Stamping of sheet metal parts today is a very common technology that produces products for almost all industries. Thanks to the use of this technology, it is possible to obtain both miniature and large parts of even complex geometric shapes from a flat metal sheet.

Sheet blanks made on a coordinate turret press

What is sheet stamping?

When talking about stamping parts made of sheet metal, we mean a technological operation during which significant pressure is applied to the workpiece. Under the influence of such pressure, the workpiece is deformed and acquires the required configuration and dimensions.

Our distant ancestors began to use such an operation (albeit in a much simplified form). It was by applying pressure to metal that they made agricultural implements, weapons, household items and various decorations.

Modern press for stamping body parts

Stamping as a technology for the production of sheet metal products received active development at the end of the 19th century. It was during that period (starting from the 1850s) that this technology was actively improved, and specialists created powerful equipment for its implementation. Stamped parts, which at that time could already be mass-produced, were of decent quality and had good performance characteristics.

Both hot and cold stamping reached a completely new level of development at the beginning of the 20th century. It was thanks to the improvement of sheet metal stamping technology that serial production of cars became possible, for which body parts were produced using this method. Starting from the 1930s, this technology began to be actively used by enterprises working in the aircraft and shipbuilding industries, and a little later (after only a couple of decades) they began to produce spacecraft parts using stamping.

The high popularity that stamping has gained over a relatively long period of its development is explained by the possibilities:

- production of products of various geometric shapes and sizes, the quality and precision of which allows them to be used immediately for their intended purpose;

- complete mechanization and automation of production processes, which is achieved, in particular, by equipping production with rotary-conveyor equipment for stamping sheet metal;

- serial production of products whose geometric parameters are particularly accurate (such products can be easily replaced with each other if the need arises).

Cold stamping on a hydraulic press

The use of a technological operation such as die stamping makes it possible to transform a metal sheet into a geometrically complex and light-weight product, the strength characteristics of which are at a high level. The use of methods for stamping parts from sheet metal makes it possible to produce both very massive products used in the production of engineering products, watercraft and aircraft, and miniature parts for electronic devices and watch mechanisms.

Hot and cold stamping is often used as a preparatory operation. For example, such technologies produce parts that are then processed by other methods - welding, cutting, etc.

Manufacturing of products from non-ferrous metals

Metal products make up a significant part of industrial products. They are in demand in both domestic and international markets. The sale of finished products is a more promising direction in comparison with the supply of metal. That is why, in addition to enterprises of the metallurgical complex, metal processing plants are being created that produce various types of rolled metal and other products.

Non-ferrous metal products are made from alloys of aluminum, titanium, copper, nickel, zinc, lead, magnesium, brass, bronze, etc.

The consumers of such products are Russian and foreign companies that operate in industries that produce public consumption products:

- production of vehicles (airplanes, cars, railway transport, etc.);

- production of packaging materials and products for construction;

- production of electrical products.

Despite the fact that the Russian Federation is one of the countries that leads in aluminum production, the level of consumption of rolled aluminum in the domestic market remains quite low. Currently, Russia imports more finished aluminum products. A similar situation is observed with rolled heavy non-ferrous metals. Volumes of non-ferrous metal products based on bronze, brass and copper remain quite low. This industry exclusively meets the demand of domestic consumers.

International companies are most often ready to buy large volumes of metal and semi-finished products in the Russian Federation, but not finished rolled metal. Against the backdrop of a low level of capacity utilization of Russian metalworking enterprises, products made of heavy non-ferrous metals are being imported into the Russian Federation.

Another important segment of non-ferrous metallurgy products consists of carbide materials with high strength and cutting characteristics. They are used for the production of cutting, stamping and measuring tools.

Heat-resistant materials have become widespread in the metal products market. Their unique characteristics allow them to resist yielding and breaking when exposed to high temperatures. Heat-resistant alloys are produced on the basis of iron, nickel, cobalt, titanium, molybdenum, niobium, and beryllium.

Such alloys are used to make parts of steam and gas turbines, engine parts, skins and external elements of supersonic aircraft bodies.

The list of non-ferrous metallurgy products also includes graphite-based materials (electrodes, refractory blocks, electrode mass, etc.). Such products are used in large quantities by aluminum smelters.

Features of the technology

The raw material for stamping can be a metal sheet, steel strip or thin tape. Cold sheet stamping has become most widespread for a number of reasons. Hot stamping technology is used in cases where the power of the equipment used is not enough to deform the metal in a cold state or when it is necessary to process a part made of metal with low ductility. As a rule, hot stamping technology is used to process sheet blanks whose thickness does not exceed 5 mm.

Depending on what needs to be done with sheet metal during the stamping process, separation and form-changing technological operations are distinguished. As a result of the first, a part of the metal is separated from the workpiece, which can occur along straight or curved lines, as well as along a certain contour. The separation of metal in such cases occurs due to the displacement of its parts relative to each other.

There are a number of separation stamping operations, which are performed using a press equipped with a special tool.

