the parameters of the welded rods.

Electrodes for inverter welding are rods that conduct electric current directly to the location where the welding process takes place. Efficiency is ensured by a number of parameters that should characterize the electrode. The main ones:

- Uniform melting of the rod itself and its coating.

- Maintaining the physical, mechanical and chemical characteristics of the rod material during storage and operation.

- Low toxicity, minimal release of harmful substances during the welding process.

During welding, he is required to provide a stable, constant combustion arc to obtain a smooth, beautiful seam, the absence of massive splashing of hot metal splashes, and easy separation of the slag formed on the surface of the seam.

Electrodes are divided into categories according to their intended use.

The rods are suitable for welding:

- Products and surfaces made of carbon or low-alloy metals.

- Parts made of heat-resistant materials with high strength and hardness.

- Stainless steel components.

- Products made of aluminum and copper alloys or corresponding pure materials.

- Parts and components made of cast iron.

- In conditions of small repair work, if necessary, surfacing on existing products.

- Surfaces made of unknown metals.

Main selection criteria

Difficulties that arise when choosing are associated with the emergence of a large number of different electrode options. When searching for the most suitable electrode, you should take into account their division into two main groups:

- Melting.

- Non-melting.

The first type of product is represented by a rod of various diameters with a coating made from a special mixture.

Due to the use of a special coating composition, the created arc behaves better at the time of welding. This is why consumable electrodes are often chosen for devices used in manual arc welding. Non-consumable - today are less common, as they are intended for welding work in a special environment. A beginner will not be able to choose them correctly, as they have a large number of features.

The selection of electrodes for welding with an inverter is carried out taking into account the material from which the workpieces to be joined are made. The properties of the metal largely determine the quality of the resulting weld.

Considering how to choose welding electrodes for an inverter, we note the following points:

- The rod for transmitting electricity and stabilizing the arc is selected for each material, taking into account its chemical composition.

- Carbon electrodes are used to connect products made of low-carbon or low-alloy steel.

- If the products to be joined are made of alloy steels, then electrodes of the MP-3, ANO-21, LB-52U and others are used during welding work.

- The best electrodes for inverter welding of other types of metal are considered to be those in the manufacture of which a core made of alloy steel is used, for example, TsL-11.

- The welding method can be used to join elements made of cast iron. In this case, OZCH-2 electrodes are used.

Experienced welders select the consumable material in question also taking into account the conditions under which the resulting product will be used.

Main characteristics of welding rods

When selecting electrodes for welding, pay attention to the following characteristics:

- Diameter. The value of this indicator is related to what parts or products need to be connected by welding methods, what their size and thickness are. This is also determined by the characteristics of the welding machine. The most common diameter is 3 mm.

- Electrode brand. Determined by the properties of the materials used in the manufacture of the rods.

- Coating. Protects the rod from corrosion processes. Another task is to create a protective cloud of gases around the welding site to prevent oxidation and slag formation.

- Storage conditions. Coatings are capable of absorbing moisture, which negatively affects the quality of the seam and ignition of the arc.

- Manufacturer's brand.

Varieties of rods, as well as the requirements for them, are described in GOST regulatory documents.

additional characteristics

Many other features of the welding carried out determine the requirements for electrodes. An example is the polarity and type of current. The welding inverters used in most cases supply direct current, which can be supplied to the welding zone according to two schemes:

- Reverse polarity involves connecting the plus to ground and the minus to the electrode.

- Straight polarity. In this case, the plus is connected to ground, the minus to the welding electrode.

Reverse polarity is selected in the following cases:

- In order to protect the metal from burn-through, the reverse polarity of the connection is selected. It allows you to work with parts that are small in thickness.

- High-alloy steels are characterized by high susceptibility to heat. That is why, when working with such material, the reverse polarity connection method is chosen.

The most important parameters of the welding process are:

- Diameter of the electrodes used.

- The strength of the welding current used.

- The thickness of the parts to be connected.

It is very important to select the electrode diameter correctly, since if the value is too high, the welding current density is significantly reduced. In this case, the degree of penetration of parts decreases, the width of the weld seam increases and its quality decreases. In addition, manufacturers often indicate what amperage the product is best suited for.

This is interesting: Inch thread: size table, markings, GOST

Types of electrodes by design and material

Important criteria by which welding rods are distinguished are design and material.

The material from which the electrodes are made

The quality characteristics of the seams depend to a large extent on the properties of the materials used in the manufacture of the rods. In accordance with State standards, two large groups of materials are used for the production of rods:

- Metals

- Non-metallic materials.

According to another classification, they are divided into two groups

- Non-consumable - made from coal material, tungsten, graphite

| Types of rods | Stamps | Application |

| Coal. Non-metallic, copper plated surface possible | SK-welding round ⌀: 4, 6, 8, 10, 15, 18 mm Length: 250 ±10 mm | Used in air-arc cutting conditions to eliminate seam defects |

| VAR - air-arc ⌀: 6,8,10,12 mm Length: 300 ±10 mm | ||

| VDK – air-arc round ⌀: 12x5, 18x5 mm Length: 350 ±10 mm | ||

| Tungsten Metal. Classified by additives in % | EVL – lanthanum tungsten (2%) | Mostly applicable for argon arc welding. Highly wear resistant |

| EVI-yttriated (2%) | ||

| EVT-thoriated (up to 1.5%) | ||

| EHF – has no additives | ||

| Graphite or graphitized. Non-metallic | Not specially produced. It is obtained by turning graphitized rods for ore-smelting furnaces using an electric arc. | Used for arc welding and cutting |

For tungsten metal rods, color coding is used:

WP (green). Alternating current. They work on magnesium, aluminum, various alloys WT-20 (red) - direct current, used for welding several types of steels: carbon, low-alloy, stainless.

WC-20 (gray). Direct and alternating current. A universal option for welding all types of steel products.

WL-15 (gold). Direct and alternating current. They work on stainless and alloy steels.

WL-20 (blue). Direct and alternating current. Weld stainless and laminated types of steel products.

WY-20 (dark blue). D.C. They work not only with stainless steel, low-alloy steel, carbon steel, but also with other metal materials: copper and titanium.

WZ-8 (white). Alternating current. Weld aluminum and magnesium products. Additives are delivered separately. The work is carried out in a gas environment to protect the elements being welded.

Non-consumable rods are distinguished by a number of positive qualities - they do not subject the metal to deformation; — provide an even, strong, durable seam; — the welding and cutting process takes place at high speed.

There are disadvantages: the gas that creates the protective bath is easily blown out when working in the air, especially in windy weather. In addition, preliminary work on the metal and cleaning of the surfaces to be welded are necessary.

- Melting – metal rods. Melting of the electrode leads to the formation of a seam.

Among them, there are two types: uncoated and coated. The first option was previously used very widely. Now it has been replaced by options with different types of coatings. The uncoated version can be used when a specialized continuous gas shielded welding technology is in operation.

The organic and inorganic substances that make up the coating create certain effects. A protective gas cloud appears around the weld pool. Part of the coating becomes liquid and covers the molten metal, separating it from air oxygen. Protective mechanisms are created for the resulting weld from environmental influences.

Powder coating solves two main problems:

— adjusts the stability and constancy of the combustion processes of the electrode material; - a change in the physico-chemical characteristics of the metal material being welded due to the ingress of elements of the rod, interaction at the level of atoms of substances.

Electrode coatings

The efficiency of welding work depends to a large extent on the coatings of the rods.

There are four types of coatings:

- Basics. Designation B.

UONI - Universal coating of a scientific research institute, works when welding on direct current. Creates strong, flexible, elastic seams that are resistant to various influences, including impact loads. They work in all spatial positions, with the exception of vertical top-down and metal products that are very thick.

- Rutile. Designation R.

Capable of working in all welding modes: constant. and change. current in any spatial directions, except vertical from top to bottom. Lights up easily even with low inverter open circuit voltage. Negative point: slag on the seams can create problems; sometimes it can only be removed with a hammer.

- Sour. Designation A.

Can be welded in all welding modes: constant. and change. current in any spatial position except vertical. It is recommended not to use for steels that contain a lot of carbon and sulfur. As disadvantages, relatively large spattering was noted, and sometimes cracks were observed in the seams. In addition, the toxicity of the acidic version requires special preparation of the workplace - equipping it with exhaust equipment.

- Pulp. Designation C.

Welding with direct and alternating current can take place in all spatial positions. Convenient to use in installation conditions. A special requirement is to prevent overheating. Large splashing and, accordingly, increased material losses.

- Mixed look. AC designation.

Possibility of welding work on various structures, pipelines, in any position of the seam, with the exception of the ceiling. Low consumption per unit of deposited metal.

Spraying is based on a number of components:

A – oxide of iron, lead or other metals.

B – two calcium-based components: carbonate and fluoride.