Cutting

During the cutting process, parts of a metal part are separated from each other along a straight or curly line. The press with which such an operation is performed is more correctly called scissors, which can be disk, vibrating or guillotine. Using cutting, products ready for further use are obtained or blanks are formed for their further processing by other methods.

Schemes for cutting sheet metal with scissors

Punching

This operation is used to form holes of various configurations in a sheet workpiece.

During the punching process, part of the material is removed as waste.

Punching

With the help of punching, a finished product with a closed contour is formed from a metal part.

An example of a part made from strip by cutting

Form-changing stamping operations, in full accordance with their name, are used to change the shape of a sheet metal workpiece, as well as its dimensions, without mechanical destruction.

Flanging

This is a technological operation of stamping sheet metal, as a result of which edges of the required size and shape are formed around the holes in the metal workpiece, as well as along its contour. Most often, the ends of pipes are flanged, on which flanges are subsequently planned to be fixed.

Scheme of flanging a part around a pre-punched hole

Drawing

This is truly volumetric stamping, the purpose of which is to obtain hollow spatial products from a flat metal sheet. Using this technological operation, it is possible to produce objects of box-shaped, hemispherical, cylindrical, conical and other shapes.

Instrumental drawing methods

Crimping

This operation is performed using a conical-type matrix. The purpose of crimping is to narrow the ends of hollow parts made of sheet metal.

When crimping, the end of the workpiece is pushed into the funnel-shaped hole of the matrix.

Bending

Using this technological operation, stamping gives sheet metal workpieces the required bend.

Bending allows you to obtain parts of various shapes, depending on which types of bending are distinguished.

Molding

This is a change in the shape and size of local sections of the workpiece, in which the external contour of the product remains unchanged.

Forming patterns

Not only sheets made of carbon and alloy steels, but also parts made of copper, aluminum and their alloys can be processed using cold stamping technology. Moreover, using a press and corresponding sheet metal stamping dies, it is possible to process materials such as leather, cardboard, rubber, and polymer alloys.

Parts for the production of which cold stamping was used are distinguished not only by the accuracy of their geometric parameters, but also by their high surface quality. The cleanliness of the latter in some cases may correspond to the 8th class. On average, the surface cleanliness of stamped products is in the range of 2–6 classes, which is quite satisfactory for consumers of such products.

Production workshop in which the sheet stamping process is carried out

It should be borne in mind that cold stamping of sheet metal is accompanied by an increase in its strength characteristics.

When choosing a press to perform such a technological operation, as well as when designing sheet metal stamping dies, you should take into account a number of parameters of the feedstock. This is the only way to ensure high quality of finished products. Such parameters, in particular, include:

- electrical and magnetic conductivity of the material to be processed;

- hardness and mechanical strength of metal;

- workpiece mass;

- impact strength possessed by the metal being processed;

- thermal conductivity of the metal, as well as its heat resistance;

- the degree of resistance of the metal to corrosion and its wear resistance, which will affect the durability that the stamped sheet will have.

Equipment

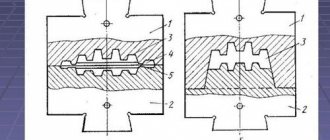

Sheet metal stamping is done using a press and a stamp. The press is used to create pressure, that is, the stamping process itself, and the stamp gives the product the desired shape. The stamp is made of tool steel and consists of a punch and a matrix.

The deformation process occurs with the help of a punch and a matrix at the moment of their approach. The movable part is the upper half of the stamp, fixed on the press, namely on its slider.

The lower half remains motionless and is located on the working surface of the equipment. If it is not steel that is being stamped, but the material is soft, then the working parts of the stamp can be made of polymer alloys or wood.

When producing a single, particularly large-sized product by stamping, it is usually not a press that is used, but a special device made of a cast iron or concrete matrix and a container with liquid (usually water). A sheet of metal is placed on the matrix, and above it is a liquid punch.

Concrete matrix fixture

To create the pressure in the liquid necessary to deform the metal into the desired shape, a gunpowder-based charge is detonated in the container or an electric discharge of sufficient power is provided to the water.

For cutting sheet metal, scissors, rather than a press, are used. They come in several types:

- with parallel knives;

- disk;

- guillotine;

- vibration.

Vibrating type scissors are most often used.

For high-quality manufacturing of products, you need to carefully select a press for each type of operation and material being processed. There are several types of presses:

- Hammer (maximum speed up to 20 m/s).

- Hydraulic press (maximum speed up to 0.3 m/s);

- Crank machine (maximum speed up to 0.5 m/s);

- Rotary type machine (maximum speed 8 m/s);

- Pulse stamping machine (maximum speed up to 300 m/s).

Crank machines are suitable for most types of operations. They can have from one to four crank mechanisms. The operating principle of the crank mechanism can be described according to the following diagram:

- The drive electric motor transmits motion to the crank shaft through a kinematic chain, which consists of a friction clutch and a V-belt drive.

- An adjustable length connecting rod drives the crank slider.

- The foot pedal through the clutch starts the working stroke of the press.

Equipment for stamping products with complex configurations may have several sliders.