C – cellulose as a basic characteristic.

R – rutile as the main element.

Other parameters for assessing rods

When choosing electrodes, pay attention to the dimensions of the rod. The diameter determines the thickness and size of metal products that can be welded with it.

There is a standard size table that shows the correspondence between the thickness of sheets or steel products and the diameter of the electrodes:

| Thickness of steel sheet or part in mm | 1,5 | 2 | 3 | 4-5 | 2-12 | Over 13 |

| Welding rod diameter in mm | 1,6 | 2-2,5 | 2,5-3 | 3,2-4 | 4-5 | 5 |

Another important indicator relates to the electrical current in amperes, which is necessary in order to successfully weld metal of a certain thickness.

| Thickness of steel sheet or part in mm | 2 | 2,5 | 3 | 4 | 5 |

| Current strength in a | 55-65 | 55-80 | 70-120 | 130-160 | 180-210 |

When work takes place in a vertical or ceiling position, the current strength can be reduced by 15-20%. in this case, the diameter of the rod is sufficient up to 4 mm.

Classification according to main characteristics

The consumable material in question is primarily classified according to its intended purpose. There are several main groups of electrodes:

- Designed to work with metals that have a low concentration of carbon and alloying elements.

- For joining heat-resistant steels with a high strength index.

- For working with high-alloy steels, for example, stainless steel, in which the concentration of chromium is high.

- Options designed to work with aluminum or copper.

- A separate group includes electrodes intended for connecting cast iron elements.

- For repair work and metal surfacing.

- Universal type products that are used to work with materials of uncertain chemical composition.

A wide variety of chemicals can be applied to the metal rod. According to the type of coating used, 4 groups of products are distinguished; only two are most widespread:

- Main. Products with a basic coating are widely used. An example would be electrodes of the UONI 13/55 brand. They are used to produce seams with high impact strength, mechanical strength and ductility. In addition, the base coating helps protect the seam from the occurrence of crystallization cracks. The choice of this design option is carried out if you need to obtain a responsible design. A significant drawback is that before welding work, the surface must be thoroughly cleaned: oil stains, rust, and scale can cause the formation of microscopic pores.

- Rutile coating. If it is necessary to make a connection on low-carbon steel, then rutile-type electrodes are often chosen. Let's call the most common brand MP-3. The second type is characterized by easy separability of the forming slag and arc stability when supplied with alternating or direct current. During the welding process, less spatter is generated, and the resulting seam has excellent decorative qualities. In addition, the second type of product is suitable for working with workpieces that have a large layer of rust or contaminants on the surface.

The other two types are extremely rare, as they are used in special cases.

Which electrodes are best for an inverter?

When choosing rods for an inverter welding machine, you should focus primarily on the material that will have to be welded. The electrode core must be similar in type to this type of metal. Stainless steels require rods of the same type, and if the steel has heat-resistant properties, you need the same steel rod with heat-resistant characteristics. To form an even, strong seam, high-alloy steels must be welded with rods with the same composition of alloying elements.

Suitable brands of rods for home and construction sites:

MR-3

Universal, well-known electrodes. Can be successfully used on slightly corroded metal. Electrodes E46, P and BR coating. Successfully used for welding structures made of carbon and low-alloy steels. It is possible to weld products with large thicknesses. Electrodes with a diameter from 3 to 5 mm are produced.

Peculiarities:

- high values of electric arc resistance;

- slight splashing;

- easy removal of the slag layer;

- easy ignition both primary and re-ignition.

There is a requirement to clean the welding surface and remove scale.

SSSI 13/55

Allows you to create high-quality seams. Experienced welders and highly qualified craftsmen can work with them. Electrode type E50A, preferably basic coating. Fluoride or carbonate spraying is acceptable; in this case, the gas content of the seam and the number of non-metallic inclusions that impair quality are reduced.

Specifications:

- diameter from 2 to 4 mm;

- deposition coefficient 9.5 g per A*h;

- 1 kg of deposited metal material requires about 1.5 kg of rods;

- yield strength 420 mPa;

- tensile strength 530 mPa;

- relative elongation rate 22%;

- Impact strength depends on temperature conditions, from 50 to 130 J/cm2.

ANO4

The rods are highly flammable and do not need to be ignited. Electrodes E46, rutile coating. The main type of use is welding steel products of carbon and low-alloy grades. They work with all types of current in any spatial directions, with the exception of the direction from top to bottom.

Available in diameters from 2 to 6 mm.

Technical specifications

- rutile coating

- deposition coefficient 8.6 g per A*h;

- productive part for surfacing 1.4 kg/h with a diameter of 4 mm.

- resistance 480 mPa;

- yield strength 380 mPa;

- relative elongation 25%.

UTP 65D

The rods are good at working with various steels and alloys, the seams will be of high quality. Applicable for direct and alternating current of different polarities. Rutile coating. Produced in Austria. Often used in automotive companies and car repair shops for body work.

Pros:

- arc stability;

- low spattering and, therefore, minimizing material loss;

- ability to work with various thicknesses of metal products, with thin- and thick-walled parts and sheets.

- smooth seams with no internal gaps. Can be processed immediately after the metal has hardened.

- possibility of cold hardening of metal material along the seam.

- easy removal of slag layers.

- good tolerance to humid environments, as well as overheating.

Features of operation: before the welding process, the rods must be dried for two hours at a temperature of 160-170 degrees. C. The area of the surfaces to be welded is cleaned. Working with large thicknesses of material requires preliminary preparation of the edge with a bevel angle of approximately 60 degrees.

Electrode selection criteria

First of all, it should be borne in mind that electrodes can be of consumable and non-consumable type. The first ones are made of a metal rod, onto the surface of which a special coating is applied, which helps protect the welding zone and increases the stability of the arc. They are used to perform manual arc welding. Products of the second category - non-consumable - are used to perform welding work in a shielding gas (argon), their varieties and features of use will be discussed in a separate article.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

When choosing electrodes for welding using an inverter, you should take into account that the material of the parts being joined will also affect the quality characteristics of the seam being formed. Accordingly, in order to weld different materials, different types of welding electrodes are used. So, for example:

- to connect products made from low-carbon and low-alloy steel grades, carbon electrodes are chosen;

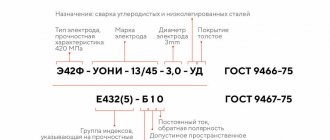

- to connect products made of alloy steel, electrodes of the corresponding brands are used: OZS-4, MR-3 (GOST 9466-75), MR-3, ANO-21, UONI 13/45 (GOST 9467-75);

- if it is necessary to carry out welding work with surfacing or other types of steel, then choose electrodes with a core made of high-alloy metal - TsL-11 (GOST 9466-75);

- in order to cook cast iron, it is also necessary to select electrodes of the appropriate brand - OZCH-2 (GOST 9466-75).

General view of MP-3 electrodes

To date, the following rating of electrodes used for welding using an inverter has been formed.

- ANO. Welding electrodes of this brand are highly flammable and do not require additional calcination. Both novice welders and professionals can work with them equally successfully.

- MP-3 is a universal type; they can even be used to connect uncleaned surfaces.

- MR-3S. Electrodes of this brand should be chosen if increased demands are placed on the characteristics of the seam.

- UONI 13/55 is used for installation of critical structures that require high quality welds. It will be difficult for a novice welder to work with them: their use requires certain experience and high qualifications.

Electrodes UONI 13/55

Requirements for electrodes

When choosing rods for work, you should carefully consider and evaluate them. The coating must be free of chips and damage, otherwise it will not be possible to achieve uniform heating and a uniform seam. At the tip of the electrode, the thickness of the lubricant should be the same as on the entire rod - thanks to this, the electric arc will pass through the center.

It is worth checking the humidity of the coating; sometimes the increased humidity of the coating does not allow the rod to light easily. Hence, the requirements for storing electrodes in a dry place, preferably hermetically sealed. Craftsmen recommend putting bags of salt in the packaging to remove excess moisture. If it happens that the electrodes become damp, they can be dried in the kitchen oven at low temperature. This parameter is indicated on the product packaging. You can also leave it in a ventilated, dry room.

During welding work, to obtain a high-quality, durable, stable seam, the following points must be taken into account:

- The correct amperage for a particular product.

- Suitable diameter of the welding electrode for the product and type of work.

- Taking into account the size and thickness of the materials being welded.

Having selected the parameters, the welder creates a stable, well-burning arc, which will ensure the implementation of welding work at a high level. Literature and sources used:

- M. D. Banov, Yu. V. Kazakov, M. G. Kozulin and others; edited by Yu. V. Kazakova. Welding and cutting materials: Textbook. — 2nd edition, stereotypical. - Publishing House, 2002.

- Kozhevnikov D.V., Kirsanov S.V. Metal cutting tools. Textbook (UMO stamp). Tomsk: Tomsk University Publishing House. 2003.

- Wikipedia article

How to properly use an inverter welding machine

In experienced hands, an inverter can produce a good seam; you need to follow three rules:

- set the optimal current strength;

- choose the correct electrode diameter;

- take into account the thickness of the parts being welded.

Diameter is the main guarantee of a high-quality seam, and the current density also depends on it. The density cannot be higher, because the arc will be unstable, which means the metal will not be welded as well and the seam will be wider.

Of course, this will not affect the quality, but if aesthetics are important, then it is better to avoid it. If you need to cook thin products, it is better to use a semi-automatic machine.

Inverter welding will produce an unreliable seam, and when choosing thick welding rods, pores will appear in the joint, which will reduce its strength.

To find out the optimal current strength when working with the selected rods, just look at the markings on the packaging. It is not recommended to deviate from this parameter.

Selection of products according to other parameters

The type of current, as well as the polarity of its connection, are the most important parameters of welding operations. Welding inverters primarily produce direct current, which can be connected to the workpiece and the electrode in two circuits.

- Straight polarity. With this scheme, the plus is connected to ground, and the minus to the welding electrode.

- Reverse polarity. This scheme involves connecting the minus to ground, and the plus, respectively, to the holder with the electrode.

If you cook with an inverter using straight polarity, the surfaces being connected are subject to significant heating, which does not happen when connecting the polarity in the opposite way. This is why choosing reverse polarity is advisable in the following situations.

- When welding parts of small thickness with an inverter. Reverse polarity in such cases will help protect the material from burn-through.

- Reverse polarity is used to weld parts made of high-alloy steels, which are very sensitive to overheating.

Working with inverter welding

Direct polarity, during which the workpiece is subjected to significant heating, is optimally used for joining materials that are very thick and massive.

When performing any welding work using an inverter, the most significant are three parameters that are interconnected:

- welding current strength;

- electrode diameter;

- thickness of the parts to be connected.

The thickness of the parts being connected has a direct influence on the choice of electrodes. If it is necessary to connect thin parts (up to 1.5 mm), manual welding is not used; semi-automatic machines or devices that allow welding in a protective argon environment are better suited for this purpose.

Options for electrode position when welding

When deciding which electrodes to choose for welding structures of a certain thickness, you can be guided by the following criteria:

- for parts whose thickness is 2 mm, electrodes Ø 2.5 mm are best suited;

- when connecting parts with a thickness of 3 mm, you should choose electrodes Ø 2.5–3 mm;

- if the thickness of the parts to be welded is 4–5 mm, then electrodes Ø 3.2–4 mm are suitable;

- parts with a thickness of 6–12 mm are best welded with electrodes Ø 4–5 mm;

- when the thickness exceeds 13 mm, then the optimal choice is electrodes Ø 5 mm.

It is very important to choose the correct diameter of the electrodes, since if this parameter is exceeded, the welding current density decreases. This will lead to the welding arc becoming unstable, the penetration of parts will deteriorate, and the width of the weld will increase. Many manufacturers indicate on the packaging information about the best current values to use.

Welding electrodes

If such information is not contained on the packaging, then you can follow the following recommendations:

- for welding with electrodes Ø 2 mm, the welding current should be set to 55–65A;

- for products Ø 2.5 mm, a current of 65–80A is used;

- electrodes Ø 3 mm - current 70–130A;

- for electrodes Ø 4 mm, choose a welding current of 130–160 A;

- products Ø 5 mm - current 180–210 A;

- It is better to cook with 6 mm electrodes at a current of 210–240 A.

As it becomes clear from all of the above, for high-quality welding with an inverter, the correct choice of electrodes according to their diameter is important. You should also set the optimal welding current. If, for example, you plan to weld thin metal with an inverter, using large-diameter electrodes, or the welding current exceeds the permissible values, then pores may form in the finished weld, which will significantly reduce its quality characteristics.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Electrodes from foreign manufacturers

Electrodes of the ESAB brand have gained great popularity in the domestic market. A characteristic feature of electrodes from the Swedish manufacturer is that their marking begins with the designation “OK”, followed by 4 digits. Among the wide variety of electrode models of this brand, the following are the most widespread.

- OK 46.00. In terms of characteristics, they are very similar to domestic MP-3 products. Using an inverter, they can cook carbon and low-alloy steels using direct as well as alternating current. When used, the resulting connection is of high quality.

- OK 48.00. They can operate exclusively on direct current; they are used for the installation of particularly critical structures.

- OK 53.70. They are a specialized type; they are used to weld root passages and connect pipe joints.

- OK 61.30 and 63.20. They are used for welding stainless steel parts with an inverter, but before purchasing them, it is important to clarify whether they are suitable for working with the grade of metal you are interested in.

- OK 68.81. Using products of this brand, inverter welding is carried out on parts made of unspecified steel grades, as well as from difficult-to-weld grades.

- OK 96.20. They work on cast iron, and also connect cast iron parts to steel ones.

- OK 92.60. Designed for welding products made of aluminum and its alloys using an inverter.

By the way, the range of electrodes of this brand also includes products that can be used to weld copper and its alloys.

Types of welding arc when welding with electrodes

Welding purpose

Welding is a common method of creating permanent joints by forming new interatomic bonds. There are several varieties of it, each of which has its own area of use:

- electric arc It is performed using a consumable electrode (N. G. Slavyanov’s method) - a universal, universally used technique used for all types of connections. Its main advantages are high productivity due to maximum mechanization of work processes, as well as good mechanical characteristics of the connection;

- manual arc. It is used when installing steel building systems and connecting pipeline elements. It can be performed even in difficult-to-reach places and in different spatial positions;

- gas. Used when working with steel elements of relatively small thickness, as well as when working with aluminum and copper alloys.

There are other ways to create permanent connections: contact, liquid welding or fastening with a special semi-automatic device.

As for the scope of application, there is probably no industry, be it industrial or agricultural production, where welding is not used. The most common examples are construction work (structures made of reinforcement), connecting pipelines for various purposes. Many owners of used cars know what it means to weld a car body. There is a place for a welding machine in the country (for example, for making a metal fence).

Advantages of welded joints:

- full use of section surfaces to connect elements;

- high level of connection reliability;

- relatively small weight of the structure;

- reduction of allowances for additional processing. This is where welding compares favorably with cast construction;

- reduction of labor and resource intensity of work, which leads to their reduction in cost;

- a good alternative to casting and forging. The use of welding joints allows you to create complex structures from cast or stamped parts;

- the ability to work with innovative alloys, lightweight profiles, rolled sheets, especially pure metals, etc.;

- increasing work safety.

Minuses:

- high risk of various seam defects, which does not have the best effect on the strength of the structure;

- the need for strict adherence to technology;

- the appearance of residual stresses due to thermal deformations;

- change in the mechanical properties of the metal near the seam;

- the need for visual (and in the case of critical structures, selective instrumental) control.

Spatial position

There are five main spatial positions of the electrodes in which welding work can be carried out:

- The lower horizontal one is considered the most convenient and productive. A special case of this is the boat position.

- The T-type is similar to the lower horizontal, but requires more welding skill. In this case, the formation of undercuts on the vertical surface and sagging on the horizontal surface is possible.

- The horizontal position of the electrode on a vertical surface is considered quite difficult. To use it in practice, a bevel is most often made on the upper edge of the elements being connected.

- Vertical seams can be welded in two ways: up or down. In the first case, better quality of seams is ensured, and in the second - higher speed.

- The ceiling spatial position is considered the most difficult. It is not suitable for connecting thin elements and is used only when it is impossible to carry out welding work in any other way.

Manufacturers must indicate in what spatial positions welding work can be carried out using electrodes.

Spatial positions of the electrode

Importance of slag

The slag formed during manual arc welding is divided into two types: “long” and “short”. In the first, the viscosity increases slowly with decreasing temperature. For this reason, electrodes with coatings that form “long” slags are not suitable for welding in vertical and overhead spatial positions. For “short” slags, the viscosity increases much faster, so they effectively prevent liquid metal from flowing out of the weld pool. This result is obtained by electrodes with basic or rutile coating.

Coatings

Manufacturers often apply special coatings to electrodes to improve their performance. Among the most common coatings are basic and rutile. The base coating is the most popular and is used by a large number of manufacturers. Thanks to him, it is possible to obtain a high quality seam. Well, in combination with the correctly selected electrode diameter and extensive experience, the welder is able to make a weld of the highest quality and weakly subject to mechanical stress.

Rutile coating is popular among craftsmen working with low-carbon steel. Thanks to this coating, the formation of pores in welds is eliminated; such electrodes can be used with alternating and direct current, and can be reused. Also, electrodes with rutile coating are simply more convenient to use when performing work in hard-to-reach places; when melted, such a coating does not emit hazardous substances (unlike other coatings), which allows you to maintain health.